Ceramic Proppant Market Size (2023 - 2030)

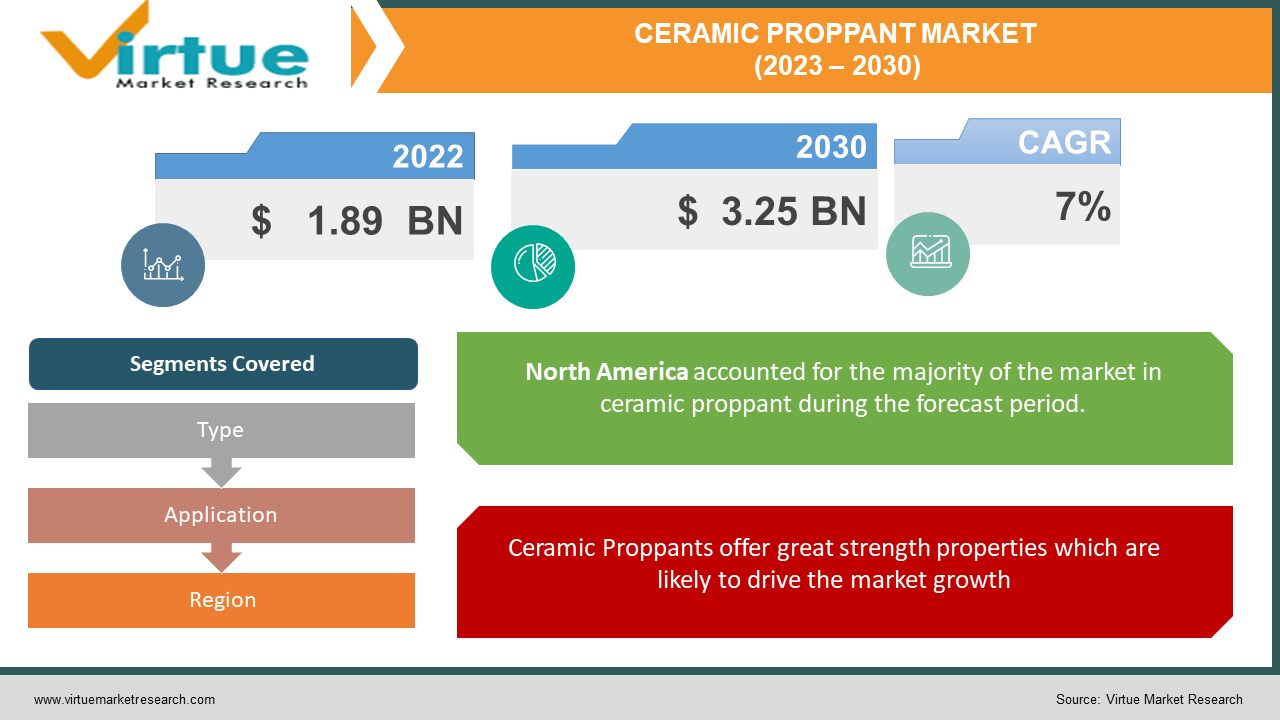

In 2022, the Global Ceramic Proppants Market was valued at $1.89 billion, and is projected to reach a market size of $3.25 billion by 2030. Over the forecast period of 2023-2030, market is projected to grow at a CAGR of 7%.

CLICK HERE To Request Sample Copy

INDUSTRY OVERVIEW

Abrasive substances called proppants are used in the fracking procedure, commonly known as hydraulic fracturing, to maintain the permeability of cracks in shale rock. By creating a route through which hydrocarbons may move more easily, they aid in the extraction of oil and gas. It is readily accessible in a variety of forms, dimensions, densities, and characteristics, and it is essential in determining the eventual permeability of fissures. Natural (frac sand) and man-made/engineered are the two varieties that are currently on the market. These are further divided into ceramic and resin-coated versions of man-made proppants. It is widely used in the oil and gas industry because it is crush resistant and conductive. A granular substance called ceramic proppant is used to support open fractures in oil and gas wells. It is often manufactured of high-strength ceramic materials like bauxite, fused alumina, or silicon carbide. Ceramic proppants are far more robust and long-lasting than conventional sand proppants, making them perfect for usage in high-pressure and high-temperature settings.

In order to maintain an open-induced hydraulic fracture during the fracturing procedure, proppant is a solid substance, usually treated with sand or synthetic ceramics. The kind of fracturing determines the content of the ceramic proppant that is added to the fracking fluid. Because sandstone wells have a high permeability to large-volume operations, ceramic proppant is used in low-volume well stimulation. Building cracks and maintaining a good balance between contact and conductivity during the lifetime of oil wells depend on the nature and effectiveness of the ceramic proppant. Produced from carefully regulated, top-notch calcined kaolin clay, lightweight ceramic proppants are economically viable. The purpose of ceramic proppant is to keep favourable fractures present throughout well formation. Ceramic proppants, which are made of silica or ash, are chosen because they have a quicker settling time and only need low viscosity fluids to carry oil and gas. Enhanced proppants, such as ultra-weight proppants, are made of silica or ash. These proppants preserve conductive hydraulic fractures and are employed as a rudimentary method of determining the geometry of hydraulic fractures as well as matrices for the gradual release of chemical additives down-hole. Ceramic proppants are produced in an environmentally responsible manner using bauxite as a raw material. Sand-based proppants are frequently utilised in the oil and gas sector because they are easily accessible and inexpensive.

COVD-19 IMPACT ON THE CERAMIC PROPPANT MARKET

Due to the drop in oil prices brought on by the COVID-19 outbreak in 2020, the volume of the proppants market shrank by 27%. Governments throughout the world forced people to stay at home, shut down companies, and limit travel as a result of the oil industry's record demand shock in 2020. Oil prices began the year 2020 strong, but by April, as a result of decreased global economic activity and an oversupply of oil on the market, oil prices had sharply fallen. The oil price war between Saudi Arabia and Russia, which began at the beginning of March as a result of the two nations' failure to reach an agreement on the levels of oil production, was another significant element that greatly aided in the freefall of oil prices. The Organization of the Petroleum Exporting Countries (OPEC) tardiness in reducing oil output to counteract the decline in demand also contributed to oil prices falling to their lowest levels in more than 20 years. All these aforementioned factors had a negative impact on the growth of the ceramic proppant market

MARKET DRIVERS:

Ceramic Proppants offer great strength properties which are likely to drive the market growth

Ceramic proppants are stronger than silica and resin-coated proppants due to their homogeneous round shape, making them the best choice for hydraulic fracturing of deep oil and gas reservoirs. This is the main reason fueling the demand for ceramic proppants on the international market. To improve the conductivity of intermediate and deep oil wells, ceramic proppants are also utilised. Due to the usage of natural resources like bauxite during production, ceramic proppants are produced in an environmentally sustainable manner. Exploration firms are utilising ceramic proppants more frequently as environmental concerns grow throughout the world and various governments give incentives for the use of eco-friendly practices.

Unconventional oil and gas deposits are being explored more which are major market drivers

Oil and gas have been in high demand for the past ten years in nations including the US, Canada, China, India, and Russia. Due to the limited supply of conventional oil and gas and their high carbon emissions, unconventional oil and gas production, such as that from coalbed methane, tight oil and gas, and shale oil and gas, has increased. Large proved quantities of unconventional oil and gas are present in countries like Brazil, Algeria, South Africa, Argentina, Mexico, and Australia, which will result in a considerable rise in proppant demand in the future which would eventually propel the market for ceramic proppant market.

MARKET RESTRAINTS:

The high cost of ceramic proppants when oil prices crash makes it least preferred which affects the market growth

Ceramic proppants are made using an energy-intensive process from sintered bauxite, kaolin, and magnesium silicate or combinations of bauxite and kaolin. The proppants must be homogeneous in size, shape, sphericity, and roundness throughout the production process in order to increase the porosity and permeability of the proppants bed. Because ceramic proppants can bear closing stresses of up to 20,000 psi, they are stronger and more resistant to crushing than frac sand. Since ceramic proppants are an engineering product with a more difficult production process, they are more expensive than uncoated or resin-coated proppants. About 50% more money is spent on ceramic proppants.

The availability of water and contamination issues are likely to hinder the growth

Proppants are mostly employed in hydraulic fracturing, and water makes up about 98 to 99.5 per cent of the fracturing fluid used in this process. Companies often employ several water sources, including groundwater, rivers, lakes, industrial wastewater treatment plant discharge water, and recycled fracturing water. The water is transported to drilling sites using temporary pipes or trucks. Depending on the area and the closeness of water sources, businesses try to use a variety of water sources. Hydraulic fracturing necessitates 3 million gallons of water on average for every well. However, there are significant regional variations in this amount. The number of phases of fracturing that are carried out at a well also affects the outcome. Regarding the utilisation of water in hydraulic fracturing, there are two main issues. First, there is a shortage of water for hydraulic fracturing, and second, there are worries about fracturing chemicals contaminating the water supply which may hamper the market growth.

CERAMIC PROPPANT MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

7% |

|

Segments Covered |

By Type, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Badger Mining Corporation, Fores LLC, Carbo Ceramics, JSC Borovichi Refractories Plant, Momentive Speciality Chemicals Inc., Imerys S.A. |

Segmentation Analysis

CERAMIC PROPPANT MARKET – BY TYPE:

-

Ultra-Low density ceramic proppants

-

Medium density ceramic proppants

-

High-density ceramic proppants

Based on type, the ceramic proppant market is segmented into Ultra-Low density ceramic proppants, Medium density ceramic proppants and High-density ceramic proppants. Among these, the Ultra-Low density ceramic proppants dominated the market in 2021. The density of ultra-low density ceramic proppants is lower than that of standard ceramic proppants. Clay, sand, and glass are among the materials used to make them. To improve the flow of hydrocarbons, ultra-low density ceramic proppants are employed in oil and gas wells. They are also utilised in building to increase concrete's strength. Compared to other kinds of ceramic proppants, ultra-low density ceramic proppants provide a variety of benefits. They may be employed in a wider variety of applications and are less prone to malfunction under stress.

The medium-density ceramic proppants are also likely to contribute significantly to the market growth over the forecast period. A form of ceramic proppant manufactured from materials with a medium density is known as a medium-density ceramic proppant. They are employed in oil and gas wells to sustain the strong walls and prop open fractures. Alumina or zirconia are frequently used to make medium-density ceramic proppants. The most popular kind of medium-density ceramic proppant is alumina. Aluminium oxide, a naturally occurring material present in the clay, is used to make it. Another kind of medium-density ceramic proppant is zirconia. It is constructed using zirconium oxide, a synthetic substance. Besides this, High-strength elements like alumina and silica are used to create high-density ceramic proppants, a particular kind of proppant. They support the wellbore and serve to prop open fractures in oil and gas wells. Because they have greater compressive strength than other kinds of proppants, high-density ceramic proppants are perfect for usage in high-pressure settings.

CERAMIC PROPPANT MARKET - BY APPLICATION:

-

Oil and Gas Sector

-

Construction

-

Others

Based on application, the ceramic proppant market is segmented into the Oil and gas sector, Construction and Others. The oil and gas sector was the major contributor to the ceramic proppant market in 2021. In the oil and gas industry, ceramic proppants are utilised during hydraulic fracturing. In process of extracting oil or gas, hydraulic fracturing involves creating cracks in the rock. Ceramic proppants aid in maintaining the cracks' openness so that the fluid may pass through and reach the reservoir. The shale boom in the United States has led to an upsurge in the usage of ceramic proppants recently. Shale plays are places with a lot of shale rock. These minerals have a poor permeability, which makes it challenging for fluids to pass through them. As a result, hydraulic fracturing is required to extract the oil and gas from these rocks.

Ceramic proppants are now being used more often in construction and are estimated to expand at a high CAGR over the forecast period. This is because they provide various advantages over conventional sand or gravel proppants. For instance, ceramic proppants are far more robust and long-lasting, allowing them to resist higher pressures without degrading. Because of this, they are perfect for use in high-pressure activities like hydraulic fracturing. Additionally, using ceramic proppants in building projects reduces the likelihood of environmental harm.

CERAMIC PROPPANT MARKET - BY REGION:

-

North America

-

Europe

-

The Asia Pacific

-

Latin America

-

The Middle East

-

Africa

By region, the Ceramic Proppant Market is grouped into North America, Europe, Asia Pacific, Latin America, The Middle East and Africa. Due to the rising demand from oil exploration corporations, North America now supplies the most ceramic proppants. The oilfield activity would be prolonged by sustained high prices, and a rebound in natural gas prices would finally serve as the main driver for ceramic proppants. Due to the gradually increasing number of oil and gas drilling activities, the Asia Pacific area is anticipated to have strong growth. The Middle Eastern nations, which have extensive mining infrastructure, are actively funding the drilling of multi-stage oil wells and the exploration of new drilling grounds. As a result, a strong increase rate in demand for ceramic proppants is anticipated in this region.

Key Market Players

Some of the major players operating in the Ceramic Proppant Market include:

-

Badger Mining Corporation,

-

Fores LLC,

-

Carbo Ceramics

-

JSC Borovichi Refractories Plant

-

Momentive Speciality Chemicals Inc.

-

Imerys S.A.

-

Others

NOTABLE HAPPENING IN THE CERAMIC PROPPANT MARKET

MARKET EXPANSION- The expansion of COVIA's Canoitas factory in Mexico was accomplished in March 2020. To accommodate the rising demand from clients in Mexico, the expansion will allow COVIA to increase its ability to produce silica by 350 tonnes annually.

ACQUISITION- In March 2020, Carbo Ceramics was acquired by Wilk Brothers, LLC through a debt-for-equity exchange.

ACQUISITION- Proppant Logistics LLC, which owns Pronghorn Logistics LLC, was bought by Hi-Crush Inc. in May 2019. The business offers complete logistical services for proppants.

INVESTMENT- In order to better service the coating and polymer end industries and establish a highly efficient contemporary facility, COVIA enlarged the North American facility's capacity in March 2020. The project's estimated cost was USD 45 million.

Chapter 1. Ceramic Proppant Market – Scope & Methodology

1.1. Market Segmentation

1.2. Assumptions

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. Ceramic Proppant Market – Executive Summary

2.1. Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.3. COVID-19 Impact Analysis

2.3.1. Impact during 2023 - 2030

2.3.2. Impact on Supply – Demand

Chapter 3. Ceramic Proppant Market – Competition Scenario

3.1. Market Share Analysis

3.2. Product Benchmarking

3.3. Competitive Strategy & Development Scenario

3.4. Competitive Pricing Analysis

3.5. Supplier - Distributor Analysis

Chapter 4. Ceramic Proppant Market Entry Scenario

4.1. Case Studies – Start-up/Thriving Companies

4.2. Regulatory Scenario - By Region

4.3 Customer Analysis

4.4. Porter's Five Force Model

4.4.1. Bargaining Power of Suppliers

4.4.2. Bargaining Powers of Customers

4.4.3. Threat of New Entrants

4.4.4. Rivalry among Existing Players

4.4.5. Threat of Substitutes

Chapter 5. Ceramic Proppant Market - Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. Ceramic Proppant Market – By Type

6.1. Ultra-Low density ceramic proppants

6.2. Medium density ceramic proppants

6.3. High-density ceramic proppants

Chapter 7. Ceramic Proppant Market – By Application

7.1. Oil and gas sector

7.2. Construction

7.3. Others

Chapter 8. Ceramic Proppant Market- By Region

8.1. North America

8.2. Europe

8.3. Asia-Pacific

8.4. Latin America

8.5. The Middle East

8.6. Africa

Chapter 9. Ceramic Proppant Market – BY COMPANIES

9.1 Badger Mining Corporation,

9.2 Fores LLC,

9.3 Carbo Ceramics

9.4 JSC Borovichi Refractories Plant

9.5 Momentive Speciality Chemicals Inc.

Imerys S.A.

Download Sample

Choose License Type

2500

4250

5250

6900