Zinc Rich Primer Market Size (2024-2030)

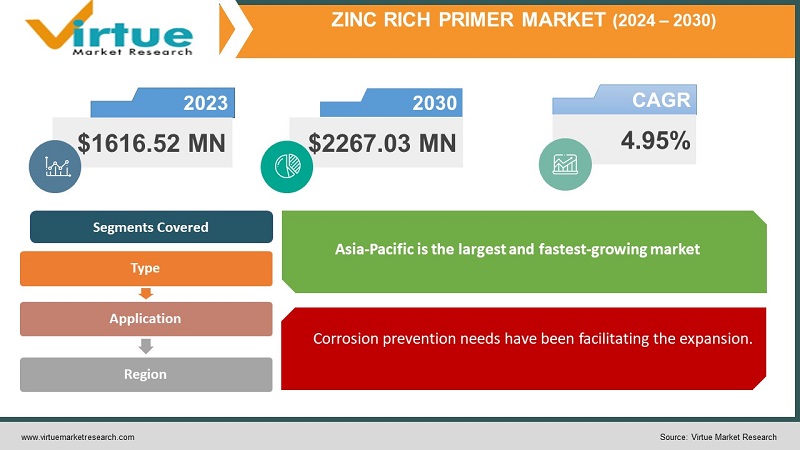

The global zinc-rich primer market was valued at USD 1616.52 million and is projected to reach a market size of USD 2267.03 million by the end of 2030. Over the forecast period of 2024–2030, the market is projected to grow at a CAGR of 4.95%.

Zinc-rich primers are compounds that have a high concentration of zinc metal in them to prevent corrosion in steel and iron substrates. Unlike conventional paints and epoxies, they shield steel electrically instead of creating an impervious barrier. Zinc-rich primers are advised for a thickness of 50–75 microns and can be applied with a brush, roller, or spray. Zinc primers have been used for many centuries. They were mainly used in marine, offshore, and industrial applications. However, there was limited awareness. Presently, the market has seen a boost owing to technological advancements and growing demand. In the future, with a focus on customization and sustainability, immense acceleration is anticipated.

Key Market Insights:

The market for zinc-rich primers is expanding as a result of strict environmental rules and the need to avoid corrosion. Zinc-rich primers are an excellent way to prevent corrosion in a variety of industries, increasing asset longevity, cost-effectiveness, and safety. Low-volatile organic compound (VOC) formulations assist companies in lowering harmful emissions and meeting environmental laws.

The market is challenged by high initial prices, doubts regarding corrosion efficacy, and fierce competition. Zinc-rich primers may be more expensive initially than conventional coatings, and their efficacy may be impacted by problems including solvent entrapment and coating cracking.

Opportunities for market expansion are presented by growing economies, formula modifications, sustainability efforts, and technological improvements. To promote sustainability, manufacturers are concentrating on creating sophisticated formulas with improved qualities, reaching out to new markets for infrastructure projects, tailoring coatings for particular uses, and employing environmentally friendly production processes.

The largest and fastest-growing market for zinc-rich primers is found in the Asia-Pacific region, where demand for high-performance coatings, infrastructural development, and industrial expansion are all contributing factors. Key markets in the area include China, India, Japan, and South Korea.

Recently, there has been a lot of interest in using nanotechnology to improve the performance characteristics of primer formulations that are rich in zinc. Zinc nanoparticles or other compounds can be added to improve properties, including adhesion, durability, and corrosion resistance.

Zinc-Rich Primer Market Drivers:

Corrosion prevention needs have been facilitating the expansion.

Zinc-rich primers are organic coatings that use electricity to stop metal from corroding. They are advised for use in industrial and maritime settings as a good substitute for dangerous chromate-based primers. Zinc-rich primers prevent corrosion on metal substrates by forming a protective layer that coats the metal surface. To produce a galvanic effect, they include large concentrations of zinc dust as a pigment with an organic binder (epoxy). The zinc particles function as anodes in the coating and corrode sacrificially in place of the steel when exposed to water, oxygen, and/or chlorides. Zinc-rich primers have protective properties mostly due to this mechanism, which is called cathodic protection. Industries like automotive, construction, marine, and other such industries use these primers to protect their resources. Zinc-rich primers are in high demand because of the need to enhance safety, save maintenance costs, and extend the lifespan of assets.

Stringent environmental regulations have been creating an upsurge.

Low-volatile organic compound (VOC) primers containing zinc help businesses adhere to laws that limit dangerous emissions and air pollution. Organic compounds known as volatile organic compounds (VOCs) can evaporate into the sky and cause smog and other problems with air quality. Industries may minimize their environmental impact and comply with regulations by utilizing coatings with low volatile organic compounds (VOCs). Zinc-rich primers are made with low concentrations of hazardous air pollutants, which are chemicals that are known or believed to hurt human health or the environment. By maintaining the integrity of buildings, machinery, and infrastructure, corrosion prevention using zinc-rich primers contributes to the protection of natural resources.

Zinc-Rich Primer Market Restraints and Challenges:

Associated costs, corrosion effectiveness, and intense competition are the main issues that the market is currently facing.

Compared to conventional primers, zinc primers have higher initial costs. This can be a major barrier for small and medium-sized companies, making them look for other affordable options. Secondly, zinc-rich primers used at thicker layers run the risk of causing solvent entrapment and coating cracking, which can result in corrosion and premature failure. If the surface roughness, film thickness, or primer formulation quality are inadequate, zinc-rich primers may not be able to effectively protect the surface. Due to their low DFT, zinc primers are more vulnerable to mechanical harm from impact and abrasion during construction, handling, and transportation. Thirdly, there is a constant search for substitutes. Researchers are looking for alternatives that are cost-effective, sustainable, and provide superior performance. Advanced polymer coatings and nanotechnological materials are in high demand owing to their traits. This can cause a competitive challenge, leading to market losses.

Zinc-Rich Primer Market Opportunities:

Technological advancements provide the industry with an ample number of possibilities. Producers are attempting to create formulas with improved adhesion, accelerated cure times, more resistance to environmental stresses, and innovative features like self-healing or antimicrobial coatings. Secondly, emerging economies provide many opportunities. Regions like Latin America, Asia-Pacific, and the Middle East have seen economic growth. This has resulted in better investments. Companies can focus on these areas to work on infrastructure and other marine projects. Thirdly, customizing formulations as per the needs of the client and industry is beneficial. This ensures customer satisfaction and loyalty. Moreover, sustainability has become an absolute priority in many industries. Businesses are working on developing primers from recycled materials and other renewable resources. Eco-friendly manufacturing techniques are being implemented to lower the environmental impact. This can include practices like local sourcing to reduce carbon footprints. Apart from this, predictive maintenance techniques may be enabled, performance monitoring can be optimized, and coating application procedures can be improved by utilizing technologies like the IoT (Internet of Things), AI (artificial intelligence), and data analytics. Digital solutions may save expenses, increase productivity, and provide clients with value-added services.

ZINC-RICH PRIMER MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

4.95% |

|

Segments Covered |

By Type, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

PPG Industries, Sherwin-Williams Company, Hempel A/S, Akzo Nobel N.V., Jotun Group, BASF SE, Axalta Coating Systems, Nippon Paint Holdings Co., Ltd., RPM International Inc., Tikkurila Oyj |

Zinc-Rich Primer Market Segmentation:

Zinc-Rich Primer Market Segmentation: By Type:

- Epoxy Zinc-Rich Coatings

- Chlorinated Rubber Zinc-Rich Coating

- Vinyl Resin Zinc-Rich Coating

- Polyurethane Zinc-Rich Coating

Epoxy zinc-rich coatings are the largest and fastest-growing type. Zinc-rich epoxy coatings have been extensively used for many years in a variety of industries because of their superior adhesion, resistance to corrosion, and durability. They account for the greatest portion of the market for zinc-rich primers, as they are often used in the infrastructure, industrial, and marine sectors. Moreover, epoxy coatings with a high zinc content function exceptionally well in abrasive, chemical, and damp conditions. Their enduring corrosion protection makes them the go-to option in situations where reducing maintenance costs and extending asset life are essential. Furthermore, they are used in a variety of substrates, such as concrete, steel, aluminum, and galvanized surfaces. Their ability to be versatile makes them useful in a range of sectors and contexts, which furthers their dominance in the market.

Zinc-Rich Primer Market Segmentation: By Application:

- Steel Tanks

- Offshore Platforms

- Bridges

- Petrochemicals & Power Plants

- Railcar Coating

Steel tanks are the largest growing application. Zinc-rich primers (ZRP) use zinc as a sacrificial anode to prevent steel from corroding in corrosive environments, including industrial sites and marine environments. Zinc-rich primers are made of powdered zinc metal that protects steel by causing galvanic corrosion, which corrodes steel preferentially. This keeps steel away from water and oxygen, all of which are needed for corrosion to happen. Offshore platforms are the fastest-growing category. Because offshore platforms are expensive, they need to be kept free from corrosion for an extended period to maintain their structural integrity and dependability. Offshore platforms utilize zinc-rich primers to shield steel surfaces from moisture and corrosion. Zinc-rich primers have 85–92% zinc metal pigments, which form a metallic zinc layer that protects the steel cathodically and serves as a physical barrier. Offshore platforms are subjected to extremely corrosive conditions, such as dampness, salinity, and strong chemicals. Zinc-rich primers act as a sacrificial barrier to stop corrosion by creating a shield that keeps moisture and other corrosive materials from getting to the metal substrate underneath. This lessens the need for maintenance and repairs and increases the lifespan of offshore constructions.

Zinc-Rich Primer Market Segmentation: Regional Analysis:

- North America

- Asia-Pacific

- Europe

- South America

- Middle East and Africa

Asia-Pacific is the largest and fastest-growing market. China is the largest market for zinc-rich primers due to its establishment in industries like petrochemicals, automotive, refineries, construction, and power plants. Other countries, like India, Japan, and South Korea, are also at the top. Asian countries have a huge manufacturing sector for this compound. As such, industrial applications have greater revenue. The booming infrastructure development increased the need for corrosion prevention techniques. This includes transportation networks, energy facilities, and other urban development initiatives. Besides, urbanization has led to changes in the standard of living and an increase in disposable income. Furthermore, the automotive sector has elevated the demand for high-performance coatings, which is contributing to its success. Well-established companies are present in this region. They have a global presence, leading to better profits. Prominent key players include Kansai Paint Co., Ltd., Nippon Paint Holdings Co., Ltd., Jotun Group, and Asian Paints Limited.

COVID-19 Impact Analysis on the Global Zinc-Rich Primer Market:

The viral epidemic caused damage to the market. The new normal included social isolation, movement restrictions, and lockdowns. Transportation, logistics, and supply chain management were impacted by this. The main emphasis was on working remotely. Manufacturing and production operations came to an end. Safety constraints presented obstacles to operations. Many companies in automotive, construction, and manufacturing saw a decline in demand for this product. An economic downturn was seen. Many people lost their jobs. The majority of the funds were supposed to go toward healthcare-related projects. This caused delays in collaborations and launches. Many only purchased necessities. Construction activities, industrial maintenance activities, and infrastructure development were halted. Because of the loosening of laws and restrictions during the epidemic, the market has begun to recover.

Latest Trends/ Developments:

Companies in this industry are motivated to increase their market share by using a range of strategies, including acquisitions, joint ventures, and investments. Businesses are

spending a lot of money to develop techniques to retain competitive pricing. Further growth has resulted from this.

Zinc-rich primer compositions are increasingly using nanotechnology to improve their performance attributes. Zinc nanoparticles or other additions are added to coatings to increase their longevity, adhesion, and resistance to corrosion. Additionally, self-healing coatings that patch up small damage and prolong the life of protective coatings are made possible by nanotechnology.

Key Players:

- PPG Industries

- Sherwin-Williams Company

- Hempel A/S

- Akzo Nobel N.V.

- Jotun Group

- BASF SE

- Axalta Coating Systems

- Nippon Paint Holdings Co., Ltd.

- RPM International Inc.

- Tikkurila Oyj

In August 2022, Eckart introduced ProFlake Zn 3000, a zinc flake pigment intended for paint systems that provide sustained corrosion protection. ProFlake Zn 3000 is intended for use in thick dry film coatings (above 80 µm) for heavy-duty corrosion prevention. It offers dual corrosion protection by combining a barrier effect with galvanic protection.

Chapter 1. GLOBAL ZINC-RICH PRIMER MARKET – Scope & Methodology

1.1. Market Segmentation

1.2. Scope, Assumptions & Limitations

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. GLOBAL ZINC-RICH PRIMER MARKET – Executive Summary

2.1. Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.2.1. Demand Side

2.2.2. Supply Side

2.3. Attractive Investment Propositions

2.4. COVID-19 Impact Analysis

Chapter 3. GLOBAL ZINC-RICH PRIMER MARKET – Competition Scenario

3.1. Market Share Analysis & Company Benchmarking

3.2. Competitive Strategy & Development Scenario

3.3. Competitive Pricing Analysis

3.4. Supplier-Distributor Analysis

Chapter 4. GLOBAL ZINC-RICH PRIMER MARKET - Entry Scenario

4.1. Regulatory Scenario

4.2. Case Studies – Key Start-ups

4.3. Customer Analysis

4.4. PESTLE Analysis

4.5. Porters Five Force Model

4.5.1. Bargaining Power of Suppliers

4.5.2. Bargaining Powers of Customers

4.5.3. Threat of New Entrants

4.5.4. Rivalry among Existing Players

4.5.5. Threat of Substitutes

Chapter 5. GLOBAL ZINC-RICH PRIMER MARKET - Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. GLOBAL ZINC-RICH PRIMER MARKET – By Type

6.1. Introduction/Key Findings

6.2. Epoxy Zinc-Rich Coatings

6.3. Chlorinated Rubber Zinc-Rich Coating

6.4. Vinyl Resin Zinc-Rich Coating

6.5. Polyurethane Zinc-Rich Coating

6.6. Y-O-Y Growth trend Analysis By Type

6.7. Absolute $ Opportunity Analysis By Type , 2024-2030

Chapter 7. GLOBAL ZINC-RICH PRIMER MARKET – By Application

7.1. Introduction/Key Findings

7.2 Steel Tanks

7.3. Offshore Platforms

7.4. Bridges

7.5. Petrochemicals & Power Plants

7.6. Railcar Coating

7.7. Y-O-Y Growth trend Analysis By Application

7.8. Absolute $ Opportunity Analysis By Application , 2024-2030

Chapter 8. GLOBAL ZINC-RICH PRIMER MARKET - By Geography – Market Size, Forecast, Trends & Insights

8.1. North America

8.1.1. By Country

8.1.1.1. U.S.A.

8.1.1.2. Canada

8.1.1.3. Mexico

8.1.2. By Application

8.1.3. By Type

8.1.4. Countries & Segments - Market Attractiveness Analysis

8.2. Europe

8.2.1. By Country

8.2.1.1. U.K.

8.2.1.2. Germany

8.2.1.3. France

8.2.1.4. Italy

8.2.1.5. Spain

8.2.1.6. Rest of Europe

8.2.2. By Application

8.2.3. By Type

8.2.4. Countries & Segments - Market Attractiveness Analysis

8.3. Asia Pacific

8.3.1. By Country

8.3.1.1. China

8.3.1.2. Japan

8.3.1.3. South Korea

8.3.1.4. India

8.3.1.5. Australia & New Zealand

8.3.1.6. Rest of Asia-Pacific

8.3.2. By Application

8.3.3. By Type

8.3.4. Countries & Segments - Market Attractiveness Analysis

8.4. South America

8.4.1. By Country

8.4.1.1. Brazil

8.4.1.2. Argentina

8.4.1.3. Colombia

8.4.1.4. Chile

8.4.1.5. Rest of South America

8.4.2. By Application

8.4.3. By Type

8.4.4. Countries & Segments - Market Attractiveness Analysis

8.5. Middle East & Africa

8.5.1. By Country

8.5.1.1. United Arab Emirates (UAE)

8.5.1.2. Saudi Arabia

8.5.1.3. Qatar

8.5.1.4. Israel

8.5.1.5. South Africa

8.5.1.6. Nigeria

8.5.1.7. Kenya

8.5.1.8. Egypt

8.5.1.8. Rest of MEA

8.5.2. By Application

8.5.3. By Type

8.5.4. Countries & Segments - Market Attractiveness Analysis

Chapter 9. GLOBAL ZINC-RICH PRIMER MARKET – Company Profiles – (Overview, Type Portfolio, Financials, Strategies & Developments)

9.1 PPG Industries

9.2. Sherwin-Williams Company

9.3. Hempel A/S

9.4. Akzo Nobel N.V.

9.5. Jotun Group

9.6. BASF SE

9.7. Axalta Coating Systems

9.8. Nippon Paint Holdings Co., Ltd.

9.9. RPM International Inc.

9.10. Tikkurila Oyj

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The global zinc-rich primer market was valued at USD 1616.52 million and is projected to reach a market size of USD 2267.03 million by the end of 2030. Over the forecast period of 2024–2030, the market is projected to grow at a CAGR of 4.95%.

Corrosion prevention needs and stringent environmental regulations are the main factors propelling the global zinc-rich primer market

Based on application, the global zinc-rich primer market is segmented into steel tanks, offshore platforms, bridges, petrochemicals & power plants, and railcar coating

Asia-Pacific is the most dominant region for the global zinc-rich primer market.

. PPG Industries, Sherwin-Williams Company, and Hempel A/S are the key players operating in the global zinc-rich primer market