Zinc-Rich Coating Market Size (2024-2030)

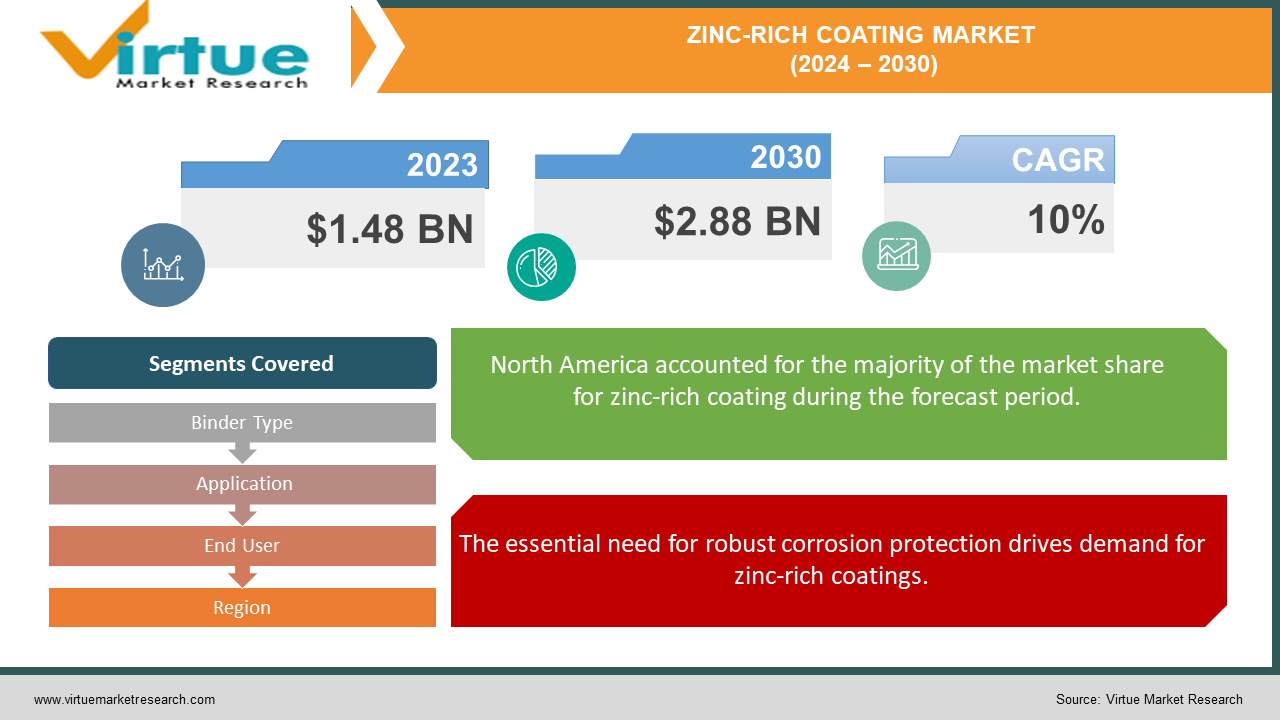

The Zinc-Rich Coating Market was valued at USD 1.48 billion in 2023 and is projected to reach a market size of USD 2.88 billion by the end of 2030. Over the cast period of 2024 – 2030, the figure for requests is projected to grow at a CAGR of 10%.

The zinc-rich coating market is on a positive trajectory, driven by the ever-present need for corrosion protection in industries like construction, transportation, oil and gas, and power generation. These coatings, applied to steel surfaces, act as a shield against rust and corrosion. Zinc-rich paints contain a high concentration of zinc particles that essentially sacrifice themselves to protect the underlying steel. The market is fueled by factors like increasing urbanization leading to more steel structures needing protection, and rising investments in infrastructure projects around the world.

Key Market Insights:

The zinc-rich coating market is thriving due to its effectiveness in combating corrosion. These coatings, packed with 65-95% zinc particles, essentially act as sacrificial shields for steel structures in industries like construction, transportation, oil and gas, and power generation. This protection is particularly crucial as urbanization drives the construction of more steel structures and global infrastructure projects ramp up. Additionally, stricter environmental regulations are phasing out less sustainable corrosion solutions, opening doors for eco-friendly zinc-rich alternatives.

However, the market faces some hurdles. Manufacturers struggle with fluctuating zinc prices, a key ingredient in the coating, which can disrupt product pricing strategies. Moreover, applying these coatings requires skilled labor, and there might be limitations on the availability of such workers in certain regions. To navigate these challenges and stay ahead of the curve, manufacturers are likely to invest in research and development, focusing on improved formulations and application techniques for zinc-rich coatings. This emphasis on innovation can create differentiation within the competitive landscape.

The Zinc-Rich Coating Market Drivers:

The essential need for robust corrosion protection drives demand for zinc-rich coatings.

The primary driver is the critical need for effective corrosion protection in various industries. Zinc-rich coatings, with their high zinc content (65-95%), offer a sacrificial layer that safeguards steel structures in construction, transportation, oil & gas, and power generation. This protection is becoming even more crucial as infrastructure development ramps up globally.

Rapid urbanization and infrastructure expansion create a constant need for steel structure protection.

Rapid urbanization creates a constant demand for new steel structures in buildings and bridges. This surge in steel usage translates to a corresponding rise in the need for corrosion protection solutions, making zinc-rich coatings a prime choice. Additionally, rising investments in global infrastructure projects like roads, railways, and power grids further fuel market growth.

Shift towards sustainable solutions opens doors for eco-friendly zinc-rich coatings.

Environmental regulations are becoming stricter, pushing industries away from less sustainable corrosion protection methods that can be harmful to the environment. This shift creates a significant growth opportunity for zinc-rich coatings, a more eco-friendly alternative. As regulations tighten, the demand for sustainable solutions like zinc-rich coatings is expected to climb.

Zinc-rich coatings offer a compelling combination of performance and cost-effectiveness.

Zinc-rich coatings offer a compelling combination of performance and cost-effectiveness. They provide excellent corrosion protection while remaining a cost-competitive option compared to some alternative methods. This balance between performance and affordability makes them an attractive choice for various industries.

Focus on innovation can lead to even more effective and user-friendly coatings.

In a competitive market, manufacturers are likely to focus on research and development to improve the formulations and application techniques for zinc-rich coatings. This focus on innovation can lead to the development of even more effective and user-friendly coatings, further driving market growth.

The Zinc-Rich Coating Market Restraints and Challenges:

The zinc-rich coating market, while boasting a promising future fuelled by the ever-present need for corrosion protection, faces challenges that require attention. A significant hurdle is the volatility of zinc prices. Since zinc constitutes a major component of these coatings, fluctuations in its price can significantly impact manufacturers. This price instability makes it difficult to maintain consistent pricing for the final product, creating uncertainty for both manufacturers and potential customers. Imagine a construction project budgeting for zinc-rich coatings based on a specific price, only to face a sudden price hike due to zinc volatility. This can disrupt project timelines and budgets, potentially leading to delays and customer dissatisfaction.

Another challenge lies in the skilled labor required for application. Applying zinc-rich coatings effectively demands a specific skill set. The market might face limitations in finding enough skilled workers in certain regions, particularly in developing economies or remote areas. This shortage could potentially delay projects and hinder overall market growth. Imagine a large infrastructure project requiring zinc-rich coatings on a tight schedule. A lack of skilled labor in the region could significantly delay the project, impacting costs and overall efficiency.

The Zinc-Rich Coating Market Opportunities:

The future of the zinc-rich coating market is bright, and brimming with exciting opportunities. Emerging economies present a significant growth prospect. As these regions experience rapid development and urbanization, the need for infrastructure projects will surge. This translates to a massive demand for corrosion protection solutions for the steel structures used in these projects. Zinc-rich coatings, with their affordability and effectiveness, are perfectly positioned to capitalize on this growing market. Additionally, the increasing focus on environmental regulations and sustainability presents another key opportunity. Compared to some traditional methods, zinc-rich coatings offer an eco-friendlier approach to corrosion protection. This "green" aspect positions the market for significant expansion. Furthermore, advancements in technology can lead to the development of even better zinc-rich coatings. Imagine formulations with improved durability, faster curing times, or easier application processes. Such advancements can attract new customers and solidify the market position of zinc-rich coatings. The development of specialty coatings tailored for specific applications can open doors to entirely new market segments. For instance, coatings designed for extreme weather conditions or high-temperature environments can cater to unique industry needs, expanding the market reach even further. Finally, by focusing on education and raising awareness about the benefits of zinc-rich coatings, particularly their long-term cost-effectiveness compared to potential maintenance costs of unprotected steel, the market can encourage wider adoption across various industries. By capitalizing on these opportunities, the zinc-rich coating market can solidify its position as a leading solution for corrosion protection for years to come.

ZINC-RICH COATING MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

10% |

|

Segments Covered |

By Binder Type, Application, End User, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

AkzoNobel, Jotun, Hempel, PPG Industries, NKM Coating, Sumter Coatings, Chugoku Marine Paints, Sherwin-Williams, MBCC Group, Kansai Paint |

Zinc-Rich Coating Market Segmentation: By Binder Type

-

Organic

-

Inorganic

In the zinc-rich coating market, segmented by binder type, organic zinc-rich coatings are currently the most dominant segment due to their lower cost compared to inorganic options. However, inorganic zinc-rich coatings are expected to be the fastest-growing segment. This is because inorganic coatings, while more expensive, offer superior corrosion protection, especially in harsh environments. As infrastructure projects around the world continue to grow, the demand for this superior protection is likely to rise.

Zinc-Rich Coating Market Segmentation: By Application

-

Construction

-

Transportation

-

Oil and Gas

-

Power Generation

Dominating the application sector is construction, with its ever-present need to protect steel structures like bridges and buildings from corrosion. This high demand is fueled by ongoing urbanization projects. The fastest-growing segment is likely Asia Pacific, driven by rapid industrialization and a surge in infrastructure development. This region's expanding steel structures necessitate robust corrosion protection solutions, making zinc-rich coatings a prime choice.

Zinc-Rich Coating Market Segmentation: By End User

-

Automotive

-

Marine

-

Oil & Gas

-

Construction

-

Infrastructure

While both construction and infrastructure projects rely heavily on zinc-rich coatings, construction likely reigns supreme in the End-User sector. The constant need to protect steel structures in buildings, bridges, and other constructions creates a steady and sizable demand. The fastest-growing segment is likely the automotive industry. As car manufacturers prioritize longevity and corrosion resistance, zinc-rich coatings become increasingly attractive for protecting car parts, especially in regions with harsh weather conditions.

Zinc-Rich Coating Market Segmentation: Regional Analysis

-

North America

-

Europe

-

Asia-Pacific

-

South America

-

Middle East and Africa

North America boasts a well-established infrastructure and a strong focus on corrosion protection in various industries. This focus translates to a high demand for zinc-rich coatings, making it a dominant player in the global market. Additionally, the presence of leading manufacturers and a mature construction sector further contribute to its strong position.

Stringent environmental regulations in Europe favor the adoption of eco-friendly solutions like zinc-rich coatings. This regulatory push, coupled with a focus on infrastructure maintenance and development, creates a significant market for zinc-rich coatings in the region.

Asia Pacific region is experiencing rapid industrialization and a surge in infrastructure development projects. These factors, combined with a growing focus on urbanization, are leading to a substantial demand for steel structures. As a result, the need for robust corrosion protection solutions like zinc-rich coatings is skyrocketing, making Asia Pacific the fastest-growing market for these coatings.

COVID-19 Impact Analysis on the Zinc-Rich Coating Market:

The global COVID-19 pandemic threw a wrench into the zinc-rich coating market. Lockdowns and travel restrictions disrupted the supply chain, making it difficult to obtain raw materials and transport finished products. Additionally, many industries that rely heavily on zinc-rich coatings, like construction and transportation, experienced slowdowns due to the pandemic. This led to a double whammy of decreased production and lower demand. Furthermore, project delays and cancellations due to the pandemic further dampened the market. Labor shortages caused by social distancing measures also added another layer of challenge, impacting project timelines for applying these coatings.

However, the future isn't all doom and gloom. As the global economy recovers, a rebound in demand is expected for zinc-rich coatings across industries like construction, transportation, and infrastructure. This pent-up demand could even lead to a period of accelerated growth. The pandemic's emphasis on environmental issues might also play a positive role. With a heightened focus on sustainability, industries might continue to Favor eco-friendly zinc-rich coatings over less sustainable alternatives. The disruption caused by the pandemic could also have a silver lining. It might spur innovation in the zinc-rich coating industry, with manufacturers looking towards more efficient production methods and exploring new application techniques. Overall, while the COVID-19 pandemic caused a temporary setback, the long-term outlook for the zinc-rich coating market remains positive, driven by economic recovery, a focus on sustainability, and potential advancements in production and application.

Latest Trends/ Developments:

The zinc-rich coating market is abuzz with innovation and a focus on sustainability. One exciting development is the exploration of nano zinc particles. These tiny particles have the potential to significantly improve corrosion protection and barrier properties in coatings. Research in this area is ongoing and could lead to even more effective zinc-rich coatings in the future. Environmental responsibility is also a key driver. Traditionally, solvent-based zinc-rich coatings posed environmental concerns. To address this, the development of water-based alternatives is gaining momentum. These eco-friendly options offer comparable performance with a lower environmental footprint, making them attractive to sustainability-focused industries.

Finally, manufacturers are increasingly developing specialized zinc-rich coatings tailored for specific applications. These coatings might be formulated to withstand extreme temperatures, harsh weather, or high humidity. By catering to the unique needs of various industries with these specialized options, the zinc-rich coating market can expand its reach and solidify its position as a leader in corrosion protection for years to come.

Key Players:

-

AkzoNobel

-

Jotun

-

Hempel

-

PPG Industries

-

NKM Coating

-

Sumter Coatings

-

Chugoku Marine Paints

-

Sherwin-Williams

-

MBCC Group

-

Kansai Paint

Chapter 1. Zinc-Rich Coating Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Zinc-Rich Coating Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Zinc-Rich Coating Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Zinc-Rich Coating Market Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Zinc-Rich Coating Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Zinc-Rich Coating Market – By Binder Type

6.1 Introduction/Key Findings

6.2 Organic

6.3 Inorganic

6.4 Y-O-Y Growth trend Analysis By Binder Type

6.5 Absolute $ Opportunity Analysis By Binder Type, 2024-2030

Chapter 7. Zinc-Rich Coating Market – By Application

7.1 Introduction/Key Findings

7.2 Construction

7.3 Transportation

7.4 Oil and Gas

7.5 Power Generation

7.6 Y-O-Y Growth trend Analysis By Application

7.7 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. Zinc-Rich Coating Market – By End-Users

8.1 Introduction/Key Findings

8.2 Automotive

8.3 Marine

8.4 Oil & Gas

8.5 Construction

8.6 Infrastructure

8.7 Y-O-Y Growth trend Analysis By End-Users

8.8 Absolute $ Opportunity Analysis By End-Users, 2024-2030

Chapter 9. Zinc-Rich Coating Market , By Geography – Market Size, Forecast, Trends & Insights

9.1 North America

9.1.1 By Country

9.1.1.1 U.S.A.

9.1.1.2 Canada

9.1.1.3 Mexico

9.1.2 By Binder Type

9.1.3 By Application

9.1.4 By By End-Users

9.1.5 Countries & Segments - Market Attractiveness Analysis

9.2 Europe

9.2.1 By Country

9.2.1.1 U.K

9.2.1.2 Germany

9.2.1.3 France

9.2.1.4 Italy

9.2.1.5 Spain

9.2.1.6 Rest of Europe

9.2.2 By Binder Type

9.2.3 By Application

9.2.4 By End-Users

9.2.5 Countries & Segments - Market Attractiveness Analysis

9.3 Asia Pacific

9.3.1 By Country

9.3.1.1 China

9.3.1.2 Japan

9.3.1.3 South Korea

9.3.1.4 India

9.3.1.5 Australia & New Zealand

9.3.1.6 Rest of Asia-Pacific

9.3.2 By Binder Type

9.3.3 By Application

9.3.4 By End-Users

9.3.5 Countries & Segments - Market Attractiveness Analysis

9.4 South America

9.4.1 By Country

9.4.1.1 Brazil

9.4.1.2 Argentina

9.4.1.3 Colombia

9.4.1.4 Chile

9.4.1.5 Rest of South America

9.4.2 By Binder Type

9.4.3 By Application

9.4.4 By End-Users

9.4.5 Countries & Segments - Market Attractiveness Analysis

9.5 Middle East & Africa

9.5.1 By Country

9.5.1.1 United Arab Emirates (UAE)

9.5.1.2 Saudi Arabia

9.5.1.3 Qatar

9.5.1.4 Israel

9.5.1.5 South Africa

9.5.1.6 Nigeria

9.5.1.7 Kenya

9.5.1.8 Egypt

9.5.1.9 Rest of MEA

9.5.2 By Binder Type

9.5.3 By Application

9.5.4 By End-Users

9.5.5 Countries & Segments - Market Attractiveness Analysis

Chapter 10. Zinc-Rich Coating Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

10.1 AkzoNobel

10.2 Jotun

10.3 Hempel

10.4 PPG Industries

10.5 NKM Coating

10.6 Sumter Coatings

10.7 Chugoku Marine Paints

10.8 Sherwin-Williams

10.9 MBCC Group

10.10 Kansai Paint

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Zinc-Rich Coating Market was valued at USD 1.48 billion in 2023 and is projected to reach a market size of USD 2.88 billion by the end of 2030. Over the cast period of 2024 – 2030, the figure for requests is projected to grow at a CAGR of 10%.

Essential Corrosion Protection, Urbanization & Infrastructure Expansion, Shift Towards Sustainability, Performance & Cost Benefits, Potential for Innovation.

Automotive, Marine, Oil & Gas, Construction, Infrastructure.

North America is the most dominant region for the Zinc-Rich Coating Market, driven by established infrastructure and a strong focus on corrosion protection.

AkzoNobel, Jotun, Hempel, PPG Industries, NKM Coating, Sumter Coatings, Chugoku Marine Paints, Sherwin-Williams, MBCC Group, Kansai Paint.