Zinc Coatings Market Size (2024-2030)

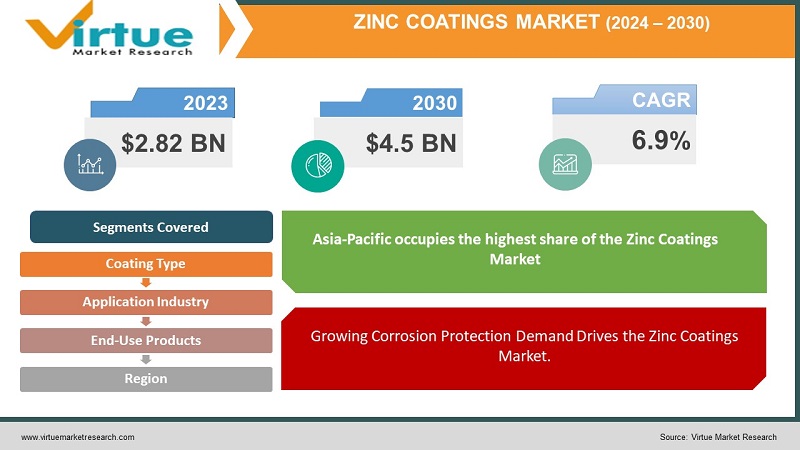

The Global Zinc Coatings Market was valued at USD 2.82 billion and is projected to reach a market size of USD 4.5 billion by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 6.9%.

Zinc coatings are used in various industries for corrosion protection of metal surfaces. The common method of applying zinc coatings is through galvanization, where a layer of zinc is applied to the surface of steel or iron. This prevents rusting. The Zinc coating market is expected to grow significantly in the coming years due to the need for corrosion protection, especially in industries such as construction, automotive, and infrastructure. Ongoing advancements in technology have led to the development of more improved zinc coatings, making them more effective and environmentally friendly. The major well-established key players in the Zinc Coatings Market are PPG Industries, Sherwin-Williams Company, AkzoNobel N.V., Nippon Paint Holdings Co., Ltd., and Valspar Corporation

Key Market Insights:

Zinc coatings are effective in preventing the oxidation of metals. The construction sector is a major consumer of zinc coatings. Zinc coatings have environmental benefits. Zinc coatings provide corrosion protection without the need for continuous maintenance or replacement. The increasing demand for corrosion protection in the construction and automotive sectors, rising infrastructure development, growing awareness of environmental benefits, technological advancements, and adherence to regulatory standards are propelling the Zinc Coatings Market. The restraints on the Zinc Coatings Market include potential environmental concerns related to zinc usage, fluctuating raw material prices, competition from alternative coatings, and economic downturns impacting the construction and automotive industries. Opportunities emerge with the development of nano-coatings, providing avenues for enhancing the performance and durability of zinc coatings across industries. Asia-Pacific occupies the highest share of the Zinc Coatings Market. Overall economic expansion in the Asia-Pacific region fuels the demand for various industries, including manufacturing, construction, and automotive. This results in increased demand for Zinc Coatings with corrosion-resistant properties.

Zinc Coatings Market Drivers:

Growing Corrosion Protection Demand Drives the Zinc Coatings Market.

The primary driver is the increasing need for corrosion protection in various industries. This is mainly due to the impact of corrosion on the structural integrity and lifespan of metal components. Zinc coatings are applied through processes like galvanization. This creates a protective layer on metal surfaces. This layer serves as a sacrificial barrier, corroding over time. This protects the underlying metal from rust and oxidation. Zinc coatings find applications in the construction, infrastructure, and automotive sectors. These industries are exposed to harsh environmental conditions and can accelerate corrosion. zinc coatings prevent corrosion. The rising awareness of the economic advantages associated with corrosion prevention, such as reduced maintenance costs and extended product lifespan, boosts the demand for zinc coatings in the market.

Construction Industry Growth is propelling the Zinc Coatings Market.

Zinc coatings act as a key component in the construction industry. Galvanized steel is widely used in the construction industry for diverse applications including structures, roofing, fencing, and other components exposed to environmental elements. The growth of the construction sector is driven by global urbanization and infrastructure development. This contributes to the demand for zinc coatings. Zinc coatings offer durability and corrosion resistance, aligning with the requirements of modern construction practices. Zinc coatings support sustainable construction practices. This is due to the recyclability of zinc. The use of zinc coatings aligns with the industry's emphasis on eco-friendly and long-lasting building materials. Zinc coatings play a crucial role where longevity, strength, and resistance to environmental factors are important.

Zinc Coatings Market Restraints and Challenges

The major challenge faced by the Zinc Coatings Market is the environmental impact of zinc. Runoff from zinc-coated surfaces, especially in industrial settings, contributes to soil and water pollution. This results in environmental and regulatory challenges. Another challenge is the fluctuations in the prices of raw materials. Fluctuations in zinc prices can affect production costs, profit margins, and overall market stability. The other restraints to the Zinc Coatings Market include competition from alternative coatings, economic downturns impacting industries, strict regulatory compliance, technological changes, global supply chain disruptions, and shifts in consumer preferences towards sustainable alternatives.

Zinc Coatings Market Opportunities:

The Zinc Coatings Market has various opportunities in the market. The increasing demand in the Renewable Energy Sector is the primary opportunity. There is a growing opportunity for the utilization of zinc coatings in renewable energy infrastructure. Zinc coatings are used in supporting structures for solar panels and components in wind turbines. Opportunities arise with anti-corrosion technology advancement. Zinc coatings can be effective solutions for various applications. Other Opportunities in the market include expansion in emerging markets, innovations in nano-coatings, collaborative efforts for sustainable practices, increasing demand in the transportation sector, and application in marine and offshore structures.

ZINC COATINGS MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

6.9% |

|

Segments Covered |

By Coating Type , End-Use Products, Application Industry, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Elantas GmbH (Germany), Axalta Coating Systems (the U.S.), Von Roll Holdings AG (Switzerland), Hitachi Chemicals Company Ltd. (Japan), 3M Company (the U.S.), and Kyocera Corporation (Japan) |

Zinc Coatings Market Segmentation

Zinc Coatings Market Segmentation: By Coating Type:

- Galvanized Coatings

- Zinc-Rich Coatings

In 2023, based on market segmentation by Coating Type, Galvanized coatings occupy the highest share of the Zinc Coatings Market. This is due to their broad applicability and established usage. Galvanized coatings are used in various industries, including construction, automotive, and infrastructure. Galvanized coatings are dominant due to their durability and cost-effectiveness.

However, Zinc-rich coatings are the fastest-growing segment during the forecast period and are projected to grow at a CAGR of 20%. This is due to increased recognition of their superior anti-corrosion properties in specific industries or applications. Zinc-rich coatings are known for their excellent anti-corrosion properties. Zinc-rich coatings are often used in more specialized or demanding applications where enhanced protection is required.

Zinc Coatings Market Segmentation: By End-Use Products:

- Steel Structures

- Transportation Components

In 2023, based on market segmentation by End-Use Products, Steel Structures the segment occupies the highest share of the Zinc Coatings Market. This is mainly due to the increasing demand for zinc-coated steel in construction and infrastructure projects. This includes a wide range of applications such as buildings, bridges, towers, and other structural components where the use of zinc coatings is crucial for corrosion protection and structural longevity.

However, Transportation Components are the fastest-growing segment during the forecast period. This is mainly due to the increasing demands in the automotive, aerospace, and other transportation industries where zinc-coated components are gaining prominence for their corrosion resistance and durability.

Zinc Coatings Market Segmentation: By Application Industry:

- Construction

- Automotive

- Marine

In 2023, based on market segmentation by the Application Industry, the Construction segment occupies the highest share of the Zinc Coatings Market. This is mainly due to the increasingly widespread application of zinc-coated materials for corrosion protection in various construction elements, including structural components, roofing, and infrastructure. Zinc coatings find extensive use in the construction industry.

However, Automotive is the fastest-growing segment during the forecast period. This growth is driven by increasing demands for zinc-coated steel in the automotive sector, where corrosion resistance is crucial for the durability and longevity of vehicles.

Zinc Coatings Market Segmentation: Regional Analysis:

- North America

- Asia-Pacific

- Europe

- South America

- Middle East and Africa

In 2023, based on market segmentation by region, Asia-Pacific occupies the highest share of the Zinc Coatings Market. The growth is due to robust industrial activities, rapid urbanization, and significant construction and infrastructure development. Countries like China, India, Japan, and South Korea have significant market share due to leading manufacturing and industrial activities. The Asia-Pacific region has witnessed a surge in construction and infrastructure projects, including residential and commercial buildings, bridges, and transportation networks. Zinc coatings are extensively used in industrial applications for corrosion protection, contributing to the region's prominence in the zinc coatings market. The ongoing process of urbanization in Asia-Pacific, marked by the growth of cities and infrastructure development, contributes to the growth in this region.

However, the Middle East and Africa is the fastest-growing segment during the forecast period. This is mainly due to the increased infrastructure projects, construction activities, and the growing industrialization in certain countries within this region. North America is a mature market with a consistent demand for zinc coatings, particularly in the construction and automotive sectors. Europe is a well-established market with a strong presence in automotive, construction, and industrial applications. South America is experiencing moderate growth with demand from the construction and transportation sectors

COVID-19 Impact Analysis on the Global Zinc Coatings Market:

The COVID-19 pandemic had a significant impact on the Zinc Coatings Market. The pandemic has caused lockdowns and other safety restrictions. This resulted in global supply chain disruptions. This affected the availability of raw materials for zinc coatings and led to fluctuations in pricing. The pandemic led to a slowdown in construction activities in many regions. A decrease in construction projects resulted in lower demand for these coatings. The automotive industry, another major user of zinc coatings, faced production slowdowns and disruptions due to the pandemic. The pandemic accelerated the adoption of digital technologies, reevaluating supply chain strategies, and implementing safety measures to ensure business continuity.

Latest Trends/ Developments:

- In December 2022, AkzoNobel successfully finalized the acquisition of Lankwitzer Lackfabrik GmbH's aluminum wheel liquid coatings business, a strategic move aimed at bolstering AkzoNobel's performance coatings portfolio.

- In June 2022, AkzoNobel announced its plans to enhance its presence in Africa through an agreement to acquire the paints and coatings activities from Kansai Paint in the region, with the completion contingent on regulatory approvals and anticipated to take place in 2023.

Key Players:

- PPG Industries

- Sherwin-Williams Company

- AkzoNobel N.V.

- Nippon Paint Holdings Co., Ltd.

- Valspar Corporation

- Kansai Paint Co., Ltd.

- Jotun A/S

- Axalta Coating Systems

- Henkel AG & Co. KGaA

- Tata Steel Limited

Chapter 1. Global Zinc Coatings Market– Scope & Methodology

1.1. Market Segmentation

1.2. Scope, Assumptions & Limitations

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. Global Zinc Coatings Market – Executive Summary

2.1. Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.2.1. Demand Side

2.2.2. Supply Side

2.3. Attractive Investment Propositions

2.4. COVID-19 Impact Analysis

Chapter 3. Global Zinc Coatings Market– Competition Scenario

3.1. Market Share Analysis & Company Benchmarking

3.2. Competitive Strategy & Development Scenario

3.3. Competitive Pricing Analysis

3.4. Supplier-Distributor Analysis

Chapter 4. Global Zinc Coatings Market - Entry Scenario

4.1. Regulatory Scenario

4.2. Case Studies – Key Start-ups

4.3. Customer Analysis

4.4. PESTLE Analysis

4.5. Porters Five Force Model

4.5.1. Bargaining Power of Suppliers

4.5.2. Bargaining Powers of Customers

4.5.3. Threat of New Entrants

4.5.4. Rivalry among Existing Players

4.5.5. Threat of Substitutes

Chapter 5. Global Zinc Coatings Market- Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. Global Zinc Coatings Market– By Coating Type

6.1. Introduction/Key Findings

6.2. Galvanized Coatings

6.3. Zinc-Rich Coatings

6.4. Y-O-Y Growth trend Analysis By Coating Type

6.5. Absolute $ Opportunity Analysis By Coating Type , 2024-2030

Chapter 7. Global Zinc Coatings Market– By Application

7.1. Introduction/Key Findings

7.2. Construction

7.3. Automotive

7.4. Marine

7.5. Y-O-Y Growth trend Analysis By Application

7.6. Absolute $ Opportunity Analysis By Application , 2024-2030

Chapter 8. Global Zinc Coatings Market– By End-User

8.1. Introduction/Key Findings

8.2. Steel Structures

8.3. Transportation Components

8.4. Y-O-Y Growth trend Analysis End-User

8.5. Absolute $ Opportunity Analysis End-User , 2024-2030

Chapter 9. Global Zinc Coatings Market, By Geography – Market Size, Forecast, Trends & Insights

9.1. North America

9.1.1. By Country

9.1.1.1. U.S.A.

9.1.1.2. Canada

9.1.1.3. Mexico

9.1.2. By Coating Type

9.1.3. By Application

9.1.4. By End-User

9.1.5. Countries & Segments - Market Attractiveness Analysis

9.2. Europe

9.2.1. By Country

9.2.1.1. U.K.

9.2.1.2. Germany

9.2.1.3. France

9.2.1.4. Italy

9.2.1.5. Spain

9.2.1.6. Rest of Europe

9.2.2. By Coating Type

9.2.3. By Application

9.2.4. By End-User

9.2.5. Countries & Segments - Market Attractiveness Analysis

9.3. Asia Pacific

9.3.2. By Country

9.3.2.2. China

9.3.2.2. Japan

9.3.2.3. South Korea

9.3.2.4. India

9.3.2.5. Australia & New Zealand

9.3.2.6. Rest of Asia-Pacific

9.3.2. By Coating Type

9.3.3. By Application

9.3.4. By End-User

9.3.5. Countries & Segments - Market Attractiveness Analysis

9.4. South America

9.4.3. By Country

9.4.3.3. Brazil

9.4.3.2. Argentina

9.4.3.3. Colombia

9.4.3.4. Chile

9.4.3.5. Rest of South America

9.4.2. By Coating Type

9.4.3. By Application

9.4.4. By End-User

9.4.5. Countries & Segments - Market Attractiveness Analysis

9.5. Middle East & Africa

9.5.4. By Country

9.5.4.4. United Arab Emirates (UAE)

9.5.4.2. Saudi Arabia

9.5.4.3. Qatar

9.5.4.4. Israel

9.5.4.5. South Africa

9.5.4.6. Nigeria

9.5.4.7. Kenya

9.5.4.8. Egypt

9.5.4.9. Rest of MEA

9.5.2. By Coating Type

9.5.3. By Application

9.5.4. By End-User

9.5.5. Countries & Segments - Market Attractiveness Analysis

Chapter 10. Global Zinc Coatings Market– Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

10.1 PPG Industries

10.2. Sherwin-Williams Company

10.3. AkzoNobel N.V.

10.4. Nippon Paint Holdings Co., Ltd.

10.5. Valspar Corporation

10.6. Kansai Paint Co., Ltd.

10.7. Jotun A/S

10.8. Axalta Coating Systems

10.9. Henkel AG & Co. KGaA

10.10. Tata Steel Limited

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Global Zinc Coatings Market was valued at USD 2.82 billion and is projected to reach a market size of USD 4.5 billion by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 6.9%.

Growing Corrosion Protection Demand and Construction Industry Growth are the market drivers of the Global Zinc Coatings Market

Galvanized Coatings, Zinc-Rich Coatings are the segments under the Global Zinc Coatings Market by Coating Type

Asia-Pacific is the most dominant region for the Global Zinc Coatings Market

PPG Industries, Sherwin-Williams Company, AkzoNobel N.V., Nippon Paint Holdings Co., Ltd., and Valspar Corporation are the key players in the Global Zinc Coatings Market.