Yarn Winding Machines Market Size (2024 – 2030)

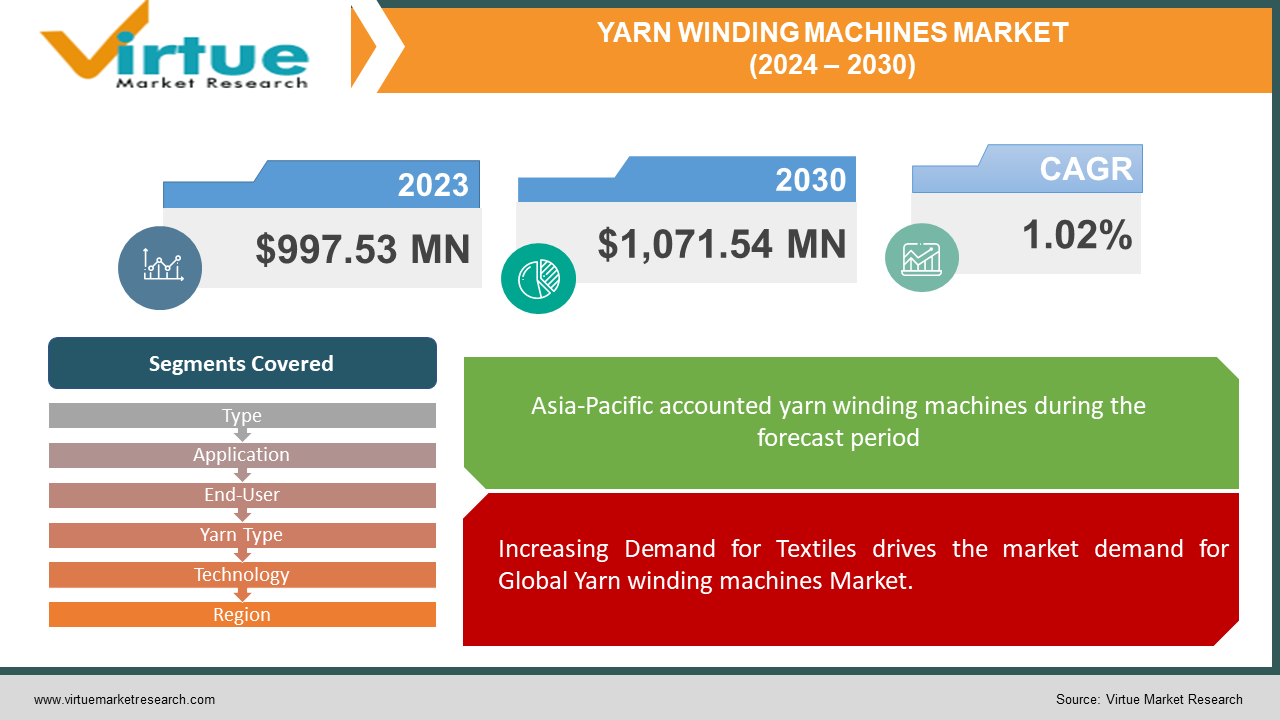

The Global Yarn Winding Machines Market is valued at USD 997.53 Million and is projected to reach a market size of USD 1,071.54 Million by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 1.02%.

A prominent trend observed in the yarn winding machines industry is the integration of Internet of Things (IoT) technology and data analytics into machine design and operation. IoT-enabled yarn winding machines are equipped with sensors and connectivity features that enable real-time monitoring of machine performance, predictive maintenance, and remote diagnostics. By leveraging IoT technology, manufacturers can optimize machine uptime, minimize downtime, and enhance overall operational efficiency. Additionally, data analytics tools allow manufacturers to gain valuable insights into production processes, identify areas for improvement, and make data-driven decisions to optimize yarn winding operations further. As the adoption of IoT technology continues to grow, it is expected to revolutionize the yarn winding machines market, driving innovation and efficiency in textile manufacturing processes.

Key Market Insights:

The global yarn winding machines market is influenced by various factors that shape its growth trajectory over the long term. One significant long-term market driver is the increasing demand for textiles across the globe. As the population grows and disposable incomes rise, the demand for textiles for clothing, home furnishings, and industrial applications continues to surge. Yarn winding machines play a crucial role in the textile manufacturing process by efficiently winding yarn onto cones or spools, thus meeting the demand for high-quality yarn products. However, the outbreak of the COVID-19 pandemic has had a mixed impact on the market. While disruptions in the global supply chain and temporary closures of manufacturing facilities led to a slowdown in production, the heightened focus on hygiene and safety measures also spurred demand for textiles such as face masks and medical garments, indirectly boosting the market for yarn winding machines.

With advancements in technology, manufacturers are increasingly investing in automated yarn winding machines equipped with features such as digital controls, precision winding mechanisms, and real-time monitoring capabilities. This shift towards automation not only enhances efficiency and productivity but also reduces labor costs and minimizes errors in the winding process. Furthermore, automation allows manufacturers to respond quickly to changing market demands and produce customized yarn products, thus driving market growth in the short term.

Global Yarn Winding Machines Market Drivers:

Increasing Demand for Textiles drives the market demand for Global Yarn winding machines Market.

One of the primary drivers of the yarn winding machines market is the rising demand for textiles across the globe. Textiles are used in various applications such as clothing, home furnishings, and industrial purposes. As the population grows and disposable incomes rise, the demand for textiles continues to surge, driving the need for efficient yarn winding machines in the textile manufacturing process.

Technological Advancements have boosted the market for Global Yarn winding machines Market.

Technological advancements in yarn winding machines have led to improved efficiency, productivity, and reliability. Manufacturers are continually innovating to develop advanced yarn winding machines equipped with features such as digital controls, precision winding mechanisms, and real-time monitoring capabilities. These advancements enhance the performance of yarn-winding machines, making them more attractive to textile manufacturers seeking to optimize their production processes.

Automation and Digitalization drive the market demand for the Global Yarn Winding Machines Market.

The adoption of automation and digitalization in textile manufacturing is another significant driver of the yarn winding machines market. Manufacturers are increasingly investing in automated yarn winding machines that offer benefits such as reduced labor costs, increased productivity, and improved quality control. Additionally, digitalization allows manufacturers to customize yarn winding processes, respond quickly to changing market demands, and achieve greater operational efficiency.

Emerging Markets for yarn winding machines have boosted the market for Global Yarn winding machines Market.

The growth of emerging markets, particularly in regions such as Asia-Pacific and Latin America, presents significant opportunities for the yarn winding machines market. Rapid industrialization, urbanization, and increasing disposable incomes in these regions are driving the demand for textiles, thereby boosting the need for yarn-winding machines. Additionally, government initiatives aimed at promoting the textile industry further contribute to market growth in emerging economies.

Global Yarn Winding Machines Market Restraints and Challenges:

One of the primary challenges faced by manufacturers and users of yarn winding machines is the high initial investment required for purchasing and installing these machines. Yarn winding machines are sophisticated equipment that involves substantial capital expenditure, especially for advanced models with automated features and digital controls. The high upfront costs may deter small and medium-sized textile manufacturers from investing in yarn winding machines, limiting market growth. In addition to the initial investment, yarn winding machines entail ongoing maintenance and operational costs, including expenses for spare parts, repairs, and energy consumption. Regular maintenance is essential to ensure optimal performance and prevent downtime, but it adds to the overall operational expenses for textile manufacturers. Moreover, the complexity of modern yarn winding machines may require specialized technicians for maintenance and repairs, further increasing operational costs.

The global yarn winding machines market is characterized by intense competition among manufacturers vying for market share. Competition is driven by factors such as product quality, price competitiveness, technological innovation, and customer service. Established players in the market face competition from both domestic and international manufacturers, as well as new entrants seeking to gain a foothold in the industry. This competitive landscape exerts pressure on manufacturers to differentiate their products and services to attract customers and sustain profitability.

Global Yarn Winding Machines Market Opportunities:

The textile industry is characterized by diverse product requirements and changing market demands, necessitating flexibility and customization in yarn winding machines. Manufacturers can seize opportunities by offering modular and customizable machine configurations that cater to specific customer needs and production requirements. By providing flexible solutions that can accommodate various yarn types, winding speeds, and package sizes, manufacturers can address the evolving needs of textile producers and enhance customer satisfaction.

Emerging economies, particularly in Asia-Pacific and Latin America, present lucrative opportunities for yarn winding machine manufacturers due to the rapid growth of the textile industry in these regions. Rising disposable incomes, urbanization, and expanding middle-class populations are driving increased demand for textiles and apparel, creating a growing market for yarn winding machines. Manufacturers can capitalize on this trend by expanding their presence in emerging markets, establishing local manufacturing facilities, and forging strategic partnerships with regional distributors and suppliers.

Collaboration and partnerships with other stakeholders in the textile value chain, such as yarn producers, textile machinery suppliers, and end-user industries, can unlock new opportunities for yarn winding machine manufacturers. By collaborating with yarn producers to co-develop innovative yarn winding solutions and technologies, manufacturers can gain insights into market trends and customer preferences, enabling them to design and deliver products that meet specific industry requirements. Similarly, partnerships with textile manufacturers and apparel brands can facilitate market access and product validation, driving adoption and market penetration for yarn winding machines.

YARN WINDING MACHINES MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

1.02% |

|

Segments Covered |

By Type, Application, End-User, Yarn Type, Technology, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Murata Machinery Ltd., Savio Macchine Tessili S.p.A., SSM Schärer Schweiter Mettler AG, Qingdao Hongda Textile Machinery Group Co., Ltd., Itema S.p.A., Zhejiang Rifa Textile Machinery Co., Ltd., Himson Engineering Pvt. Ltd., Rieter Holding AG, Batliboi Ltd., Xingxing Textile Machinery (China) Co., Ltd., Lakshmi Machine Works Ltd. (LMW), Toyoda Textile Machinery Inc., Ningbo Dingming Machinery Manufacturing Co., Ltd., Benninger AG, Crosrol Limited, Voltas Limited, Marzoli Spinning Solutions S.p.A., A.T.E. Enterprises Private Limited, Textile Machinery Associates, Inc., Xorella AG |

Global Yarn Winding Machines Market Segmentation: By Type

-

Precision Winding Machines

-

Drum Winding Machines

-

Cone Winding Machines

In the realm of manufacturing, yarn winding machines play a vital part in the cloth and vesture diligence, icing the effective winding of yarn onto colorful packages. These machines are also essential in other diligence like automotive, electronics, and more, where yarn plays a pivotal part in the product process. The global yarn winding machines request is segmented by operation, with the cloth assiduity arising as the largest member. The cloth assiduity relies heavily on yarn winding machines for the product of colorful fabrics, including apparel, home fabrics, and artificial fabrics. The perfection and effectiveness of these machines are vital in icing the quality and thickness of the yarn, which directly impacts the final product's quality. While the cloth assiduity remains the largest member, the electronics assiduity is the swift-growing member in the global yarn winding machines request. This growth is driven by the adding demand for electronic factors that use fine yarns, similar to those used in the product of circuit boards and electrical lines. Yarn winding machines play a pivotal part in icing the precise winding of these fine yarns, meeting the strict conditions of the electronics assiduity. As the electronics assiduity continues to expand, the demand for yarn winding machines in this sector is anticipated to grow significantly, driving invention and growth in the request.

Global Yarn Winding Machines Market Segmentation: By Application

-

Textile Industry

-

Apparel Industry

-

Automotive Industry

-

Electronics Industry

-

Others

The services segment is the largest in the aircraft smart maintenance market. It includes a wide range of services such as maintenance planning, predictive maintenance, system integration, training, and support. Service providers offer comprehensive solutions to help airlines implement and optimize smart maintenance technologies effectively.

The software segment is the fastest-growing segment in the aircraft smart maintenance market. With the increasing adoption of digitalization and automation in maintenance operations, the demand for software solutions that enable predictive analytics, remote monitoring, and data management is on the rise. Software providers offer innovative solutions to address the evolving needs of airlines and improve maintenance efficiency.

Global Yarn Winding Machines Market Segmentation: By End-User

-

Small and Medium Enterprises (SMEs)

-

Large Enterprises

Large enterprises, with their substantial manufacturing capacities and extensive operations, require advanced yarn winding machines to support their production processes effectively. These enterprises typically handle large-scale manufacturing operations, producing significant quantities of textile products, apparel items, automotive components, electronics, and other goods. As a result, they heavily invest in high-capacity yarn winding machines capable of meeting their production demands efficiently. Given their considerable market presence and demand for sophisticated machinery, large enterprises hold a significant share of the yarn winding machines market.

On the other hand, the fastest-growing segment in the global yarn winding machines market comprises small and medium enterprises (SMEs). While SMEs may not have the same scale of operations as large enterprises, they represent a diverse and dynamic segment of the market. SMEs play a vital role in various industries, contributing to innovation, job creation, and economic growth. In recent years, there has been a noticeable trend of SMEs increasingly adopting yarn winding machines to enhance their manufacturing capabilities and improve productivity.

Global Yarn Winding Machines Market Segmentation: By Yarn Type

-

Natural Yarns

-

Synthetic Yarns

-

Blended Yarns

In the global yarn winding machines market, the choice of yarn type significantly influences the selection of appropriate machinery for the manufacturing process. Yarn winding machines are designed to handle various types of yarn, including natural yarns, synthetic yarns, and blended yarns. Among these, synthetic yarns emerge as the largest segment in terms of usage and demand. Synthetic yarns, made from man-made fibers such as polyester, nylon, and acrylic, dominate the market due to their versatility, durability, and cost-effectiveness. These yarns are widely used in various industries, including textiles, apparel, automotive, and electronics, for their superior strength, resistance to wrinkles, and ease of maintenance. As a result, the demand for yarn winding machines capable of handling synthetic yarns remains consistently high across different regions.

On the other hand, blended yarns represent the fastest-growing segment in the global market. Blended yarns are made by combining natural and synthetic fibers, offering the benefits of both materials. By blending fibers, manufacturers can create yarns with enhanced properties such as softness, breathability, and moisture-wicking capabilities. Blended yarns are increasingly preferred in applications where comfort, performance, and sustainability are essential considerations, such as sportswear, activewear, and home textiles. As a result, there is a growing demand for yarn winding machines that can efficiently handle blended yarns and meet the evolving needs of the market.

Global Yarn Winding Machines Market Segmentation: By Technology

-

Conventional Yarn Winding Machines

-

CNC (Computer Numerical Control) Yarn Winding Machines

-

PLC (Programmable Logic Controller) Controlled Yarn Winding Machines

Conventional yarn winding machines are widely used in the industry due to their simplicity and cost-effectiveness. These machines are manually operated and do not require sophisticated programming or control systems, making them suitable for small-scale operations and budget-conscious businesses. Despite the advancements in technology, conventional yarn winding machines continue to be popular, especially in regions where cost considerations are paramount.

On the other hand, PLC-controlled yarn winding machines represent the fastest-growing segment in the global market. PLC technology offers significant advantages over conventional machines, including precise control, automation capabilities, and real-time monitoring. These machines can be programmed to perform complex winding patterns, adjust tension levels, and optimize production processes, leading to higher efficiency and productivity. As a result, many manufacturers are increasingly adopting PLC-controlled yarn winding machines to enhance their manufacturing processes and gain a competitive edge in the market.

Global Yarn Winding Machines Market Segmentation: Regional Analysis

-

North America

-

Asia-Pacific

-

Europe

-

South America

-

Middle East and Africa

Among these regions, Asia-Pacific emerges as the largest segment in terms of market share and demand for yarn winding machines. The Asia-Pacific region is home to some of the world's largest textile manufacturing hubs, including China, India, Bangladesh, and Vietnam. These countries have a strong presence in the textile and apparel industries, driven by factors such as abundant raw materials, skilled labor, and favorable government policies. As a result, there is a significant demand for yarn winding machines in the Asia-Pacific region to support the production of various textile products.

Furthermore, Asia-Pacific also holds the distinction of being the fastest-growing segment in the global yarn winding machines market. The rapid industrialization, urbanization, and economic growth witnessed in countries across the region have led to an increased demand for textiles and garments. Additionally, the rising disposable incomes and changing consumer preferences towards high-quality textiles and clothing drive the need for advanced yarn winding machinery. Manufacturers in the Asia-Pacific region are investing in modernizing their production facilities with state-of-the-art yarn winding machines to enhance efficiency, productivity, and product quality.

COVID-19 Impact Analysis on Global Yarn Winding Machines Market:

The sharp decline in air travel demand during the pandemic has resulted in reduced airline operations and flight frequencies. With fewer flights and grounded fleets, the need for aircraft maintenance and repair services has decreased significantly. Airlines have scaled back their maintenance activities, deferred non-essential maintenance tasks, and postponed fleet expansion plans to conserve cash and mitigate financial losses.

The economic impact of the pandemic has intensified the focus on cost optimization and efficiency improvement within the aviation industry. Airlines and maintenance providers are seeking ways to reduce operating costs, streamline maintenance processes, and improve resource utilization. While smart maintenance solutions offer long-term benefits in terms of efficiency and reliability, the immediate priority for many organizations is to minimize expenses and preserve liquidity.

Latest Trends/ Developments:

Manufacturers of yarn winding machines are increasingly incorporating Industry 4.0 technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning to enhance operational efficiency and productivity. Smart yarn winding machines equipped with IoT sensors allow real-time monitoring of machine performance, predictive maintenance, and remote troubleshooting, reducing downtime and optimizing production processes.

Yarn winding machines are increasingly equipped with intuitive user interfaces and connectivity features to streamline operations and enhance user experience. Touchscreen displays, graphical user interfaces (GUI), and user-friendly controls simplify machine operation and programming, while connectivity options such as Wi-Fi and Bluetooth enable seamless integration with other production equipment and software systems for data exchange and process optimization.

Yarn winding machine manufacturers are forming strategic partnerships and collaborations with industry players, technology providers, and research institutions to leverage complementary expertise, resources, and capabilities. These collaborations facilitate knowledge exchange, technology transfer, and joint innovation initiatives, driving product development and market expansion opportunities.

Key Players:

-

Murata Machinery Ltd.

-

Savio Macchine Tessili S.p.A.

-

SSM Schärer Schweiter Mettler AG

-

Qingdao Hongda Textile Machinery Group Co., Ltd.

-

Itema S.p.A.

-

Zhejiang Rifa Textile Machinery Co., Ltd.

-

Himson Engineering Pvt. Ltd.

-

Rieter Holding AG

-

Batliboi Ltd.

-

Xingxing Textile Machinery (China) Co., Ltd.

-

Lakshmi Machine Works Ltd. (LMW)

-

Toyoda Textile Machinery Inc.

-

Ningbo Dingming Machinery Manufacturing Co., Ltd.

-

Benninger AG

-

Crosrol Limited

-

Voltas Limited

-

Marzoli Spinning Solutions S.p.A.

-

A.T.E. Enterprises Private Limited

-

Textile Machinery Associates, Inc.

-

Xorella AG

Chapter 1. Yarn Winding Machines Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Yarn Winding Machines Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Yarn Winding Machines Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Yarn Winding Machines Market Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Yarn Winding Machines Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Yarn Winding Machines Market – By Type

6.1 Introduction/Key Findings

6.2 Precision Winding Machines

6.3 Drum Winding Machines

6.4 Cone Winding Machines

6.5 Y-O-Y Growth trend Analysis By Type

6.6 Absolute $ Opportunity Analysis By Type, 2024-2030

Chapter 7. Yarn Winding Machines Market – By Application

7.1 Introduction/Key Findings

7.2 Textile Industry

7.3 Apparel Industry

7.4 Automotive Industry

7.5 Electronics Industry

7.6 Others

7.7 Y-O-Y Growth trend Analysis By Application

7.8 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. Yarn Winding Machines Market – By End-User

8.1 Introduction/Key Findings

8.2 Small and Medium Enterprises (SMEs)

8.3 Large Enterprises

8.4 Y-O-Y Growth trend Analysis By End-User

8.5 Absolute $ Opportunity Analysis By End-User, 2024-2030

Chapter 9. Yarn Winding Machines Market – By Yarn Type

9.1 Introduction/Key Findings

9.2 Natural Yarns

9.3 Synthetic Yarns

9.4 Blended Yarns

9.5 Y-O-Y Growth trend Analysis By Yarn Type

9.6 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 10. Yarn Winding Machines Market – By Technology

10.1 Introduction/Key Findings

10.2 Conventional Yarn Winding Machines

10.3 CNC (Computer Numerical Control) Yarn Winding Machines

10.4 PLC (Programmable Logic Controller) Controlled Yarn Winding Machines

10.5 Y-O-Y Growth trend Analysis By Technology

10.6 Absolute $ Opportunity Analysis By Technology, 2024-2030

Chapter 11. Yarn Winding Machines Market, By Geography – Market Size, Forecast, Trends & Insights

11.1 North America

11.1.1 By Country

11.1.1.1 U.S.A.

11.1.1.2 Canada

11.1.1.3 Mexico

11.1.2 By Type

11.1.2.1 By Application

11.1.3 By End-User

11.1.4 By Technology

11.1.5 Countries & Segments - Market Attractiveness Analysis

11.2 Europe

11.2.1 By Country

11.2.1.1 U.K

11.2.1.2 Germany

11.2.1.3 France

11.2.1.4 Italy

11.2.1.5 Spain

11.2.1.6 Rest of Europe

11.2.2 By Type

11.2.3 By Application

11.2.4 By End-User

11.2.5 By Yarn Type

11.2.6 By Technology

11.2.7 Countries & Segments - Market Attractiveness Analysis

11.3 Asia Pacific

11.3.1 By Country

11.3.1.1 China

11.3.1.2 Japan

11.3.1.3 South Korea

11.3.1.4 India

11.3.1.5 Australia & New Zealand

11.3.1.6 Rest of Asia-Pacific

11.3.2 By Type

11.3.3 By Application

11.3.4 By End-User

11.3.5 By Yarn Type

11.3.6 By Technology

11.3.7 Countries & Segments - Market Attractiveness Analysis

11.4 South America

11.4.1 By Country

11.4.1.1 Brazil

11.4.1.2 Argentina

11.4.1.3 Colombia

11.4.1.4 Chile

11.4.1.5 Rest of South America

11.4.2 By Type

11.4.3 By Application

11.4.4 By End-User

11.4.5 By Yarn Type

11.4.6 By Technology

11.4.7 Countries & Segments - Market Attractiveness Analysis

11.5 Middle East & Africa

11.5.1 By Country

11.5.1.1 United Arab Emirates (UAE)

11.5.1.2 Saudi Arabia

11.5.1.3 Qatar

11.5.1.4 Israel

11.5.1.5 South Africa

11.5.1.6 Nigeria

11.5.1.7 Kenya

11.5.1.8 Egypt

11.5.1.9 Rest of MEA

11.5.2 By Type

11.5.3 By Application

11.5.4 By End-User

11.5.5 By Yarn Type

11.5.6 By Technology

11.5.7 Countries & Segments - Market Attractiveness Analysis

Chapter 12. Yarn Winding Machines Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

12.1 Murata Machinery Ltd.

12.2 Savio Macchine Tessili S.p.A.

12.3 SSM Schärer Schweiter Mettler AG

12.4 Qingdao Hongda Textile Machinery Group Co., Ltd.

12.5 Itema S.p.A.

12.6 Zhejiang Rifa Textile Machinery Co., Ltd.

12.7 Himson Engineering Pvt. Ltd.

12.8 Rieter Holding AG

12.9 Batliboi Ltd.

12.10 Xingxing Textile Machinery (China) Co., Ltd.

12.11 Lakshmi Machine Works Ltd. (LMW)

12.12 Toyoda Textile Machinery Inc.

12.13 Ningbo Dingming Machinery Manufacturing Co., Ltd.

12.14 Benninger AG

12.15 Crosrol Limited

12.16 Voltas Limited

12.17 Marzoli Spinning Solutions S.p.A.

12.18 A.T.E. Enterprises Private Limited

12.19 Textile Machinery Associates, Inc.

12.20 Xorella AG

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Global Yarn Winding Machines Market is valued at USD 997.53 Million and is projected to reach a market size of USD 1,071.54 Million by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 1.02%.

Increasing Demand for Textiles, Technological Advancements, Automation and Digitalization, and Emerging Markets for yarn winding machines are the market drivers of the Global Yarn Winding Machines Market.

Natural Yarns, Synthetic Yarns, and Blended Yarns are the segments under the Global Yarn Winding Machines Market by Yarn Type.

Asia-Pacific is the most dominant region for the Global Yarn Winding Machines Market.

Asia-Pacific is the fastest-growing region in the Global Yarn Winding Machines Market.