Global Ultrasonic Level Transmitter Market Size (2023 – 2030)

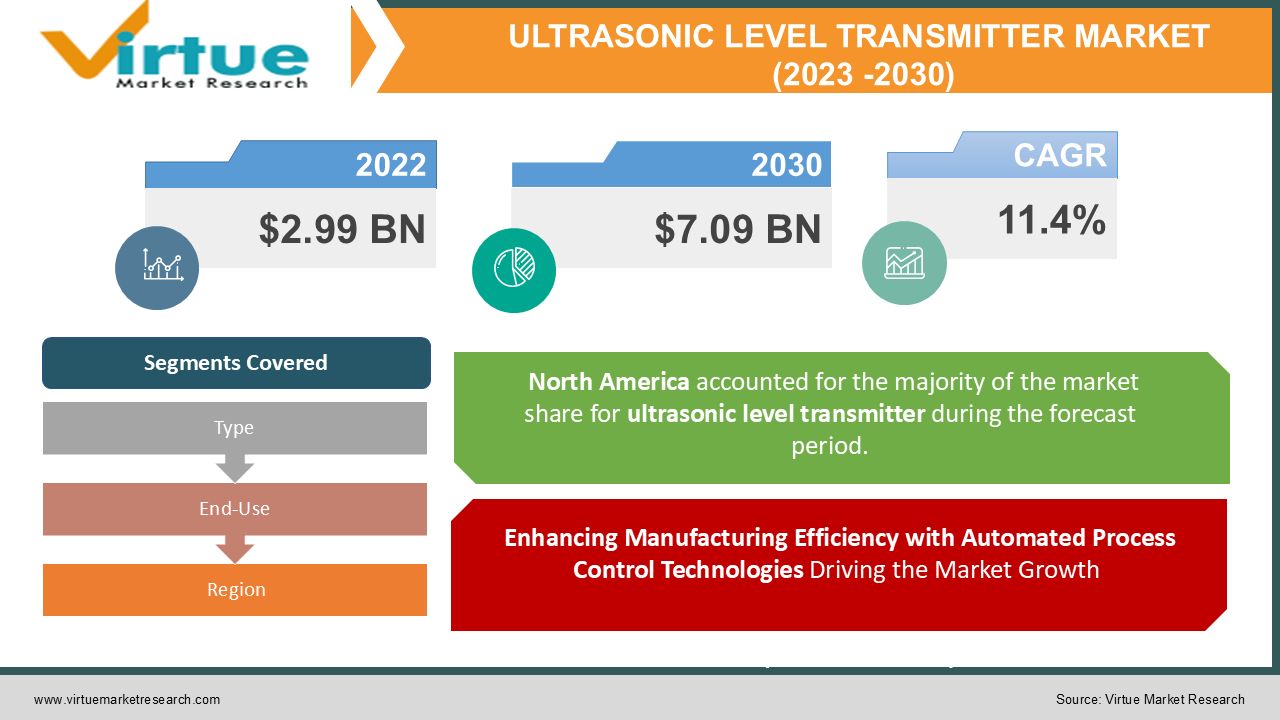

In 2022, the Global Ultrasonic Level Transmitter Market was valued at USD 2.99 billion and is projected to reach a market size of USD 7.09 billion by 2030. Over the forecast period of 2023-2030, the market is projected to grow at a CAGR of 11.4%.

Industry Overview:

An electrical sensor called an ultrasonic level transmitter monitors the elevation of liquids and gases based on how long it takes for sound to travel a certain distance, commonly measured in feet or meters. Two transducers, one at the top and one at the bottom of a tank or pipe, emit sound waves of known frequency to calculate the measurement. The time it takes for the waves to return is then recorded. Applications for ultrasonic level transmitters include the chemical, oil and gas, and food and beverage industries, among others. Depending on the type and application, it provides accurate liquid level detection even when other variables vary quickly. Its measurement range ranges from 0-5000ft/1524m or higher.

Nearly 30% of the global market share for ultrasonic level sensors was held by the organized sector. Businesses in the organized sector have good operations and sales infrastructure spread across important regions, and some of them have a global presence. These businesses' primary strategies consist of growing their manufacturing capabilities and introducing new goods to broaden their product line. Additionally, these businesses plan to buy local businesses both domestically and abroad.

Impact of Covid-19 on the Industry:

The worldwide economy and all global industries have been greatly impacted by COVID-19. The fundamental cause of this is global supply chain disruptions. Due to the sharp drop in product demand, economies all around the world have suffered. The pandemic-related lack of raw materials has curtailed production across all industries. The main causes of the output reduction are the decline in exports and supply chain interruptions. COVID-19 has had an impact on the level transmitter industry as a result. As a result, the predicted year-over-year growth rate for 2020 is lower than it was for 2019.

Market Drivers:

Enhancing Manufacturing Efficiency with Automated Process Control Technologies Driving the Market Growth

For a manufacturing company to succeed, maintaining the quality of a final product through careful monitoring of raw materials and accurate regulation of production processes is crucial. Automated process control technologies are now being used by several manufacturers for quicker, better, and less expensive manufacturing. Across a variety of process industries, industrial automation lowers operational costs, enhances product quality, boosts productivity, and resolves industrial health and safety-related challenges. Both discrete and process sectors have focused on implementing the best practices to decrease waste and boost plant productivity. Making better business and operational decisions based on plant data, such as real-time production data, is the key to improving efficiency and optimizing manufacturing processes. Consequently, there is a growing emphasis on integrating systems and software, including level transmitters, that could make this job easier.

Growing demand for radar level transmitter fuelling the market growth:

Process industries place a high value on radar-level transmitters because they are the most dependable, accurate, and suitable for unstable process settings. In practically every application involving solids and liquids, level measuring is made easier by radar-level technology. Additionally effective with boiling surfaces, recirculating fluids, propeller mixers, and aeration tanks are radar-level transmitters. As a result, they are employed in about 90% of level measurement applications. Additionally, guided wave radar technology has several advantages for processes that involve dust, foam, and heavy vapors. The technology enables the measuring signal to pass through the upper product and deliver measurement of the lower product wherever there is a need for interface measurement (such as oil on water).

Market Restraints:

Network congestion in continuous level measurement:

Level measurement is carried out using a level transmitter, which also transmits the measured data to distant monitoring systems across a network. Utilizing computers throughout the production process allows for automation in industries. As a result, continuous level measurement generates a lot of data, which may cause network congestion. The flow of data communication may be slowed down by excessive data in systems utilized throughout the industry.

Difficulties associated with High-level measurement in tanks with floating roof:

The roof of storage tanks for explosive substances like gasoline, naphtha, and organic compounds is designed to float on the liquid. This minimizes evaporation, lowers the possibility of fire or explosion, eliminates the buildup of vapors, and reduces both product loss and air pollution. The detection of high-level measurements and the overfilling of tanks and containers, however, present significant difficulties for the floating roof. Traditional level switches, like tuning forks or ultrasonic gap switches, cannot be used to measure liquids since the roof is a solid object.

ULTRASONIC LEVEL TRANSMITTER MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

11.4 % |

|

Segments Covered |

By Type, End User, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

ABB Ltd., AMETEK, Inc., Balluff GmbH, Banner Engineering Corporation, Baumer SA, Christian Burkert GmbH & Co. KG, Continental AG, Endress+Hauser AG, Gems Sensors & Controls, Hans Turck GmbH & Co. KG, Honeywell International, Inc., Keyence Corporation of America, KROHNE Messtechnik GmbH, Migatron Corp., Omega Engineering, Inc. |

This research report on the global ultrasonic level transmitter market has been segmented and sub-segmented based on, and Geography & region.

Global Ultrasonic Level Transmitter Market- By Type

-

Straight Rod Type Transmitter

-

Flange Type Transmitter

-

Screw-Type Transmitter

An example of an ultrasonic level transmitter is a straight rod type transmitter. This kind of transmitter features an L-shaped frame with one side above the container being measured. Its sensing elements can be either a straight rod or a flexible probe. The probe is connected to a pivot rod that is installed on top of the frame at one end and the threaded shaft of the straight rod at the other. Such a transmitter might be an ultrasonic level sensor with two straight rods, one above and one below the water's surface. These rods rotate in tandem when liquid passes between them, providing information about the liquid's surface's measured distance.

A flange-type transmitter features a circular frame with one side above the container being measured. Its sensing components can be either a straight rod or a flexible probe. The probe is installed on top of the frame with one end of the probe attached to the top of an L-shaped flange and the other end of the probe attached to the pivot rod. An ultrasonic level sensor with one straight rod and one flexible probe as its sensing elements would be an illustration of a flange-type transmitter. These two sensing components rotate in tandem while liquid passes between them, transmitting data regarding the measurement of the distance to the liquid's surface.

To measure the height or depth of the fluid, electronic equipment called a screw-type ultrasonic level transmitter is utilized. It is divided into two parts: A sensor with electronics for data transmission coupled by wires, a piezoelectric crystal fastened to a metal rod, and another component called the transmitter that detects voltage changes, amplifies them, and transmits the signal to a receiver. The sensor is attached to a screw that can be spun manually or by an electric motor using gears and belts. Through electrical connections, such as wires or cables that go from the bottom up into fluid reserves, the transmitter section makes touch with fluids in tanks.

Global Ultrasonic Level Transmitter Market- By End User

-

Medical

-

Automotive

-

Industrial

-

Food & Beverage

-

Cement

-

Pulp & Paper

-

Chemical

-

Water & Waste Water Management

-

Oil & Gas

In the upcoming years, there will likely be a significant increase in demand for ultrasonic level sensors in the industrial sector. There is a lot of room for the industrial sector to expand quickly given the rising demand for consumer items like food, beverages, chemicals, and cement. In 2025, the industrial end-use segment is anticipated to account for more than 44% of the worldwide market share and is projected to expand at a CAGR of 10.2%. Water and wastewater management, oil & gas, and the industrial industry all exhibit strong potential and are anticipated to grow at considerable CAGRs during the research period.

Global Ultrasonic Level Transmitter Market- By Region

-

North America

-

Europe

-

Asia-Pacific

-

Latin America

-

The Middle East and Africa

In the United States, the market for ultrasonic level sensors is anticipated to reach US$47.6 million by 2020. The second-largest economy in the world, China, is anticipated to grow at a CAGR of 11.2 percent from 2020 to 2030 to reach a projected market size of US$64.7 million. Japan and Canada are two more notable geographic markets, with growth rates of 4 and 6.6 percent over the 2020–2030 timeframe, respectively. Germany is anticipated to expand within Europe at a CAGR of roughly 4.7 percent.

The process, healthcare, petrochemical, chemical, and power sectors are well-established in the area. Due to their extensive urbanization and quick economic growth, India and China are seen as enormous markets for level transmitters. High industrial growth is being seen in China and India. Additionally, the region's chemical and food & beverage sectors are expanding. The treatment facilities for the aforementioned businesses' water-intensive industries are anticipated to increase demand for level transmitters.

Global Ultrasonic Level Transmitter Market- By Companies

-

ABB Ltd.

-

AMETEK, Inc.

-

Balluff GmbH

-

Banner Engineering Corporation

-

Baumer SA

-

Christian Burkert GmbH & Co. KG

-

Continental AG

-

Endress+Hauser AG

-

Gems Sensors & Controls

-

Hans Turck GmbH & Co. KG

-

Honeywell International, Inc.

-

Keyence Corporation of America

-

KROHNE Messtechnik GmbH

-

Migatron Corp.

-

Omega Engineering, Inc.

NOTABLE HAPPENINGS IN THE ULTRASONIC LEVEL TRANSMITTER MARKET IN THE RECENT PAST:

-

Product Launch: - In 2020, Endress+Hauser Middle East was founded, increasing the company's presence in the region. The new business, which will have its headquarters in Dubai, United Arab Emirates, will manage and support all regional sales, service, and solutions initiatives, including those of Endress+Hauser sales offices and Middle Eastern sales representatives.

-

Product Launch: - In 2020, For inventory management and crucial process control, Siemens introduced the Sitrans LR250 PLA (polypropylene lens antenna), a radar level measuring transmitter. Chemical levels can be checked using this solution at nominal pressure and temperature.

-

Product Launch: - In 2020, In November 2019, Vega added 80 GHz radar level sensors for the water and wastewater industries, expanding its radar product line.

Chapter 1. Global Ultrasonic Level Transmitter Market – Scope & Methodology

1.1. Market Segmentation

1.2. Assumptions

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. Global Ultrasonic Level Transmitter Market – Executive Summary

2.1. Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.3. COVID-19 Impact Analysis

2.3.1. Impact during 2023 - 2030

2.3.2. Impact on Supply – Demand

Chapter 3. Global Ultrasonic Level Transmitter Market – Competition Scenario

3.1. Market Share Analysis

3.2. Product Benchmarking

3.3. Competitive Strategy & Development Scenario

3.4. Competitive Pricing Analysis

3.5. Supplier - Distributor Analysis

Chapter 4. Global Ultrasonic Level Transmitter Market Entry Scenario

4.1. Case Studies – Start-up/Thriving Companies

4.2. Regulatory Scenario - By Region

4.3 Customer Analysis

4.4. Porter's Five Force Model

4.4.1. Bargaining Power of Suppliers

4.4.2. Bargaining Powers of Customers

4.4.3. Threat of New Entrants

4.4.4. Rivalry among Existing Players

4.4.5. Threat of Substitutes

Chapter 5. Global Ultrasonic Level Transmitter Market - Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. Global Ultrasonic Level Transmitter Market – By Type

6.1. Straight Rod Type Transmitter

6.2. Flange Type Transmitter

6.3. Screw-Type Transmitter

Chapter 7. Global Ultrasonic Level Transmitter Market – By End User

7.1. Medical

7.2. Automotive

7.3. Industrial

7.4. Food & Beverage

7.5. Cement

7.6. Pulp & Paper

7.7. Chemical

7.8. Water & Waste Water Management

7.9. Oil & Gas

Chapter 8. Global Ultrasonic Level Transmitter Market- By Region

8.1. North America

8.2. Europe

8.3. Asia-Pacific

8.4. Latin America

8.5. The Middle East

8.6. Africa

Chapter 9. Global Ultrasonic Level Transmitter Market – Company Profiles – (Overview, Product Portfolio, Financials, Developments)

9.1 ABB Ltd.

9.2 AMETEK, Inc.

9.3 Balluff GmbH

9.4 Banner Engineering Corporation

9.5 Baumer SA

9.6 Christian Burkert GmbH & Co. KG

9,7 Continental AG

9.8 Endress+Hauser AG

9.9 Gems Sensors & Controls

9.10 Hans Turck GmbH & Co. KG

9.11 Honeywell International, Inc.

9.12 Keyence Corporation of America

913 KROHNE Messtechnik GmbH

9.14 Migatron Corp.

Download Sample

Choose License Type

2500

4250

5250

6900