Teflon Coating Market Size (2023-2030)

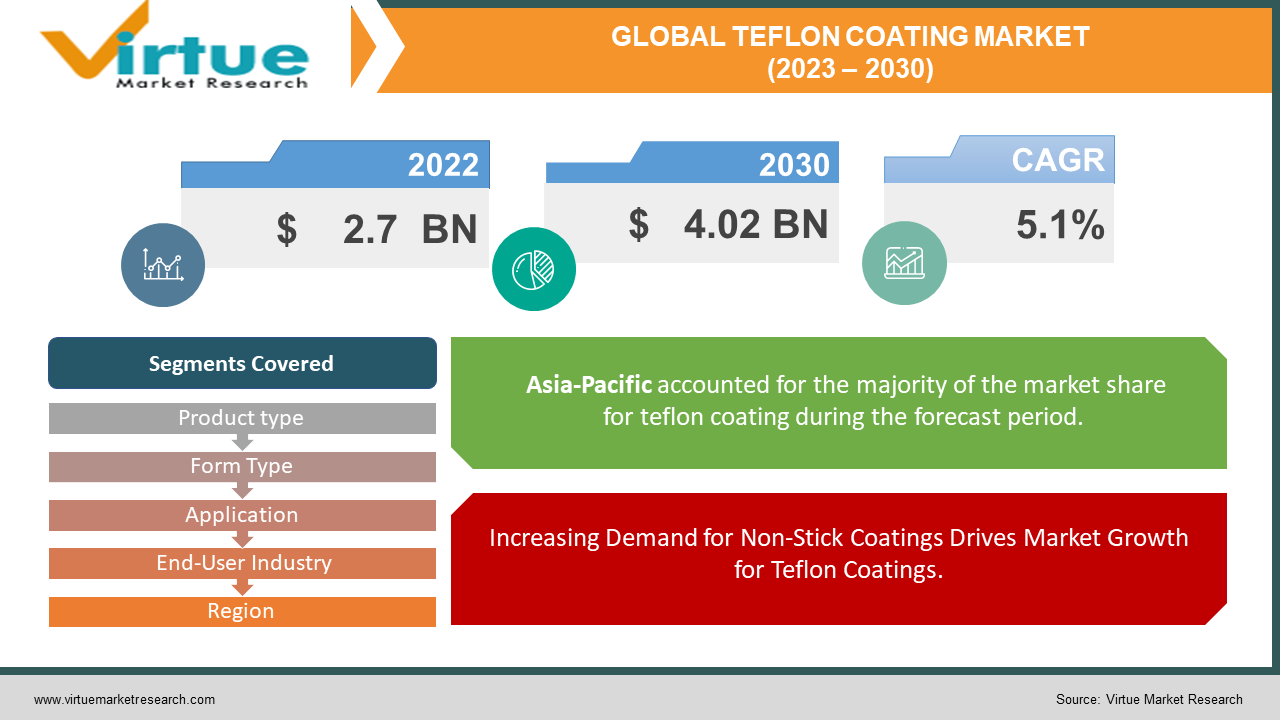

The Teflon Coating Market was valued at USD 2.7 Billion in 2022 and is anticipated to reach USD 4.02 Billion by 2030, with a strong CAGR of 5.1% during the forecast period 2023-2030.

Teflon coatings, also known as Polytetrafluoroethylene (PTFE) coatings, have gained significant prominence as a class of non-stick coatings, offering exceptional surface enhancement properties. The market for Teflon coatings has experienced substantial growth owing to their distinctive attributes, including high chemical resistance, excellent non-stick behavior, low coefficient of friction, and remarkable heat resistance. These coatings have found widespread applications across diverse industries, such as automotive, cookware, electronics, aerospace, and industrial equipment. Within the automotive sector, Teflon coatings play a vital role in enhancing engine components' performance by reducing friction, resulting in improved fuel efficiency and component longevity. In the cookware industry, Teflon coatings contribute to a hassle-free cooking experience with their non-stick surface, making cleanup effortless. Moreover, the electronics and aerospace industries rely on Teflon coatings for their outstanding insulation capabilities and protection against environmental elements. The ever-growing demand for durable, high-performance coatings with superior surface properties continues to drive the adoption of Teflon coatings in numerous applications and industries, establishing them as a pivotal element in surface engineering solutions.

Global Teflon Coating Market Drivers:

Increasing Demand for Non-Stick Coatings Drives Market Growth for Teflon Coatings.

The demand for non-stick coatings has been steadily rising across various industries, thanks to the convenience they offer with easy cleaning and reduced friction. Teflon coatings, renowned for their exceptional non-stick behavior, have emerged as the preferred choice for cookware, bakeware, and food processing equipment, opening significant growth opportunities for the Teflon coating market. Moreover, in industrial settings, the application of Teflon coatings on equipment and machinery, where material sticking or adhesion can cause operational inefficiencies and maintenance challenges, further drives market growth.

Growing Awareness of Environmental and Health Benefits Accelerates Teflon Coating Demand.

Teflon coatings are renowned for their environmental and health benefits, setting them apart as they are free from harmful perfluorooctanoic acid (PFOA) and other toxic substances. As consumers and industries become increasingly conscious of environmental and health impacts, there is a growing preference for eco-friendly and safe coating solutions. Teflon coatings, with their non-toxic nature and minimal environmental footprint, perfectly align with these preferences, resulting in higher demand across various end-use industries. Furthermore, the capability of Teflon coatings to prolong equipment lifespan and reduce the need for frequent replacements promotes a more sustainable approach in several applications, further driving market growth.

Expanding Automotive and Electronics Industries Propel Teflon Coating Adoption.

The automotive and electronics industries have experienced remarkable global growth, driven by continuous innovation and technological advancements. Teflon coatings have emerged as crucial contributors to these industries, providing essential properties such as lubricity, corrosion resistance, and electrical insulation. In the automotive sector, Teflon coatings are instrumental in optimizing engine components like piston rings and bearings, reducing friction, and enhancing fuel efficiency. Similarly, in the electronics industry, Teflon coatings are applied to critical components such as connectors, switches, and printed circuit boards, significantly improving their performance and reliability. With the ongoing expansion of the automotive and electronics sectors, Teflon coating manufacturers are presented with promising opportunities to meet the surging demand for high-performance, long-lasting coatings in these industries.

Rising Demand for Aerospace Applications Drives Teflon Coating Market Growth.

In the aerospace industry, the demand for materials and coatings with exceptional performance and durability is crucial to withstand extreme conditions. Teflon coatings have proven to be highly suitable for aerospace applications, offering outstanding properties such as resistance to high temperatures, chemicals, and abrasion. As a result, these coatings find extensive use on critical aircraft components, including engine parts, fasteners, and aircraft interiors, to enhance overall performance, reduce wear and tear, and ensure safety. With the continuous growth in air travel and the increasing need for more fuel-efficient aircraft, the aerospace industry's demand for Teflon coatings is expected to experience steady growth, driving the expansion of the Teflon coating market.

Global Teflon Coating Market Challenges:

Environmental Regulations Pose Challenges for Teflon Coating Manufacturers consequently hampering market expansion

Although Teflon coatings offer significant environmental benefits, their production and application processes are subject to strict environmental regulations and standards. The presence of specific fluorinated chemicals in Teflon coating production raises concerns about potential environmental pollution and adverse impacts on ecosystems. Consequently, manufacturers face the imperative of investing in sustainable and environmentally friendly production processes to comply with regulations and uphold their market position. Meeting these regulatory requirements can present challenges for some manufacturers and may necessitate additional investments in research and development to discover greener alternatives that maintain coating performance without compromising environmental integrity.

Competition from Alternative Coating Technologies Hampers Market Growth.

The Teflon coating market encounters competition from alternative coating technologies that may offer similar or specialized properties tailored to specific applications. Ceramic coatings and various fluorinated alternatives have emerged as potential substitutes for Teflon coatings in certain industries. These alternative coatings often assert comparable non-stick behavior, thermal resistance, or chemical resistance, contributing to market competition. To maintain their competitiveness, Teflon coating manufacturers must engage in continuous innovation and emphasize the distinctive advantages and superior properties of Teflon coatings compared to available alternatives.

Global Teflon Coating Market Opportunities:

Expanding Application Scope in Emerging Industries Presents Growth Opportunities.

Teflon coatings have already established a strong presence in traditional industries like cookware, automotive, and electronics. However, the potential for market expansion in emerging industries, such as renewable energy, medical devices, and consumer electronics, presents significant opportunities. The rapid growth of the renewable energy sector, particularly in solar panels and wind turbines, demands protective and durable coatings that can withstand harsh environmental conditions. Teflon coatings offer excellent solutions in this regard, making them a favorable choice for manufacturers seeking reliable and long-lasting coatings. Furthermore, the medical devices industry seeks advanced coatings with biocompatibility and lubricious properties, and Teflon coatings hold promise for various medical applications.

R&D Focus on High-Performance Teflon Coatings Opens New Avenues.

Continued research and development initiatives focused on enhancing Teflon coatings' properties, including increased durability, higher thermal resistance, and improved adhesion, hold the potential to create novel opportunities and applications. By customizing Teflon coatings to cater to the distinct demands of various industries, manufacturers can unlock untapped markets and propel further growth. Furthermore, innovations in production processes, such as the development of water-based formulations and sustainable sourcing of raw materials, can align Teflon coatings with evolving sustainability trends, making them even more appealing to environmentally conscious customers and industries.

Growing Demand for Teflon Coatings in Food Packaging and Processing Industries.

The food packaging and processing industries are experiencing a growing need for top-quality coatings that offer non-stick properties, chemical resistance, and utmost food safety. Teflon coatings, renowned for their exceptional non-stick behavior and non-toxic nature, present significant advantages for food contact applications. With food safety regulations becoming increasingly stringent, the demand for Teflon coatings in food processing equipment and packaging is projected to witness a considerable surge. Manufacturers catering to these industries have a unique opportunity to capitalize on this rising demand and position Teflon coatings as the preferred choice for various food-related applications.

TEFLON COATING MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

5.1% |

|

Segments Covered |

By Product type, Form Type, Application, End-User Industry, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

The 3M Company, Daikin Fluorochemicals Limited, Solvay, Gujarat Fluorochemicals Limited, HaloPolymer, OJSC |

Teflon Coating Market Segmentation – By Product Type

-

Virgin PTFE

-

Stainless Steel Filled PTFE

-

Bronze Filled PTFE

-

Glass Filled PTFE

-

Others

Based on the market segmentation by Product Type, Virgin PTFE holds the largest market share due to its original and pure form, providing excellent non-stick properties and chemical resistance. It is a preferred choice for applications where non-toxic and non-reactive coatings are required, such as in cookware, bakeware, and food processing equipment.

However, Stainless Steel PTFE is growing at a rapid rate in the market because of its specific applications where enhanced mechanical properties, wear resistance, or thermal conductivity are required.

Teflon Coating Market Segmentation – By Form Type

-

Granular

-

Fine Powder

-

Dispersion

-

Micronized

Based on the market segmentation by, Form Type the Granular form has the largest market share due to its extensive use in manufacturing seal rings, valve seats, bearings, fittings, and electrical insulations. Its versatility in molding various shapes and its suitability for different applications make it a preferred choice in industries. The growing demand for industrial parts in various sectors is expected to further drive the demand for this segment in the PTFE market.

Teflon Coating Market Segmentation – By Application

-

Sheets

-

Coatings

-

Pipes

-

Films

-

Others

Based on segmentation by Application, Coatings have the highest demand in the Teflon coating market due to their versatility, non-stick properties, chemical resistance, and easy application. They find extensive use in various industries, including cookware, bakeware, machinery, and food processing equipment, enhancing product performance and ensuring smooth operation.

Teflon Coating Market Segmentation – By End-User Industry

-

Automotive

-

Aerospace

-

Electrical & Electronics

-

Industrial & Chemical Processing

-

Construction

-

Others

Based on the segmentation by End-User Industry, The Industrial & Chemical Processing segment has the highest market share. This industry utilizes Teflon coatings for various industrial processing purposes, including linings, gaskets, washers, seals, pump interiors, and spacers. The use of PTFE films in the chemical processing sector provides enhanced strength and resistance against harsh substances, making it a preferred choice for critical applications.

However, the Electrical & Electronics segment is the fastest growing segment due to its excellent electrical insulation properties, making them ideal for coating electrical connectors, switches, and printed circuit boards. Additionally, they protect against moisture, chemicals, and high temperatures, ensuring the reliability and durability of electronic components.

Global Teflon Coating Market Segmentation: By Region

-

North America

-

Europe

-

Asia-Pacific

-

Middle East and Africa

-

South America

Based on market segmentation by region, Asia-Pacific accounts for the largest market share and is also the fastest-growing market for Teflon coatings due to the region's rapid industrialization and growth in the automotive and electronics industries.

Moreover, North America and Europe are the leading regions, driven by constant technological advancements in end products, creating a high demand for PTFE especially in automotive and aerospace that fuels substantial market growth. The region’s focus on research, development, and innovation reinforces the widespread adoption of Teflon coatings, ensuring enhanced product performance and customer satisfaction.

Global Teflon Coating Market Key Players:

-

The 3M Company

-

Daikin Fluorochemicals Limited

-

Solvay

-

Gujarat Fluorochemicals Limited

-

HaloPolymer, OJSC

Chapter 1. Teflon Coating Market – Scope & Methodology

1.1 Market Segmentation

1.2 Assumptions

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Teflon Coating Market – Executive Summary

2.1 Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.3 COVID-19 Impact Analysis

2.3.1 Impact during 2023 – 2030

2.3.2 Impact on Supply – Demand

Chapter 3. Teflon Coating Market – Competition Scenario

3.1 Market Share Analysis

3.2 Product Benchmarking

3.3 Competitive Strategy & Development Scenario

3.4 Competitive Pricing Analysis

3.5 Supplier - Distributor Analysis

Chapter 4. Teflon Coating Market - Entry Scenario

4.1 Case Studies – Start-up/Thriving Companies

4.2 Regulatory Scenario - By Region

4.3 Customer Analysis

4.4 Porter's Five Force Model

4.4.1 Bargaining Power of Suppliers

4.4.2 Bargaining Powers of Customers

4.4.3 Threat of New Entrants

4.4.4 .Rivalry among Existing Players

4.4.5 Threat of Substitutes

Chapter 5. Teflon Coating Market - Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Teflon Coating Market - By Product Type

6.1 Virgin PTFE

6.2 Stainless Steel Filled PTFE

6.3 Bronze Filled PTFE

6.4 Glass Filled PTFE

6.5 Others

Chapter 7. Teflon Coating Market - By Form Type

7.1 Granular

7.2 Fine Powder

7.3 Dispersion

7.4 Micronized

Chapter 8. Teflon Coating Market - By Application

8.1 Sheets

8.2 Coatings

8.3 Pipes

8.4 Films

8.5 Others

Chapter 9. Teflon Coating Market - By End-User Industry

9.1 Automotive

9.2 Aerospace

9.3 Electrical & Electronics

9.4 Industrial & Chemical Processing

9.5 Construction

9.6 Others

Chapter 10. Teflon Coating Market – By Region

10.1 North America

10.2 Europe

10.3 Asia-Pacific

10.4 Latin America

10.5 The Middle East

10.6 Africa

Chapter 11. Teflon Coating Market – Key Players

11.1 The 3M Company

11.2 Daikin Fluorochemicals Limited

11.3 Solvay

11.4 Gujarat Fluorochemicals Limited

11.5 HaloPolymer, OJSC

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Teflon Coating Market was valued at USD 2.7 Billion in 2022 and is anticipated to reach USD 4.02 Billion by 2030, with a strong CAGR of 5.1% during the forecast period 2023-2030.

Increasing demand for non-stick coatings, growing awareness of environmental and health benefits, expanding automotive and electronics industries, and rising demand for aerospace applications are the market drivers for the Global Teflon Coating Market.

Virgin PTFE, Stainless Steel Filled PTFE, Bronze Filled PTFE, Glass Filled PTFE, and Others are the segments under the Global Teflon Coating Market by Product Type.

Asia-Pacific dominates the market in the Global Teflon Coating Market.

The Electrical & Electronics segment is the fastest growing segment due to its excellent electrical insulation properties, making them ideal for coating electrical connectors, switches, and printed circuit boards.