GLOBAL ROBOTIC CONTROL SYSTEM MARKET SIZE (2023 - 2030)

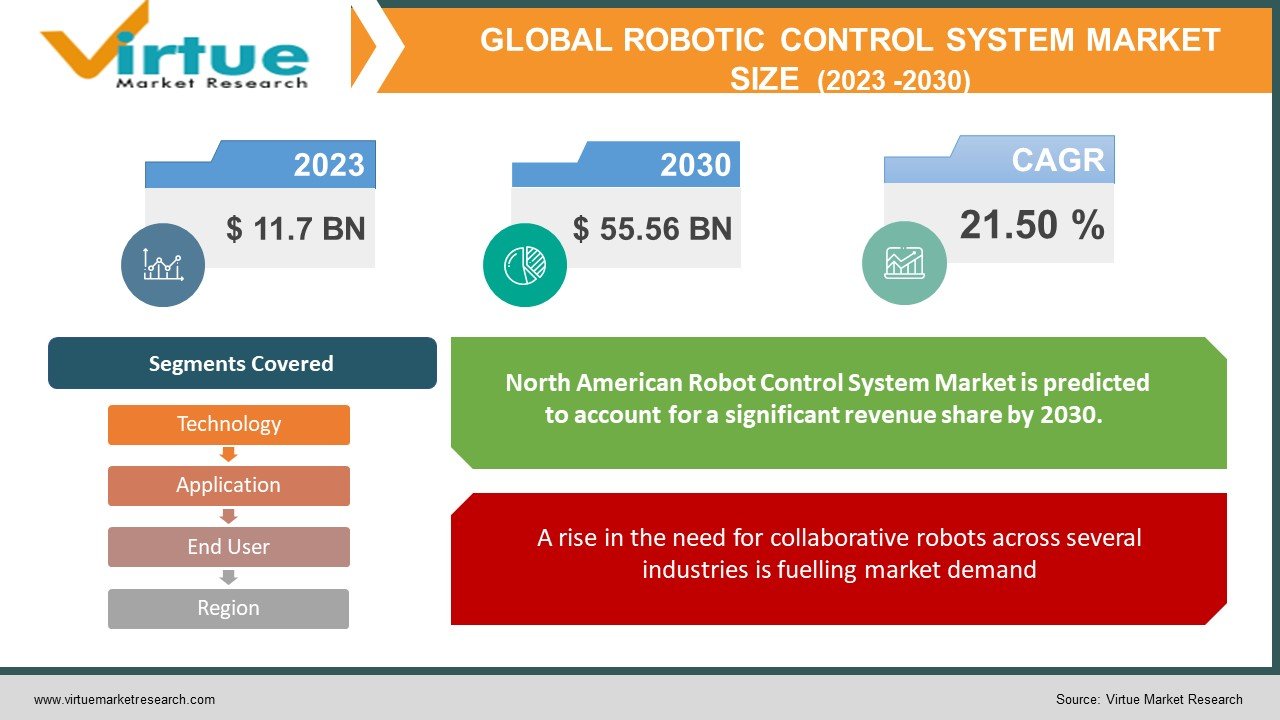

The Global Robotic Control System Market was estimated at USD 11.7 Billion in 2023 and is projected to reach a value of USD 55.56 Billion by 2030, growing at a fast CAGR of 21.50% during the forecast period 2023-2030.

Robotics aims to create computer programmable devices that can do jobs more quickly and accurately. In the modern period, robotics has a wide range of applications, including automated manufacturing, self-driving automobiles, logistics, unmanned aerial aircraft, and many more. The robotic control systems aid in regulating the robot's actions and movements during various automation processes. Automation is essential because it boosts overall effectiveness, lowers operating expenses, and keeps businesses competitive. The business is primarily expanding due to favorable government initiatives and policies, the growing use of collaborative robots across numerous industries, and the advent of the fourth industrial revolution. The size of the market is anticipated to rise rapidly throughout the projection period. This is caused by the growing demand from small and medium-sized businesses and the increased use of robots in the automotive industry for various applications. Due to its ability to address important manufacturing sector challenges such as scarcity of competent labor, technology mechanization is growing at a rapid rate throughout most industrial organizations. As a result, it is anticipated that the need for industrial robot processors would increase in the coming years. The biggest opportunity in the market for industrial robot control systems is the growth of automation in the electrical and electronics sector since it will allow electronics companies to continue to innovate and create prototypes more quickly and cheaply.

Specialized robots have been created by some businesses. For instance, the most recent robot improvised mobilization was developed in part by ABB Robotics. The Kuka Group is a participant in the most recent market development involving the integration of robotic automation technology. Because of its effectiveness and adaptability, the KR C4 control system requires less maintenance. Kuka's KR 3 AGLIUS is designed for quick cycle times in tasks like handling circuit boards and screens, polishing smartphone cases, and installing tiny screws.

Global Robotic Control System Market Drivers:

A rise in the need for collaborative robots across several industries is fuelling market demand :

-

Industrial robots are being used by a lot of businesses in both developed and developing countries as a solution to the high cost of labor and the shortage of competent workers. It offers excellent products with excellent efficiency, increasing the businesses' profit margins. To increase worker safety from completing risky activities, businesses in the chemical sector are turning to robot software. Additionally, robotic technologies are used in the healthcare sector because there is a growing demand for surgical robotics. Due to rising business competitiveness and a lack of labor, shipping, and e-commerce companies are concentrating on automating a sizable portion of their operations.

The industrial revolution is beginning to take shape and resulting in the increase in demand for Robotic Control Systems in the global market:

-

Industrial robots are required to transform production facilities into smart, linked factories as a result of the growth in demand for precision manufacturing. Manufacturers in the food and beverage industry are using robot technology to automate the production process and mass-produce products as a result of the rising demand for packaged food products. Robotic controller demand is increasing as a result of the growing need for industrial robots to lower production costs by enhancing quality, speeding up production, and maintaining dependability and security. The rise of Industry 4.0 is generating a promising future for the market for robot control systems.

Global Robotic Control System Market Challenges:

A robotic control system's implementation costs might be high, which deters certain businesses from utilizing the technology. The intricacy of the hardware and software needed for the technology is what causes the high cost of robotic control systems. Due to the recent development of robotics technology, there is a dearth of qualified individuals who can design, develop, and manage robotic control systems. Organizations may find it difficult to embrace the technology as a result of this skill gap since they may have trouble locating the personnel required to run and maintain the systems. Robotics is being used more and more in a variety of businesses, which has raised concerns about the technology's security. Robotic control systems are significantly at risk from cybersecurity threats because they may physically hurt robots.

Global Robotic Control System Market Opportunities:

Technologies like artificial intelligence and machine learning are developing quickly and have a lot of potential for enhancing robotic control systems. Robots may be equipped with the ability to learn from their surroundings and modify their behavior in response to changing conditions if AI is included in their control systems. Robotic control systems can assist boost productivity, save costs, and improve safety in manufacturing, logistics, and other industries. Robotic control systems are in greater demand due to the industry's ongoing trend toward automation. Robotic surgery, rehabilitation, and remote patient monitoring are just a few of the uses for robotic control systems that have the potential to revolutionize the healthcare industry. There is an increasing need for creative ideas to enhance patient outcomes and save costs as the population ages and healthcare prices rise.

COVID-19 Impact on the Global Robotic Control System Market:

Manufacturing facilities are closed, and logistics and transportation have been severely impacted, disrupting supply chains. Robotic control systems are being used more frequently to help with tasks that would typically require human involvement. Robotic control systems now have prospects in fields like telemedicine, virtual aid, and remote inspection. This has caused a slowdown in the market by delaying the production and distribution of robotic control systems. The pandemic has brought to light the value of automation in sectors including manufacturing, logistics, and healthcare. As a result, there has been an upsurge in interest in robotic control systems as a way to minimize human interaction and boost productivity. Due to the pandemic, many organizations are now working remotely.

Global Robotic Control System Market Recent Developments:

-

In September 2022, the new robot studio software from ABB allow customers to create and simulate robotic systems before they are really implemented. Users of the software can also speed up programming and improve robot performance.

-

In January 2022, the new palletizing robot from KUKA, which can manage payloads up to 1,300 kg, was unveiled. The robot is intended for use in demanding industrial settings, such as the production of automobiles.

-

In March 2021, The UR16e e-Series robot from Universal Robots was unveiled; it has a reach of 900 mm and a payload capacity of 16 kg. The robot is intended for use in demanding tasks including palletizing and machine tending.

GLOBAL ROBOTIC CONTROL SYSTEM MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

21.50 % |

|

Segments Covered |

By Technology, Application, End User and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

ABB Ltd., AIBrain Inc., Brain Corporation Clearpath Robotics Inc., Furhat Robotics, H2O.ai Inc., International Business Machines Corporation, Neurala Inc., NVIDIA Corporation, Teradyne Inc., The Boeing Company, Alfa Industrial Group, Arburg GmbH + Co KG, ENGEL AUSTRIA GmbH, Epson America, Inc., FANUC UK Limited, Hans Hundegger AG, HARMO LLC, iRobot Corporation |

Global Robotic Control System Market Segmentation:

Global Robotic Control System Market Segmentation: By Technology

-

Traditional Robot Control Systems

-

Sensing and Perception

-

Machine Learning and Artificial Intelligence

-

Natural Language Processing

-

Motion Control

This technique makes use of pre-programmed, semi-autonomous robotic devices. These systems follow predetermined rules and are designed to carry out specified tasks.

Robots can feel and comprehend their surroundings with the use of sensing and perception technology, which makes use of sensors, cameras, and other detection tools. Robots can work more autonomously and adapt to changing conditions thanks to this technology. Through the use of this technology, robots can interact with people more successfully in applications like customer service and healthcare. Advanced algorithms are used in motion control technologies to regulate the location and movement of robotic devices. Robots can now carry out intricate actions with higher accuracy and precision due to this technology. Robotic control systems are rapidly incorporating machine learning and AI technology to allow robots to learn from their surroundings and modify their behavior accordingly. Robots may now function more autonomously and successfully in challenging conditions due to this technology. Computer algorithms are used in natural language processing technology to comprehend and translate human language.

Global Robotic Control System Market Segmentation: By Application

-

Automotive

-

Agriculture

-

Electrical & Electronics

-

Servicing and Maintenance

-

Chemicals & Materials

-

Machinery

-

Others

In 2022, the oil and gas industry had a sizeable portion of the market for robot control systems. However, the automotive category is anticipated to experience the largest CAGR growth over the course of the forecast period due to factors like increased automation and the use of collaborative robots. Automation is used in the production facilities of different automakers to maintain efficiency, which is anticipated to promote market expansion.

Global Robotic Control System Market Segmentation: By End-User

-

Automotive Industry

-

Electronics and Semiconductor Industry

-

Healthcare Industry

-

Food and Beverage Industry

-

Aerospace Industry

-

Logistics Industry

-

Others

Robotic control systems are extensively used in the automotive sector for processes including assembling, painting, and welding. Robotic control systems are used in the logistics sector for operations including order fulfilment and material handling. Robotic control systems are employed by the electronics and semiconductor industries for operations like inspection, testing, and assembly. The operations include surgery, drug dispensing, and patient monitoring, the healthcare sector uses robotic control systems. The activities that include drilling, machining, and assembling aircraft components, the aerospace sector uses robotic control systems.

Global Robotic Control System Market Segmentation: By Region

-

North America

-

Europe

-

Asia Pacific

-

Rest of the World

Due to expanding demand and production for robotic units throughout the region as well as an increasing reliance on automation to fuel the growth of the electric car manufacturing sector, the North American Robot Control System Market is predicted to account for a significant revenue share by 2030. The most profitable markets in this area are those in Germany and France. For automated driving assistance, vehicle maintenance, passenger infotainment, and vehicle-to-vehicle communications, the automotive and manufacturing sectors in the area adopt the bulk of automation technologies. For instance, in 2022, Ericsson and Audi collaborated to create a 5G testbed at the Audi P-Labs site in Germany to test Ultra-reliable Low-latency Communication (URLLC) capabilities for factory automation.

This is due to the emergence of Industry 4.0, the widespread use of robotics in key industries like banking, food and beverage, financial services and insurance (BFSI), electrical, automotive, chemical, manufacturing, healthcare, and logistics, as well as the region's powerful manufacturing sector. The widespread manufacturing and marketing of industrial robots in this area also contributes to the market's expansion. Due to the fact that businesses are currently transitioning towards robots and automation, China is anticipated to hold the greatest market share over the projection period. Due to the rising adoption of automation technologies in the manufacturing industry, rising investment in technologies related to the Industry 4.0 movement, and smart factory norms, the Latin American Robot Control System Market is anticipated to have considerable expansion during the forecast period.

Global Robotic Control System Market Key Players:

-

ABB Ltd.

-

AIBrain Inc.

-

Brain Corporation

-

Clearpath Robotics Inc.

-

Furhat Robotics

-

H2O.ai Inc.

-

International Business Machines Corporation

-

Neurala Inc.

-

NVIDIA Corporation

-

Teradyne Inc.

-

The Boeing Company

-

Alfa Industrial Group

-

Arburg GmbH + Co KG

-

ENGEL AUSTRIA GmbH

-

Epson America, Inc.

-

FANUC UK Limited

-

Hans Hundegger AG

-

HARMO LLC

-

iRobot Corporation

Chapter 1. ROBOTIC CONTROL SYSTEM MARKET – Scope & Methodology

1.1. Market Segmentation

1.2. Assumptions

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. ROBOTIC CONTROL SYSTEM MARKET – Executive Summary

2.1. Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.3. COVID-19 Impact Analysis

2.3.1. Impact during 2023 - 2030

2.3.2. Impact on Supply – Demand

Chapter 3. ROBOTIC CONTROL SYSTEM MARKET – Competition Scenario

3.1. Market Share Analysis

3.2. Product Benchmarking

3.3. Competitive Strategy & Development Scenario

3.4. Competitive Pricing Analysis

3.5. Supplier - Distributor Analysis

Chapter 4. ROBOTIC CONTROL SYSTEM MARKET - Entry Scenario

4.1. Case Studies – Start-up/Thriving Companies

4.2. Regulatory Scenario - By Region

4.3 Customer Analysis

4.4. Porter's Five Force Model

4.4.1. Bargaining Power of Suppliers

4.4.2. Bargaining Powers of Customers

4.4.3. Threat of New Entrants

4.4.4. Rivalry among Existing Players

4.4.5. Threat of Substitutes

Chapter 5. ROBOTIC CONTROL SYSTEM MARKET - Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. ROBOTIC CONTROL SYSTEM MARKET – By Technology

6.1. Traditional Robot Control Systems

6.2. Sensing and Perception

6.3. Machine Learning and Artificial Intelligence

6.4. Natural Language Processing

6.5. Motion Control

Chapter 7. ROBOTIC CONTROL SYSTEM MARKET – By Application

7.1. Automotive

7.2. Agriculture

7.3. Electrical & Electronics

7.4. Servicing and Maintenance

7.5. Chemicals & Materials

7.6. Machinery

7.7. Others

Chapter 8. ROBOTIC CONTROL SYSTEM MARKET – By End User

8.1. Automotive Industry

8.2. Electronics and Semiconductor Industry

8.3. Healthcare Industry

8.4. Food and Beverage Industry

8.5. Aerospace Industry

8.6. Logistics Industry

8.7. Others

Chapter 9. ROBOTIC CONTROL SYSTEM MARKET – By Region

9.1. North America

9.2. Europe

9.3. Asia-P2acific

9.4. Latin America

9.5. The Middle East

9.6. Africa

Chapter 10. ROBOTIC CONTROL SYSTEM MARKET – By Companies

10.1. ABB Ltd.

10.2. AIBrain Inc.

10.3. Brain Corporation

10.4. Clearpath Robotics Inc.

10.5. Furhat Robotics

10.6. H2O.ai Inc.

10.7. International Business Machines Corporation

10.8. Neurala Inc.

10.9. NVIDIA Corporation

10.10. Teradyne Inc.

10.11. The Boeing Company

10.12. Alfa Industrial Group

10.13. Arburg GmbH + Co KG

10.14. ENGEL AUSTRIA GmbH

10.15. Epson America, Inc.

10.16. FANUC UK Limited

10.17. Hans Hundegger AG

10.18. HARMO LLC

10.19. Robot Corporation

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Global Robotic Control System Market was estimated at USD 11.7 Billion in 2022 and is projected to reach a value of USD 55.56 Billion by 2030, growing at a fast CAGR of 21.50% during the forecast period 2023-2030.

The Global Robotic Control System Market is driven by the Increasing Adoption of Automation, Technological Advancements, Growing Demand from Emerging Economies, and the Increasing Need for Safety and Quality.

The Segments under the Global Robotic Control System Market by the application are Automotive, Agriculture, Electrical & Electronics, Servicing and Maintenance.

China, Japan, South Korea, Singapore, and India are the most dominating countries in the Asia Pacific region for the Global Robotic Control System Market.

ABB Ltd., AIBrain Inc., Brain Corporation are the three major leading players in the Global Robotic Control System Market.