Global Robot Palletizer Market size (2023 – 2030)

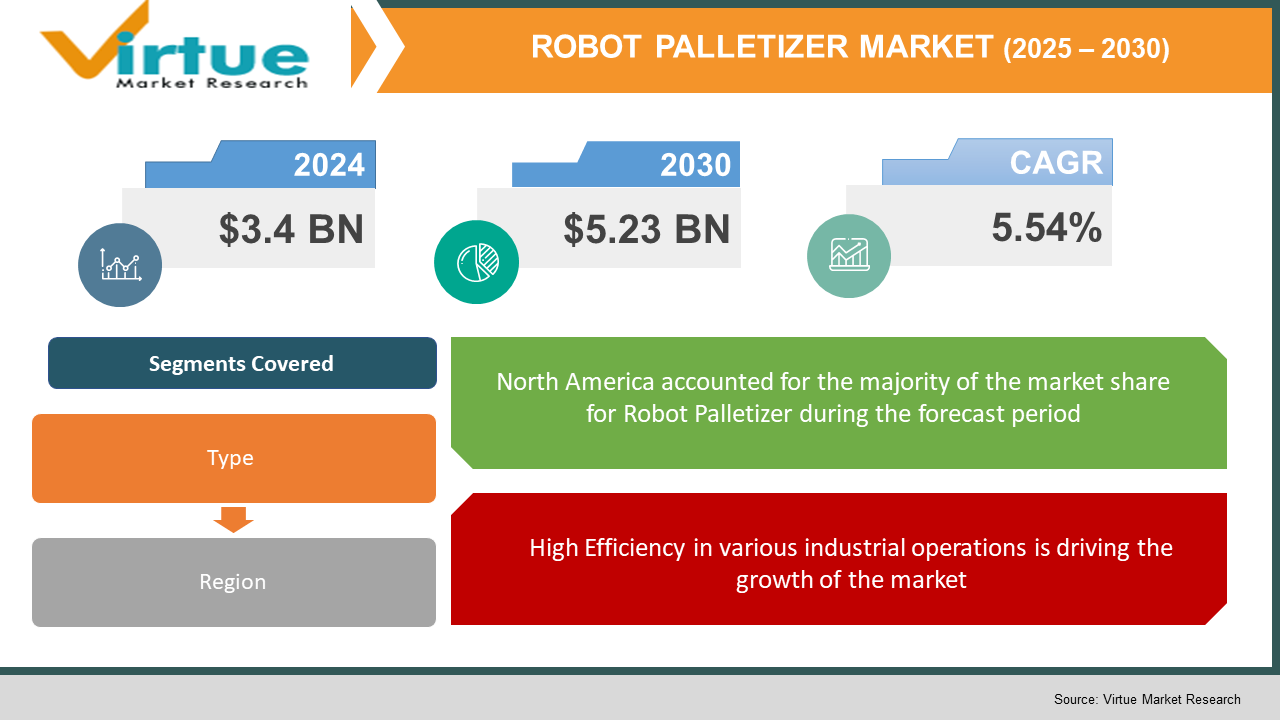

The global Robot Palletizer Market size is estimated to grow from USD 3.4 Billion in 2022 to USD 5.23 billion by 2030. The market is witnessing a healthy CAGR of 5.54 % from 2023 - 2030. An increase in the number of space exploration programs is the major factor that is driving the growth of the industry.

Industry Overview:

Robotic palletizing is a semi- and totally computerized robotic structure that is significantly taking over the guide selecting approaches as they can be utilized in severe climatic stipulations with the most pace and accuracy.

Rising preferences for automation in packaging options together with robotic palletizers & de-palletizers will provide fulfilling possibilities for the producers in the upcoming years. Depalletizing is a widely widespread manufacturing endeavor that has obtained a lot of interest in current years as an end result of a variety of industrial labor challenges, ranging from a lack of reachable employees to initiatives to reduce the danger of employee injuries.

With the rising demand from end-users to automate operations and limit guide labor, the adoption of robots is growing for industrial purposes inclusive of cloth coping with purposes such as palletizing. Unlike human labor, robots no longer tire out or get bored of repeating equal tasks, which makes them perfect for operations. Some of the key advantages of automation in quite a number of industries encompass value reduction, extension in productivity, greater availability, higher reliability, and performance.

COVID-19 impact on the Robot Palletizer Market

The furnish chain of agencies around the world has been affected with the aid of COVID-19, which is affecting the packaging enterprise as well. The demand had been severely affected via the discontinuation of manufacturing in many areas, such as North America, Europe, and Asia, which have been accountable for the sizeable use of robotic palletizers and de-palletizers.

However, manufacturers are seeing massive innovation with the aid of leveraging technology, so as to re-purpose manufacturing and packaging traces genuinely rapidly to deal with the needs of consumers. From that viewpoint, human beings are additionally accepting indispensable technological know-how and automation greater than ever before. Nevertheless, by means of the 2nd half of the yr 2021, the robotic palletizers & de-palletizers enterprise has begun returning to its toes with new steps to restrict infections, restore provide chains, and stabilize e-commerce.

However, this scenario is predicted to enhance as authorities have commenced enjoyable norms around the world for resuming enterprise activities.

MARKET DRIVERS:

High Efficiency in various industrial operations is driving the growth of the market

Manual palletizing is no longer possible for giant or heavy pallet loads. Also, the chance of mishandling pallets main to the destruction of merchandise is very high. Furthermore, quite a few allowances are preferred by way of the labor for job pride and productive working. All these elements lead to a low tempo of operation when accomplished manually.

Advancement in technological know-how has decreased the requirement of established preservation of the machinery. Palletizing structures are successful in working at a lot greater tempo barring making any error as in contrast to guide palletizing. Robotic palletizers and de-palletizers can function constantly all day lengthy and cope with a good deal heavier load. All these advantages of robotic palletizers and de-palletizers lead to surprisingly productive overall performance and are consequently using the demand for palletizing structures over traditional palletizing.

MARKET RESTRAINTS:

High cost related to the equipment is restraining the growth of the market

The excessive price of deploying and keeping automation structures is difficult for the robotic palletizer market growth. Robotic palletizers provide an excessive ROI over a quick period. However, their adoption consists of excessive switching costs. As the robots are built-in into the manufacturing system, any malfunction or breakdown can lead to the possible shutdown of the whole manufacturing line. Thus, these elements are anticipated to avert the market boom all through the forecast period.

GLOBAL ROBOT PALLETIZER MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

5.54% |

|

Segments Covered |

By Type and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

ABB Ltd., Alligator Automations, Armstrong, Columbia/Okura LLC, DENSO Corp., Douglas Machine Inc., FANUC Corp., Fuji Yusoki Kogyo Co. Ltd., Illinois Tool Works Inc., Informa Plc, Kawasaki Heavy Industries Ltd., KRONES AG, MIDEA GROUP, MMCI Automation, Premier Tech Digital Ltd., Serpa Packaging Solutions LLC |

This research report on the global Robot Palletizer Market has been segmented and sub-segmented based on the Type, and region.

Robot Palletizer Market - By Type:

-

- Conventional

- Traditional

- Others

Based on Type, Conventional palletizing structures have dominated the market seeing that for a long time however, producers are experiencing a shift in the direction of robotics. Robotic palletizers & de-palletizers grant flexibility and the functionality to palletize exceptional inventory retaining gadgets with minimal trade over time.

Existing standard palletizers are going older and producers have been getting extra requests from customers to change ordinary buildings with robotics. Conventional palletizers can't control many inventory maintaining gadgets efficiently. Over the previous few years, packaging patterns have modified dramatically. It is increasingly hard for typical palletizers to accommodate these new packets. To make the product greater sought-after for customers, the packaging producers will alternate something about the packaging. Such changes require versatility, a function missing by means of most out-of-date typical palletizers. As ordinary palletizers make room for robotic palletizers & de-palletizers the use of smaller robots, the system is much less centralized. The pass toward this configuration and a cross away from the traditional configuration has already begun.

Robot Palletizer Market - By Region:

- North America

- Europe

- Asia-Pacific

- Latin America

- The Middle East

- Africa

Geographically, North America used to be severely affected by means of COVID-19, which considerably hindered the utilization of robotic palletizers & de-palletizers between March 2020 and September 2021. Moderate shutdowns in manufacturing flowers coupled with labor strikes and job cuts had slowed down the increased charge for robotic palletizers & de-palletizers in the region. However, the market is getting lower back to normalcy in the post-Covid era.

The Asia-Pacific is anticipated to return to furnish chain normalcy due to availability bouncing again of production of uncooked substances in the region. This regional market is anticipated to provide workable value-creation possibilities for the duration of the forecast period.

Europe is the third-most affected area by means of coronavirus outbreak and the second-largest consumer of robotic palletizers & de-palletizers, additionally impacted through the pandemic. Italy, Spain, France, Germany, Russia, and United Kingdom is the most- affected international locations had skilled slow increase then. However, the state of affairs is anticipated to enhance going forward.

Robot Palletizer Market Share by Company

Companies like

- ABB Ltd.

- Alligator Automations

- Armstrong

- Columbia/Okura LLC

- DENSO Corp.

- Douglas Machine Inc.

- FANUC Corp.

- Fuji Yusoki Kogyo Co. Ltd.

- Illinois Tool Works Inc.

- Informa Plc

- Kawasaki Heavy Industries Ltd.

- KRONES AG

- MIDEA GROUP

- MMCI Automation

- Premier Tech Digital Ltd.,

- Serpa Packaging Solutions LLC

are playing a pivotal role in the market.

Mujin Corp. desires to introduce mixed-case robotic palletizing with adaptive buffering and re-sequencing. The new application, in accordance with the Tokyo-based company, demonstrates how robots can do hard selecting and packing operations besides the use of intricate programming.

The robotic arm of the depalletizer is guided by using Honeywell's imaginative and prescient grasp technology, permitting instances to be plucked from a single- or mixed-SKU pallet in constant or cellular locations. The company’s laptop imaginative and prescient science locates every case on the pallet, and its synthetic intelligence-driven understanding software program detects a huge variety of packing codecs automatically.

The new TopTier Robot Pick n PlaceTM palletizer has been launched via ROBOPAC and TOP TIER. This contemporary gear provides unrivaled skills for low- to moderate-volume functions at a fee that approves any manufacturing line to be automated.

NOTABLE HAPPENINGS IN THE GLOBAL Robot Palletizer Market IN THE RECENT PAST:

Collaboration -In Feb 2021, FANUC has its AI learning functionality in its robot’s product portfolio in collaboration with Preferred Network Inc.

Chapter 1. Robot Palletizer Market – Scope & Methodology

1.1. Market Segmentation

1.2. Assumptions

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. Robot Palletizer Market – Executive Summary

2.1. Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.3. COVID-19 Impact Analysis

2.3.1. Impact during 2023 - 2030

2.3.2. Impact on Supply – Demand

Chapter 3. Robot Palletizer Market – Competition Scenario

3.1. Market Share Analysis

3.2. Product Benchmarking

3.3. Competitive Strategy & Development Scenario

3.4. Competitive Pricing Analysis

3.5. Supplier - Distributor Analysis

Chapter 4. Robot Palletizer Market Entry Scenario

4.1. Case Studies – Start-up/Thriving Companies

4.2. Regulatory Scenario - By Region

4.3 Customer Analysis

4.4. Porter's Five Force Model

4.4.1. Bargaining Power of Suppliers

4.4.2. Bargaining Powers of Customers

4.4.3. Threat of New Entrants

4.4.4. Rivalry among Existing Players

4.4.5. Threat of Substitutes

Chapter 5. Robot Palletizer Market - Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. Robot Palletizer Market – By Type

6.1. Conventional

6.2. Traditional

6.3. Others

Chapter 7. Robot Palletizer Market- By Region

7.1. North America

7.2. Europe

7.3. Asia-Pacific

7.4. Latin America

7.5. The Middle East

7.6. Africa

Chapter8. Robot Palletizer Market – Company Profiles – (Overview, Product Portfolio, Financials, Developments)

8.1. ABB Ltd.

8.2. Alligator Automations

8.3. Armstrong

8.4. Columbia/Okura LLC

8.5. DENSO Corp.

8.6. Douglas Machine Inc.

8.7. FANUC Corp.

8.8. Fuji Yusoki Kogyo Co. Ltd.

8.9. Illinois Tool Works Inc.

8.10. Informa Plc

8.11. Kawasaki Heavy Industries Ltd.

8.12. KRONES AG

8.13. MIDEA GROUP

8.14. MMCI Automation

8.15. Premier Tech Digital Ltd.,

8.16. Serpa Packaging Solutions LLC

Download Sample

Choose License Type

2500

4250

5250

6900