Reinforced Polyester Market Size (2024 – 2030)

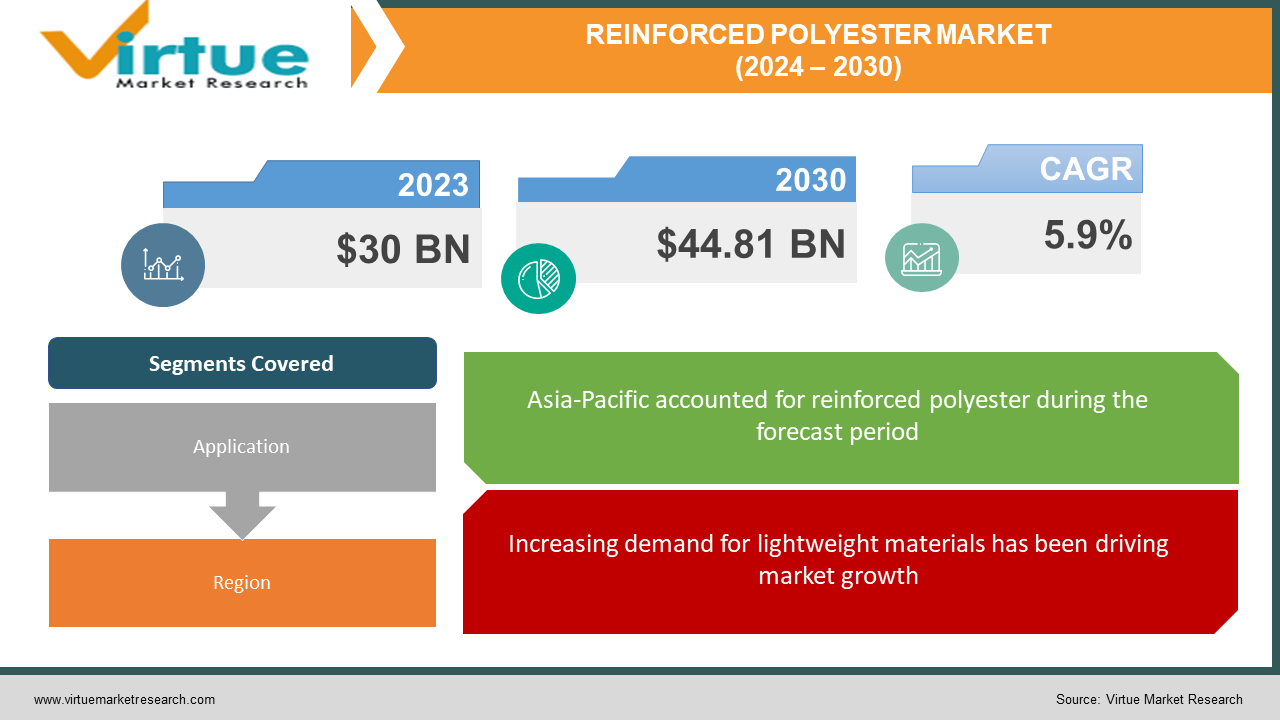

The global reinforced polyester market was valued at USD 30 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 5.9% from 2024 to 2030, reaching USD 44.81 billion by 2030.

Reinforced polyester (FRP/GRP) is a strong, lightweight, and affordable material made by combining polyester resin with fibers, usually glass. This makes it useful in construction, transportation, marine, wind energy, and other industries. While strong and corrosion-resistant, it can be brittle and degrade in sunlight, requiring careful design and use.

Key Market Insights:

The growth is driven by the increasing demand for lightweight and durable materials in construction, transportation, and wind energy. The material's versatility shines in applications like roofing panels, boat hulls, and turbine blades, offering high strength, corrosion resistance, and affordability. However, challenges like brittleness and UV degradation exist. Fortunately, trends like sustainable bio-based resins and advanced manufacturing techniques promise a brighter future, with Asia-Pacific leading the charge due to its booming infrastructure and disposable income. Overall, the reinforced polyester market exhibits potential for sustained growth as innovation and sustainability pave the way.

Reinforced Polyester Market Drivers:

Increasing demand for lightweight materials has been driving market growth.

Reinforced polyester (RP) is revolutionizing industries by combining the flexibility of resin with the muscle of fibers like glass, carbon, or aramid. This material has a lot of strength, making it a very useful element in transportation applications like sleek car parts, construction applications like robust pipes and panels, and even wind energy applications like towering turbine blades. RP also shaves off fuel consumption and emissions, making it a sustainable option. With constant advancements in resin systems, fiber reinforcements, and manufacturing, RP is poised for even greater feats.

Growing demand from the transportation industry has been facilitating the expansion.

Car companies are revving up their use of reinforced polyester (RP), a lightweight compound that's transforming automobiles. Hoods, bumpers, and even entire body panels sculpted from RP can be done without slashing weight and sacrificing strength. This translates to fewer pounds on the road, meaning zippier cars, happier fuel gauges, and cleaner tailpipes. But RP's impact goes beyond mere numbers. Aerodynamic designs can be made because of their flexibility, or interiors where complex shapes translate effortlessly.

Rising demand for wind energy has been contributing to market development.

Reinforced polyester (RP), a strong and lightweight material for wind turbine blades, highlights the importance of sustainability. Its strength enables taller, more powerful turbines, maximizing energy capture. Driven by the surge in renewable energy demands, RP thrives in this field due to its lightness, reducing stress on structures, affordability, and ability to withstand harsh conditions. While challenges like UV degradation exist, ongoing research in advanced resins and coatings promises a smooth flight for RP in powering a greener future.

Reinforced Polyester Market Challenges and Restraints:

Prices of key materials like polyester resin and fibers can be volatile, impacting production costs and potentially hindering market adoption

Associated costs can be a barrier for the market. The reinforced polyester (RP) market faces a balancing act: its lightweight strength is alluring for industries seeking efficiency and sustainability, but volatile raw material costs threaten its affordability. This can demotivate the manufacturers from using this compound, causing significant losses for the company. These fluctuations impact the entire RP value chain, hindering market growth. Solutions like diversifying resin sources, securing stable supplier contracts, and investing in recycling infrastructure are crucial to mitigate cost volatility and ensure RP's lightweight potential translates into a sustainable future.

Stringent environmental regulations can cause difficulties.

The latest difficulty facing the reinforced polyester (RP) sector is navigating a maze of increasingly stringent environmental laws on emissions and recyclability. Reformulating resin systems and establishing efficient recycling infrastructure add complexity and cost, potentially jeopardizing affordability. These hurdles, although pushing for positive environmental change, can burden manufacturers. Collaboration with regulatory bodies, investment in R&D for eco-friendly solutions, and exploring sustainable alternatives like bio-based resins are crucial for the RP market to walk this tightrope. By proactively addressing these challenges, the industry can transform regulations into opportunities for innovation, ensuring a sustainable future without compromising affordability and market competitiveness.

Alternative materials are hindering market growth.

RP's wind turbine blade reign faces challenges from steel, aluminum, and carbon fiber. Steel's unmatched strength comes with a hefty weight, limiting energy capture. Aluminum offers agility but raises cost and fatigue concerns. Carbon fiber boasts ultimate lightness but at an astronomical price. As technology evolves and costs shift, the competition also increases. RP's future hinges on continuous improvement to stay relevant in this high-stakes duel for wind energy dominance.

Market Opportunities:

Because of their strength, lightweight, and corrosion resistance, reinforced polyester products are well-suited for a range of construction applications, including roofing, cladding, and structural components. This makes the growing construction sector, especially in emerging economies, an attractive market for them. Reinforced polyester composites provide the potential for usage in vehicle components, such as interior panels, external body pieces, and structural elements, as the automotive industry places a greater emphasis on lightweight materials to increase fuel economy and lower emissions. Due to their high strength-to-weight ratio, resistance to corrosion, and fatigue, reinforced polyester materials used in wind turbine blades have prospects in the growing renewable energy industry, notably in wind energy. The demand for eco-friendly reinforced polyester materials made from recycled materials or bio-based resins is rising as a result of regulations encouraging sustainable practices and growing environmental concerns. This presents an opportunity for manufacturers to differentiate their goods and reach environmentally conscious consumers.

REINFORCED POLYESTER MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

5.9% |

|

Segments Covered |

By Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

BASF SE, Solvay, Dow Chemical Company, Eastman Chemical Company, LyondellBasell Industries NV, Owens Corning, Hexcel Corporation, Jushi Group Co., Ltd., PPG Industries, Chongqing Polycomp International Corporation (CPIC) |

Reinforced Polyester Market Segmentation: By Application

-

Transportation

-

Construction

-

Wind Energy

-

Electronics

Construction is the largest segment based on application in this market. It utilizes RP for its strength and weather resistance in building panels, pipes, and even roofing materials. They are lightweight yet robust panels for quick construction or durable pipes for plumbing and drainage. Reinforced polyester is a material of choice for architects and builders because of its remarkable durability, due to which it finds applications in everything from building facades to infrastructure projects. Wind energy is the fastest-growing application. This segment emphasizes sustainability and thereby harnesses RP's strength and lightness in its towering turbine blades. These giants spin efficiently due to RP's contribution. As countries all around the world step up their efforts to switch to greener energy sources, the wind energy industry is expanding quickly. Reinforced polyester composites are essential parts of wind turbine blades in this ever-changing environment, allowing for effective wind power harvesting. The market for reinforced polyester in wind energy applications is expected to grow significantly as renewable energy continues to gain popularity. The transportation segment also shows significant growth. Cars, trucks, and even boats heavily rely on RP for lightweight, durable body panels, bumpers, and marine components. Sleek car hoods and sturdy boat hulls are possible because of this compound. Electronics, while benefiting from RP's lightweight properties, use it less extensively. Housings and circuit boards often prioritize heat resistance and electrical conductivity, qualities better met by specialized plastics or metals.

Reinforced Polyester Market Segmentation: Regional Analysis

-

North America

-

Asia-Pacific

-

Europe

-

South America

-

Middle East and Africa

Asia-Pacific has the largest market share in 2023. Its rapid urbanization is one of the primary reasons. With the economy achieving stability, there has been a rising middle class and an increase in disposable income. This region is involved in a lot of construction projects. This raised the demand for these compounds. With this booming infrastructure development, the demand for this material has seen an upsurge. Additionally, a growing focus on lightweight materials fuels its leadership. Besides, this area has well-established players that have a global presence. This results in greater revenue generation. A few of the prominent companies include Jushi Group Co., Ltd., Chongqing Polycomp International Corporation (CPIC), Teijin Limited, and Toray Industries, Inc. Countries like China, Japan, India, and South Korea are at the forefront. North America, a mature market with established automotive and construction sectors, follows closely. This is the fastest-growing region. Countries like the United States and Canada are the notable ones. This area has a good economy, and funding and investing in various projects are easier. There have been many research and developmental activities to improve the existing compounds and find better ones. Along with this, governmental initiatives have been contributing to the success. Europe, known for its stringent environmental regulations, has seen good growth. Here, innovation reigns supreme, driving the development of eco-friendly RP solutions. Sustainable building materials and next-generation wind turbine components are pushing the boundaries of RP's potential. Germany and the United Kingdom are the two most profitable markets. Latin America is an emerging market with immense potential. While its growth is slower than that of the leaders, its upward trajectory holds exciting possibilities for the future of RP in the region. The Middle East and Africa show the slowest growth. However, in the upcoming period, notable developments are anticipated because of governmental initiatives and economic growth.

COVID-19 Impact Analysis on the Reinforced Polyester Market

The outbreak of the virus hurt the market. Disrupted supply chains and slumped demand in key sectors like automotive hit hard, causing production slowdowns and job losses. However, the surge in hygiene focus drove RP use in medical equipment, PPE, and easy-clean building materials. The e-commerce boom also fueled demand for lightweight packaging. Now, the market's recovering, with a pre-pandemic demand return expected by 2025. Future trends like cost-effective, sustainable solutions, rising demand from emerging markets, and technological advancements in RP's performance and affordability are crucial to watch for continued growth. By staying informed and proactive, the RP market can navigate uncertainties and achieve a sustainable future.

Latest trends/Developments

The future of reinforced polyester is woven with threads of sustainability, innovation, and global expansion. Bio-based resins, born from renewable resources, aim to break free from fossil fuel dependence, while recyclable composites embrace circularity and minimize waste. Even used products find new life through efficient recovery methods. Automation and robots march into factories, boosting efficiency and safety, while 3D printers weave intricate, customized components, minimizing waste and speeding up production. New fiber technologies promise lighter, stronger composites, pushing the boundaries of performance. Asia-Pacific emerges as a growth engine, driven by booming infrastructure and rising disposable incomes, fueling demand in construction, transportation, and wind energy. Medical devices, electronics, and even aerospace beckon, attracted by the material's lightweight charm and impressive performance. Specialty grades are formulated for specific needs, offering fire resistance, high-temperature tolerance, or superior electrical conductivity. However, challenges loom like storm clouds. Fluctuating raw material prices threaten stability, while stricter environmental regulations demand innovation and adaptation. Competition from metals, thermoplastics, and other composites keeps the pressure on, pushing for continuous improvement in cost and performance. Yet, the reinforced polyester market stands poised for sustained growth, with its versatility, affordability, and commitment to sustainability weaving a bright tapestry for the future.

Companies in this industry are motivated to increase their market share by using a range of strategies, including acquisitions, joint ventures, and investments. Companies are spending a lot of money to develop techniques to retain competitive pricing. Further growth has resulted from this.

Key Players:

-

BASF SE

-

Solvay

-

Dow Chemical Company

-

Eastman Chemical Company

-

LyondellBasell Industries NV

-

Owens Corning

-

Hexcel Corporation

-

Jushi Group Co., Ltd.

-

PPG Industries

-

Chongqing Polycomp International Corporation (CPIC)

Chapter 1. REINFORCED POLYESTER MARKET – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. REINFORCED POLYESTER MARKET – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. REINFORCED POLYESTER MARKET – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. REINFORCED POLYESTER MARKET Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. REINFORCED POLYESTER MARKET – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. REINFORCED POLYESTER MARKET – By application

6.1 Introduction/Key Findings

6.2 Transportation

6.3 Construction

6.4 Wind Energy

6.5 Electronics

6.6 Y-O-Y Growth trend Analysis By application

6.7 Absolute $ Opportunity Analysis By application, 2023-2030

Chapter 7. REINFORCED POLYESTER MARKET , By Geography – Market Size, Forecast, Trends & Insights

7.1 North America

7.1.1 By Country

7.1.1.1 U.S.A.

7.1.1.2 Canada

7.1.1.3 Mexico

7.1.2 By application

7.1.3 Countries & Segments - Market Attractiveness Analysis

7.2 Europe

7.2.1 By Country

7.2.1.1 U.K

7.2.1.2 Germany

7.2.1.3 France

7.2.1.4 Italy

7.2.1.5 Spain

7.2.1.6 Rest of Europe

7.2.2 By application

7.2.3 Countries & Segments - Market Attractiveness Analysis

7.3 Asia Pacific

7.3.1 By Country

7.3.1.1 China

7.3.1.2 Japan

7.3.1.3 South Korea

7.3.1.4 India

7.3.1.5 Australia & New Zealand

7.3.1.6 Rest of Asia-Pacific

7.3.2 By application

7.3.3 Countries & Segments - Market Attractiveness Analysis

7.4 South America

7.4.1 By Country

7.4.1.1 Brazil

7.4.1.2 Argentina

7.4.1.3 Colombia

7.4.1.4 Chile

7.4.1.5 Rest of South America

7.4.2 By application

7.4.3 Countries & Segments - Market Attractiveness Analysis

7.5 Middle East & Africa

7.5.1 By Country

7.5.1.1 United Arab Emirates (UAE)

7.5.1.2 Saudi Arabia

7.5.1.3 Qatar

7.5.1.4 Israel

7.5.1.5 South Africa

7.5.1.6 Nigeria

7.5.1.7 Kenya

7.5.1.8 Egypt

7.5.1.9 Rest of MEA

7.5.2 By application

7.5.3 Countries & Segments - Market Attractiveness Analysis

Chapter 8. REINFORCED POLYESTER MARKET – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

8.1 BASF SE

8.2 Solvay

8.3 Dow Chemical Company

8.4 Eastman Chemical Company

8.5 LyondellBasell Industries NV

8.6 Owens Corning

8.7 Hexcel Corporation

8.8 Jushi Group Co., Ltd.

8.9 PPG Industries

8.10 Chongqing Polycomp International Corporation (CPIC)

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The global reinforced polyester market was valued at USD 30 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 5.9% from 2024 to 2030, reaching USD 44.81 billion by 2030.

Increasing demand for lightweight materials, growing demand from the transportation industry, and rising demand for wind energy are the reasons that are driving the market.

Based on application, it is divided into four segments: transportation, construction, wind energy, and electronics

Asia-Pacific is the most dominant region for the reinforced polyester market.

BASF SE, Solvay, Dow Chemical Company, Eastman Chemical Company, and LyondellBasell Industries NV are the major players.