Recycled Polyester Filament Yarn Market Size (2024 – 2030)

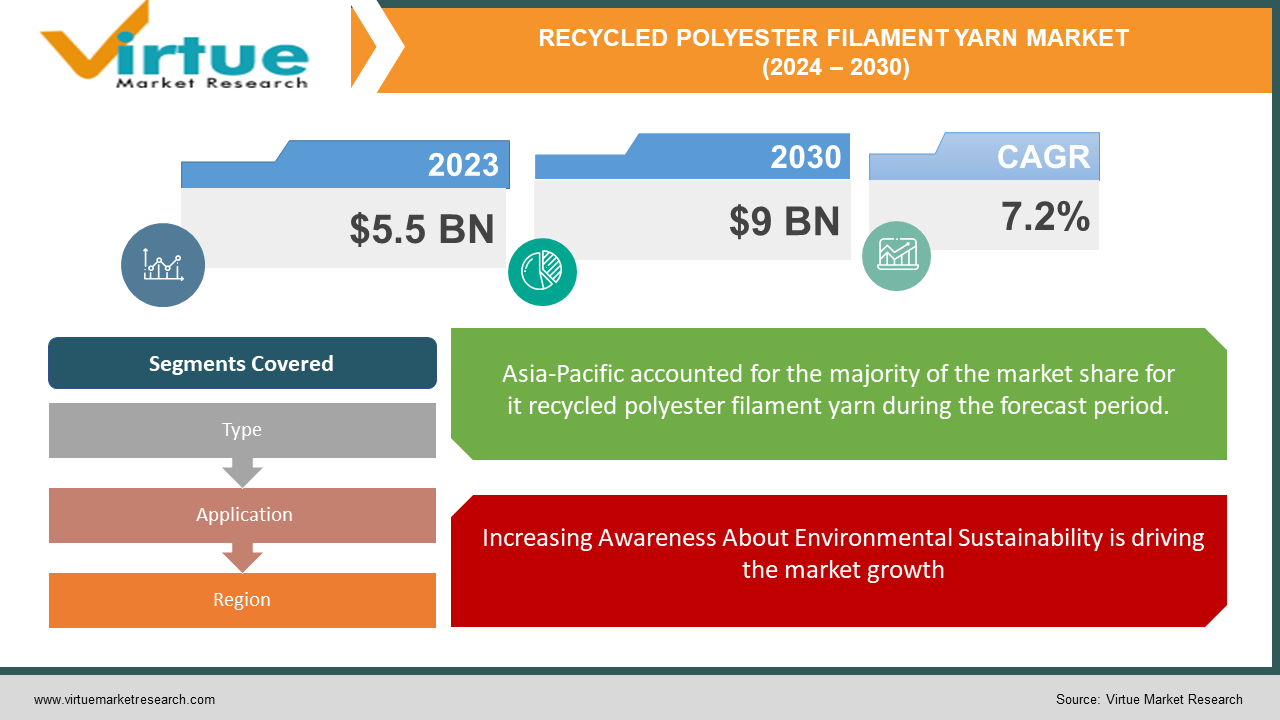

The Global Recycled Polyester Filament Yarn Market was valued at USD 5.5 billion in 2023 and is projected to grow at a CAGR of 7.2% from 2024 to 2030. The market is expected to reach USD 9 billion by 2030.

The increasing awareness about environmental sustainability, coupled with the rising demand for eco-friendly materials in the textile industry, is driving the growth of the recycled polyester filament yarn market. Additionally, advancements in dyeing and finishing technologies are enhancing the performance and aesthetics of recycled polyester filament yarn, making it suitable for a wider range of applications.

Key Market Insights:

The apparel segment dominates the market due to the high demand for sustainable clothing.

Asia-Pacific leads the market, followed by North America and Europe.

The increasing focus on reducing plastic waste and promoting circular economy principles are significant drivers of market growth.

The increasing focus on sustainability and the adoption of circular economy principles present significant opportunities for the growth and innovation of the recycled polyester filament yarn market.

Global Recycled Polyester Filament Yarn Market Drivers:

Increasing Awareness About Environmental Sustainability is driving the market growth

The growing awareness about environmental sustainability is one of the primary drivers of the recycled polyester filament yarn market. Consumers are becoming more conscious of the environmental impact of their purchasing decisions, leading to a rise in demand for eco-friendly and sustainable products. The textile industry, known for its significant environmental footprint, is under increasing pressure to adopt sustainable practices. Recycled polyester filament yarn, made from post-consumer plastic bottles and other recycled polyester waste, offers a sustainable alternative to conventional polyester yarn. It helps in reducing plastic waste, conserving natural resources, and lowering greenhouse gas emissions. The increasing awareness about the benefits of recycled polyester filament yarn among consumers, manufacturers, and retailers is driving its adoption in the textile industry, thereby fueling market growth.

Rising Demand for Sustainable Clothing is driving the market growth.

The demand for sustainable clothing is on the rise, driven by the growing consumer preference for environmentally friendly and ethically produced apparel. Sustainable fashion is becoming a significant trend in the fashion industry, with many brands and retailers incorporating recycled materials into their product lines. Recycled polyester filament yarn is widely used in the production of sustainable clothing due to its durability, versatility, and eco-friendly properties. It is used to manufacture a wide range of apparel, including activewear, casual wear, and outdoor clothing. The rising demand for sustainable clothing is encouraging textile manufacturers to adopt recycled polyester filament yarn, driving market growth. Additionally, the increasing adoption of sustainable practices by major fashion brands and retailers is further boosting the demand for recycled polyester filament yarn in the apparel segment.

Government Initiatives and Regulations Promoting Recycling is driving the market growth.

Governments and regulatory bodies worldwide are implementing initiatives and regulations to promote recycling and reduce plastic waste. These initiatives are aimed at addressing the environmental challenges posed by plastic pollution and encouraging the adoption of sustainable materials. For instance, several countries have implemented plastic waste management policies, recycling targets, and extended producer responsibility (EPR) programs to promote the recycling of plastic waste. These regulations are driving the demand for recycled polyester filament yarn as manufacturers seek to comply with sustainability requirements and reduce their environmental impact. Government incentives and subsidies for recycling projects are also encouraging investments in recycling infrastructure and technologies, further supporting the growth of the recycled polyester filament yarn market.

Global Recycled Polyester Filament Yarn Market Challenges and Restraints:

High Production Costs are restricting the market growth

One of the significant challenges faced by the recycled polyester filament yarn market is the high production costs associated with recycling and processing plastic waste. The recycling process involves collecting, sorting, cleaning, and converting plastic waste into usable polyester filament yarn. These processes require specialized equipment, technology, and skilled labor, which contribute to higher production costs compared to conventional polyester yarn. Additionally, the cost of sourcing and transporting plastic waste for recycling can be substantial, further adding to the overall production expenses. The higher production costs can make recycled polyester filament yarn less competitive in terms of pricing, especially in price-sensitive markets. The challenge for the market is to find ways to reduce production costs and improve the cost-effectiveness of recycling processes to make recycled polyester filament yarn more affordable and accessible.

Limited Availability of High-Quality Recycled Materials is restricting the market growth.

The limited availability of high-quality recycled materials is another significant restraint for the recycled polyester filament yarn market. The quality of recycled polyester filament yarn depends on the quality of the plastic waste used as raw material. Contamination and degradation of plastic waste during the recycling process can affect the quality and performance of the recycled yarn. Ensuring a consistent supply of high-quality recycled materials is crucial for maintaining the quality standards of recycled polyester filament yarn. However, the availability of clean and high-quality plastic waste is limited, posing a challenge for manufacturers. The challenge for the market is to develop efficient recycling technologies and processes that can produce high-quality recycled polyester filament yarn from diverse and contaminated plastic waste sources.

Market Opportunities:

The recycled polyester filament yarn market presents several significant opportunities for growth and innovation. One of the key opportunities lies in the increasing demand for sustainable materials in the automotive and home textiles sectors. The automotive industry is increasingly adopting sustainable materials for interior applications, such as seat fabrics, upholstery, and carpets. Recycled polyester filament yarn offers an eco-friendly alternative to conventional materials, helping automotive manufacturers reduce their environmental footprint. Similarly, the home textiles sector is witnessing a growing demand for sustainable products, including bed linens, curtains, and rugs made from recycled polyester filament yarn. Additionally, advancements in recycling technologies and processes present opportunities for improving the quality and cost-effectiveness of recycled polyester filament yarn. Innovations in chemical recycling, for example, can enhance the efficiency of recycling processes and produce high-quality recycled yarn with minimal environmental impact.

RECYCLED POLYESTER FILAMENT YARN MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

7.2% |

|

Segments Covered |

By Type, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Unifi, Inc., Teijin Limited, Toray Industries, Inc., Indorama Ventures Public Company Limited, Alpine SAB de CV, Reliance Industries Limited, Hyosung Corporation, Zhejiang Jiaren New Materials, Martex Fiber Southern Corporation, Far Eastern New Century Corporation |

Recycled Polyester Filament Yarn Market Segmentation - by Type

-

Solid Recycled Polyester Filament Yarn

-

Hollow Recycled Polyester Filament Yarn

The solid recycled polyester filament yarn segment is the most dominant in the market. Solid yarns are widely used in the textile industry for manufacturing a variety of products, including apparel, home textiles, and industrial fabrics. The versatility and durability of solid recycled polyester filament yarn make it a preferred choice for many applications.

Recycled Polyester Filament Yarn Market Segmentation - by Application

-

Apparel

-

Home Textiles

-

Automotive

-

Industrial

-

Others

The apparel segment is the most dominant application segment in the recycled polyester filament yarn market. The increasing demand for sustainable clothing and the rising consumer preference for eco-friendly fashion drive the adoption of recycled polyester filament yarn in the apparel industry. The versatility of recycled polyester filament yarn makes it suitable for a wide range of clothing items, including activewear, casual wear, and outdoor clothing.

Recycled Polyester Filament Yarn Market Segmentation - Region

-

North America

-

Asia-Pacific

-

Europe

-

South America

-

Middle East and Africa

Asia-Pacific is the most dominant region in the recycled polyester filament yarn market. The region's large textile manufacturing industry, coupled with the increasing focus on sustainability and environmental regulations, drives the demand for recycled polyester filament yarn. Countries like China, India, and Japan are significant contributors to the market's growth in the region.

COVID-19 Impact Analysis on the Recycled Polyester Filament Yarn Market:

The COVID-19 pandemic had a mixed impact on the recycled polyester filament yarn market. The initial phases of the pandemic led to disruptions in the supply chain, affecting the collection and recycling of plastic waste. The closure of recycling facilities and restrictions on movement hampered the production of recycled polyester filament yarn. However, as the pandemic progressed, the demand for sustainable materials witnessed a resurgence. The increased focus on environmental sustainability and the growing consumer preference for eco-friendly products drove the demand for recycled polyester filament yarn. The pandemic also accelerated the adoption of digital technologies and e-commerce platforms in the textile industry, facilitating the sale of sustainable clothing and home textiles. Additionally, the increased use of personal protective equipment (PPE) during the pandemic generated a significant amount of plastic waste, highlighting the need for effective recycling solutions. The post-pandemic recovery phase is expected to witness a continued focus on sustainability, driving the demand for recycled polyester filament yarn.

Latest Trends/Developments:

The recycled polyester filament yarn market is witnessing several key trends and developments. One notable trend is the increasing use of chemical recycling technologies. Chemical recycling involves breaking down plastic waste into its basic chemical components, which can be used to produce high-quality recycled polyester filament yarn. This technology offers several advantages, including the ability to recycle contaminated and mixed plastic waste and produce yarn with properties similar to virgin polyester. Another significant trend is the collaboration between textile manufacturers and recycling companies to develop closed-loop recycling systems. These systems aim to collect, recycle, and reuse polyester waste within the textile industry, promoting circular economy principles. The rise of sustainable fashion is also driving innovations in recycled polyester filament yarn. Fashion brands are increasingly using recycled yarn to create eco-friendly collections, incorporating sustainability into their brand values and marketing strategies. Overall, the recycled polyester filament yarn market is witnessing rapid technological advancements and innovations, driven by the increasing focus on sustainability and circular economy practices.

Key Players:

-

Unifi, Inc.

-

Teijin Limited

-

Toray Industries, Inc.

-

Indorama Ventures Public Company Limited

-

Alpine SAB de CV

-

Reliance Industries Limited

-

Hyosung Corporation

-

Zhejiang Jiaren New Materials

-

Martex Fiber Southern Corporation

-

Far Eastern New Century Corporation

Chapter 1. Recycled Polyester Filament Yarn Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Recycled Polyester Filament Yarn Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Recycled Polyester Filament Yarn Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Recycled Polyester Filament Yarn Market - Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Recycled Polyester Filament Yarn Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Recycled Polyester Filament Yarn Market – By Types

6.1 Introduction/Key Findings

6.2 Solid Recycled Polyester Filament Yarn

6.3 Hollow Recycled Polyester Filament Yarn

6.4 Y-O-Y Growth trend Analysis By Types

6.5 Absolute $ Opportunity Analysis By Types, 2024-2030

Chapter 7. Recycled Polyester Filament Yarn Market – By Application

7.1 Introduction/Key Findings

7.2 Apparel

7.3 Home Textiles

7.4 Automotive

7.5 Industrial

7.6 Others

7.7 Y-O-Y Growth trend Analysis By Application

7.8 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. Recycled Polyester Filament Yarn Market , By Geography – Market Size, Forecast, Trends & Insights

8.1 North America

8.1.1 By Country

8.1.1.1 U.S.A.

8.1.1.2 Canada

8.1.1.3 Mexico

8.1.2 By Types

8.1.3 By Application

8.1.4 Countries & Segments - Market Attractiveness Analysis

8.2 Europe

8.2.1 By Country

8.2.1.1 U.K

8.2.1.2 Germany

8.2.1.3 France

8.2.1.4 Italy

8.2.1.5 Spain

8.2.1.6 Rest of Europe

8.2.2 By Types

8.2.3 By Application

8.2.4 Countries & Segments - Market Attractiveness Analysis

8.3 Asia Pacific

8.3.1 By Country

8.3.1.1 China

8.3.1.2 Japan

8.3.1.3 South Korea

8.3.1.4 India

8.3.1.5 Australia & New Zealand

8.3.1.6 Rest of Asia-Pacific

8.3.2 By Types

8.3.3 By Application

8.3.4 Countries & Segments - Market Attractiveness Analysis

8.4 South America

8.4.1 By Country

8.4.1.1 Brazil

8.4.1.2 Argentina

8.4.1.3 Colombia

8.4.1.4 Chile

8.4.1.5 Rest of South America

8.4.2 By Types

8.4.3 By Application

8.4.4 Countries & Segments - Market Attractiveness Analysis

8.5 Middle East & Africa

8.5.1 By Country

8.5.1.1 United Arab Emirates (UAE)

8.5.1.2 Saudi Arabia

8.5.1.3 Qatar

8.5.1.4 Israel

8.5.1.5 South Africa

8.5.1.6 Nigeria

8.5.1.7 Kenya

8.5.1.8 Egypt

8.5.1.9 Rest of MEA

8.5.2 By Types

8.5.3 By Application

8.5.4 Countries & Segments - Market Attractiveness Analysis

Chapter 9. Recycled Polyester Filament Yarn Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

9.1 Unifi, Inc.

9.2 Teijin Limited

9.3 Toray Industries, Inc.

9.4 Indorama Ventures Public Company Limited

9.5 Alpine SAB de CV

9.6 Reliance Industries Limited

9.7 Hyosung Corporation

9.8 Zhejiang Jiaren New Materials

9.9 Martex Fiber Southern Corporation

9.10 Far Eastern New Century Corporation

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Global Recycled Polyester Filament Yarn Market was valued at USD 5.5 billion in 2023 and is projected to reach USD 9.4 billion by 2030, growing at a CAGR of 7.2% from 2024 to 2030.

The market is driven by increasing awareness about environmental sustainability, rising demand for sustainable clothing, and government initiatives promoting recycling.

The market is segmented by type into solid and hollow recycled polyester filament yarn. It is also segmented by application into apparel, home textiles, automotive, industrial, and others.

Asia-Pacific is the most dominant region due to its large textile manufacturing industry, increasing focus on sustainability, and environmental regulations.

Leading players in the market include Unifi, Inc., Teijin Limited, Toray Industries, Inc., Indorama Ventures Public Company Limited, Alpek S.A.B. de C.V., Reliance Industries Limited, Hyosung Corporation, Zhejiang Jiaren New Materials Co., Ltd., Martex Fiber Southern Corporation, and Far Eastern New Century Corporation.