Global PVC Resin for Automotive Market Size (2023-2030)

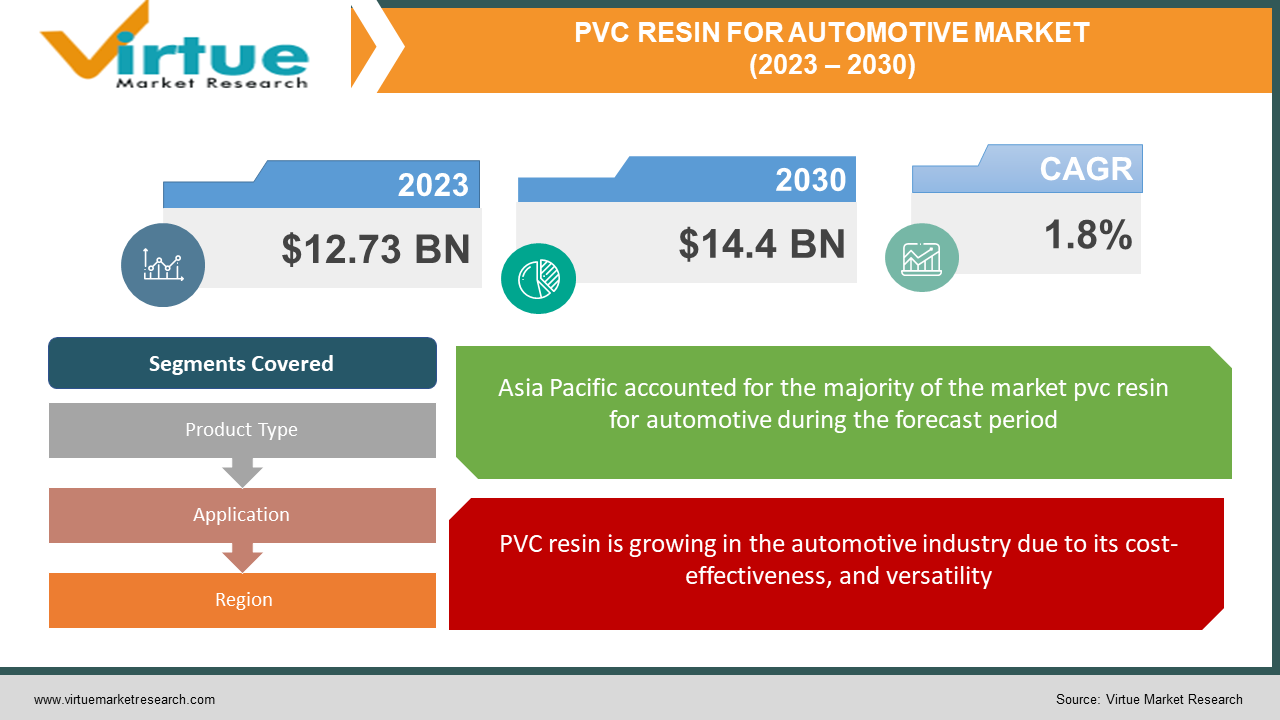

The Global PVC Resin for Automotive Market was valued at USD 12.73 Billion and is projected to reach a market size of USD 14.4 Billion by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 1.8%.

Polyvinyl chloride (PVC) resin finds diverse applications in the automotive industry due to its flexibility, durability, and cost-effectiveness. Key uses include interior components like dashboard panels, seat covers, and door panels, as well as exterior components such as weather strips, body-side moldings, and window seals. PVC is also employed for wire harness insulation, flexible tubing, and hoses, thanks to its resistance to environmental factors and chemicals. It's utilized in electrical systems, soundproofing, and insulation due to its insulating properties. While PVC offers advantages, sustainability concerns, and evolving regulations drive the exploration of alternative materials. The automotive sector's dynamic nature may prompt shifts in PVC resin usage as it responds to changing market demands and environmental considerations.

Global PVC Resin for Automotive Market Drivers:

PVC resin is growing in the automotive industry due to its cost-effectiveness, and versatility.

The use of PVC resin in the automotive market is driven by its cost-effectiveness, design versatility, durability, and ease of processing. It offers benefits such as weight reduction, electrical insulation, UV resistance, and noise reduction, making it suitable for interior, exterior, and under-the-hood applications. PVC meets regulatory standards and enables customization while benefiting from an established supply chain. However, growing environmental concerns and a push for sustainability are prompting consideration of alternative materials that balance performance and eco-friendliness in the automotive industry.

The rising awareness of environmental concerns and a growing emphasis on reducing ecological impact have spurred a notable demand for PVC resin-based solutions in the automotive market.

The PVC Resin for Automotive Market has made significant strides propelled by its versatile applications, technological advancements, and a growing focus on environmental considerations. Just as diatomite presents a sustainable solution aligned with compostable bioplastics, PVC resin offers a compelling answer. By employing efficient manufacturing processes and harnessing the material's recyclability, PVC resin aligns with circular economy principles. This robust material possesses durability while also being recyclable, reducing waste and promoting responsible disposal. Similar to the eco-friendly decomposition of compostable bioplastics, PVC resin contributes to a reduced ecological footprint and aligns with sustainable practices, making a positive impact on resource conservation and environmental well-being.

Global PVC Resin for Automotive Market Challenges:

In the automotive industry, PVC resin face challenges in ensuring its longevity and resistance to weathering, as components must endure diverse conditions. Environmental concerns arise due to traditional PVC production's ecological impact, necessitating sustainable alternatives. Additionally, the industry's reliance on global supply chains makes it vulnerable to disruptions, impacting material availability. Addressing these challenges involves developing weather-resistant PVC formulations, exploring eco-friendly production processes, promoting responsible disposal, and implementing resilient supply chain strategies. Balancing performance, environmental responsibility, and supply chain stability is essential for the effective use of PVC resin in the automotive sector.

Global PVC Resin for Automotive Market Opportunities:

The PVC Resin for Automotive Market offers opportunities through sustainable innovations, advanced additives, recycling initiatives, bio-based alternatives, collaboration with automakers, lightweighting efforts, the electric vehicle segment, emerging markets, smart interiors, customization trends, and safety enhancements. Adapting to these opportunities necessitates research, innovation, and alignment with evolving market trends, enabling PVC resin to play a crucial role in the automotive sector's growth and sustainability efforts.

COVID-19 Impact on the Global PVC Resin for Automotive Market:

The COVID-19 pandemic brought significant challenges to the PVC Resin for Automotive Market. Supply chain disruptions, arising from lockdowns and travel restrictions, affected PVC resin availability. Production halts resulted from reduced workforce availability and decreased consumer demand, impacting both automotive production and the demand for PVC resin components. Financial pressures within the automotive industry led to cost-cutting measures, potentially affecting material choices like PVC resin. The market's recovery will depend on adaptive strategies, supply chain resilience, and informed decision-making as the industry navigates post-pandemic uncertainties.

PVC RESIN FOR AUTOMOTIVE MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

1.8% |

|

Segments Covered |

By Product Type, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

BASF, Shin-Etsu Chemical, LG Chem, KEM ONE, Solvay, INEOS Group, Mexichem |

Global PVC Resin for Automotive Market Segmentation: By Product Type

-

Rigid

-

Flexible

Flexible PVC resin is experiencing the highest growth in the automotive industry due to its advantages in interior applications. It is used for components like dashboard covers, door panels, seat covers, and floor mats due to its ability to conform to shapes and provide comfort. Factors such as urbanization, ride-sharing trends, and consumer demand for comfortable interiors contribute to its growth. Furthermore, PVC resin is lightweight and durable, making it cost-effective and resource-efficient. It is also recyclable, contributing to sustainability and environmental protection.

Rigid PVC resin is experiencing the fastest growth in the automotive industry due to its suitability for exterior applications. It is used for parts like window profiles, body side moldings, and exterior trim due to its durability and weather resistance. Cost-effectiveness, dimensional stability, safety, and regulatory compliance are driving its adoption. The expansion of commercial vehicles and SUVs further accelerates its growth. Technological advancements in the automotive industry have made PVC resin even more attractive for exterior applications. Automotive manufacturers are increasingly using rigid PVC resin to reduce vehicle weight and fuel consumption. This further helps them comply with the stringent emission regulations.

Global PVC Resin for Automotive Market Segmentation: By Application

-

Interior Components

-

Exterior Components

-

Others

Interior components, including dashboard panels, door trims, seat covers, and floor mats, are experiencing the highest growth in the PVC resin market. PVC resins are favored for their comfort, customization options, and adaptability to innovative features. Evolving consumer preferences for personalized, comfortable interiors, urbanization trends, and sustainability initiatives are driving this growth. As a result, automotive OEMs are experimenting with different polymer blends and are increasingly incorporating PVC resins into their interior components. This is leading to an increase in the demand for PVC resins in the automotive industry.

Exterior components like window profiles, body side moldings, and trim are seeing the fastest growth in the PVC resin market. PVC's durability, weather resistance, and cost-effectiveness make it a preferred choice for these parts. Vehicle safety, regulatory compliance, growth in commercial vehicles, and the need for low-maintenance, long-lasting materials are driving this growth. Automotive manufacturers are increasingly using PVC for exterior components due to its cost advantages, lightweight properties, and ability to meet stringent environmental standards. PVC also offers superior design flexibility, enabling manufacturers to create innovative designs.

Global PVC Resin for Automotive Market Segmentation: By Region

-

North America

-

Europe

-

Asia Pacific

-

Middle East and Africa

-

South America

Asia Pacific experiences the highest growth due to its role as a major automotive manufacturing hub. Rising automobile production, increasing consumer demand, and manufacturing investments are driving the demand for PVC resins in vehicles. Countries like China, Japan, South Korea, and India are significant contributors to this growth.

The Middle East and Africa show fast growth, propelled by infrastructure development, economic growth, and government initiatives. Investments in infrastructure, rising vehicle ownership rates due to economic growth, and government support for local manufacturing contribute to PVC resin demand. Governments in the Middle East and Africa are encouraging domestic manufacturing of PVC resin, which is helping to bolster growth in the region. The region's increasing energy efficiency also drives the demand for PVC resin. Overall, the area is poised for solid growth in the coming years.

Global PVC Resin for Automotive Market Key Players:

-

BASF

-

Shin-Etsu Chemical

-

LG Chem

-

KEM ONE

-

Solvay

-

INEOS Group

-

Mexichem

Chapter 1. PVC Resin for Automotive Market – Scope & Methodology

1.1 Market Segmentation

1.2 Assumptions

1.3 Research Methodology

1.4 Primary Sour

1.5 Secondary Sources

Chapter 2. PVC Resin for Automotive Market – Executive Summary

2.1 Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.3 COVID-19 Impact Analysis

2.3.1 Impact during 2023 – 2030

2.3.2 Impact on Supply – Demand

Chapter 3. PVC Resin for Automotive Market – Competition Scenario

3.1 Market Share Analysis

3.2 Product Benchmarking

3.3 Competitive Strategy & Development Scenario

3.4 Competitive Pricing Analysis

3.5 Supplier - Distributor Analysis

Chapter 4. PVC Resin for Automotive Market - Entry Scenario

4.1 Case Studies – Start-up/Thriving Companies

4.2 Regulatory Scenario - By Region

4.3 Customer Analysis

4.4 Porter's Five Force Model

4.4.1 Bargaining Power of Suppliers

4.4.2 Bargaining Powers of Customers

4.4.3 Threat of New Entrants

4.4.4 .Rivalry among Existing Players

4.4.5 Threat of Substitutes

Chapter 5. PVC Resin for Automotive Market - Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. PVC Resin for Automotive Market - By Product Type

6.1 Rigid

6.2 Flexible

Chapter 7. PVC Resin for Automotive Market - By Application

7.1 Interior Components

7.2 Exterior Components

7.3 Others

Chapter 8. PVC Resin for Automotive Market – By Region

8.1 North America

8.2 Europe

8.3 Asia-Pacific

8.4 Latin America

8.5 The Middle East

8.6 Africa

Chapter 9. PVC Resin for Automotive Market – Key Players

9.1 BASF

9.2 Shin-Etsu Chemical

9.3 LG Chem

9.4 KEM ONE

9.5 Solvay

9.6 INEOS Group

9.7 Mexichem

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

Key players in the PVC resin market for the automotive industry include Shin-Etsu Chemical, INEOS Group, Westlake Chemical, Mexichem, and LG Chem.

Sustainability drives the adoption of eco-friendly PVC resin formulations in automotive applications, aligning with environmental regulations and consumer preferences.

The primary applications of PVC resin in the automotive industry include interior components, exterior components, and wiring applications.

The demand for flexible PVC resin is driven by its comfortable and customizable interior components, while rigid PVC resin is sought after for durable and weather-resistant exterior parts in the automotive market.

Asia Pacific region, including countries like China, Japan, South Korea, and India, is experiencing the highest growth in the PVC resin market for automotive applications.