Precast Concrete Beams & Columns Market Size (2024 –2030)

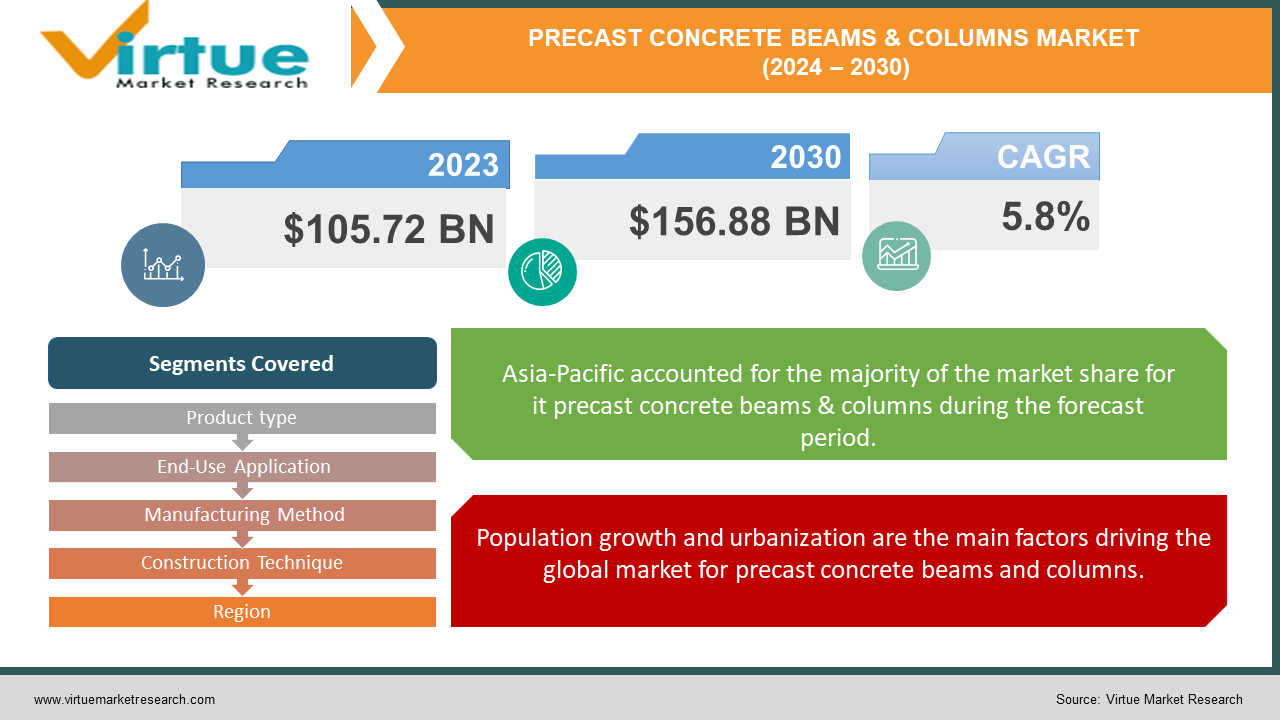

The Global Precast Concrete Beams & Columns Market is valued at USD 105.72 Billion and is projected to reach a market size of USD 156.88 Billion by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 5.8%.

The need for more environmentally friendly building techniques is one of the primary drivers of the rising demand for precast concrete beams and columns. With increased public awareness of environmental issues, the construction industry is searching for energy- and waste-saving solutions. Because precast concrete beams and columns are manufactured in factories, there is less waste and higher quality is guaranteed. Compared to conventional on-site concrete pouring, this technique is more environmentally friendly. Precast concrete is becoming more and more in demand due to environmental regulations and the drive for green building certifications.

Key Market Insights:

Precast concrete beams account for approximately 55% of the precast concrete beams and columns market share, driven by their widespread use in various construction projects, including bridges, buildings, and parking structures.

The commercial construction segment constitutes around 40% of the demand for precast concrete beams and columns, reflecting the growing adoption of prefabricated elements in office buildings, retail spaces, and hotels for faster construction times and improved quality control.

In terms of region, Asia-Pacific holds the largest market share of about 35% for precast concrete beams and columns, attributed to rapid urbanization, infrastructure development, and the increasing adoption of modern construction techniques in countries like China and India.

The adoption of high-performance precast concrete beams and columns, incorporating advanced materials and designs for enhanced strength and durability, is growing at a rate of approximately 10% annually, driven by the demand for more resilient and sustainable building solutions.

Global Precast Concrete Beams & Columns Market Drivers:

Population growth and urbanization are the main factors driving the global market for precast concrete beams and columns.

The market for precast concrete beams and columns is expanding primarily due to urbanization and population growth. There is an increasing demand for residential and commercial real estate as well as infrastructure projects as more people are born and relocated to cities. Rapid urbanization in emerging economies necessitates the use of expedient and effective construction techniques. Because they enable quicker construction and require less labor on-site, precast concrete beams and columns are a good option. They are therefore ideal for urban projects with constrained time and space constraints.

The demand for precast concrete beams and columns is driven by sustainable construction practices in the global market.

Precast concrete beams and columns are becoming increasingly popular around the world as sustainable construction methods gain more attention. Waste reduction and energy conservation are becoming more popular in the construction industry as people become more conscious of environmental issues and the need to reduce carbon emissions. Pouring concrete on-site is less environmentally friendly than making precast concrete in factories. Less waste and improved quality control are made possible by this process. Precast concrete buildings are also more durable and require less upkeep, which makes them a wise and sustainable option for developers and builders looking to minimize their environmental effects.

The global market demand for precast concrete beams and columns is driven by technological advancements in manufacturing.

The global market for precast concrete beams and columns is experiencing innovation due to technological advancements in manufacturing. Production is becoming more precise and efficient as automation, robotics, and sophisticated machinery are employed. Automation lowers production costs, eliminates the need for manual labor, and enhances the quality of the finished product. Robotics opens up new possibilities for structural and architectural applications by improving consistency and accuracy when creating complex shapes and designs. Businesses that make these cutting-edge technology investments acquire a competitive edge by providing superior products at reduced prices and with shorter lead times.

Precast concrete beams and columns are in high demand worldwide due to investments and infrastructure development.

Precast concrete beams and columns are in high demand worldwide due in large part to investment and infrastructure development. To promote economic growth, governments and private investors are investing heavily in infrastructure projects such as public utilities, roads, bridges, and airports. Because it is strong, long-lasting, and easy to install, precast concrete is well-liked for these kinds of projects. Compared to conventional construction methods, it saves money and time, which makes it perfect for large-scale projects. Global infrastructure investment is predicted to increase demand for precast concrete beams and columns, which will drive market growth.

Precast Concrete Beams & Columns Market Challenges and Restraints:

The high upfront costs associated with setting up manufacturing facilities and purchasing the required machinery and equipment present one of the primary obstacles facing the precast concrete beams and columns market. The initial costs of molds, formwork, casting beds, mixing equipment, and curing facilities are high when starting a precast concrete production facility. To increase productivity, specialized equipment and automation technologies are also required. These high startup costs can be a significant obstacle for smaller businesses or new market entrants, making it difficult for them to compete. Investment decisions are further complicated by the possibility of an uncertain long-term return on investment, particularly in regions with strong competition or fluctuating demand.

Precast Concrete Beams & Columns Market Opportunities:

The growing need for sustainable construction solutions presents a significant opportunity in the global market for precast concrete beams and columns. A growing trend is the use of environmentally friendly building materials and techniques as regulations tighten and environmental concerns grow. Because of their benefits, precast concrete beams and columns are increasingly being used in environmentally friendly building projects. First off, compared to conventional on-site concrete pouring, precast concrete production uses fewer resources. Optimized material utilization, decreased waste, and less environmental pollution are possible when manufacturing takes place in controlled factory environments. Precast concrete buildings also require less upkeep and have a longer lifespan than traditional building materials, which helps with sustainability initiatives.

PRECAST CONCRETE BEAMS & COLUMNS MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

5.8% |

|

Segments Covered |

By Product type, End-Use Application, Manufacturing Method, Construction Technique, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

LafargeHolcim Ltd. (Switzerland), Elematic (Finland), Bison Manufacturing (United Kingdom), Coreslab Structures (Canada), Tindall Corporation (United States), Forterra (United States), Spancrete (United States), Boral Limited (Australia), Metromont Corporation (United States), CEMEX S.A.B. de C.V. (Mexico) |

Global Precast Concrete Beams & Columns Market Segmentation: By Product Type

-

Prestressed Concrete Beams

-

Non-Prestressed Concrete Beams

-

Prestressed Concrete Columns

-

Non-Prestressed Concrete Columns

Prestressed concrete beams have a high strength-to-weight ratio, which makes them popular in many building projects. They can therefore span greater distances while consuming less material. They are frequently utilized in commercial and industrial buildings, as well as in infrastructure projects like highways and bridges. The efficiency and adaptability of prestressed concrete columns are contributing to their increasing popularity. They provide advantages like better structural performance, faster construction times, and increased load-bearing capacity. They are a popular option for infrastructure projects and high-rise buildings because of these benefits.

Global Precast Concrete Beams & Columns Market Segmentation: By End-Use Application

-

Residential Buildings

-

Commercial Buildings

-

Industrial Buildings

-

Infrastructure

-

Others

Due to the extensive usage of precast concrete beams and columns in office buildings, shopping malls, hotels, and other commercial structures, the commercial buildings segment has the largest market share. A few of the factors driving this demand are affordability, speed of construction, and design flexibility. The market for residential buildings is expanding swiftly as the demand for affordable housing rises due to urbanization and population growth. Precast concrete columns and beams are common in residential construction because they provide more customization options, longer building lifespans, and quicker building times. Precast concrete components are expected to become much more in demand in residential construction as governments and developers strive to address the housing shortage.

Global Precast Concrete Beams & Columns Market Segmentation: By Manufacturing Method

-

Wet-Cast Method

-

Dry-Cast Method

The wet-cast method remains the largest segment in the precast concrete beams and columns market due to its long-standing history and widespread use in the industry. This method involves pouring concrete into molds and allowing it to cure over time, resulting in high-quality precast components with smooth surfaces and consistent properties. The dry-cast method is witnessing rapid growth driven by advancements in manufacturing technology and increasing demand for efficient production processes. This method involves using a low-slump concrete mix that is compacted and cured in a controlled environment, resulting in faster production times and higher productivity. The dry-cast method is particularly favored for large-scale production of precast concrete beams and columns in infrastructure projects.

Global Precast Concrete Beams & Columns Market Segmentation: By Construction Technique

-

Cast-In-Situ

-

Precast

The precast construction technique is the largest segment in the market, accounting for the majority of precast concrete beams and columns used in construction projects worldwide. Precast elements are manufactured off-site in controlled factory conditions, allowing for higher quality control and faster installation on-site. The cast-in-situ construction technique is experiencing rapid growth due to its advantages in certain types of construction projects, such as high-rise buildings and complex structures. In cast-in-situ construction, concrete elements are poured and cured on-site, offering greater flexibility in design and customization compared to precast components. This technique is increasingly used in projects where intricate architectural designs or site-specific requirements are essential.

Global Precast Concrete Beams & Columns Market Segmentation: Regional Analysis

-

North America

-

Europe

-

Asia-Pacific

-

Latin America

-

Middle East & Africa

Precast concrete beams and columns are typically most in demand in areas with substantial infrastructure development and high rates of urbanization. Asia Pacific is currently the world's largest market for precast concrete due to extensive infrastructure projects, rapid urbanization, and population growth. Significant urbanization is occurring in nations like China and India, which is driving up demand for residential, commercial, and industrial buildings as well as infrastructure like roads, bridges, and railroads. Asia Pacific is now the largest market region for precast concrete beams and columns due to the construction boom in these countries. In the meantime, the precast concrete market worldwide is known to be expanding at the quickest rate in the Middle East and Africa (MEA) region. This place is rapidly becoming more urbanized and industrialized due to factors like population growth, economic expansion, and government programs to increase infrastructure spending. The Gulf Cooperation Council (GCC), which includes the United Arab Emirates, Saudi Arabia, and Qatar, is investing heavily in infrastructure projects that include roads, seaports, airports, and commercial buildings. All of these projects require precast concrete components. Furthermore, there is a lot of construction going on in Africa, particularly in Nigeria, Kenya, and South Africa, which is boosting the precast concrete market there. Urbanization, infrastructure spending, and building activity all work together to make the MEA region a vibrant and quickly growing market for precast concrete beams and columns.

COVID-19 Impact on the Global Precast Concrete Beams & Columns Market:

The pandemic caused significant disruptions to the global supply chain, which affected the availability of components and raw materials required for the production of precast concrete. Production was hampered by lockdowns, travel restrictions, and factory closures that delayed the procurement of supplies and machinery. Transport and logistics problems made these issues worse by delaying the delivery of precast concrete products to construction sites. Lockdown protocols and social distancing mandates also compelled the global suspension or postponement of building projects. In an effort to contain the virus, governments banned non-essential construction activities, which led to project delays and cancellations. The demand for precast concrete beams and columns was greatly decreased by this downturn in construction activity, which had an impact on suppliers and manufacturers in the sector.

Latest Trend/Development:

By improving project visualization, planning, and execution, digital technologies and Building Information Modeling (BIM) are revolutionizing the manufacturing and construction processes of precast concrete. Using BIM software, engineers, contractors, and architects can model building structures in three dimensions, including precast concrete components like columns and beams. By using these models, possible conflicts can be found and resolved prior to the start of construction. This lessens mistakes and rework during the construction stage. The precast concrete industry is also seeing a rise in automation and robotics. Robotic systems and automated production lines improve efficiency and quality control by increasing the precision of precast concrete element fabrication. When compared to manual labor, robots can perform tasks like pouring concrete, installing reinforcements, and finishing surfaces more accurately and consistently. This leads to faster production rates and better-quality products, which highlights the growing trend of automation in manufacturing facilities.

Key Players:

-

LafargeHolcim Ltd. (Switzerland)

-

Elematic (Finland)

-

Bison Manufacturing (United Kingdom)

-

Coreslab Structures (Canada)

-

Tindall Corporation (United States)

-

Forterra (United States)

-

Spancrete (United States)

-

Boral Limited (Australia)

-

Metromont Corporation (United States)

-

CEMEX S.A.B. de C.V. (Mexico)

Market News:

-

To investigate the possibility of constructing a carbon capture plant in the Southern Highlands of New South Wales, Boral Limited partnered with Calix Limited in May 2022. They were given funding to investigate the feasibility of building a facility that can absorb and condense up to 100,000 tons of CO2 emissions from the cement industry's decomposition of limestone.

Chapter 1. Precast Concrete Beams & Columns Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Precast Concrete Beams & Columns Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Precast Concrete Beams & Columns Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Precast Concrete Beams & Columns Market Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Precast Concrete Beams & Columns Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Precast Concrete Beams & Columns Market – By Product Type

6.1 Introduction/Key Findings

6.2 Prestressed Concrete Beams

6.3 Non-Prestressed Concrete Beams

6.4 Prestressed Concrete Columns

6.5 Non-Prestressed Concrete Columns

6.6 Y-O-Y Growth trend Analysis By Product Type

6.7 Absolute $ Opportunity Analysis By Product Type, 2024-2030

Chapter 7. Precast Concrete Beams & Columns Market – By End-Use Application

7.1 Introduction/Key Findings

7.2 Residential Buildings

7.3 Commercial Buildings

7.4 Industrial Buildings

7.5 Infrastructure

7.6 Others

7.7 Y-O-Y Growth trend Analysis By End-Use Application

7.8 Absolute $ Opportunity Analysis By End-Use Application, 2024-2030

Chapter 8. Precast Concrete Beams & Columns Market – By Manufacturing Method

8.1 Introduction/Key Findings

8.2 Wet-Cast Method

8.3 Dry-Cast Method

8.4 Y-O-Y Growth trend Analysis End-Use Industry

8.5 Absolute $ Opportunity Analysis End-Use Industry, 2024-2030

Chapter 9. Precast Concrete Beams & Columns Market – By Construction Technique

9.1 Introduction/Key Findings

9.2 Cast-In-Situ

9.3 Precast

9.4 Y-O-Y Growth trend Analysis End-User

9.5 Absolute $ Opportunity Analysis End-User, 2024-2030

Chapter 10. Precast Concrete Beams & Columns Market, By Geography – Market Size, Forecast, Trends & Insights

10.1 North America

10.1.1 By Country

10.1.1.1 U.S.A.

10.1.1.2 Canada

10.1.1.3 Mexico

10.1.2 By Product Type

10.1.2.1 By End-Use Application

10.1.3 By Manufacturing Method

10.1.4 Countries & Segments - Market Attractiveness Analysis

10.2 Europe

10.2.1 By Country

10.2.1.1 U.K

10.2.1.2 Germany

10.2.1.3 France

10.2.1.4 Italy

10.2.1.5 Spain

10.2.1.6 Rest of Europe

10.2.2 By Product Type

10.2.3 By End-Use Application

10.2.4 By Manufacturing Method

10.2.5 By Construction Technique

10.2.6 Countries & Segments - Market Attractiveness Analysis

10.3 Asia Pacific

10.3.1 By Country

10.3.1.1 China

10.3.1.2 Japan

10.3.1.3 South Korea

10.3.1.4 India

10.3.1.5 Australia & New Zealand

10.3.1.6 Rest of Asia-Pacific

10.3.2 By Product Type

10.3.3 By End-Use Application

10.3.4 By Manufacturing Method

10.3.5 By Construction Technique

10.3.6 Countries & Segments - Market Attractiveness Analysis

10.4 South America

10.4.1 By Country

10.4.1.1 Brazil

10.4.1.2 Argentina

10.4.1.3 Colombia

10.4.1.4 Chile

10.4.1.5 Rest of South America

10.4.2 By Product Type

10.4.3 By End-Use Application

10.4.4 By Manufacturing Method

10.4.5 By Construction Technique

10.4.6 Countries & Segments - Market Attractiveness Analysis

10.5 Middle East & Africa

10.5.1 By Country

10.5.1.1 United Arab Emirates (UAE)

10.5.1.2 Saudi Arabia

10.5.1.3 Qatar

10.5.1.4 Israel

10.5.1.5 South Africa

10.5.1.6 Nigeria

10.5.1.7 Kenya

10.5.1.8 Egypt

10.5.1.9 Rest of MEA

10.5.2 By Product Type

10.5.3 By End-Use Application

10.5.4 By Manufacturing Method

10.5.5 By Construction Technique

10.5.6 Countries & Segments - Market Attractiveness Analysis

Chapter 11. Precast Concrete Beams & Columns Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

11.1 LafargeHolcim Ltd. (Switzerland)

11.2 Elematic (Finland)

11.3 Bison Manufacturing (United Kingdom)

11.4 Coreslab Structures (Canada)

11.5 Tindall Corporation (United States)

11.6 Forterra (United States)

11.7 Spancrete (United States)

11.8 Boral Limited (Australia)

11.9 Metromont Corporation (United States)

11.10 CEMEX S.A.B. de C.V. (Mexico)

Download Sample

Choose License Type

2500

4250

5250

6900

Related Reports

Frequently Asked Questions

The Global Precast Concrete Beams & Columns Market is valued at USD 105.72 Billion and is projected to reach a market size of USD 156.88 Billion by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 5.8%.

Urbanization and Population Growth, Sustainable Construction Practices, Technological Advancements & Infrastructure Development, and Investment are the major drivers of the Global Precast Concrete Beams & Columns Market.

Wet-Cast Method & Dry-Cast Method are the segments under the Global Precast Concrete Beams & Columns Market by manufacturing method.

Asia Pacific is the most dominant region for the Global Precast Concrete Beams & Columns Market.

Middle East and Africa are the fastest-growing regions in the Global Precast Concrete Beams & Columns Market.