Polyimide Monomer Market Size (2023-2030)

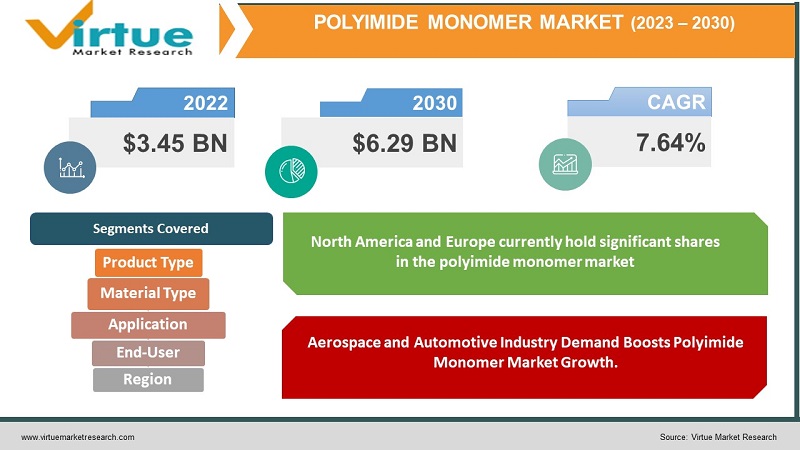

The Polyimide Monomer Market was valued to be worth USD 3.45 Billion in 2022 and is projected to reach USD 6.29 Billion by the end of 2030, exhibiting a robust CAGR of 7.64% during the forecast period from 2023 to 2030.

Polyimide monomers are versatile and high-performance chemical compounds that find widespread use in diverse industries, including aerospace, electronics, automotive, and healthcare. Renowned for their exceptional thermal stability, mechanical strength, and chemical resistance, these monomers prove to be the perfect choice for applications in extreme and demanding environments. The surging demand for lightweight yet robust materials in the aerospace and automotive sectors is propelling the adoption of polyimide monomers. With outstanding dielectric properties, these monomers are indispensable for manufacturing electronic components and circuit boards in the ever-evolving electronics industry. Moreover, their remarkable ability to withstand high temperatures and exhibit biocompatibility has led to their widespread utilization in the healthcare and medical domain, serving vital roles in surgical instruments and medical devices. Notably, continuous progress in polyimide monomer production processes and their application is anticipated to unlock fresh growth opportunities for the market during the forecast period. As industries seek advanced materials to meet evolving demands, polyimide monomers remain at the forefront, fueling innovation and addressing the evolving needs of multiple sectors with their exceptional properties and diverse range of applications.

Global Polyimide Monomer Market Drivers:

Aerospace and Automotive Industry Demand Boosts Polyimide Monomer Market Growth.

The increasing need for lightweight and strong materials to improve fuel efficiency and performance in the aerospace and automotive industries has led to the rising adoption of polyimide monomers. These industries are turning to polyimide monomers for their outstanding mechanical properties, such as high tensile strength and low coefficient of thermal expansion, which contribute to enhanced material performance and overall system efficiency.

Electronics and Semiconductor Applications Drive Market Growth.

The electronics and semiconductor industries have a strong dependence on polyimide monomers, primarily due to their remarkable dielectric properties and high thermal stability. These monomers are extensively utilized in the production of flexible circuit boards, connectors, and insulating materials for electronic components. As the demand for miniaturized and high-performance electronic devices continues to rise, polyimide monomers have become indispensable in these applications.

Healthcare and Medical Industry Adoption Fosters Market Expansion.

Polyimide monomers are gaining prominence in healthcare and medical applications due to their biocompatibility and high-temperature resistance. These properties make them well-suited for use in surgical instruments, medical devices, and dental tools, where biocompatibility and durability are essential requirements. As the healthcare industry continues to progress with advancements in medical technologies and materials, the demand for polyimide monomers is expected to witness considerable growth.

Global Polyimide Monomer Market Challenges:

Cost and Processing Complexity hinder widespread Market Adoption.

The production cost and processing complexity of polyimide monomers poses a challenge to their widespread market adoption. The multistep reactions and precise temperature controls involved in the manufacturing process make it relatively expensive compared to other polymers. This cost factor and processing intricacies may limit their usage in some cost-sensitive applications, thus potentially restricting market penetration. To overcome this challenge, ongoing research and development efforts are crucial to optimize production processes and explore cost-effective alternatives.

Regulatory Compliance and Environmental Concerns pose challenges.

Polyimide monomers are subject to strict regulatory compliance due to their potential environmental impact during production and disposal. Concerns surrounding volatile organic compounds (VOCs) and hazardous by-products necessitate addressing these environmental issues to meet stringent regulations and establish sustainable production practices. Manufacturers must prioritize the development of environmentally friendly and compliant processes to mitigate these challenges effectively. By adopting eco-friendly manufacturing practices, the industry can ensure long-term market viability while adhering to environmental standards and promoting a greener approach to polyimide monomer production.

Global Polyimide Monomer Market Opportunities:

Advancements in Process Technologies Drive Market Growth.

Continuous advancements in process technologies are expected to unlock new growth opportunities for the polyimide monomer market. Innovations in polymerization techniques, functionalization methods, and purification processes can lead to improved material properties, reduced production costs, and enhanced performance of polyimide monomers. Manufacturers investing in process development and optimization are likely to gain a competitive edge in the market and attract new business opportunities.

Expanding Applications in Emerging Industries propel Market Expansion.

The adoption of polyimide monomers is expanding into emerging industries, such as renewable energy, optical devices, and 3D printing. These industries demand high-performance materials with thermal stability and excellent mechanical properties, making polyimide monomers an attractive choice. As emerging sectors continue to grow and explore advanced materials, the demand for polyimide monomers in these applications is anticipated to boost market growth, creating new avenues for expansion.

Focus on Research and Development drives Innovation.

Research and development efforts focused on exploring novel applications and functional modifications of polyimide monomers can lead to innovative solutions and diversify market prospects. Novel formulations, hybrid materials, and tailor-made polyimide monomers can cater to specific industry needs, opening doors to niche markets and niche applications. By investing in research and development, industry players can foster innovation and foster the polyimide monomer market's sustainable growth.

POLYIMIDE MONOMER MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

7.64% |

|

Segments Covered |

By Product Type, Material Type, Application, End-User, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

SABIC, Solvay S.A, Daken Chemical Limited, Mitsui Chemicals Inc., Kaneka Corporation |

Global Polyimide Monomer Market Segmentation: By Product Type

-

Polyimide

-

Polyetherimide

-

Polyamideimides

-

Others

Based on the market segmentation by Product Type, Polyimide holds the largest share. Polyimide monomers are extensively used in high-temperature applications, including aerospace, electronics, automotive, and healthcare. The polyimide's ability to withstand extreme temperatures makes it suitable for applications where other materials might fail. It is commonly used in manufacturing electronic components, circuit boards, and insulating materials for the electronics industry.

However, Polyetherimide is the fastest growing because of its high-temperature resistance, excellent mechanical strength, and good electrical properties. It is commonly used in applications requiring high-performance materials, such as aerospace, automotive, electronics, and medical devices.

Global Polyimide Monomer Market Segmentation: By Material Type

-

Thermoplastic

-

Thermosetting

Based on the market segmentation based on Material Type, Thermosetting Polyimides have the largest demand because of their excellent thermal stability, mechanical strength, and chemical resistance. These properties make them suitable for high-temperature applications, such as aerospace, electronics, and automotive industries.

However, Thermoplastic polyimide monomers can be melted and re-molded multiple times without significant degradation in their properties. While they also offer good thermal and mechanical performance, they may not be as well-suited for extreme high-temperature applications as thermosetting polyimides.

Global Polyimide Monomer Market Segmentation: By Application

-

Resins

-

Films

-

Fibers

-

Others

Based on the segmentation by Application, Resins hold the largest share of the market as they are widely used in various industries, including aerospace, electronics, automotive, and healthcare. Polyimide resins are commonly used as matrix materials in composites, coatings, adhesives, and other applications where high-performance materials are required.

However, Polyimide films are the fastest-growing segment owing to their exceptional thermal stability, mechanical strength, and electrical insulation properties. They are commonly used in a wide range of applications, including flexible printed circuit boards (PCBs), aerospace components, electronic displays, insulating materials, and various other high-performance applications.

Global Polyimide Monomer Market Segmentation: By End-User

-

Electrical & Electronics

-

Aerospace & Defence

-

Healthcare

-

Transportation

-

Others

Based on the segmentation by End-User, the Electrical & Electronics industry is the highest demand generator in the market because of the extensive use of polyimide films and coatings in electronics applications, such as flexible printed circuit boards (FPCBs), insulating materials, and electronic displays. Moreover, the Aerospace & Defence Industry is the fastest growing in the present scenario because of their need for exceptional thermal stability, mechanical strength, and chemical resistance.

Global Polyimide Monomer Market Segmentation: By Region

-

North America

-

Europe

-

Asia-Pacific

-

Middle East and Africa

-

South America

Based on market segmentation by region, North America and Europe currently hold significant shares in the polyimide monomer market, primarily driven by their thriving aerospace and electronics industries. However, the Asia-Pacific region is anticipated to witness substantial growth due to the rising demand for lightweight materials in the automotive and aerospace sectors and the growth of the electronics industry in the region.

Recent Industry Developments:

- In June 2023, Arkema announced the acquisition of the leading Polyimide Film Manufacturer, PI Advanced Material (PIAM). PIAM is a company with unique technological positioning and advanced production facilities. This acquisition will allow Arkema to be at the forefront of high-performance materials in high-growth end markets supported by trends such as electric vehicles and advanced electronics.

Global Polyimide Monomer Market Key Players:

-

SABIC

-

Solvay S.A

-

Daken Chemical Limited

-

Mitsui Chemicals Inc.

-

Kaneka Corporation

Chapter 1. Polyimide Monomer Market – Scope & Methodology

1.1 Market Segmentation

1.2 Assumptions

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Polyimide Monomer Market – Executive Summary

2.1 Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.3 COVID-19 Impact Analysis

2.3.1 Impact during 2023 – 2030

2.3.2 Impact on Supply – Demand

Chapter 3. Polyimide Monomer Market – Competition Scenario

3.1 Market Share Analysis

3.2 Product Benchmarking

3.3 Competitive Strategy & Development Scenario

3.4 Competitive Pricing Analysis

3.5 Supplier - Distributor Analysis

Chapter 4. Polyimide Monomer Market - Entry Scenario

4.1 Case Studies – Start-up/Thriving Companies

4.2 Regulatory Scenario - By Region

4.3 Customer Analysis

4.4 Porter's Five Force Model

4.4.1 Bargaining Power of Suppliers

4.4.2 Bargaining Powers of Customers

4.4.3 Threat of New Entrants

4.4.4 .Rivalry among Existing Players

4.4.5 Threat of Substitutes

Chapter 5. Polyimide Monomer Market - Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Polyimide Monomer Market - By Product Type

6.1 Polyimide

6.2 Polyetherimide

6.3 Polyamideimides

6.4 Others

Chapter 7. Polyimide Monomer Market - By Material Type

7.1 Thermoplastic

7.2 Thermosetting

Chapter 8. Polyimide Monomer Market - By Application

8.1 Resins

8.2 Films

8.3 Fibers

8.4 Others

Chapter 9. Polyimide Monomer Market - By End-User

9.1 Electrical & Electronics

9.2 Aerospace & Defence

9.3 Healthcare

9.4 Transportation

9.5 Others

Chapter 10. Polyimide Monomer Market – By Region

10.1 North America

10.2 Europe

10.3 Asia-Pacific

10.4 Latin America

10.5 The Middle East

10.6 Africa

Chapter 11. Polyimide Monomer Market – Key Players

11.1 SABIC

11.2 Solvay S.A

11.3 Daken Chemical Limited

11.4 Mitsui Chemicals Inc.

11.5 Kaneka Corporation

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Polyimide Monomer Market was valued to be worth USD 3.45 Billion in 2022 and is projected to reach USD 6.29 Billion by the end of 2030, exhibiting a robust CAGR of 7.64% during the forecast period from 2023 to 2030.

Growing demand from the aerospace and automotive industries, increasing applications in electronics and semiconductors, and adoption in healthcare and medical sectors are the market drivers for the Global Polyimide Monomer Market.

Electrical & Electronics, Aerospace & Defence, Healthcare, and Others are the segments under the Global Polyimide Monomer Market by application.

North America and Europe dominate the Global Polyimide Monomer Market.

The Asia-Pacific region is the fastest-growing segment in the Global Polyimide Monomer Market.