Paper Pulp Drying System Market Size (2024 – 2030)

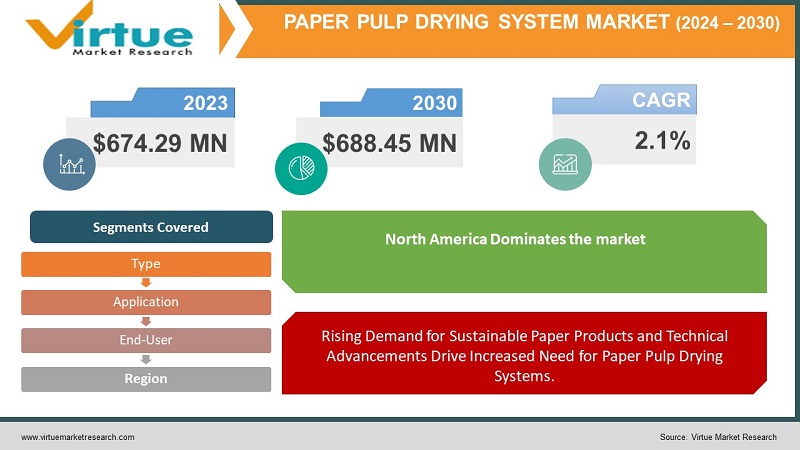

In 2022, the Global Paper Pulp Drying System Market was valued at USD 674.29 million and is projected to reach a market size of USD 688.45 million by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 2.1%.

Over time, paper pulp drying systems have evolved from being reliable but energy-intensive components of paper manufacturing to cutting-edge solutions prioritizing efficiency and sustainability. In the past, these systems played a crucial role in the industry, albeit with higher energy consumption and emissions. However, in response to growing global environmental concerns, they have undergone a remarkable transformation. Incorporating advanced technologies, they now substantially reduce energy usage and emissions, exemplifying the paper industry's commitment to eco-conscious practices. This ongoing evolution, driven by sustainability imperatives, positions paper pulp drying systems as leaders in the industry's sustainable journey, ensuring a future marked by heightened efficiency and environmental responsibility.

Key Market Insights:

In 2022, the demand for paper pulp drying systems witnessed a significant influence from the paper and pulp manufacturing industry, which held a dominant market share exceeding 60.0%. This strong presence was primarily driven by the increasing requirements within emerging economies like China, India, and Brazil. These economies had a growing demand for wood-based papers, particularly in various packaging applications.

This growth in the application segment was propelled by two key factors. First, there were notable technological advancements within the industry, which led to improved manufacturing processes and increased efficiency. Second, there was a growing awareness of environmental concerns. Consequently, there was a notable shift towards adopting eco-friendly products, with dryer laminates leading the way.

These dryer laminates were crafted from recycled materials, including corrugated cardboard and newspaper sheets, making them not only eco-conscious but also cost-effective. They gained widespread acceptance within the industry.

Additionally, the applications of paper pulp drying systems extended to the food packaging industry. Here, their exceptional moisture resistance properties were instrumental in enhancing food containers and manufacturing processes. This not only contributed to reduced carbon emissions but also played a pivotal role in advancing sustainable development initiatives.

Paper Pulp Drying System Market Drivers:

Rising Demand for Sustainable Paper Products and Technical Advancements Drive Increased Need for Paper Pulp Drying Systems.

The expansion of the packaging industry, the rise in e-commerce, and even the demand for recyclable packaging materials and paper goods. The demand for paper pulp drying systems has increased due to the need for them in the production of high-quality paper goods. The advent of new technologies, such as continuous drying systems, the use of superheated steam, and complex control algorithms, has made paper pulp drying more effective, quick, and sustainable. Even the market is expanding due to the increased use of these technologies.

Demand for energy-efficient paper pulp drying systems in the expanding pulp and paper industry is driven by government regulations and sustainability.

The government has introduced regulations that need to be adopted all over the world to reduce environmental pollution and promote sustainability. This has caused the adoption of more energy-efficient, eco-friendly paper pulp drying systems. The marketplace is growing as a result of manufacturers investing in these systems to comply with regulations. The demand for sustainable packaging materials, the development of e-commerce, and the growth of the packaging industry all contribute to the growth of the pulp and paper sector. As a result, manufacturers are looking to enhance the quantity and efficacy of their production processes which is going to drive up demand for paper pulp drying systems.

Paper Pulp Drying System Market Restraints and Challenges:

High Initial Investment requires a significant upfront investment posing a challenge for smaller paper mills.

Implementing advanced paper pulp drying systems demands a substantial upfront financial commitment, which can be particularly challenging for smaller paper mills with limited capital resources. These mills may face barriers to entry or expansion due to the considerable cost associated with acquiring and installing modern drying technology. Consequently, the adoption of energy-efficient and eco-friendly drying systems, although advantageous in the long run, may pose a formidable obstacle to smaller players in the paper industry striving to compete and remain sustainable in an increasingly eco-conscious market.

Maintenance and Operating Costs can be costly, impacting the economies of scale.

The ongoing operational expenses and maintenance requirements of paper pulp drying systems can be a significant financial burden for paper mills of all sizes. These systems necessitate regular upkeep and monitoring to ensure optimal performance and longevity. The costs associated with maintenance, repairs, energy consumption, and labor can erode profit margins and impact economies of scale. Efficient management and cost-effective maintenance strategies are essential for paper mills to mitigate the financial challenges posed by these ongoing expenditures while maintaining competitiveness in the market.

Paper Pulp Drying System Market Opportunities:

Global Shift to Eco-Friendly Practices provides an opportunity for manufacturers to develop and market eco-friendly drying solutions.

In the contemporary landscape, there is a prominent global shift towards eco-friendly practices and sustainability across various industries, including paper manufacturing. This shift presents a substantial opportunity for manufacturers operating in the paper pulp drying system market. Manufacturers can capitalize on this trend by innovating and offering eco-conscious drying solutions that reduce energy consumption and environmental impact. These solutions align with the increasing demand for sustainable and responsible production processes, making them not only environmentally friendly but also commercially viable in a market driven by green initiatives and conscious consumer preferences.

Customized Drying Solutions for different paper types can lead to rising demand for drying systems.

The paper industry encompasses a diverse range of paper types, each with distinct characteristics and requirements during the drying process. This diversity presents a promising opportunity for manufacturers of paper pulp drying systems. By developing and offering customized drying solutions tailored to the specific needs of different paper types, manufacturers can cater to a growing demand for efficient and specialized systems. These tailored solutions can optimize drying efficiency, enhance product quality, and reduce production costs, thereby gaining favor among paper mills seeking to streamline their processes and adapt to evolving market preferences. This opportunity underscores the significance of flexibility and adaptability in meeting the paper industry's diverse requirements.

PAPER PULP DRYING SYSTEM MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

2.1% |

|

Segments Covered |

By Type, Application, End-User, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Valmet Corporation, Andritz AG, Kadant Inc., Metso Corporation, Toscotec S.p.A, PMP Group Inc., Voith GmbH & Co. KGaA, AB Svenska Cellulosa Aktiebolaget (SCA), Mitsubishi Heavy Industries, Ltd., Runtech Systems Oy |

Paper Pulp Drying System Market Segmentation: By Type

-

Rotary Drying

-

Flash Drying

-

Ring-Type Drying

-

Others

In the year 2022, the Rotary Drying System established its dominance in the market for paper pulp drying systems capturing a market share of 25.12%. This system employs a rotating drum to effectively remove moisture from the pulp. The process involves introducing steam or hot air into the drum, where it interacts with the paper pulp. As this hot air comes into contact with the pulp, it causes the moisture within to evaporate. To separate the dried pulp from the remaining moisture, a cyclone separator is employed in this system. The paper pulp undergoes a series of steps within heated rings, each of which progressively reduces the moisture content. Ultimately, after this process, the dried pulp is collected and ready for further use.

Moreover, the Flash Drying category is the fastest-growing with a CAGR of 4.3% in the paper pulp drying system market. This growth is fueled by the need for rapid and efficient drying solutions in paper production. Flash drying systems excel in quickly removing moisture from pulp, reducing processing time, and increasing productivity. As paper manufacturers seek to streamline their operations and meet market demands for faster production, the adoption of flash drying systems is on the rise, driving the segment's rapid growth.

Paper Pulp Drying System Market Segmentation: By Application

-

Packaging Paper

-

Tissue Paper

-

Printing Paper

-

Others

In 2022, the Packaging Paper application holds the largest market share in the paper pulp drying system market. This dominance is primarily driven by the extensive use of packaging paper in various industries, including food, logistics, and e-commerce. The demand for efficient drying systems in the production of high-quality packaging materials is consistently high due to the importance of preserving product integrity during transportation and storage.

Moreover, The Tissue Paper segment is experiencing the fastest growth with a CAGR of 4.01% within the paper pulp drying system market. This rapid expansion can be attributed to the increasing demand for tissue paper products in personal hygiene and healthcare sectors worldwide. Efficient drying systems are critical to maintaining the softness, strength, and absorbency of tissue paper products, aligning with consumer expectations for quality and comfort. Additionally, the growing focus on hygiene and sanitation, especially in the wake of global health concerns, further propels the demand for tissue paper, driving the growth of this segment.

Paper Pulp Drying System Market Segmentation: By End-User

-

Pulp and Paper Industry

-

Packaging Industry

-

Printing and Writing Industry

-

Others

In 2022, the Pulp and Paper Industry stands as the segment with the largest market share in the paper pulp drying system market. This dominance is primarily due to the intrinsic need for efficient drying processes within the very core of paper production. The pulp and paper industry relies heavily on these drying systems to transform wet pulp into dry paper sheets, ensuring the quality and integrity of the final product. The long-established presence of this industry further solidifies its leading market share.

Moreover, the Packaging Industry emerges as the fastest-growing segment within the paper pulp drying system market. This accelerated growth can be attributed to the ever-expanding demand for eco-friendly packaging materials. As sustainability becomes a paramount concern, the packaging industry increasingly seeks advanced drying systems to produce high-quality, environmentally responsible packaging papers. Additionally, the surge in e-commerce and food delivery services has intensified the need for efficient packaging materials, further propelling the growth of this segment. The packaging industry's commitment to reducing its environmental footprint is a key driver of its rapid expansion in the paper pulp drying system market.

Paper Pulp Drying System Market Segmentation: By Region

-

North America

-

Europe

-

Asia-Pacific

-

South America

-

Middle East & Africa

In 2022, North America held the largest market share of 36.21% in the paper pulp drying system market. This dominance is attributed to the region's well-established pulp and paper industry, which continually demands efficient drying solutions to meet the growing market needs. Additionally, North America's focus on sustainability and technological advancements has spurred the adoption of eco-friendly and advanced drying systems, further strengthening its market position.

Moreover, the Asia-Pacific region has seen rapid growth, closely followed by Europe and Japan. This growth is driven by several factors, including the expanding pulp and paper industry in these regions, which demands efficient drying solutions. The increasing use of paper in packaging, driven by evolving consumer preferences, is also a significant contributor. Environmental consciousness plays a pivotal role, encouraging a shift toward eco-friendly paper products and fueling demand for advanced drying systems. Manufacturers in these regions are increasingly recognizing the importance of optimizing their paper production processes. This recognition is boosting the adoption of advanced technologies, such as customized drying systems like pocket ventilation, which streamline and enhance the drying process.

COVID-19 Impact Analysis on the Global Paper Pulp Drying System Market:

The expansion and the demand for hygiene products and even e-commerce sites have resulted in a surge in the demand for paper products, particularly tissue paper and packaging materials. This has resulted in an increasing demand that has fuelled the direct growth of the paper industry and has even increased the need for techniques for paper pulp drying. The pandemic has effects on the economy that have decreased consumer demand for specific paper goods, which has harmed the pulp and paper industry. The pandemic also caused production shutdowns and supply chain delays, which had an impact on raw material availability and delayed the installation of new paper pulp drying equipment.

Latest Trends/Developments:

In the dynamic paper pulp drying system market, several notable trends are shaping the industry. Firstly, advanced automation is taking center stage, with the integration of sophisticated control systems and sensors. These technologies enable real-time monitoring, data analysis, and predictive maintenance, ultimately enhancing system efficiency and minimizing downtime.

Secondly, sustainability remains a key driver, prompting innovations in energy-efficient drying systems. Manufacturers are increasingly focused on reducing energy consumption while maintaining drying quality. Heat recovery technologies and energy-efficient components are gaining prominence as the industry strives to minimize its environmental footprint. Moreover, customization, the adoption of eco-friendly materials, and the integration of digital twin technology are further enriching the evolving landscape of paper pulp drying systems, ensuring they remain at the forefront of efficiency, sustainability, and innovation. For instance, in 2021, The Valmet Fiberline Analyzer was introduced to test the pulp's quality in real time. This method can improve the drying process, boosting the efficiency and standard of paper pulp drying systems.

Key Players:

-

Valmet Corporation

-

Andritz AG

-

Kadant Inc.

-

Metso Corporation

-

Toscotec S.p.A

-

PMP Group Inc.

-

Voith GmbH & Co. KGaA

-

AB Svenska Cellulosa Aktiebolaget (SCA)

-

Mitsubishi Heavy Industries, Ltd.

-

Runtech Systems Oy

In August 2023, Valmet developed an energy-efficient and flexible Fiber Flash Dryer system, driven by the growing demand for CTMP (Chemical Thermomechanical Pulp) lines. This system can adapt to various processes and pulp qualities, including recycled fiber. It boasts a total energy efficiency of over 91%. The dryer utilizes different heat sources, such as steam/air heat exchangers or gas burners, depending on site conditions. The Valmet Fiber Flash Dryer ensures easy operation, high capacity, and minimal maintenance, making it an ideal solution for pulp mills seeking reliable and cost-effective drying technology.

In February 2022, Kadant announced that it had acquired Joh. Clouth is a well-known German manufacturer of equipment for the pulp and paper industry. With this acquisition, Kadant will have a wider range of products for the pulp and paper sector, including drying systems for paper pulp.

Chapter 1. Paper Pulp Drying System Market– Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Paper Pulp Drying System Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Paper Pulp Drying System Market– Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Paper Pulp Drying System MarketEntry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Paper Pulp Drying System Market- Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Paper Pulp Drying System Market– By Type

6.1 Introduction/Key Findings

6.2 Rotary Drying

6.3 Flash Drying

6.4 Ring-Type Drying

6.5 Others

6.6 Y-O-Y Growth trend Analysis By Type

6.7 Absolute $ Opportunity Analysis By Type, 2024-2030

Chapter 7. Paper Pulp Drying System Market– By Application

7.1 Introduction/Key Findings

7.2 Packaging Paper

7.3 Tissue Paper

7.4 Printing Paper

7.5 Others

7.6 Y-O-Y Growth trend Analysis By Application

7.7 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. Paper Pulp Drying System Market- By End-User

8.1 Introduction/Key Findings

8.2 Pulp and Paper Industry

8.3 Packaging Industry

8.4 Printing and Writing Industry

8.5 Others

8.6 Y-O-Y Growth trend Analysis By End-User

8.7 Absolute $ Opportunity Analysis By End-User, 2024-2030

Chapter 9. Paper Pulp Drying System Market , By Geography – Market Size, Forecast, Trends & Insights

9.1 North America

9.1.1 By Country

9.1.1.1 U.S.A.

9.1.1.2 Canada

9.1.1.3 Mexico

9.2 By By Type

9.3 By Application

9.4 By End-User

9.5 Countries & Segments - Market Attractiveness Analysis

9.6 Europe

9.6.1 By Country

9.6.1.1 U.K.

9.6.1.2 Germany

9.6.1.3 France

9.6.1.4 Italy

9.6.1.5 Spain

9.6.1.6 Rest of Europe

9.7 By Type

9.8 By Application

9.9 By End-User

9.10 Countries & Segments - Market Attractiveness Analysis

9.11 Asia Pacific

9.11.1 By Country

9.11.1.1 China

9.11.1.2 Japan

9.11.1.3 South Korea

9.11.1.4 India

9.11.1.5 Australia & New Zealand

9.11.1.6 Rest of Asia-Pacific

9.12 By Type

9.13 By Application

9.14 By End-User

9.15 Countries & Segments - Market Attractiveness Analysis

9.16 South America

9.16.1 By Country

9.16.1.1 Brazil

9.16.1.2 Argentina

9.16.1.3 Colombia

9.16.1.4 Chile

9.16.1.5 Rest of South America

9.17 By Type

9.18 By Application

9.19 By End-User

9.20 Countries & Segments - Market Attractiveness Analysis

9.21 Middle East & Africa

9.21.1 By Country

9.21.1.1 United Arab Emirates

9.21.1.2 Saudi Arabia

9.21.1.3 Qatar

9.21.1.4 Israel

9.21.1.5 South Africa

9.21.1.6 Nigeria

9.21.1.7 Kenya

9.21.1.8 Egypt

9.21.1.9 Rest of MEA

9.22 By Type

9.23 By Application

9.24 By End-User

9.25 Countries & Segments - Market Attractiveness Analysis

Chapter 10. Paper Pulp Drying System Market– Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

10.1 Valmet Corporation

10.2 Andritz AG

10.3 Kadant Inc.

10.4 Metso Corporation

10.5 Toscotec S.p.A

10.6 PMP Group Inc.

10.7 Voith GmbH & Co. KGaA

10.8 AB Svenska Cellulosa Aktiebolaget (SCA)

10.9 Mitsubishi Heavy Industries, Ltd.

10.10 Runtech Systems Oy

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

Global Paper Pulp Drying System Market was valued at USD 674.29 million and is projected to reach a market size of USD 688.45 million by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 2.1%.

Packaging Paper, Tissue Paper, Printing Paper, and Others are the segments under the Global Paper Pulp Drying System Market by Application.

North America held the largest market share of 36.21% in the paper pulp drying system market. This dominance is attributed to the region's well-established pulp and paper industry.

The Asia-Pacific region has seen rapid growth, closely followed by Europe and Japan. This growth is driven by several factors, including the expanding pulp and paper industry in these regions, which demands efficient drying solutions.

Valmet Corporation, Andritz AG, Kadant Inc., Metso Corporation, Toscotec S.p.A, PMP Group Inc., and Voith GmbH & Co. KGaA are some of the Key Players.