Nylon-Based Nanofiber Market Size (2024-2030)

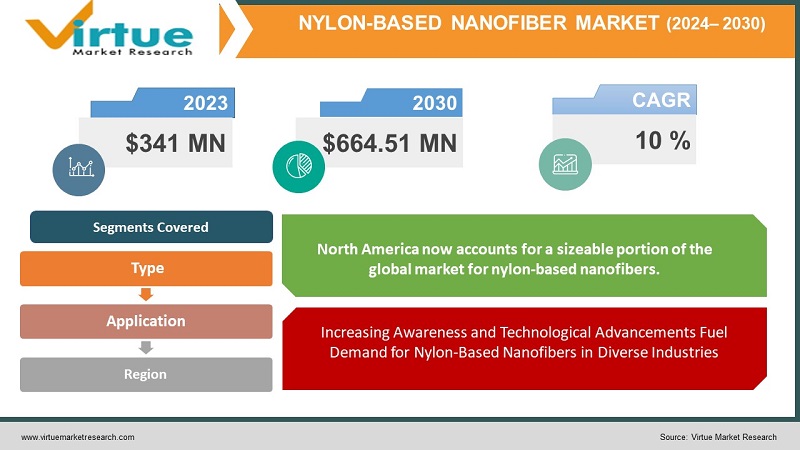

In 2023, the Nylon-Based Nanofiber Market was valued at $341 Million and is projected to reach a market size of $664.51 Million by 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 10%.

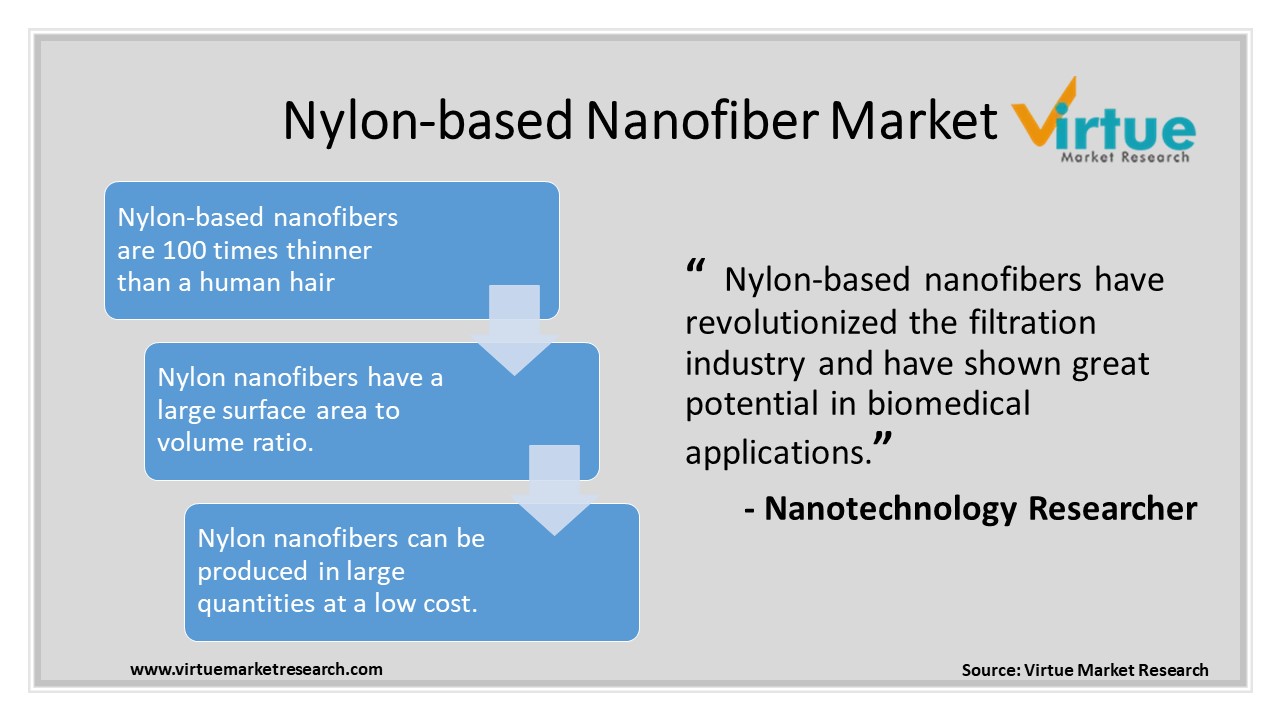

The market for nanofibers is largely made of nylon or polyamide materials and is referred to as the Nylon-Based Nanofiber Market. Ultrafine fibers known as nanofibers generally have sizes between 1 and 100 nanometres. These nanofibers have special qualities and may be used in filtration, healthcare, textiles, electronics, energy, and many other fields. Several technologies, including electrospinning, melt-blowing, or other polymer processing techniques, are used to create nylon-based nanofibers. The basis material for the creation of nanofibers is frequently nylon polymers, which are renowned for their excellent strength, durability, and chemical resistance. The diameter, shape, and surface characteristics of the nanofibers may be adjusted to suit particular applications by adjusting the process parameters and composition. The growing demand for sophisticated materials with improved performance characteristics has led to a major increase in the market for nanofibers made of nylon on a worldwide scale. High surface area-to-volume ratio, good mechanical qualities, higher filtering effectiveness, and the possibility for functionalization are just a few benefits of nylon nanofibers. They are used in a variety of applications, including sensors, energy storage devices, protective garments, wound dressings, tissue engineering scaffolds, and air and liquid filtration.

Due to their exceptional qualities, including large surface area, porosity, and flexibility, nanofibers are becoming more and more in demand across a range of end-use sectors, including healthcare, energy, textiles, and electronics. Further propelling the market's expansion is the COVID-19 pandemic, which has increased demand for nylon-based nanofibers used to make face masks, air filters, and other personal protective equipment (PPE) items.

Global Nylon-Based Nanofiber Market Drivers:

Increasing Awareness and Technological Advancements Fuel Demand for Nylon-Based Nanofibers in Diverse Industries:

- Due to their high surface area to volume ratio and small fiber diameter, nylon-based nanofibers provide outstanding filtering performance. In sectors including healthcare, automotive, electronics, and air and water purification, there is an increasing need for sophisticated filtering technologies. Nylon nanofibers are used in filters to improve the efficiency with which tiny particles, germs, viruses, and other pollutants are captured, which promotes market expansion. Industries are starting to take notice of the advantages of nanofibers, which include their high strength, durability, chemical resistance, and distinctive surface features. The demand for nylon-based nanofibers in several applications, including textiles, composites, energy storage, sensors, and medicinal goods, is rising as knowledge of the advantages of nanofibers rises. It is now simpler to make nylon-based nanofibers in large quantities and with better control over their characteristics because of improvements in nanofiber production processes including electrospinning and melt blowing. These developments have increased market growth by lowering production costs, enhancing scalability, and broadening the possible applications.

Versatile Materials Driving Innovations in Aerospace, Automotive, and Sports Industries Fuelling market growth:

Nanofibers made of nylon have drawn a lot of interest from the biological and healthcare industries. They are utilized in applications including tissue engineering scaffolds, medication delivery mechanisms, and diagnostic tools for wounds. The need for nylon-based nanofibers in various fields is being fuelled by the increased emphasis on personalized medicine, regenerative medicine, and improved healthcare outcomes. Nanofibers made of nylon have exceptional mechanical qualities, including high strength, flexibility, and low weight. Due to the increasing need for lightweight materials with improved performance and durability, these characteristics make them suitable for use in the sports, automotive, and aerospace sectors.

Global Nylon-Based Nanofiber Market Challenges:

Nanofibers made of nylon require sophisticated manufacturing techniques and specific tools to produce. These elements raise the cost of manufacture, which prevents the widespread use of nanofibers made of nylon in several fields and applications. It can be difficult to scale up the manufacture of nanofibers made of nylon to suit commercial demand. For a market to expand, it is imperative to achieve consistent quality and quantity in large-scale production. However, doing so can be technically challenging and expensive in terms of infrastructure and manufacturing capacities. Nylon-based nanofibers must adhere to strict regulatory requirements to be used in healthcare and biological applications. It may be time-consuming and expensive to meet regulatory criteria for safety, efficacy, and quality, which makes it difficult to enter new markets and grow existing ones. The development of the market for nylon-based nanofibers may be hampered by the absence of standardized production procedures, material requirements, and characterization techniques. To guarantee product quality, interoperability, and comparability across many manufacturers and applications, standardization is essential.

Global Nylon-Based Nanofiber Market Opportunities:

Nanofibers made of nylon have huge development potential in the biological and healthcare industries. Advanced wound dressings, tissue engineering scaffolds, medication delivery systems, and diagnostic tools might all be developed. Opportunities for nylon-based nanofibers to contribute to creative solutions are presented by the growing emphasis on personalized treatment, regenerative medicine, and better healthcare outcomes. In sectors including air purification, water treatment, and industrial processes, there is a growing need for high-performance filtering solutions. With their better filtering effectiveness, nylon-based nanofibers can be quite helpful in satisfying these requirements. Opportunities exist to create and market high-tech filtration goods made of nanofibers derived from nylon, satisfying the expanding need for better liquid and air filtration. Lightweight materials that offer improved performance and fuel economy are widely sought after by the aerospace and automotive sectors. With their superior mechanical qualities and lightweight attributes, nylon-based nanofibers may be used in filtration systems, insulating materials, and structural components. Opportunities exist to work with key players in the sector to create cutting-edge solutions that satisfy particular requirements.

COVID-19 Impact on Global Nylon-Based Nanofiber Market:

During the pandemic, the need for efficient PPE, such as face masks, gloves, and protective apparel, increased. Nanofibers made of nylon were used to create high-performance filtration layers in masks, increasing the effectiveness of their filtration. The market grew as a result of the rising usage of nanofiber technologies based on nylon and the rise in PPE demand.

During the pandemic, the value of air filtration and quality in reducing the transmission of airborne infections became clear. To enhance indoor air quality and lessen the spread of infections, nylon-based nanofibers were used in HVAC filters and air filtration systems due to their high filtering efficiency. The market for nanofibers made of nylon has benefited from the greater awareness of the problems associated with airborne transmission. The COVID-19 epidemic sparked an increase in the study and use of nanofibers. The creation of nanofiber-based diagnostic tools for quick testing as well as antiviral and antibacterial coatings received a lot of attention. These programs attempted to solve the difficulties brought on by the pandemic and promoted the use of nanofibers based on nylon in the biological and healthcare fields.

Global Nylon-Based Nanofiber Market Recent Developments:

- In July 2022, IntexarTM Heat, a novel nylon-based nanofiber technology from DuPont de Nemours, Inc., is intended to provide warmth and comfort in clothes and textiles. The technology is supposed to be breathable, flexible, and lightweight, making it ideal for usage in outdoor clothing and sportswear.

- In March 2022, a novel nanofiber-based material was created by scientists at North Carolina State University that is capable of efficiently removing hazardous airborne particles, such as virus-carrying aerosols. The fabric is believed to have a high level of filtration effectiveness and breathability and is comprised of a mixture of nylon and chitosan, a biopolymer produced from shellfish.

- In June 2021, a Texas-based firm called SNS Nano Fiber Technology LLC announced the creation of a new range of air and liquid filtration solutions using nylon-based nanofibers. The goods are reportedly appropriate for usage in a variety of sectors due to their high filtering effectiveness, minimal pressure drop, and extended service life.

NYLON-BASED NANOFIBER MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

10% |

|

Segments Covered |

By Type, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

DuPont de Nemours, Inc., Donaldson Company, Inc., FibeRio® Technology Corporation, eSpin Technologies, Inc., SNS Nano Fiber Technology LLC, Revolution Fibres Ltd., Nanofiber Solutions, Bioinicia S.L., Argonide Corporation, Ahlstrom-Munksjö |

Global Nylon-Based Nanofiber Market Segmentation:

Global Nylon-Based Nanofiber Market Segmentation: By Type

- Electrospun Nanofibers

- Melt-Blown Nanofibers

- Composite Nanofibers

- Core-Shell Nanofibers

The process of electrospinning is frequently employed to create nanofibers. Electrostatic forces drive a technique that produces nylon-based electrospun nanofibers with dimensions in the nanometer range. These nanofibers can be employed in filtration, tissue engineering, sensors, and electronics because of their high surface area-to-volume ratio. Nylon polymers are melted and extruded in a technique known as melt-blowing to create ultrafine fibers. Then, a collection of these fibers is made to create melt-blown nanofiber mats. Nanofibers made from melt-blown nylon are frequently utilized in air and liquid filtration because they have excellent filtering properties. Nanofibers made of nylon are combined with other substances, such as polymers, ceramics, or carbon, to create composite nanofibers.

The addition of other materials to nylon increases the nanofibers' functions and characteristics and broadens the range of possible uses for them. Composite nanofibers are used in fields including biomedical engineering, electronics, and energy storage. Core-Shell Nanofibers: Core-shell nanofibers are made up of a shell layer made of nylon and a core substance. The nanofiber's core-shell structure enables the inclusion of various materials, providing customized characteristics and capabilities. These nanofibers have uses in the administration of drugs, tissue engineering, and catalysis.

Global Nylon-Based Nanofiber Market Segmentation: By Application

- Filtration

- Healthcare and Biomedical

- Textiles and Apparel

- Electronics and Energy Storage

- Aerospace and Automotive

In filtration applications, such as air, water, and industrial process filtration, nylon-based nanofibers are widely employed. Their large surface area to volume ratio and small fiber diameter enable effective particle, pollutant, and microbe removal. Nanofibers made of nylon have several uses in the biomedical and healthcare industries. They are used as bandages, scaffolds for tissue engineering, medication delivery systems, and diagnostic tools. Their special qualities allow for regulated medication release, better wound healing, and increased biocompatibility.

To improve the performance and usefulness of textiles and clothing, nylon-based nanofibers are used in these materials. They may be utilized to make textiles that are more breathable, better at controlling moisture, and more antibacterial. Sportswear, outdoor clothes, and protective gear are among the industries where nanofiber-based textiles are used. Electronic equipment and energy storage systems use nanofibers made of nylon. They can be employed as parts in wearable technology, flexible electronics, sensors, and energy storage systems. These materials are ideal for boosting the performance of these applications due to their high mechanical strength and lightweight design.

Global Nylon-Based Nanofiber Market Segmentation: By Region

- North America

- Europe

- Asia Pacific

- Middle East and Africa

- Latin America

Due to the presence of prominent market players, technical breakthroughs, and expanding applications across many sectors like healthcare, filtration, and electronics, North America now accounts for a sizeable portion of the global market for nylon-based nanofibers. Another important location in the market for nanofibers made of nylon is Europe. The adoption of nylon-based nanofibers in the filtration, textile, and automotive sectors has been facilitated by the region's strong emphasis on sustainability and environmental applications. The market for nylon-based nanofibers is expanding quickly in the Asia Pacific area. The presence of a sizable industrial base increased R&D spending, and expanding demand for innovative materials in the electronics, healthcare, and automotive industries are some of the factors propelling market expansion. The nylon-based nanofiber market in Latin America has significant potential. There are prospects for the adoption of nylon-based nanofibers due to the region's rising healthcare industry, increased knowledge of the advantages of nanofibers, and growing emphasis on improving air and water quality.

Global Nylon-Based Nanofiber Market Key Players:

- DuPont de Nemours, Inc.

- Donaldson Company, Inc.

- FibeRio® Technology Corporation

- eSpin Technologies, Inc.

- SNS Nano Fiber Technology LLC

- Revolution Fibres Ltd.

- Nanofiber Solutions

- Bioinicia S.L.

- Argonide Corporation

- Ahlstrom-Munksjö

Chapter 1. NYLON-BASED NANOFIBER MARKET – Scope & Methodology

1.1. Market Segmentation

1.2. Assumptions

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. NYLON-BASED NANOFIBER MARKET – Executive Summary

2.1. Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.3. COVID-19 Impact Analysis

2.3.1. Impact during 2024 – 2030

2.3.2. Impact on Supply – Demand

Chapter 3. NYLON-BASED NANOFIBER MARKET – Competition Scenario

3.1. Market Share Analysis

3.2. Product Benchmarking

3.3. Competitive Strategy & Development Scenario

3.4. Competitive Pricing Analysis

3.5. Supplier - Distributor Analysis

Chapter 4. NYLON-BASED NANOFIBER MARKET - Entry Scenario

4.1. Case Studies – Start-up/Thriving Companies

4.2. Regulatory Scenario - By Region

4.3 Customer Analysis

4.4. Porter's Five Force Model

4.4.1. Bargaining Power of Suppliers

4.4.2. Bargaining Powers of Customers

4.4.3. Threat of New Entrants

4.4.4. Rivalry among Existing Players

4.4.5. Threat of Substitutes

Chapter 5. NYLON-BASED NANOFIBER MARKET - Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. NYLON-BASED NANOFIBER MARKET – By Type

6.1. Electrospun Nanofibers

6.2. Melt-Blown Nanofibers

6.3. Composite Nanofibers

6.4. Core-Shell Nanofibers

Chapter 7. NYLON-BASED NANOFIBER MARKET – By Application

7.1. Filtration

7.2. Healthcare and Biomedical

7.3. Textiles and Apparel

7.4. Electronics and Energy Storage

7.5. Aerospace and Automotive

Chapter 8. NYLON-BASED NANOFIBER MARKET – By Region

8.1. North America

8.2. Europe

8.3.The Asia Pacific

8.4.Latin America

8.5. Middle-East and Africa

Chapter 9. NYLON-BASED NANOFIBER MARKET – Company Profiles – (Overview, Product Portfolio, Financials, Developments)

9.1. DuPont de Nemours, Inc.

9.2. Donaldson Company, Inc.

9.3. FibeRio® Technology Corporation

9.4. eSpin Technologies, Inc.

9.5. SNS Nano Fiber Technology LLC

9.6. Revolution Fibres Ltd.

9.7. Nanofiber Solutions

9.8. Bioinicia S.L.

9.9. Argonide Corporation

9.10. Ahlstrom-Munksjö

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

In 2023, the Nylon-Based Nanofiber Market was valued at $341 Million and is projected to reach a market size of $664.51 Million by 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 10%.

The Global Nylon-Based Nanofiber Market is driven by Growing Demand in Healthcare and Biomedical Applications, Rising Need for Advanced Filtration Solutions, Lightweight Materials in Aerospace and Automotive Industries, and Advancements in Electronics and Energy Storage.

The Segments under the Global Nylon-Based Nanofiber Market by the application are Filtration, Healthcare and Biomedical, Textiles and Apparel, Electronics and Energy Storage, Aerospace and Automotive.

China, Japan, South Korea, Singapore, and India are the most dominating countries in the Asia Pacific region for the Global Nylon-Based Nanofiber Market.

DuPont de Nemours, Inc., Donaldson Company, Inc., and eSpin Technologies, Inc. are the three major leading players in the Global Nylon-Based Nanofiber Market.