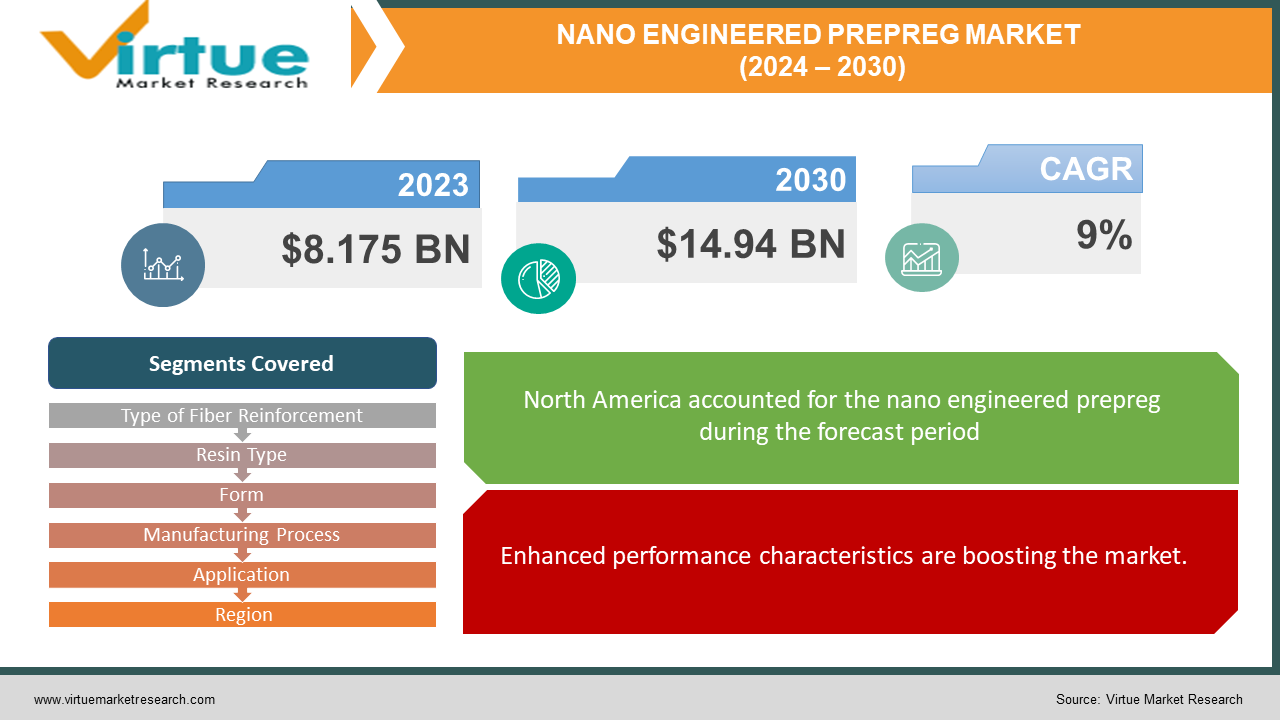

Nano Engineered Prepreg Market Size (2024 – 2030)

With a market valuation of USD 8.175 billion in 2023, the nanoengineered prepreg market is expected to develop at a strong rate throughout the forecast period, with a compound annual growth rate (CAGR) of 9% from 2024 to 2030, reaching a valuation of USD 14.94 billion by the end of 2030.

Advanced composite materials known as nano-engineered prepregs include nanoscale reinforcements incorporated into a resin matrix to provide better mechanical and lightweight qualities. These materials' improved strength-to-weight ratio, thermal stability, and corrosion resistance allow them to find widespread use in a variety of industries, including electronics, wind energy, automotive, aerospace, and sporting goods. The market is being propelled by the growing need across many end-use industries for lightweight and high-performance materials, as well as developments in manufacturing techniques and nanotechnology. Furthermore, strict laws encouraging sustainability, fuel economy, and environmental preservation are driving up market expansion. As a result of ongoing expenditures in R&D and growing applications, the market is developing.

Key Market Insights:

The market for nanoengineered prepreg is expected to increase significantly because of rising demand from a variety of sectors, including sports, automotive, electronics, and aerospace. The better strength, lightweight nature, and increased mechanical and thermal performance of prepreg materials with nanoengineered features are the reasons for this growth. Research and development efforts are booming in the industry to create new materials and production techniques that will drive even more market growth. Additionally, new prepreg compositions with specialized features to fulfill industry requirements are being developed due to breakthroughs in nanotechnology. Intense competition among major competitors in the industry often drives strategic alliances, mergers, and acquisitions as a means of bolstering market share and diversifying product offerings. The adoption of eco-friendly materials is being pushed by strict regulations and rising investments in sustainable solutions; therefore, the nano-engineered prepreg market is anticipated to rise steadily over the coming years.

Nanoengineered Prepreg Market Drivers:

Enhanced performance characteristics are boosting the market.

In comparison to conventional materials, nano-engineered prepreg materials have better performance qualities, such as greater strength, durability, and lightweight qualities. They are very sought-after in a variety of industries, including electronics, automotive, and aerospace, because of these improved qualities.

One of the factors propelling the market is technological advancement.

Continuous developments in nanotechnology have resulted in the creation of novel prepreg compositions with specialized qualities to satisfy particular industry demands. Nano-engineered prepreg materials are becoming more and more popular in a variety of applications due to these technological breakthroughs.

The increasing need for lightweight materials is facilitating the expansion.

In sectors like aerospace and automotive, there is a growing need for lightweight materials due to the increased focus on environmental sustainability and fuel efficiency. For use in these industries, nano-engineered prepreg materials provide a lightweight substitute for conventional materials without sacrificing performance.

Growing research and development expenditures are one of the main market drivers.

Research and development efforts are becoming more and more funded to create novel nano-engineered prepreg materials and manufacturing techniques. Growth in the market is being driven by these investments, which are fostering the development of innovative materials with better performance and features.

Nano-Engineered Prepreg Market Restraints and Challenges:

Although the nanoengineered prepreg market has bright prospects, there are several obstacles and difficulties to overcome. The high manufacturing costs of nano-engineered materials, which include costs for R&D and specialized production techniques, present one major obstacle. Further impeding market expansion are worries about the mass production and scalability of nano-engineered prepreg materials. In addition, the market landscape becomes more complex due to regulatory obstacles and standard compliance requirements, which might influence market growth. Furthermore, market penetration and acceptance rates may be hampered by producers' and end users' inadequate knowledge of and comprehension of nano-engineered materials.

Nano-engineered Prepreg Market Opportunities:

The nanoengineered prepreg market offers numerous prospects for growth and advancement, despite the obstacles. The growing need for high-performance, lightweight materials in a variety of sectors, such as sports, automotive, electronics, and aerospace, represents significant potential. Prepreg materials that have been nanoengineered have special qualities like increased durability and strength-to-weight ratio, which makes them ideal for certain uses. Furthermore, continuing developments in material science and nanotechnology offer chances for new product development and innovation, which propels the release of enhanced and novel nano-engineered prepreg formulations. Additionally, it is anticipated that the increased emphasis on environmental preservation and sustainability will increase demand for eco-friendly materials. This will present a chance for industry participants to create environmentally friendly prepreg solutions that are both consumer- and regulatory-satisfied and sustainable, due to nano-engineered materials. Furthermore, market expansion and improved product offerings can be achieved through strategic alliances and collaborations between major industry players, which will further propel market growth in the next few years.

NANO ENGINEERED PREPREG MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

9% |

|

Segments Covered |

By Type of Fiber Reinforcement, Resin Type, Form, Manufacturing Process, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Mitsubishi Chemical Group Corporation, Park Aerospace Corp., Solvay Group, Gurit Holding AG, Teijin Limited, Plastic Reinforcement Fabrics Ltd., Hexcel Corporation, SGL Group, Toray Industries, Inc., Axiom Materials |

Nano-engineered Prepreg Market Segmentation: By Type of Fiber Reinforcement

-

Carbon Fiber Prepreg

-

Glass Fiber Prepreg

-

Others (aramid fiber, natural fibers, etc.)

The carbon fiber prepreg is the largest and fastest-growing category among the several subsegments. Carbon fiber prepreg is widely sought after in the sporting goods, automotive, and aerospace industries due to its remarkable strength-to-weight ratio, high stiffness, and corrosion resistance. It is anticipated that these industries' growing need for lightweight materials to enhance performance and fuel economy will propel the carbon fiber prepreg market's expansion.

Nano-engineered Prepreg Market segmentation: By Resin Type

-

Thermoset Prepreg

-

Thermoplastic Prepreg

Thermoset prepreg is the largest growing segment. In the past, thermoset prepregs have been more extensively utilized and well-established in a variety of industries, including wind energy, automotive, and aerospace. Because of their superior mechanical qualities, resistance to heat and chemicals, and dimensional stability, they are appropriate for demanding applications requiring high-performance materials. The thermoplastic prepreg category is the one with the fastest growth. Compared to thermoset prepregs, thermoplastic prepregs provide better durability, faster processing times, and the capacity to be recycled. Because of these qualities, they are becoming more and more common in sectors including electronics production, aerospace, and the automobile industry. The demand for strong, long-lasting, and eco-friendly materials in applications that call for thermoplastic prepregs is anticipated to fuel the expansion of this market niche within the nanoengineered prepreg industry.

Nano-engineered Prepreg Market segmentation: By Form

-

Tow Prepreg

-

Fabric Prepreg

The fabric prepreg category has the largest market share among these subsegments. Fabric prepreg uses resin-impregnated woven or non-woven fabrics as a form of fiber reinforcement. It is a versatile material that can be used in a wide range of applications and shapes. This makes it ideal for intricate geometries and large-scale manufacturing in sectors including wind energy, automotive, and aerospace. Tow prepreg is the fastest-growing segment, made up of continuous, resin-impregnated fiber strands that are usually wound onto a spool. Fabric prepregs are recommended for challenging applications where strength, stiffness, and durability are crucial because they can be tailored with variable weave patterns, fiber orientations, and weights to match specific performance requirements.

Nano-engineered Prepreg Market Segmentation: By Manufacturing Process

-

Hot-Melt Process

-

Solvent Dip Process

The category with the largest and fastest rate of growth among the many manufacturing processes is the hot-melt process. To provide superior resin impregnation and adherence, this process entails heating the resin matrix to a molten condition before impregnating the reinforcing fibers. Because the hot-melt process has advantages like shorter cycle times, lower energy usage, and better process control, it is becoming more and more popular in sectors where efficiency and quality are crucial, such as wind energy, aerospace, and the automobile industry.

Nano-engineered Prepreg Market Segmentation: By Application

-

Aerospace & Defense

-

Wind Energy

-

Automotive

-

Sporting Goods

-

Electronics (PCB)

-

Others (marine, construction, medical, etc.)

Among these, the most dominant sector with the largest market share is the aerospace & defense industry. Prepreg materials offer exceptional strength-to-weight ratio and durability, making them ideal for aerospace applications such as aircraft components, satellites, and UAVs. The defense sector also relies heavily on prepreg materials for manufacturing lightweight and high-performance equipment. With the increasing demand for advanced materials in aerospace and defense applications, driven by technological advancements and the need for improved performance, the aerospace and defense segment is expected to witness significant growth in the nano-engineered prepreg market. Wind energy is the fastest-growing end-user. Prepreg materials are suited for the harsh circumstances seen in wind turbine blades because of their remarkable strength, rigidity, and durability, which are reinforced with sophisticated fibers like carbon or glass. These prepreg materials allow for the creation of strong, lightweight blades that maximize energy collection efficiency and can endure strong winds and turbulent situations.

Nano-engineered Prepreg Market Segmentation: Regional Analysis

-

North America

-

Europe

-

Asia-Pacific

-

South America

-

Middle East and Africa

Among these regions, the largest region is North America. The United States, in particular, is one of the biggest markets for nano-engineered prepregs because of its strong position in important industries including wind energy, automotive, and aerospace. The region's strong supply chain infrastructure, technological know-how, and sophisticated manufacturing skills all contribute to its global dominance. Prepreg materials are also widely utilized in North America's sizable aerospace and defense industry, which produces aircraft parts and structures. The Asia-Pacific region is witnessing the fastest growth in industries such as aerospace, automotive, wind energy, and electronics, all of which are significant consumers of nano-engineered prepreg materials. Factors such as increasing industrialization, rising investments in infrastructure development, and a shift towards lightweight and high-performance materials are driving the demand for prepreg materials in the region. Additionally, favorable government policies and initiatives to promote renewable energy sources and technological advancements further contribute to the growth of the nano-engineered prepreg market in the Asia-Pacific region.

COVID-19 Impact Analysis on the Nano-Engineered Prepreg Market:

The market for nanoengineered prepreg has been severely disrupted by the COVID-19 pandemic, leading to lower consumer demand and bottlenecks in the supply chain. The implementation of lockdown measures and travel restrictions aimed at mitigating the virus's spread has caused hindrances to production activities and disruptions to global trade, thereby affecting the supply of raw materials and components essential for the fabrication of prepreg. As a result, sectors that use prepreg materials extensively, like wind energy, aerospace, and automobiles, had a downturn in business, which lowered demand for these goods. Nonetheless, the market is anticipated to rebound as immunization campaigns advance and economic activity progressively picks back up. This will be fueled by pent-up demand, the restart of projects that have been put on hold, and rising infrastructure development expenditures.

Latest Trends/ Developments:

The COVID-19 pandemic has presented obstacles, but the nanoengineered prepreg market has seen some notable trends and advancements. The growing focus on technological innovations in prefab manufacturing processes to improve product performance and efficiency is one such development. To fulfill the changing needs of end-use industries, manufacturers are investing in research and development operations to create new formulations, enhance curing procedures, and optimize material qualities. Furthermore, there is a growing trend of strategic alliances and partnerships amongst major firms to utilize complementary skills to broaden their market reach and quicken their pace of product development. These patterns demonstrate the industry's ability to bounce back from difficult circumstances and reposition itself for long-term success in the wake of the pandemic.

Key Players:

-

Mitsubishi Chemical Group Corporation

-

Park Aerospace Corp.

-

Solvay Group

-

Gurit Holding AG

-

Teijin Limited

-

Plastic Reinforcement Fabrics Ltd.

-

Hexcel Corporation

-

SGL Group

-

Toray Industries, Inc.

-

Axiom Materials

Chapter 1. Nano Engineered Prepreg Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Nano Engineered Prepreg Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Nano Engineered Prepreg Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Nano Engineered Prepreg Market Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Nano Engineered Prepreg Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Nano Engineered Prepreg Market – By Type of Fiber Reinforcement

6.1 Introduction/Key Findings

6.2 Carbon Fiber Prepreg

6.3 Glass Fiber Prepreg

6.4 Others (aramid fiber, natural fibers, etc.)

6.5 Y-O-Y Growth trend Analysis By Type of Fiber Reinforcement

6.6 Absolute $ Opportunity Analysis By Type of Fiber Reinforcement, 2024-2030

Chapter 7. Nano Engineered Prepreg Market – By Application

7.1 Introduction/Key Findings

7.2 Aerospace & Defense

7.3 Wind Energy

7.4 Automotive

7.5 Sporting Goods

7.6 Electronics (PCB)

7.7 Others (marine, construction, medical, etc.)

7.8 Y-O-Y Growth trend Analysis By Application

7.9 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. Nano Engineered Prepreg Market – By Resin Type

8.1 Introduction/Key Findings

8.2 Thermoset Prepreg

8.3 Thermoplastic Prepreg

8.4 Y-O-Y Growth trend Analysis By Resin Type

8.5 Absolute $ Opportunity Analysis By Resin Type, 2024-2030

Chapter 9. Nano Engineered Prepreg Market – By Form

9.1 Introduction/Key Findings

9.2 Tow Prepreg

9.3 Fabric Prepreg

9.4 Y-O-Y Growth trend Analysis End-User

9.5 Absolute $ Opportunity Analysis End-User, 2024-2030

Chapter 10. Nano Engineered Prepreg Market – By Manufacturing Process

10.1 Introduction/Key Findings

10.2 Hot-Melt Process

10.3 Solvent Dip Process

10.4 Y-O-Y Growth trend Analysis By Manufacturing Process

10.5 Absolute $ Opportunity Analysis By Manufacturing Process, 2024-2030

Chapter 11. Nano Engineered Prepreg Market, By Geography – Market Size, Forecast, Trends & Insights

11.1 North America

11.1.1 By Country

11.1.1.1 U.S.A.

11.1.1.2 Canada

11.1.1.3 Mexico

11.1.2 By Type of Fiber Reinforcement

11.1.2.1 By Application

11.1.3 By Resin Type

11.1.4 By Texture

11.1.5 By Manufacturing Process

11.1.6 Countries & Segments - Market Attractiveness Analysis

11.2 Europe

11.2.1 By Country

11.2.1.1 U.K

11.2.1.2 Germany

11.2.1.3 France

11.2.1.4 Italy

11.2.1.5 Spain

11.2.1.6 Rest of Europe

11.2.2 By Type of Fiber Reinforcement

11.2.3 By Application

11.2.4 By Resin Type

11.2.5 By Form

11.2.6 By Texture

11.2.7 By Manufacturing Process

11.2.8 Countries & Segments - Market Attractiveness Analysis

11.3 Asia Pacific

11.3.1 By Country

11.3.1.1 China

11.3.1.2 Japan

11.3.1.3 South Korea

11.3.1.4 India

11.3.1.5 Australia & New Zealand

11.3.1.6 Rest of Asia-Pacific

11.3.2 By Type of Fiber Reinforcement

11.3.3 By Application

11.3.4 By Resin Type

11.3.5 By Form

11.3.6 By Texture

11.3.7 By Manufacturing Process

11.3.8 Countries & Segments - Market Attractiveness Analysis

11.4 South America

11.4.1 By Country

11.4.1.1 Brazil

11.4.1.2 Argentina

11.4.1.3 Colombia

11.4.1.4 Chile

11.4.1.5 Rest of South America

11.4.2 By Type of Fiber Reinforcement

11.4.3 By Application

11.4.4 By Resin Type

11.4.5 By Form

11.4.6 By Texture

11.4.7 By Manufacturing Process

11.4.8 Countries & Segments - Market Attractiveness Analysis

11.5 Middle East & Africa

11.5.1 By Country

11.5.1.1 United Arab Emirates (UAE)

11.5.1.2 Saudi Arabia

11.5.1.3 Qatar

11.5.1.4 Israel

11.5.1.5 South Africa

11.5.1.6 Nigeria

11.5.1.7 Kenya

11.5.1.8 Egypt

11.5.1.9 Rest of MEA

11.5.2 By Type of Fiber Reinforcement

11.5.3 By Application

11.5.4 By Resin Type

11.5.5 By Form

11.5.6 By Texture

11.5.7 By Manufacturing Process

11.5.8 Countries & Segments - Market Attractiveness Analysis

Chapter 12. Nano Engineered Prepreg Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

12.1 Mitsubishi Chemical Group Corporation

12.2 Park Aerospace Corp.

12.3 Solvay Group

12.4 Gurit Holding AG

12.5 Teijin Limited

12.6 Plastic Reinforcement Fabrics Ltd.

12.7 Hexcel Corporation

12.8 SGL Group

12.9 Toray Industries, Inc.

12.10 Axiom Materials

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

Energy consumption during manufacturing, the recyclability of the final product, and the sustainability of raw materials are the main environmental factors in the production of nanoengineered materials.

Nano-engineered prepreg materials offer better mechanical qualities at a lower total weight, which improves performance, durability, and fuel efficiency across a range of applications. This helps to progress the development of lightweight, high-performance goods.

Advanced composite materials that include nanoscale reinforcements in a resin matrix to improve mechanical and lightweight qualities are referred to as nano-engineered prepregs. By adding nanoscale reinforcements, they offer better mechanical qualities, lightweight features, and improved performance compared to conventional prepreg.

Applications for nanoengineered prepreg materials can be found in a variety of industries, including electronics, wind energy, sports goods, automotive, and aerospace.

When compared to traditional materials, the use of nanoengineered prepreg improves overall performance, corrosion resistance, thermal stability, and strength-to-weight ratio.