Multistage Ultrasonic Cleaning Equipment Market Size (2024 – 2030)

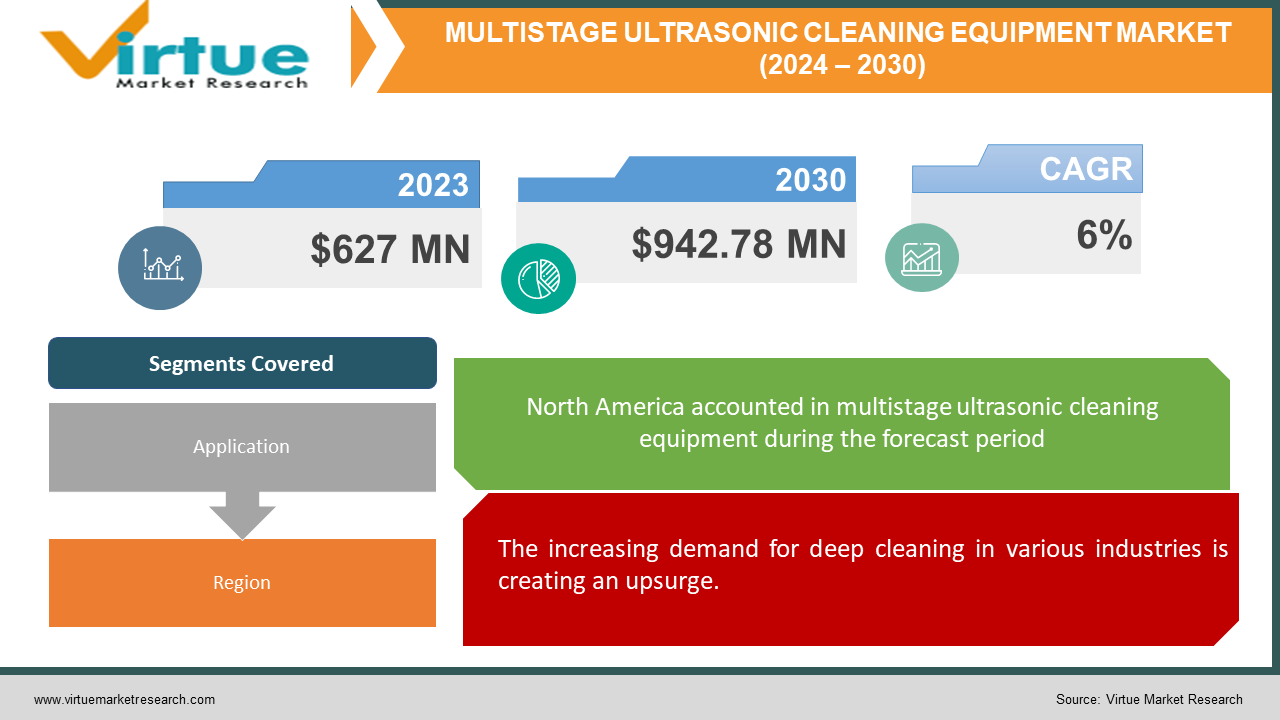

The global multistage ultrasonic cleaning equipment market was valued at USD 627 million in 2023 and will grow at a CAGR of 6% from 2024 to 2030. The market is expected to reach USD 942.78 million by 2030.

Multiple processing tanks, each with a distinct purpose, are used by multistage ultrasonic cleaning equipment to clean components. Usually, there are four tanks: an ultrasonic cleaning tank in the first, a rinsing tank in the second, a drying tank in the fourth, and a dip tank for preventing rust in the third. Using a pneumatically powered dunking platform with adjustable vertical reciprocation, the components are cleaned inside the liquid medium. The way multistage ultrasonic cleaning equipment operates is by producing ultrasonic waves, which are high-frequency sound waves that cause tiny cavitation bubbles to form in a cleaning solution. When these bubbles come into contact with the component surfaces, they burst, displacing dirt, impurities, and other undesired particles. Precision cleaning of complex parts, as well as degreasing and descaling, may be accomplished with multistage ultrasonic cleaning equipment. Additionally, it may be used to restore components to their original condition.

Key Market Insights:

The need for multistage ultrasonic cleaners is being driven by industries including electronics, automotive, aerospace, and healthcare because of their capacity to provide exacting cleanliness, which is essential for vital applications.High-volume manufacturing operations may benefit greatly from the considerable time savings and enhanced productivity that multistage ultrasonic cleaning systems bring about by streamlining procedures, automating cleaning duties, and minimizing downtime.Opportunities include teaching audiences about the advantages of multistage cleaning, technological developments, and increasing market penetration via creativity and inclusion. Challenges include early investments and a lack of knowledge.

Global Multistage Ultrasonic Cleaning Equipment Market Drivers:

The increasing demand for deep cleaning in various industries is creating an upsurge.

Critical cleaning applications in industries like automotive, aerospace, healthcare, and electronics demand a meticulous approach where even microscopic contaminants can be disastrous. Multistage ultrasonic cleaners address this challenge perfectly by offering a comprehensive, multi-step cleaning process. Unlike traditional methods, these cleaners utilize a sequence of tanks, each tackling a specific task. The first stage might involve a pre-cleaning soak to loosen larger particles. After this, high-frequency sound waves create microscopic cavitation bubbles that implode on surfaces, dislodging even the most stubborn dirt trapped in crevices and blind holes. Subsequent stages focus on rinsing away the dislodged contaminants with clean water, often heated for enhanced cleaning power. Finally, a drying stage might utilize hot air or a vacuum to ensure the cleaned parts are completely spotless and ready for further processing or use. This multi-pronged approach ensures an unmatched level of cleanliness, making multistage ultrasonic cleaning the go-to solution for critical applications where failure is not an option.

A growing focus on efficiency and productivity is enabling development.

High-volume manufacturing thrives on efficiency, and traditional cleaning methods can often become bottlenecks. Multistage ultrasonic cleaning tackles this challenge head-on by streamlining the process for significant time savings and increased productivity. Unlike manual cleaning, which can be labor-intensive and time-consuming, ultrasonic cleaning automates much of the work. Parts are simply loaded into the multistage system, and the machine takes care of the rest. The pre-programmed cleaning cycles ensure consistent and thorough cleaning across all parts, eliminating human error and the need for constant supervision. Additionally, the multistage approach itself speeds things up. By dedicating separate stages for pre-cleaning, ultrasonic cleaning, rinsing, and drying, each step can occur simultaneously or efficiently, one after another. This eliminates the need for manual transfers between cleaning solutions and drying stations, significantly reducing overall cleaning time. This translates to faster turnaround times, allowing manufacturers to keep production lines moving and maximize output. In today's competitive landscape, where even minor downtime can impact profits, multistage ultrasonic cleaning offers a clear advantage for high-volume operations.

Environmental regulations and sustainability are boosting the market.

The growing emphasis on environmental responsibility is converging perfectly with the benefits of multistage ultrasonic cleaning systems. Unlike traditional cleaning methods that often rely on harsh chemicals and solvents, these ultrasonic systems frequently utilize water-based cleaning solutions. These solutions are not only gentler on delicate parts but also biodegradable and less hazardous to dispose of. This aligns with stricter environmental regulations being implemented across various industries. Moreover, water-based solutions can often be filtered and reused within the multistage system, further reducing waste and environmental impact. This focus on sustainability extends beyond just cleaning solutions. Multistage systems themselves are designed for efficiency, minimizing energy consumption during operation. Additionally, the cavitation process itself uses minimal cleaning solutions compared to traditional methods that can involve large volumes of solvents. This combination of eco-friendly cleaning solutions, reusability, and efficient operation makes multistage ultrasonic cleaning a clear winner for environmentally conscious manufacturers who are striving to adopt sustainable practices without sacrificing cleaning performance.

Global Multistage Ultrasonic Cleaning Equipment Market Challenges and Restraints:

High initial investments can create hindrances.

The upfront cost of multistage ultrasonic cleaning systems presents a major hurdle, particularly for smaller companies or those with limited budgets. Unlike traditional cleaning methods, which might involve simple buckets and solvents, multistage systems are complex machines packed with advanced technology. This translates to a hefty price tag that can be a significant investment, especially compared to the lower initial cost of more basic cleaning solutions. For smaller companies, this initial investment can be a tough pill to swallow, even when considering the long-term benefits of faster cleaning times, reduced labor costs, and superior cleaning performance. This creates a barrier to entry, potentially hindering wider adoption of this technology by businesses that could greatly benefit from it.

Lack of awareness is another issue.

Even though the overall concept of ultrasonic cleaning is gaining traction, there's a knowledge gap regarding the specific benefits of multistage systems, especially in emerging markets. This can lead companies to overlook this powerful technology and stick with traditional cleaning methods they're more comfortable with. Unlike basic ultrasonic cleaners, multistage systems offer a comprehensive, multi-step process for superior cleaning. Companies in emerging markets might not be fully aware of the advantages this multi-step approach offers, such as dedicated pre-cleaning for stubborn contaminants, thorough ultrasonic cleaning for microscopic particles, and automated rinsing and drying for a spotless finish. This lack of understanding about the unique capabilities of multistage systems can cause them to be perceived as simply more expensive versions of basic ultrasonic cleaners, leading them to choose traditional methods that may not deliver the same level of cleanliness and efficiency.

Lack of technical expertise leads to complexities.

Unlike simple cleaning methods that require minimal training, operating and maintaining multistage ultrasonic cleaning systems effectively can be a challenge. These complex machines involve sophisticated technology and require a certain level of technical expertise to function optimally. Companies might need to invest in training programs for their staff to ensure proper use of the equipment. This training could cover aspects like selecting the right cleaning solution for specific materials and contaminants, optimizing cleaning cycles for different parts, and understanding the intricacies of the multistage process. Alternatively, companies might need to hire personnel with pre-existing knowledge of ultrasonic cleaning technology. However, both options add to the overall cost of ownership. This can be a deterrent for companies with limited resources, potentially leading them to shy away from multistage systems despite their long-term benefits in terms of efficiency and cleaning quality.

Global Multistage Ultrasonic Cleaning Equipment Market Opportunities:

The multistage ultrasonic cleaning equipment market presents a lot of exciting opportunities. Firstly, the ever-increasing demand for deep cleaning in critical industries like automotive, aerospace, healthcare, and electronics is a major growth driver. Traditional methods often struggle with microscopic contaminants, whereas multistage systems offer a multi-step solution with pre-cleaning, an ultrasonic bath, rinsing, and drying, ensuring a level of cleanliness crucial for these industries. This translates to improved product performance, reduced risk of malfunctions, and enhanced safety. Secondly, the focus on efficiency and productivity in high-volume manufacturing perfectly aligns with the strengths of multistage ultrasonic cleaning. Automation, faster cleaning cycles through dedicated stages, and minimal downtime for cleaning all contribute to significant time and cost savings. This resonates with manufacturers striving to optimize production lines and maximize output. Thirdly, the growing emphasis on environmental responsibility presents a significant opportunity. Multistage systems often utilize eco-friendly, water-based cleaning solutions that are biodegradable and require less hazardous disposal compared to harsh chemicals. Additionally, water reusability and energy-efficient operation further elevate their sustainability profile, making them attractive to environmentally conscious manufacturers. Furthermore, advancements in technology are constantly improving the capabilities of multistage ultrasonic cleaning. This includes more powerful cavitation for superior cleaning, better control over the process, and integration with automation systems. These advancements cater to the specific needs of different industries and ensure even more effective cleaning. Finally, a growing awareness of the technology's benefits presents an opportunity to bridge the knowledge gap, especially in emerging markets. By educating potential customers about the advantages of multistage cleaning over traditional methods, the market can witness wider adoption and unlock its full potential. In conclusion, the multistage ultrasonic cleaning equipment market is poised for significant growth fueled by its ability to deliver superior cleaning, efficiency gains, environmental benefits, and continuous technological advancements. By addressing challenges like upfront costs and knowledge gaps, the market can witness a surge in adoption across various industries.

MULTISTAGE ULTRASONIC CLEANING EQUIPMENT MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

6% |

|

Segments Covered |

By Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Branson Ultrasonics Corporation (US), Mettler Electronics Corp (US), L&R Manufacturing Company (US), Elma Schmidbauer GmbH (Germany), Crest Ultrasonics Corporation (US), SharperTek (US), GT Sonic (China), Blue Wave Ultrasonics (US), Kemet International Limited (UK), TierraTech (US) |

Multistage Ultrasonic Cleaning Equipment Market Segmentation: By Application

-

Automotive

-

Aerospace & Defense

-

Healthcare

-

Electrical & Electronics

-

Food & Beverage

-

Others

The healthcare sector has the highest market share in 2023. This is due to the strict hygienic standards in medical and pharmaceutical environments, where surgical instruments, medical equipment, and pharmaceutical production components are cleaned and sterilized thoroughly using ultrasonic cleaning technology. Furthermore, it is anticipated that the need for sophisticated cleaning solutions in the healthcare industry will only increase due to the continued emphasis on infection control and patient safety. The automotive sector is the fastest-growing application. In the automotive sector, it tackles critical components like engine parts, fuel injectors, and transmission assemblies. The ever-increasing complexity of these parts, with tighter tolerances and intricate designs, demands a superior cleaning approach. Multistage systems deliver exactly that, ensuring microscopic contaminant removal that traditional methods might miss.

Multistage Ultrasonic Cleaning Equipment Market Segmentation: Regional Analysis

-

North America

-

Europe

-

Asia-Pacific

-

South America

-

Middle East and Africa

North America currently reigns supreme holding over 37% of the market share with its established manufacturing base and focus on quality control, driving demand for high-performance cleaning systems. The fastest-growing market is Asia Pacific, fueled by rapid industrialization and investments in sectors like automotive and electronics. However, bridging the knowledge gap regarding multistage advantages compared to traditional methods will be crucial in this region. Europe thrives on innovation, catering to high-tech industries, and the Middle East & Africa are emerging markets poised for growth due to their rising demand for quality manufactured goods and the development of the oil & gas sector. South America prioritizes cost-effectiveness, requiring emphasis on the long-term benefits of multistage systems.

COVID-19 Impact Analysis on the Global Multistage Ultrasonic Cleaning Equipment Market

The COVID-19 pandemic caused a ripple effect on the multistage ultrasonic cleaning equipment market. Initial disruptions were felt due to lockdowns and supply chain disruptions. Production slowdowns in major manufacturing hubs and a decline in demand from automotive and aerospace sectors, which heavily rely on multistage cleaning for critical components, hampered market growth. Additionally, project delays and budget constraints due to the pandemic might have pushed back purchasing decisions for some companies. However, the tide seems to be turning. The increasing focus on hygiene and sterilization in the healthcare sector due to COVID-19 has opened new avenues for multistage cleaning systems. Their ability to effectively clean medical instruments and equipment aligns perfectly with the heightened hygiene requirements. Furthermore, as economies recover and manufacturing ramps up again, the demand for high-performance cleaning solutions is expected to rise. The long-term benefits of multistage systems, such as efficiency gains, automation, and potential cost savings in the long run, might become even more attractive in a post-pandemic environment where businesses strive to optimize operations. Overall, while the pandemic caused a temporary setback, the multistage ultrasonic cleaning equipment market is expected to regain momentum as the global economy recovers and the value proposition of these systems resonates with a wider range of industries.

Latest trends/Developments

The industry is seeing creative breakthroughs, including the utilization of plant-based ingredients, flavor-enhancing fermentation methods, an emphasis on sustainability using repurposed materials, and less water consumption. Along with the emergence of significant food corporations, specialized multistage ultrasonic cleaning equipment is being developed for specialized uses, such as cheese manufacturing, indicating more rivalry and broader market penetration.

Key Players:

-

Branson Ultrasonics Corporation (US)

-

Mettler Electronics Corp (US)

-

L&R Manufacturing Company (US)

-

Elma Schmidbauer GmbH (Germany)

-

Crest Ultrasonics Corporation (US)

-

SharperTek (US)

-

GT Sonic (China)

-

Blue Wave Ultrasonics (US)

-

Kemet International Limited (UK)

-

TierraTech (US)

Chapter 1. MULTISTAGE ULTRASONIC CLEANING EQUIPMENT MARKET – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. MULTISTAGE ULTRASONIC CLEANING EQUIPMENT MARKET – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. MULTISTAGE ULTRASONIC CLEANING EQUIPMENT MARKET – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. MULTISTAGE ULTRASONIC CLEANING EQUIPMENT MARKET Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. MULTISTAGE ULTRASONIC CLEANING EQUIPMENT MARKET – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. MULTISTAGE ULTRASONIC CLEANING EQUIPMENT MARKET – By Application

6.1 Introduction/Key Findings

6.2 Automotive

6.3 Aerospace & Defense

6.4 Healthcare

6.5 Electrical & Electronics

6.6 Food & Beverage

6.7 Others

6.8 Y-O-Y Growth trend Analysis By Application

6.9 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 7. MULTISTAGE ULTRASONIC CLEANING EQUIPMENT MARKET , By Geography – Market Size, Forecast, Trends & Insights

7.1 North America

7.1.1 By Country

7.1.1.1 U.S.A.

7.1.1.2 Canada

7.1.1.3 Mexico

7.1.2 By Application

7.1.3 Countries & Segments - Market Attractiveness Analysis

7.2 Europe

7.2.1 By Country

7.2.1.1 U.K

7.2.1.2 Germany

7.2.1.3 France

7.2.1.4 Italy

7.2.1.5 Spain

7.2.1.6 Rest of Europe

7.2.2 By Application

7.2.3 Countries & Segments - Market Attractiveness Analysis

7.3 Asia Pacific

7.3.1 By Country

7.3.1.1 China

7.3.1.2 Japan

7.3.1.3 South Korea

7.3.1.4 India

7.3.1.5 Australia & New Zealand

7.3.1.6 Rest of Asia-Pacific

7.3.2 By Application

7.3.3 Countries & Segments - Market Attractiveness Analysis

7.4 South America

7.4.1 By Country

7.4.1.1 Brazil

7.4.1.2 Argentina

7.4.1.3 Colombia

7.4.1.4 Chile

7.4.1.5 Rest of South America

7.4.2 By Application

7.4.3 Countries & Segments - Market Attractiveness Analysis

7.5 Middle East & Africa

7.5.1 By Country

7.5.1.1 United Arab Emirates (UAE)

7.5.1.2 Saudi Arabia

7.5.1.3 Qatar

7.5.1.4 Israel

7.5.1.5 South Africa

7.5.1.6 Nigeria

7.5.1.7 Kenya

7.5.1.8 Egypt

7.5.1.9 Rest of MEA

7.5.2 By Application

7.5.3 Countries & Segments - Market Attractiveness Analysis

Chapter 8. MULTISTAGE ULTRASONIC CLEANING EQUIPMENT MARKET – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

8.1 Branson Ultrasonics Corporation (US)

8.2 Mettler Electronics Corp (US)

8.3 L&R Manufacturing Company (US)

8.4 Elma Schmidbauer GmbH (Germany)

8.5 Crest Ultrasonics Corporation (US)

8.6 SharperTek (US)

8.7 GT Sonic (China)

8.8 Blue Wave Ultrasonics (US)

8.9 Kemet International Limited (UK)

8.10 TierraTech (US)

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

Ans. The global multistage ultrasonic cleaning equipment market was valued at USD 627 million in 2023 and will grow at a CAGR of 6% from 2024 to 2030. The market is expected to reach USD 942.78 million by 2030.

Increasing demand for deep cleaning in various industries, a growing focus on efficiency & productivity, and environmental regulations & sustainability are the reasons that are driving the market.

Based on application, the market is divided into automotive, aerospace & defense, healthcare, electrical & electronics, food & beverage, and others.

North America is the most dominant region for the global multistage ultrasonic cleaning equipment market.

Branson Ultrasonics Corporation, Mettler Electronics Corp., L&R Manufacturing Company, Elma Schmidbauer GmbH, and Crest Ultrasonics Corporation are the major players in the global multistage ultrasonic cleaning equipment market.