Metaverse in Industrial Manufacturing Market Size (2024 – 2030)

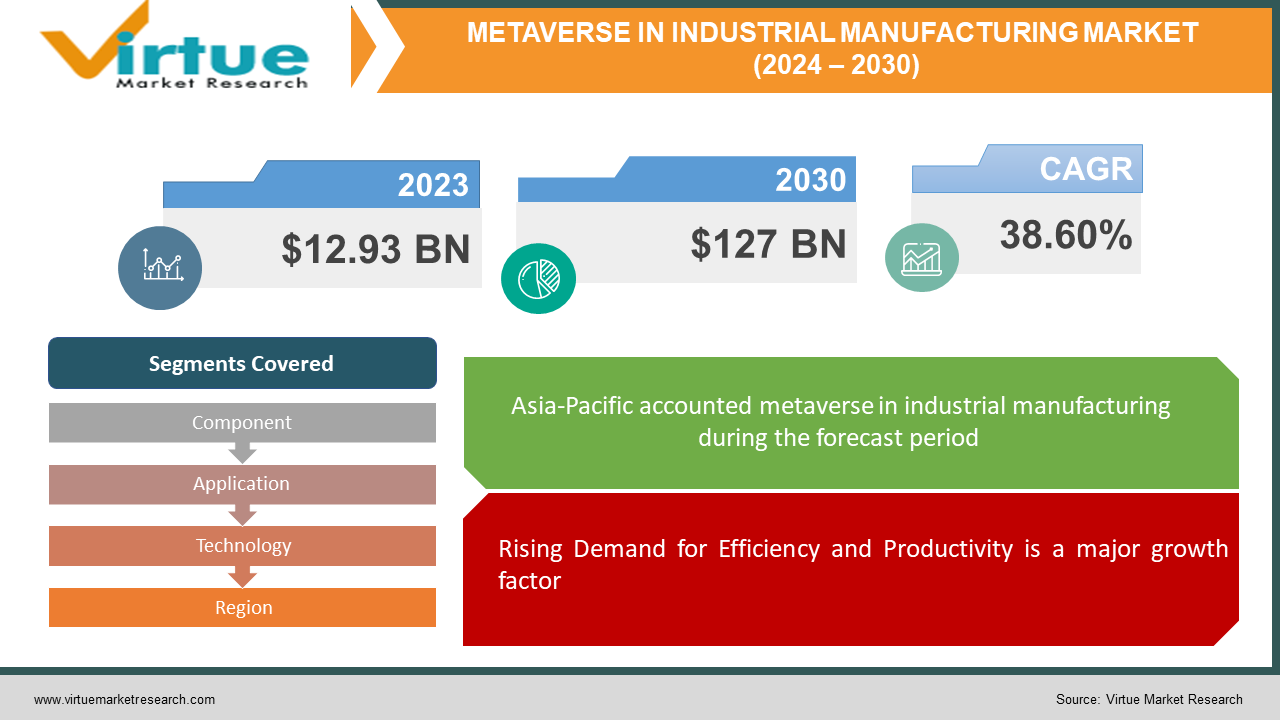

The Global Metaverse in Industrial Manufacturing Market was valued at USD 12.93 billion in 2023 and is projected to reach a market size of USD 127 billion by the end of 2030. Over the forecast period of 2024-2030, the market is expected to grow at a CAGR of 38.60%.

Key Market Insights:

According to the region, Asia-Pacific holds more than 33% of the market share in 2023. According to Component, the hardware segment has the largest market share of 56% in 2023. According to the application, the product designing and development segment generated over 24% of the market share in 2023. A key application of the metaverse in industrial manufacturing is for training and collaboration. A recent study found that 72% of manufacturers believe the metaverse has the potential to revolutionize industrial training.

Market Drivers:

Rising Demand for Efficiency and Productivity is a major growth factor.

The pressure to be ever more efficient and productive is driving manufacturing to embrace the metaverse. This virtual world offers a powerful solution by allowing companies to create digital twins in their factories. These simulated environments can be used to test and refine production lines before any changes are made in the real world, minimizing downtime, waste, and resource allocation. Additionally, the metaverse facilitates remote monitoring and control with real-time data visualization. This enables faster identification and resolution of problems on the production line, ultimately boosting uptime and productivity.

Skilled Workforce Shortage and Training Needs is driving the market growth

The manufacturing sector's skilled labor gap can be addressed by the metaverse's potential for immersive training. This technology can create engaging simulations for workers to learn new skills and practice procedures safely, reducing training time and cost while improving knowledge retention. Furthermore, the metaverse can provide flexible learning modules for existing workers, allowing them to upskill and reskill continuously as technologies evolve and their field advances.

Evolving Consumer Demands and Product Customization is giving the market a boost.

Modern consumers crave personalization, and the metaverse is poised to revolutionize product customization. Companies can utilize this virtual world to create immersive design experiences where customers can interact with and customize products in real time before buying. The metaverse doesn't stop there – it can also be a platform for enhanced after-sales support. Imagine receiving virtual demonstrations on product use and troubleshooting, all within the metaverse, leading to happier and more loyal customers.

Market Restraints and Challenges:

Technological Immaturity and High Costs is a challenge for the market

The metaverse in industrial manufacturing is still a nascent concept. Core technologies like high-fidelity VR headsets with advanced haptic feedback and powerful processors for real-time rendering are under development and often come with a hefty price tag. Additionally, building and maintaining the complex virtual environments needed for industrial applications requires significant investment in software development and ongoing infrastructure upgrades. This can be a barrier for many manufacturers, particularly small and medium-sized enterprises.

Data Security and Privacy Concerns are a major challenge

The industrial metaverse relies heavily on data collected from sensors, machines, and user interactions within the virtual environment. This raises concerns about data security and privacy. Manufacturers need to establish robust cybersecurity protocols to prevent unauthorized access and ensure compliance with data privacy regulations like GDPR and CCPA. Building trust with the workforce regarding data collection and usage practices will also be crucial for successful adoption.

Lack of Standardization and Interoperability is restricting the market growth

Currently, there's no single dominant metaverse platform. Different companies are developing their virtual environments with varying levels of compatibility. This lack of standardization can hinder collaboration between teams and across the supply chain. Manufacturers need interoperable solutions that allow them to seamlessly work within different metaverse platforms. The absence of clear standards can create uncertainty and slow down wider adoption of the technology.

Market Opportunities:

Remote Collaboration and Maintenance for Globally Distributed Operations is opening new doors for the market

Modern consumers crave personalization, and the metaverse is poised to revolutionize product customization. Companies can utilize this virtual world to create immersive design experiences where customers can interact with and customize products in real time before buying. The metaverse doesn't stop there – it can also be a platform for enhanced after-sales support. Imagine receiving virtual demonstrations on product use and troubleshooting, all within the metaverse, leading to happier and more loyal customers.

Advanced Product Development and Customer Experience is a major opportunity

The metaverse is transforming product development and customer experience. Companies can create virtual showrooms where customers can interact with customized products in realistic settings, like a car manufacturer offering virtual test drives. The metaverse can also be used for interactive after-sales support, providing virtual tutorials that increase product satisfaction and brand loyalty. These engaging experiences give manufacturers a competitive edge by setting them apart from the competition.

METAVERSE IN INDUSTRIAL MANUFACTURING MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

38.60% |

|

Segments Covered |

By Component, Application, Technology, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Microsoft Corporation, Unity Technologies, NVIDIA Corporation, PTC Inc., Siemens AG, Autodesk, Inc., EON Reality, Inc., Magic Leap, Inc., HTC Corporation, Meta |

Metaverse in Industrial Manufacturing Market Segmentation: By Component

-

Hardware

-

Services

The metaverse in industrial manufacturing presents a vast and rapidly growing market opportunity. This growth is driven by several factors, including the rising demand for efficiency and productivity in manufacturing, the need to address skilled workforce shortages through immersive training, and the evolving consumer demands for personalization.

To capitalize on this opportunity, the market requires a strong foundation across both hardware and service segments. On the hardware side, advancements in VR headsets, haptic feedback suits, and spatial computing glasses are crucial for creating realistic and immersive virtual environments. The services segment plays a vital role in developing and maintaining the complex software infrastructure required for the metaverse, along with ensuring data security and privacy compliance. Additionally, consulting services will be essential to guide manufacturers in integrating the metaverse effectively into their existing operations and workflows. As the technology matures and standards for interoperability are established, the metaverse in industrial manufacturing has the potential to revolutionize the way products are designed, manufactured, and serviced.

Metaverse in Industrial Manufacturing Market Segmentation: By Application

-

Supply Chain Management

-

Product Design and Development of Factory Landscape

-

Virtual Warehouse

-

Others

The industrial metaverse is poised to revolutionize manufacturing. Imagine a virtual environment where disruptions anywhere in the global supply chain can be visualized and addressed in real time, fostering unprecedented transparency and collaboration. This can significantly improve efficiency and minimize delays.

The metaverse extends beyond supply chains, impacting every aspect of manufacturing. Design teams can leverage virtual environments to create and test prototypes collaboratively, regardless of location. Immersive training simulations can equip workers with the skills needed for this new landscape. Digital twins of factories can be created for virtual walkthroughs, remote equipment monitoring, and production line optimization. The concept of a virtual warehouse offers exciting possibilities for inventory management and logistics. While some applications are still under development, the industrial metaverse has the potential to disrupt manufacturing from design to logistics.

Metaverse in Industrial Manufacturing Market Segmentation: By Technology

-

Augmented Reality (AR)

-

Virtual Reality (VR)

-

Mixed Reality (MR)

-

Internet of Things (IoT)

-

Artificial Intelligence (AI)

The industrial metaverse is a powerful combination of emerging technologies that will revolutionize manufacturing. Augmented reality (AR) allows technicians to see digital information overlaid in the real world, like repair instructions or machine data. This can improve accuracy and efficiency during maintenance and troubleshooting. Virtual reality (VR) creates completely virtual environments for training simulations, product design reviews, and even collaboration between geographically dispersed teams. A recent study showed that most manufacturers believe VR has the potential to significantly improve industrial training.

Beyond AR and VR, the industrial metaverse incorporates mixed reality (MR), which combines the physical and digital worlds. This allows workers to see and interact with virtual objects while working on physical equipment, which can be helpful for tasks like product assembly or operating machinery. The Internet of Things (IoT) plays a crucial role by collecting real-time data from sensors throughout factories. This data is fed into the metaverse to enable real-time monitoring, predictive maintenance, and data-driven process optimization. Artificial intelligence (AI) analyzes this vast amount of data to detect anomalies, predict maintenance needs, and even optimize production line layouts. As these technologies develop and work together, the industrial metaverse will become even more sophisticated, leading to a future of intelligent, connected, and data-driven manufacturing.

Metaverse in Industrial Manufacturing Market Segmentation: By Region

-

Asia-Pacific

-

North America

-

Europe

-

South America

-

Middle East and Africa

The industrial metaverse is poised for significant growth in the manufacturing sector worldwide. The Asia-Pacific region is expected to lead the charge, driven by its large manufacturing base, government support for digital transformation, and a strong tech talent pool. North America, with its existing technological infrastructure and established industrial players, is also anticipated to experience substantial growth. Europe is another key player, but stricter data privacy regulations and a fragmented market might hinder its pace compared to Asia-Pacific.

Emerging markets in South America the Middle East and Africa hold immense potential. While their current market share is smaller, increasing investments in infrastructure, rising internet penetration, and a growing focus on industrial modernization are expected to fuel future growth. Overcoming limited access to advanced technologies, developing skilled workforces, and establishing robust digital infrastructure will be crucial for the success of the industrial metaverse in these regions. As the technology matures and becomes more affordable, the industrial metaverse has the potential to bridge the digital divide and revolutionize manufacturing on a global scale.

COVID-19 Impact Analysis on the Global Metaverse in Industrial Manufacturing Market:

The COVID-19 pandemic acted as a catalyst for the industrial metaverse market. Global lockdowns and social distancing measures disrupted traditional manufacturing processes, forcing companies to seek innovative solutions for remote collaboration and training. This created a surge in interest in technologies that could facilitate these needs, such as virtual reality and augmented reality.

The pandemic also highlighted the importance of supply chain resilience and agility. The metaverse offers a potential solution by enabling real-time visualization and management of complex global supply chains. This allows for faster identification and response to disruptions, minimizing delays and ensuring business continuity. While the industrial metaverse is still in its early stages, the challenges posed by COVID-19 have accelerated its development and adoption, paving the way for a more efficient, connected, and resilient future for manufacturing.

Latest Trends/Developments:

Focus on Interoperability and Open Standards:

One of the key challenges for the wider adoption of the industrial metaverse is the lack of interoperability between different metaverse platforms. This creates silos and hinders collaboration across the supply chain. The latest trend is a growing focus on establishing open standards that ensure different metaverse platforms can work together seamlessly. Industry consortiums and tech giants are collaborating to develop these standards, paving the way for a more unified and interoperable industrial metaverse.

Rise of the Industrial Metaverse Cloud:

As the industrial metaverse becomes more complex, with ever-increasing demands for processing power and data storage, cloud computing is becoming a critical enabler. The latest trend is the emergence of specialized industrial metaverse cloud platforms that offer high-performance computing, secure data storage, and on-demand access to metaverse development tools and resources. This allows manufacturers to leverage the metaverse without the need for significant upfront investments in hardware infrastructure.

The Convergence of the Metaverse and Digital Twins:

Digital twins, virtual replicas of physical assets and processes, have been around for a while. The latest trend is the convergence of digital twins with the industrial metaverse. By integrating real-time data from sensors and machines into the digital twin within the metaverse, companies can create a dynamic and interactive virtual representation of their entire manufacturing operations. This allows for more sophisticated simulations, predictive maintenance, and data-driven optimization of processes across the entire value chain.

Key Players:

-

Microsoft Corporation

-

Unity Technologies

-

NVIDIA Corporation

-

PTC Inc.

-

Siemens AG

-

Autodesk, Inc.

-

EON Reality, Inc.

-

Magic Leap, Inc.

-

HTC Corporation

-

Meta

Hyundai Motor Company and Unity announced in January 2022 that they will be working together to develop a metaverse roadmap and platform for Meta-Factory. Based on the metaverse, this revolutionary digital-twin factory optimizes plant operations while presenting a virtual area for innovative problem-solving inside an engaging virtual work environment.

Chapter 1. METAVERSE IN INDUSTRIAL MANUFACTURING MARKET – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. METAVERSE IN INDUSTRIAL MANUFACTURING MARKET – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. METAVERSE IN INDUSTRIAL MANUFACTURING MARKET – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. METAVERSE IN INDUSTRIAL MANUFACTURING MARKET Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. METAVERSE IN INDUSTRIAL MANUFACTURING MARKET – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. METAVERSE IN INDUSTRIAL MANUFACTURING MARKET – By Component

6.1 Introduction/Key Findings

6.2 Hardware

6.3 Services

6.4 Y-O-Y Growth trend Analysis By Component

6.5 Absolute $ Opportunity Analysis By Component, 2024-2030

Chapter 7. METAVERSE IN INDUSTRIAL MANUFACTURING MARKET – By Application

7.1 Introduction/Key Findings

7.2 Supply Chain Management

7.3 Product Design and Development of Factory Landscape

7.4 Virtual Warehouse

7.5 Others

7.6 Y-O-Y Growth trend Analysis By Application

7.7 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. METAVERSE IN INDUSTRIAL MANUFACTURING MARKET – By Technology

8.1 Introduction/Key Findings

8.2 Augmented Reality (AR)

8.3 Virtual Reality (VR)

8.4 Mixed Reality (MR)

8.5 Internet of Things (IoT)

8.6 Artificial Intelligence (AI)

8.7 Y-O-Y Growth trend Analysis By Technology

8.8 Absolute $ Opportunity Analysis By Technology, 2024-2030

Chapter 9. METAVERSE IN INDUSTRIAL MANUFACTURING MARKET , By Geography – Market Size, Forecast, Trends & Insights

9.1 North America

9.1.1 By Country

9.1.1.1 U.S.A.

9.1.1.2 Canada

9.1.1.3 Mexico

9.1.2 By Component

9.1.3 By Application

9.1.4 By Technology

9.1.5 Countries & Segments - Market Attractiveness Analysis

9.2 Europe

9.2.1 By Country

9.2.1.1 U.K

9.2.1.2 Germany

9.2.1.3 France

9.2.1.4 Italy

9.2.1.5 Spain

9.2.1.6 Rest of Europe

9.2.2 By Component

9.2.3 By Application

9.2.4 By Technology

9.2.5 Countries & Segments - Market Attractiveness Analysis

9.3 Asia Pacific

9.3.1 By Country

9.3.1.1 China

9.3.1.2 Japan

9.3.1.3 South Korea

9.3.1.4 India

9.3.1.5 Australia & New Zealand

9.3.1.6 Rest of Asia-Pacific

9.3.2 By Component

9.3.3 By Application

9.3.4 By Technology

9.3.5 Countries & Segments - Market Attractiveness Analysis

9.4 South America

9.4.1 By Country

9.4.1.1 Brazil

9.4.1.2 Argentina

9.4.1.3 Colombia

9.4.1.4 Chile

9.4.1.5 Rest of South America

9.4.2 By Component

9.4.3 By Application

9.4.4 By Technology

9.4.5 Countries & Segments - Market Attractiveness Analysis

9.5 Middle East & Africa

9.5.1 By Country

9.5.1.1 United Arab Emirates (UAE)

9.5.1.2 Saudi Arabia

9.5.1.3 Qatar

9.5.1.4 Israel

9.5.1.5 South Africa

9.5.1.6 Nigeria

9.5.1.7 Kenya

9.5.1.8 Egypt

9.5.1.9 Rest of MEA

9.5.2 By Component

9.5.3 By Application

9.5.4 By Technology

9.5.5 Countries & Segments - Market Attractiveness Analysis

Chapter 10. METAVERSE IN INDUSTRIAL MANUFACTURING MARKET – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

10.1 Microsoft Corporation

10.2 Unity Technologies

10.3 NVIDIA Corporation

10.4 PTC Inc.

10.5 Siemens AG

10.6 Autodesk, Inc.

10.7 EON Reality, Inc.

10.8 Magic Leap, Inc.

10.9 HTC Corporation

10.10 Meta

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Global Metaverse in Industrial Manufacturing Market was valued at USD 12.93 billion in 2023 and is projected to reach a market size of USD 127 billion by the end of 2030. Over the forecast period of 2024-2030, the market is expected to grow at a CAGR of 38.60%.

Key drivers include the Rising Demand for Efficiency and Productivity, Skilled Workforce Shortage and Training Needs, and Evolving Consumer Demands and Product Customization.

Asia-Pacific dominates the market with a significant share of over 33%.

Microsoft Corporation, Unity Technologies, NVIDIA Corporation, PTC Inc., Siemens AG, Autodesk, Inc., EON Reality, Inc., Magic Leap, Inc., HTC Corporation, and Meta are some leading players in the Global Metaverse in the Industrial Manufacturing Market.

The lack of standardization can hinder collaboration between teams and across the supply chain. Manufacturers need interoperable solutions that allow them to seamlessly work within different metaverse platforms. The absence of clear standards can create uncertainty and slow down wider adoption of the technology.