Metallocene Polyolefin Market Size (2024-2030)

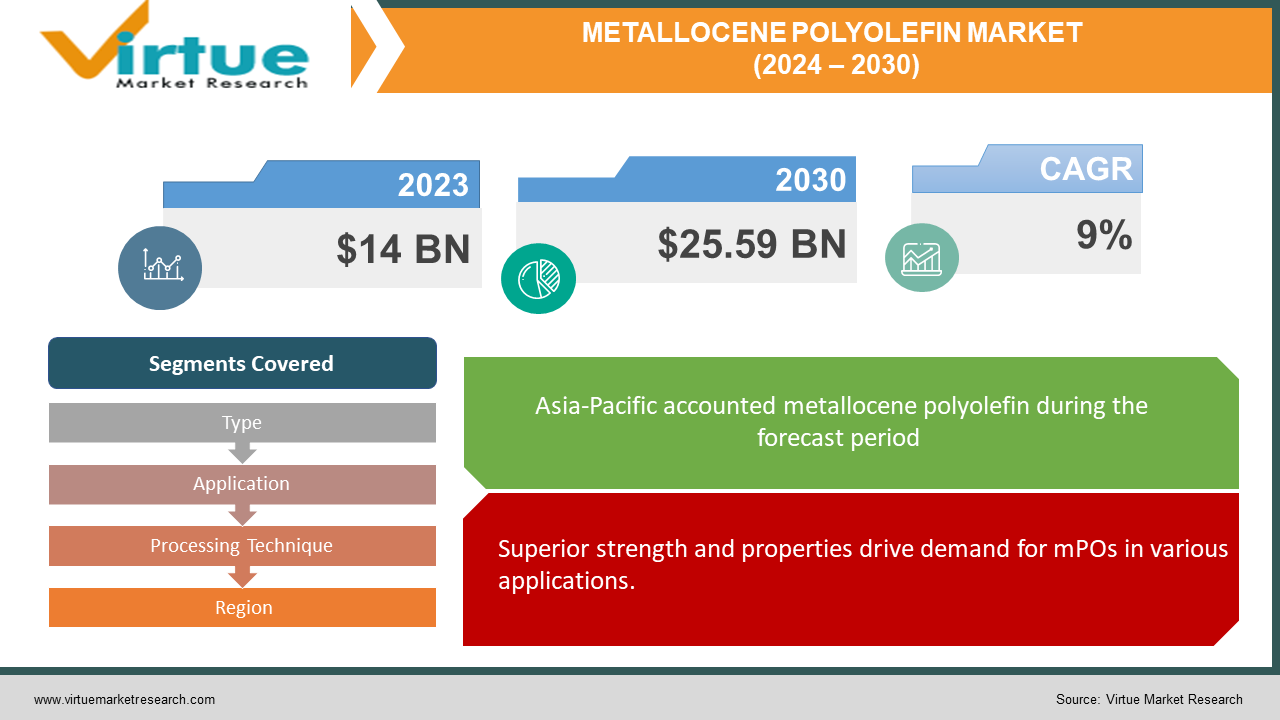

The Metallocene Polyolefin Market was valued at USD 14 billion in 2023 and is projected to reach a market size of USD 25.59 billion by the end of 2030. Over the cast period of 2024 – 2030, the figure for requests is projected to grow at a CAGR of 9%.

Metallocene polyolefins, or mPOs for short, are a new generation of plastics with some impressive qualities. Unlike traditional polyolefins, mPOs are created using metallocene catalysts, which give them a more precise structure and superior properties. This translates to stronger, stiffer materials with better clarity and gloss. They can also withstand higher heat and are more resistant to chemicals. These advancements make mPOs ideal for a wide range of applications, from packaging films to medical devices. As the demand for high-performance materials continues to grow, so does the market for mPOs.

Key Market Insights:

Compared to traditional plastics, mPOs boast roughly 20-30% greater strength and around 50-70% improved heat resistance. These advancements make mPOs perfect for a wide range of applications, from food packaging to medical devices.

The demand for high-performance materials is driving the mPO market forward. Industries across the board are looking for stronger, more durable options, and mPOs delivery. The packaging industry alone reflects this trend, with mPOs capturing a significant share exceeding 20% of the high-performance packaging market.

The Metallocene Polyolefin Market Drivers:

Superior strength and properties drive demand for mPOs in various applications.

mPOs boast significant advantages over traditional plastics. Their enhanced strength, clarity, heat resistance, and chemical resistance make them ideal for demanding applications where traditional plastics fall short.

Packaging industry revolutionized by mPOs' ability to create strong, flexible films.

The packaging industry is a major growth engine for mPOs. Their ability to create strong yet flexible films and sheets makes them perfect for food packaging, medical packaging, and other applications requiring both protection and visibility. This is revolutionizing the way products are packaged.

mPOs go beyond packaging, finding uses in diverse areas like automotive parts and medical devices.

The market is expanding due to mPOs' ability to go beyond packaging. They are finding uses in diverse areas like automotive parts (for lighter, stronger components), medical devices (for improved biocompatibility), pipes and tubes (for enhanced durability), and even building and construction materials (offering superior performance).

Constant innovation with new mPO variations keeps the market competitive.

Manufacturers are constantly pushing boundaries by developing new mPO variations with tailored properties. This ongoing research and development is crucial for maintaining market competitiveness and creating solutions for even more demanding applications.

The Metallocene Polyolefin Market Restraints and Challenges:

While the future of metallocene polyolefins (mPOs) is bright, there are some hurdles to overcome. The biggest challenge is cost. mPOs are currently more expensive than traditional plastics, which can be a dealbreaker for manufacturers working with tight budgets. Additionally, processing mPOs can be trickier than traditional plastics, requiring adjustments or even new equipment in factories. This adds another layer of complexity for companies considering switching to mPOs.

The market can also be impacted by fluctuations in raw material prices. Since mPO production relies on specific raw materials, price swings can cause instability and affect overall production costs. Finally, the current range of mPOs with specific properties might be limited compared to traditional plastics. While research and development are creating new variations, this limited selection can restrict the use of mPOs in some applications where a very specific characteristic is needed. Despite these challenges, the ongoing development of mPOs and their clear performance advantages suggest that these hurdles can be addressed, paving the way for wider adoption in the future.

The Metallocene Polyolefin Market Opportunities:

The future of metallocene polyolefins (mPOs) is brimming with exciting opportunities. Sustainability is a key area of focus, with the development of bio-based mPOs offering a chance to cater to environmentally conscious consumers and create new eco-friendly markets. The medical device industry stands to benefit greatly from mPOs' biocompatibility, allowing for the creation of advanced implants and other sterilized, chemical-resistant medical equipment. Beyond healthcare, mPOs present a significant opportunity for performance-driven applications. The automotive industry could see a revolution with lighter, more fuel-efficient cars thanks to mPOs, while aerospace and construction can leverage their superior properties for high-performance projects. Developing regions in Asia Pacific offer a vast, untapped market for mPOs. Their growing demand for high-quality packaging, medical devices, and infrastructure will fuel market expansion. Finally, continuous advancements in research and development hold the key to unlocking even more potential. New mPO variations with specialized properties will open doors to innovative uses, while advancements in processing techniques can make mPOs more cost-effective and easier to work with, accelerating their widespread adoption.

METALLOCENE POLYOLEFIN MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

9% |

|

Segments Covered |

By Type, Application, Processing Technique, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

ExxonMobil, The Dow Chemical Company, LyondellBasell Industries Holdings B.V., Chevron Phillips Chemical Company LLC, Total S.A., SABIC, Japan Polychem Corporation Ltd, Braskem S.A., LG Chem Ltd. |

Metallocene Polyolefin Market Segmentation: By Type

-

Metallocene Polyethylene (mPE)

-

Metallocene Polypropylene (mPP)

The metallocene polyolefin market is segmented by type, with Metallocene Polyethylene (mPE) being the most dominant segment valued for its versatility in packaging, molding, and construction applications. However, Metallocene Polypropylene (mPP) is the fastest-growing segment, gaining traction due to its improved heat resistance in automotive parts, pipes, and medical devices.

Metallocene Polyolefin Market Segmentation: By Application

-

Film & Sheet

-

Injection Moulding

-

Pipes & Panels

-

Other Applications

The dominant segment by application is 'Film & Sheet', driven by the demand for high-performance packaging. Meanwhile, 'Injection Moulding' is experiencing the fastest growth due to its use in creating strong, clear, and heat-resistant components across various industries.

Metallocene Polyolefin Market Segmentation: By Processing Technique

-

Film Extrusion

-

Injection Moulding

-

Blow Moulding

While information on the dominant processing technique for mPOs isn't readily available, injection molding is likely a key technique for creating strong, clear, and heat-resistant components. However, the market segmentation by processing technique is less prominent compared to segmentation by type, application, and region. On the other hand, the Asia Pacific region is forecast to be the fastest-growing market due to its rapid industrialization and demand for high-performance materials.

Metallocene Polyolefin Market Segmentation: Regional Analysis

-

North America

-

Europe

-

Asia-Pacific

-

South America

-

Middle East and Africa

North America: This established market boasts well-known players like ExxonMobil and Dow. The demand for mPOs is high across various industries, with applications in packaging, automotive parts, and construction materials. With a strong foundation, North America continues to be a significant force in the mPO landscape.

Europe: Innovation and sustainability are at the forefront of the European mPO market. Regulations and environmental concerns drive research into bio-based mPOs, ensuring a future-focused approach. This focus on eco-friendly solutions positions Europe as a leader in responsible mPO development.

Asia Pacific: Buckle up because this region is the fastest-growing market for mPOs. Rapid industrialization and a booming demand for high-performance materials are fueling this growth. From packaging and infrastructure projects to consumer goods, mPOs are finding widespread use across various sectors. China and India are key players in this dynamic market, shaping the future of mPOs in Asia.

South America: While still developing, South America holds significant potential for mPO adoption. The packaging, automotive, and construction sectors are prime targets for mPOs. As infrastructure projects and industrial activity increase, the demand for mPOs is expected to rise, propelling South America's role in the mPO market.

Middle East & Africa: This emerging market is on the rise, driven by infrastructure development and economic diversification. mPOs are expected to see increased use in pipes, cables, and construction materials, playing a crucial role in building these regions' futures. The Middle East & Africa offer exciting possibilities for future mPO growth.

COVID-19 Impact Analysis on the Metallocene Polyolefin Market:

The COVID-19 pandemic undeniably shook the metallocene polyolefin (mPO) market. Lockdowns caused a temporary drop in demand from key industries like automotive and construction, leading to decreased production and a potential surplus of mPOs. The recovery has been uneven across regions. Sectors like packaging, fueled by the e-commerce boom, continued to require mPOs for food and medical supplies. However, car part production slowdowns hampered the use of mPOs in the automotive industry. Global restrictions also disrupted supply chains for raw materials and mPOs themselves, causing temporary shortages and price fluctuations. On a positive note, the pandemic's emphasis on hygiene could increase the use of mPOs in healthcare applications like sterilization trays and packaging for hygiene products. Furthermore, the growing focus on sustainability might accelerate the development of bio-based mPOs, offering eco-friendly solutions. Despite the short-term disruptions, the long-term outlook for mPOs remains promising. The rising demand for high-performance materials, along with potential growth in healthcare and sustainable packaging sectors, suggests the mPO market will bounce back and emerge even stronger.

Latest Trends/ Developments:

The metallocene polyolefin (mPO) market is buzzing with exciting developments. Sustainability is a major focus, with the rise of bio-based mPOs derived from renewable resources. These eco-friendly alternatives cater to a growing demand for responsible materials and open doors to new, environmentally conscious markets. The medical device industry is also embracing mPOs due to their enhanced biocompatibility. These mPOs can be sterilized and resist chemicals, making them ideal for implants, syringes, and other crucial equipment. Research continues to develop mPOs with even better biocompatibility for specific medical needs. Innovation isn't limited to materials; advancements in metallocene catalysts are allowing for even more precise control over mPO properties. This translates to creating mPOs with characteristics perfectly suited for specific applications, further expanding their potential uses. Additionally, new processing techniques are being developed to make mPOs easier and more cost-effective to work with, potentially through advancements in film extrusion and injection molding. Easier processing would make mPOs even more attractive across various industries. The future holds even more possibilities, with research exploring the use of mPOs in additive manufacturing (3D printing). Their unique properties could be a game-changer for creating high-performance 3D printed parts with superior strength, heat resistance, and other desirable characteristics. These trends showcase the continuous evolution of the mPO market, with a focus on sustainability, healthcare applications, improved processing, and even venturing into 3D printing, ensuring mPOs will stay at the forefront of innovation for years to come.

Key Players:

-

ExxonMobil

-

The Dow Chemical Company

-

LyondellBasell Industries Holdings B.V.

-

Chevron Phillips Chemical Company LLC

-

Total S.A.

-

SABIC

-

Japan Polychem Corporation Ltd

-

Braskem S.A.

-

LG Chem Ltd.

Chapter 1. METALLOCENE POLYOLEFIN MARKET – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. METALLOCENE POLYOLEFIN MARKET – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. METALLOCENE POLYOLEFIN MARKET – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. METALLOCENE POLYOLEFIN MARKET Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. METALLOCENE POLYOLEFIN MARKET – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. METALLOCENE POLYOLEFIN MARKET – By Type

6.1 Introduction/Key Findings

6.2 Metallocene Polyethylene (mPE)

6.3 Metallocene Polypropylene (mPP)

6.4 Y-O-Y Growth trend Analysis By Type

6.5 Absolute $ Opportunity Analysis By Type, 2024-2030

Chapter 7. METALLOCENE POLYOLEFIN MARKET – By Application

7.1 Introduction/Key Findings

7.2 Film & Sheet

7.3 Injection Moulding

7.4 Pipes & Panels

7.5 Other Applications

7.6 Y-O-Y Growth trend Analysis By Application

7.7 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. METALLOCENE POLYOLEFIN MARKET – By Processing Technique

8.1 Introduction/Key Findings

8.2 Film Extrusion

8.3 Injection Moulding

8.4 Blow Moulding

8.5 Y-O-Y Growth trend Analysis By Processing Technique

8.6 Absolute $ Opportunity Analysis By Processing Technique, 2024-2030

Chapter 9. METALLOCENE POLYOLEFIN MARKET , By Geography – Market Size, Forecast, Trends & Insights

9.1 North America

9.1.1 By Country

9.1.1.1 U.S.A.

9.1.1.2 Canada

9.1.1.3 Mexico

9.1.2 By Type

9.1.3 By Application

9.1.4 By Processing Technique

9.1.5 Countries & Segments - Market Attractiveness Analysis

9.2 Europe

9.2.1 By Country

9.2.1.1 U.K

9.2.1.2 Germany

9.2.1.3 France

9.2.1.4 Italy

9.2.1.5 Spain

9.2.1.6 Rest of Europe

9.2.2 By Type

9.2.3 By Application

9.2.4 By Processing Technique

9.2.5 Countries & Segments - Market Attractiveness Analysis

9.3 Asia Pacific

9.3.1 By Country

9.3.1.1 China

9.3.1.2 Japan

9.3.1.3 South Korea

9.3.1.4 India

9.3.1.5 Australia & New Zealand

9.3.1.6 Rest of Asia-Pacific

9.3.2 By Type

9.3.3 By Application

9.3.4 By Processing Technique

9.3.5 Countries & Segments - Market Attractiveness Analysis

9.4 South America

9.4.1 By Country

9.4.1.1 Brazil

9.4.1.2 Argentina

9.4.1.3 Colombia

9.4.1.4 Chile

9.4.1.5 Rest of South America

9.4.2 By Type

9.4.3 By Application

9.4.4 By Processing Technique

9.4.5 Countries & Segments - Market Attractiveness Analysis

9.5 Middle East & Africa

9.5.1 By Country

9.5.1.1 United Arab Emirates (UAE)

9.5.1.2 Saudi Arabia

9.5.1.3 Qatar

9.5.1.4 Israel

9.5.1.5 South Africa

9.5.1.6 Nigeria

9.5.1.7 Kenya

9.5.1.8 Egypt

9.5.1.9 Rest of MEA

9.5.2 By Type

9.5.3 By Application

9.5.4 By Processing Technique

9.5.5 Countries & Segments - Market Attractiveness Analysis

Chapter 10. METALLOCENE POLYOLEFIN MARKET – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

10.1 ExxonMobil

10.2 The Dow Chemical Company

10.3 LyondellBasell Industries Holdings B.V.

10.4 Chevron Phillips Chemical Company LLC

10.5 Total S.A.

10.6 SABIC

10.7 Japan Polychem Corporation Ltd

10.8 Braskem S.A.

10.9 LG Chem Ltd.

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Metallocene Polyolefin Market was valued at USD 14 billion in 2023 and is projected to reach a market size of USD 25.59 billion by the end of 2030. Over the cast period of 2024 – 2030, the figure for requests is projected to grow at a CAGR of 9%.

Superior Performance, Packaging Transformation, Application Versatility, Innovation and R&D.

Film & Sheet, Injection Molding, Pipes & Panels, Other Applications.

The most dominant region for the Metallocene Polyolefin Market is currently North America, but Asia Pacific is forecast to be the fastest-growing market due to rapid industrialization.

ExxonMobil, The Dow Chemical Company, LyondellBasell Industries Holdings B.V., Chevron Phillips Chemical Company LLC, Total S.A., SABIC, Japan Polychem Corporation Ltd, Braskem S.A., LG Chem Ltd..