Manufacturing Execution System (MES) Market Size (2023 – 2030)

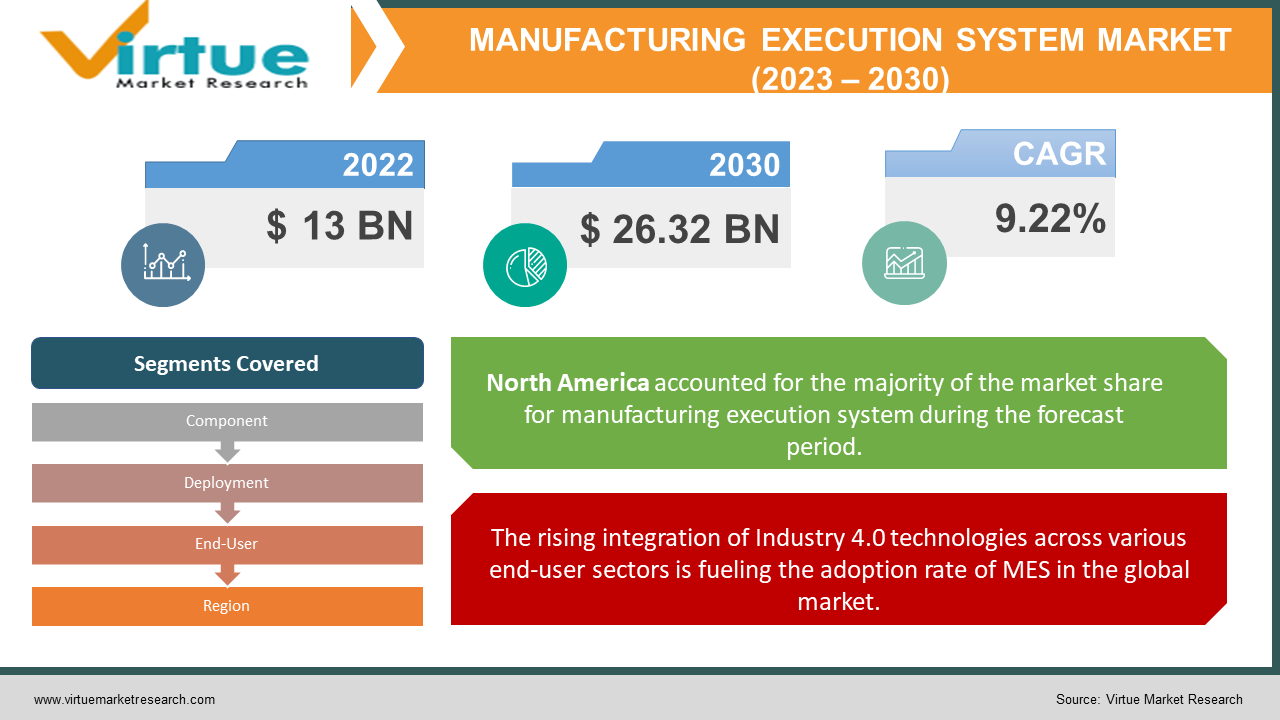

The Global Manufacturing Execution System (MES) is estimated to be worth USD 13 Billion in 2022 and is projected to reach a value of USD 26.32 Billion by 2030, growing at a fast CAGR of 9.22% during the forecast period 2023-2030.

The manufacturing process is managed and tracked in real-time by the Manufacturing Execution System (MES), a computer system. It offers transparency into the manufacturing process and helps manufacturers in analysing, regulate, and optimize their operations. Planning, scheduling, resource allocation, material tracking, quality control, and reporting are just a few of the manufacturing process elements that are connected by MES software solutions. Manufacturers can increase quality, reduce wastage, increase production efficiency, and comply with regulatory requirements because of MES systems. They also enable firms to make data-driven decisions by giving real-time visibility into the performance of the production process. To create a fully connected and streamlined manufacturing operation, MES systems can be coupled with other systems like Enterprise Resource Planning (ERP) and Product Lifecycle Management (PLM) systems.

Global Manufacturing Execution System (MES) Market Drivers:

The rising integration of Industry 4.0 technologies across various end-user sectors is fuelling the adoption rate of MES in the global market:

The demand for MES solutions has been driven by the use of Industry 4.0 technologies like the Internet of Things (IoT), big data analytics, and artificial intelligence (AI). In Industry 4.0 environments, MES systems are crucial for simplifying the production process and enabling real-time decision-making. Manufacturers are under constant pressure to improve productivity and can save expenditures. MES systems help manufacturers in simplifying their operations, reducing waste, and raising productivity, which boosts efficiency and reduces costs.

The increasing disposable income along with the rise in urbanization is boosting the growth of MES:

The need for highly connected supply-chain management systems is a major driver for the MES market. For smooth information flow and efficient production capabilities, businesses are opting for these advanced technologies to make the transit time lesser and more accountable. Additionally, the rise in industrialization and urbanization in developing countries is supporting the adoption of MES in these nations to form a more robust manufacturing system.

Global Manufacturing Execution System (MES) Market Challenges:

Installing and sustaining MES solutions can be expensive, especially for medium-sized and small companies (SMEs). Therefore, the cost could prove to be a major deterrent to adoption, particularly in industries with narrow profit margins. A few manufacturing plants use outdated systems that are incompatible with MES today. These system’s integration can be difficult and expensive, costing a lot of effort and money. Also, MES solutions are susceptible to cyberattacks because they collect and transmit sensitive data. Good security procedures must be put in place by manufacturers since security failures can cause significant financial and reputational harm to the firms.

Global Manufacturing Execution System (MES) Market Opportunities:

The manufacturing industry is expanding significantly in emerging markets like Asia-Pacific and Latin America. Manufacturers can benefit from this expansion by increasing their operations and putting MES solutions in place to boost productivity and efficiency. Compared to on-premise solutions, cloud-based MES solutions have a number of benefits, such as lower deployment and maintenance costs, scalability, and flexibility. Manufacturers are anticipated to employ cloud-based MES solutions more frequently as cloud computing spreads.

Impact of COVID-19 on the Global Manufacturing Execution System (MES) Market:

Manufacturing activities have become more digital as a result of the pandemic as companies seek to reduce physical contact and maintain social distance. Due to this, MES solutions that allow for remote monitoring and management of production processes are in higher demand. Global supply chains have been hindered by the pandemic, which has caused delays and a shortage of raw materials and components. This has hindered manufacturers' ability to implement MES solutions and caused implementation delays. Because of workforce shortages and supply chain disruptions, the pandemic has drawn the spotlight on the importance of automation in the manufacturing industry. Because of this, there is now more demand for MES systems that allow for the automation and remote observation of production processes.

Global Manufacturing Execution System (MES) Market Recent Industry Developments:

- In January 2021, Schneider Electric announced the launch of its new EcoStruxure Automation Expert, a cloud-native software platform that integrates with existing MES systems and provides real-time data analytics and remote control of manufacturing operations.

- In February2022, Siemens Digital Industries Software announced the acquisition of FORCAM, a provider of MES solutions for discrete manufacturing. The acquisition is predicted to strengthen Siemens' position in the MES market and expand its offerings for Industry 4.0.

- In August 2021, Rockwell Automation announced the acquisition of Oylo, a provider of industrial cybersecurity services. The acquisition is estimated to enhance Rockwell Automation's cybersecurity offerings for MES systems.

MANUFACTURING EXECUTION SYSTEM MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

9.22% |

|

Segments Covered |

By Component, Deployment, End-User, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

ABB Ltd., Dassault Systèmes, Emerson Electric Co., General Electric Co., Honeywell International Inc., Rockwell Automation, Inc., SAP SE, Schneider Electric SE, Siemens AG, Werum IT Solutions GmbH |

Global Manufacturing Execution System (MES) Market Segmentation: By Component

-

Software

-

Services

A variety of MES software solutions, including those for production tracking, scheduling, quality management, inventory management, and maintenance management, can be found in the software segment. To help manufacturers in implementing and maintaining MES solutions in their facilities, MES vendors provide a range of consulting, implementation, and support services under the banner of the service segment. Understanding the different MES offerings that are available on the market and the relative sizes of the software and service categories is made easier with the help of this segmentation. Also, it aids manufacturers in choosing the right MES solutions that best meet their needs as well as any support services they might need to effectively implement and maintain such solutions.

Global Manufacturing Execution System (MES) Market Segmentation: By Deployment

-

On-premise

- Cloud

The manufacturer's IT department installs and maintains on-premise MES solutions on-site. On the other hand, cloud-based MES solutions can be accessed online and are hosted in the cloud. The vendor will update and maintain cloud-based solutions, freeing up internal IT resources for other initiatives. So far, some manufacturers preferred on-premises solutions due to security concerns or because they have already made important infrastructure spending. For MES vendors, it's essential to understand the deployment preferences of manufacturers since this information may help them personalise their solutions to meet specific customer needs and offer the most reasonable pricing and service alternatives.

Global Manufacturing Execution System (MES) Market Segmentation: By End-User

-

Food & Beverage

-

Pharmaceutical & Lifesciences

-

Oil & Gas

MES technologies are utilised to enhance quality control, simplify production processes, and ensure compliance with food safety regulations. Manufacturing companies can use MES solutions to improve production, reduce waste and downtime, and monitor and control the production process in real-time. Manufacturers can follow their products from beginning to end with help of MES solutions, which also ensure batch quality and improve supply chain visibility. A few diverse industries use MES solutions to increase production efficiency, ensure compliance with legal requirements, and enhance quality control. Manufacturers are able to select from a variety of MES solutions because they can be customized to meet the specific needs of different industries.

Global Manufacturing Execution System (MES) Market Segmentation: By Region

-

North America

-

Europe

-

Asia Pacific

-

Middle East

-

Latin America

One of the largest markets for MES solutions is in North America, where manufacturers have a high adoption rate. The MES market in North America has grown as a result of the presence of major manufacturers like General Electric, Ford, and Boeing. Another significant market for MES products is Europe, with a major emphasis on Industry 4.0 and digital transformation projects. The region is among many major MES market players, including Siemens and Dassault Systemes, and it has a fully advanced manufacturing industry. Asia-Pacific is likely to have the fastest growth in the market for MES solutions, due to the manufacturing industry's growing adoption of automation and digitization. China, Japan, and South Korea are leading the region of employing MES solutions.

Global Manufacturing Execution System (MES) Market - Key Players:

- ABB Ltd.

- Dassault Systèmes

- Emerson Electric Co.

- General Electric Co.

- Honeywell International Inc.

- Rockwell Automation, Inc.

- SAP SE

- Schneider Electric SE

- Siemens AG

- Werum IT Solutions GmbH

Chapter 1. Global Manufacturing Execution System (MES) Market Segmentation – Scope & Methodology

1.1. Market Segmentation

1.2. Assumptions

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. Global Manufacturing Execution System (MES) Market Segmentation – Executive Summary

2.1. Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.3. COVID-19 Impact Analysis

2.3.1. Impact during 2023 - 2030

2.3.2. Impact on Supply – Demand

Chapter 3. Global Manufacturing Execution System (MES) Market Segmentation – Competition Scenario

3.1. Market Share Analysis

3.2. Product Benchmarking

3.3. Competitive Strategy & Development Scenario

3.4. Competitive Pricing Analysis

3.5. Supplier - Distributor Analysis

Chapter 4. Global Manufacturing Execution System (MES) Market Segmentation - Entry Scenario

4.1. Case Studies – Start-up/Thriving Companies

4.2. Regulatory Scenario - By Region

4.3 Customer Analysis

4.4. Porter's Five Force Model

4.4.1. Bargaining Power of Suppliers

4.4.2. Bargaining Powers of Customers

4.4.3. Threat of New Entrants

4.4.4. Rivalry among Existing Players

4.4.5. Threat of Substitutes

Chapter 5. Global Manufacturing Execution System (MES) Market Segmentation - Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. Global Manufacturing Execution System (MES) Market Segmentation - By Component

6.1 Software

6.2 Services

Chapter 7. Global Manufacturing Execution System (MES) Market Segmentation - By Deployment

7.1 On-premise

7.2 Cloud

Chapter 8. Global Manufacturing Execution System (MES) Market Segmentation - By End-User

8.1 Food & Beverage

8.2 Pharmaceutical & Lifesciences

8.3 Oil & Gas

Chapter 9. Global Manufacturing Execution System (MES) Market Segmentation - By Region

9.1 North America

9.2 Europe

9.3 Asia Pacific

9.4 Middle East

9.5 Latin America

Chapter 10. Global Manufacturing Execution System (MES) Market - Key Players

10.1 ABB Ltd.

10.2 Dassault Systèmes

10.3 Emerson Electric Co.

10.4 General Electric Co.

10.5 Honeywell International Inc.

10.6 Rockwell Automation, Inc.

10.7 SAP SE

10.8 Schneider Electric SE

10.9 Siemens AG

10.10 Werum IT Solutions GmbH

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Global Manufacturing Execution System (MES) is estimated to be worth USD 13 Billion in 2022 and is projected to reach a value of USD 26.32 Billion by 2030, growing at a fast CAGR of 9.22% during the forecast period 2023-2030.

The Global Manufacturing Execution System (MES) Market drivers are new and innovative technology to eradicate communication barriers or generated gaps between various devices.

The Segments under the Global Manufacturing Execution System (MES) Market by the end-user are Food & Beverage, Pharmaceutical & Lifesciences, and Oil & Gas.

China, Japan, South Korea, Australia, and India are the most dominating countries in the Asia Pacific region for the Global Manufacturing Execution System (MES) Market.

ABB Ltd., Dassault Systemes, Emerson Electric Co are the three major leading players in the Global Manufacturing Execution System (MES) Market.