Infrared Brazing Market Size (2023 - 2030)

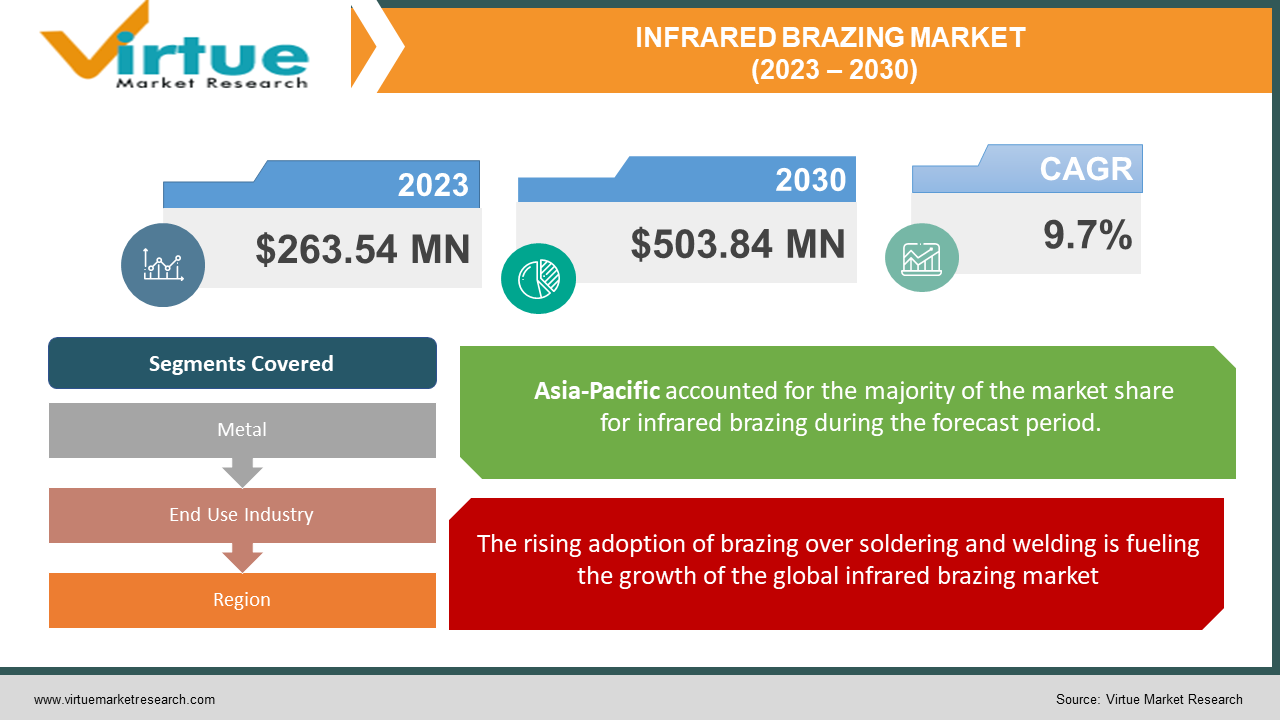

The Global Infrared Brazing Market was valued at USD 263.54 Million and is projected to reach a market size of USD 503.84 Million by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 9.7%.

Brazing is a method of joining two or more metals together by melting and flowing a filler metal, which has a lower melting point than the metal next to it, into the joint. In contrast to welding, brazing does not involve the melting of the workpieces. Brazing is different from soldering because it uses a higher temperature and has much tighter tolerances for the parts than soldering does. The filler metal moves through the space between close-fitting components using capillary action during the brazing process. While being protected from the elements by a suitable atmosphere, typically a flux, the filler metal is heated slightly above its liquidus (melting) point. After that, it flows over the base metal in a process called wetting and the workpieces are joined together by cooling it. The ability to join the same metal or different metals with substantial strength is a major advantage of brazing.

Infrared brazing is a process of brazing that utilizes infrared radiation to heat and melt a filler material to join two or more metal parts together. Infrared brazing offers a number of advantages over other joining processes. It provides rapid heating and a fast thermal cycle to avoid the formation of brittle intermetallics. It has the capability to join dissimilar metallic components. It is a non-contact process, which does not allow physical contact between the heating source and the parts being joined, thus lowering the risk of distortion or damage to the parts. In addition, it is a versatile brazing process, which enables the joining of a wide range of metals, including copper, iron, aluminum, nickel, and others. As a result of these advantages, the global infrared brazing market is estimated to have a fast CAGR during the forecasted period.

Global Infrared Brazing Market Drivers:

The rising adoption of brazing over soldering and welding is fueling the growth of the global infrared brazing market.

Brazing is the process of joining two or more metals together by melting and flowing a filler metal into the joint. In electrical earthing systems ranging in voltage from high to low, it is frequently used to join metal conductors. Various industries have started to adopt the process of brazing over soldering and welding owing to the advantages it offers over other processes, including lowering processing temperature and power input, producing joints with minimal thermal distortion and residual stresses, not requiring a post-processing heat treatment, having the ability to join dissimilar base materials, and producing stronger joints. Therefore, this factor drives the demand for infrared brazing.

The increasing demand for infrared brazing in the electronics and electrical industry is another factor contributing to the growth of the global infrared brazing market.

Manufacturers in the electronics and electrical industry are increasingly utilizing the process of infrared brazing as it is considered one of the ideal processes for joining thin and delicate electronics and electrical components that require precise and controlled heating to prevent damage or distortion. As a non-contact, localized heating method that can produce high-quality, leak-tight joints with excellent mechanical properties, infrared brazing is an excellent choice for electrical and electronic applications. Therefore, this factor also drives the demand for infrared brazing.

Global Infrared Brazing Market Challenges:

The global infrared brazing market is encountering challenges, primarily in terms of a shortage of skilled workers and high equipment costs. The process of infrared brazing requires skilled workers to use the equipment and conduct the brazing process. However, as infrared brazing is a more complicated process than other brazing processes owing to the requirement of specialized equipment and more precise control over the heating process, there is a lack of skilled workers, which restraints the use of this process. Moreover, the infrared brazing process requires the use of specialized equipment, which can be costly to purchase and difficult to maintain. Thus, these challenges inhibit the growth of the global infrared brazing market.

Global Infrared Brazing Market Opportunities:

Expansion of the infrared brazing process to other industries presents a lucrative opportunity in the global infrared brazing market. Given the rising demand for the process of infrared brazing due to the rising adoption of brazing over soldering and welding and the increasing usage of this process in the electronics and electrical industry, major service providers of infrared brazing process can stand to gain significantly from this opportunity by expanding their services to other industries, including the HVACR industry and construction industry, in order to broaden their customer base and boost their overall revenue.

COVID-19 Impact on the Global Infrared Brazing Market:

The outbreak of the COVID-19 pandemic substantially impacted the global infrared brazing market. The implementation of strict lockdowns, traveling restrictions, and social distancing measures across several nations hindered many companies' manufacturing capacities and caused a shortage of skilled workforce. The pandemic caused disruptions in supply chains and distribution of goods and services, which highly affected the production and distribution of infrared brazing specialized equipment. Moreover, many infrared brazing service providers were forced to shut down or reduce their operations owing to the worldwide lockdown, which further affected the provision of infrared brazing services. These factors negatively impacted the growth of the global infrared brazing market. Despite these challenges, the global infrared brazing market is projected to recover and grow in the coming years.

Global Infrared Brazing Market Recent Developments:

- In March 2023, FOCO Induction, a leading manufacturer of induction heating machines, unveiled its newest brazing product, the Handheld Induction Brazing Machine. This state-of-the-art equipment is made to serve the needs of a variety of industries, including automotive, aerospace, electrical, etc. The Handheld Induction Brazing Machine is a small, easy-to-carry machine that brazes a variety of metals using induction heating technology.

- In February 2023, UltraFlex Power Technologies, a US-based supplier of heating equipment, showcased the time- and energy-efficient induction brazing process in hydrogen environments. This revolutionizing solution can assist customers in achieving enhanced productivity, increased brazing quality, enhanced energy efficiency, and upgraded process safety.

- In February 2023, Aalberts Surface Technologies GmbH, a Germany-based global service provider specializing in surface treatments, heat treatments, and brazing, unveiled the formation of a new HIP, braze, and heat treatment business unit in the United States through a merger of two existing business units, Aalberts surface technologies – Specialized Heat Treatment US and Aalberts surface technologies – accurate brazing.

INFRARED BRAZING MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

9.7% |

|

Segments Covered |

By Metal, End Use Industry, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Aimtek, Inc. (United States), Morgan Advanced Materials (United Kingdom), Bodycote plc (United Kingdom), Johnson Matthey (United Kingdom), Bellman-Melcor (United States), Ipsen International Holding GmbH (Germany), L&L Special Furnace Co, Inc. (United States), SRA Solder (United States), Lucas-Milhaupt, Inc. (United States), Cupro Alloys Corporation (India) |

Global Infrared Brazing Market Segmentation:

Global Infrared Brazing Market Segmentation: By Metal

- Aluminum

- Copper

- Iron

- Magnesium

- Nickel

- Others

Based on the metal, the global infrared brazing market is segmented into aluminum, copper, iron, magnesium, nickel, and others. In 2022, the copper segment held the highest market share. The growth can be attributed to copper being the most ideal metal for making electrical connections, in comparison to other metals, as they provide high thermal and electrical conductivity and resistance to corrosion. It is also widely used in the applications of the automotive industry, such as car radiators, exhaust systems, and brake pads. Generally, copper is highly required for brazing nickel, copper-nickel, carbon steel, and stainless steel.

Due to the increasing demand for metal that possesses high-level properties, such as high thermal conductivity and lightweight, in the aerospace and defense industry, the aluminum segment is anticipated to expand at the quickest rate over the forecast period.

Global Infrared Brazing Market Segmentation: By End-Use Industry

- Automotive

- Aerospace & Defense

- Building & Construction

- Electronics & Electrical

- Marine

- Others

Based on the end-use industry, the global infrared brazing market is segmented into automotive, aerospace and defense, building and construction, electronics and electrical, marine, and others. In 2022, the electronics and electrical segment held the highest market share. The growth can be attributed to the increasing use of the infrared brazing process for joining thin and delicate electronics and electrical components, including semiconductors and sensors, that require precise and controlled heating to prevent damage or distortion. Additionally, infrared brazing is a highly preferred process for joining dissimilar metals and providing consistent and high-quality bonds, which further propels this segment's growth.

Due to the increasing demand for an efficient process for joining distinct metals with minimal distortion that can assist in producing high-quality engine conditioning systems and fuel systems, the automotive segment is anticipated to expand at the quickest rate over the forecast period.

Global Infrared Brazing Market Segmentation: By Region

- North America

- Europe

- Asia-Pacific

- Rest of the World

In 2022, the region of Asia-Pacific held the largest share of the global infrared brazing market. The growth can be attributed to the presence of large and well-established manufacturing facilities for infrared brazing specialized equipment, the rising capital expenditure of infrastructure development projects, and the increasing adoption of infrared brazing in the automotive, electronics and electrical, and aerospace industries. In addition, the region is home to several significant market players, including Hua Guang Welding, VBC Group Asia Pacific, Indian Solder and Brazing Alloys, Cupro Alloys Corporation, and Zhejiang Asia General Soldering and Brazing Material Co., Ltd.

Due to the presence of key market players, including Aimtek, Inc., Bellman-Melcor, and L&L Special Furnace Co, Inc., and the rising adoption of high-quality brazing processes for the production of critical components in the automotive and aerospace industries, the region of North America is anticipated to expand at the quickest rate over the forecast period.

Global Infrared Brazing Market Key Players:

- Aimtek, Inc. (United States)

- Morgan Advanced Materials (United Kingdom)

- Bodycote plc (United Kingdom)

- Johnson Matthey (United Kingdom)

- Bellman-Melcor (United States)

- Ipsen International Holding GmbH (Germany)

- L&L Special Furnace Co, Inc. (United States)

- SRA Solder (United States)

- Lucas-Milhaupt, Inc. (United States)

- Cupro Alloys Corporation (India)

Chapter 1. INFRARED BRAZING MARKET – Scope & Methodology

1.1. Market Segmentation

1.2. Assumptions

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. INFRARED BRAZING MARKET – Executive Summary

2.1. Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.3. COVID-19 Impact Analysis

2.3.1. Impact during 2023 – 2030

2.3.2. Impact on Supply – Demand

Chapter 3. INFRARED BRAZING MARKET – Competition Scenario

3.1. Market Share Analysis

3.2. Product Benchmarking

3.3. Competitive Strategy & Development Scenario

3.4. Competitive Pricing Analysis

3.5. Supplier - Distributor Analysis

Chapter 4. INFRARED BRAZING MARKET - Entry Scenario

4.1. Case Studies – Start-up/Thriving Companies

4.2. Regulatory Scenario - By Region

4.3 Customer Analysis

4.4. Porter's Five Force Model

4.4.1. Bargaining Power of Suppliers

4.4.2. Bargaining Powers of Customers

4.4.3. Threat of New Entrants

4.4.4. Rivalry among Existing Players

4.4.5. Threat of Substitutes

Chapter 5. INFRARED BRAZING MARKET - Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. INFRARED BRAZING MARKET – By Metal

6.1. Aluminum

6.2. Copper

6.3. Iron

6.4. Magnesium

6.5. Nickel

6.6. Others

Chapter 7. INFRARED BRAZING MARKET – By End-Use Industry

7.1. Automotive

7.2. Aerospace & Defense

7.3. Building & Construction

7.4. Electronics & Electrical

7.5. Marine

7.6. Others

Chapter 8. INFRARED BRAZING MARKET – By Region

8.1. North America

8.2. Europe

8.3.The Asia Pacific

8.4.Latin America

8.5. Middle-East and Africa

Chapter 9. INFRARED BRAZING MARKET – Company Profiles – (Overview, Product Portfolio, Financials, Developments)

9.1. Aimtek, Inc. (United States)

9.2. Morgan Advanced Materials (United Kingdom)

9.3. Bodycote plc (United Kingdom)

9.4. Johnson Matthey (United Kingdom)

9.5. Bellman-Melcor (United States)

9.6. Ipsen International Holding GmbH (Germany)

9.7. L&L Special Furnace Co, Inc. (United States)

9.8. SRA Solder (United States)

9.9. Lucas-Milhaupt, Inc. (United States)

9.10. Cupro Alloys Corporation (India)

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

Global Infrared Brazing Market is estimated to be worth USD 240.24 Million in 2022 and is projected to reach a value of USD 503.85 Million by 2030, growing at a CAGR of 9.7% during the forecast period 2023-2030.

The Global Infrared Brazing Market Drivers are the Rising Adoption of Brazing over Soldering and Welding and the Increasing Demand for Infrared Brazing in the Electronics and Electrical Industry.

Based on the Metal, the Global Infrared Brazing Market is segmented into Aluminum, Copper, Iron, Magnesium, Nickel, and Others.

China and India are the most dominating countries in the region of Asia-Pacific for the Global Infrared Brazing Market.

Aimtek, Inc., Morgan Advanced Materials, and Bodycote plc are the leading players in the Global Infrared Brazing Market.