Industrial Wireless Remote Control Market Size (2024 – 2030)

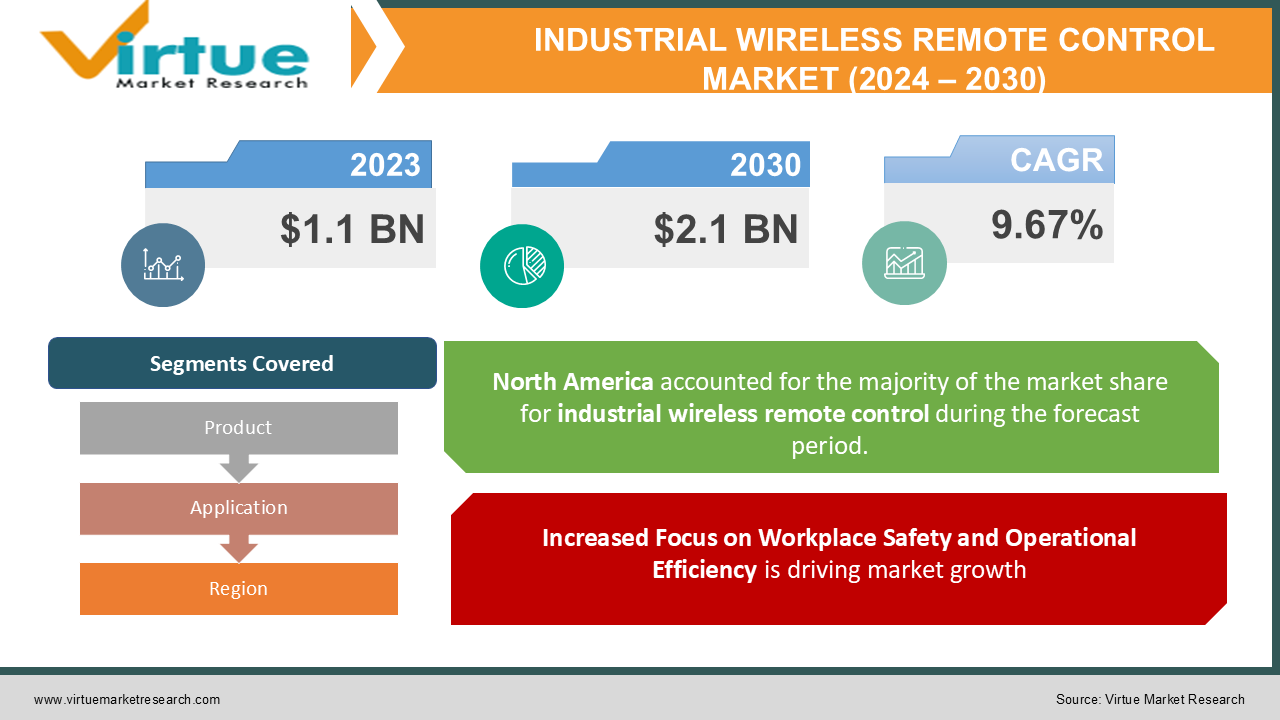

The Global Industrial Wireless Remote Control Market was valued at USD 1.1 billion in 2023 and will grow at a CAGR of 9.67% from 2024 to 2030. The market is expected to reach USD 2.1 billion by 2030.

The Industrial Wireless Remote Control Market focuses on wireless devices that enable the remote operation of machinery and equipment in industrial settings. These remote controls are designed to increase efficiency, safety, and flexibility in sectors such as manufacturing, construction, mining, and logistics. With the shift towards automation and increased demand for safety in hazardous environments, the adoption of wireless remote controls is expected to rise. This technology facilitates seamless communication between operators and machines without requiring direct contact, driving operational excellence and workplace safety.

Key Market Insights:

-

Manufacturing industries hold the largest market share as these are used for controlling cranes, hoists, and conveyors, thereby improving the operations' efficiency while reducing time and labor inputs.

-

Hazardous-location termination panel market in North America and Europe is the largest due to strict regulations from the beginning regarding automation solutions, where safe practices are strongly implemented. The Asia-Pacific region is growing rapidly due to infrastructure projects and industrial activities.

-

With new technologies, interference in signals and performance of the battery are being addressed with fewer interferences and smooth operations in industrial space.

-

Competition among the key players is a merger-acquisition type of activity along with introducing new products that propel an increased presence in developing economies like India, China, and Brazil.

Global Industrial Wireless Remote Control Market Drivers:

Increased Focus on Workplace Safety and Operational Efficiency is driving market growth: As industries become more safety-conscious, wireless remote controls are being integrated to ensure the safe operation of heavy machinery and equipment. In sectors like construction, mining, and logistics, where workers are exposed to hazardous environments, remote control devices enable operators to handle machines from a safe distance, significantly reducing the risk of accidents. Additionally, these remotes eliminate the need for wired setups, offering greater mobility and flexibility, which improves operational efficiency. Businesses are also increasingly adopting these solutions to meet stringent occupational safety standards and regulations, further driving demand.

Adoption of Automation and Industry 4.0 Practices is driving market growth: With the rise of Industry 4.0, which emphasizes digitalization and the use of smart technologies, industrial wireless remote controls are becoming an essential part of modern manufacturing setups. Automation solutions rely heavily on remote control systems to monitor and control machinery remotely. These wireless devices also allow integration with IoT platforms, enabling predictive maintenance, reducing downtime, and optimizing productivity. As factories move towards becoming smart factories, the need for reliable remote control systems is expected to rise significantly.

Increasing Infrastructure Development and Expansion of Industrial Operations are driving market growth: Emerging economies such as India, China, and Brazil are witnessing a surge in infrastructure projects, including construction, oil and gas, and transportation, which drives the demand for advanced remote control systems. Wireless remote controls are used extensively in cranes, excavators, and other heavy equipment to ensure precision handling and smooth operations. The expansion of industrial facilities in these regions also creates new opportunities for remote control providers, as businesses seek efficient ways to control and monitor machinery across vast industrial sites.

Global Industrial Wireless Remote Control Market Challenges and Restraints:

Technical Limitations and Signal Interference Issues are restricting market growth: One of the primary challenges faced by the industrial wireless remote control market is signal interference, which can occur due to the presence of electromagnetic fields, multiple wireless devices operating within the same frequency range, or environmental factors such as weather conditions. Signal loss or disruptions can lead to operational inefficiencies, especially in critical industrial applications where seamless communication is essential. Although manufacturers are focusing on developing more reliable technologies, ensuring uninterrupted connectivity across complex industrial environments remains a significant challenge.

High Initial Investment and Maintenance Costs are restricting market growth: Industrial wireless remote control systems often require significant initial investments, which can act as a restraint, especially for small and medium enterprises. These systems include not only remote control devices but also receivers, communication modules, and sometimes custom software solutions. Additionally, maintaining these systems requires periodic battery replacements and technical support to ensure smooth functioning. The cost associated with replacing or repairing malfunctioning components can also be high, deterring smaller companies from adopting these solutions.

Market Opportunities:

The industrial wireless remote control market presents several growth opportunities as industries continue to embrace automation and advanced control systems. One significant opportunity lies in the development of customized solutions tailored to specific industry needs. For example, mining operations require rugged remotes with long-range capabilities, while the manufacturing sector demands compact and user-friendly devices with precise control features. Companies offering tailored solutions are likely to gain a competitive edge in the market. Furthermore, the integration of wireless remote controls with cloud-based platforms and IoT ecosystems provides opportunities for enhanced functionality and data-driven decision-making. As businesses seek real-time monitoring and predictive maintenance, remote controls equipped with sensors and data analytics capabilities will play a vital role in the transition toward smart manufacturing. The increasing focus on sustainability also presents an opportunity for manufacturers to develop eco-friendly remote controls with energy-efficient designs and recyclable materials, aligning with global environmental initiatives.

INDUSTRIAL WIRELESS REMOTE CONTROL MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

9.67% |

|

Segments Covered |

By Product, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

HBC-radiometric, Cattron Group International, ABB Ltd., Telecrane, Hetronic Group, Schneider Electric SE, Ikusi, Conductix-Wampfler, Autec Safety Remote Control, Jay Electronique |

Industrial Wireless Remote Control Market Segmentation: By Product

-

Joystick Controls

-

Push Button Controls

-

Toggle Switch Controls

-

Touchscreen Controls

-

Others

Joystick controls are the most dominant segment, as they offer precise control over heavy machinery, especially in industries like construction, manufacturing, and mining. Their ergonomic design and ability to handle multi-axis movements make them essential for applications requiring fine-tuned operations.

Industrial Wireless Remote Control Market Segmentation: By Application

-

Manufacturing

-

Construction

-

Mining

-

Oil & Gas

-

Logistics & Warehousing

-

Others

The manufacturing sector is the most dominant application segment due to the widespread adoption of automation. Wireless remote controls are extensively used to manage conveyor belts, cranes, and robotic systems, enabling efficient and uninterrupted operations across production lines.

Industrial Wireless Remote Control Market Segmentation: By Region

-

North America

-

Asia-Pacific

-

Europe

-

South America

-

Middle East and Africa

North America holds the largest market share, driven by the high adoption of automation solutions, stringent safety regulations, and a well-established industrial base. The region's focus on enhancing operational efficiency and worker safety further contributes to the demand for industrial wireless remote control systems.

COVID-19 Impact Analysis on the Industrial Wireless Remote Control Market:

The COVID-19 pandemic ran deep through the industrial wireless remote control market, causing severe damage to supply chains and slowing down construction and manufacturing projects. However, the pandemic also highlighted how crucial this need for remote operation was, accelerating the spread of applications of wireless control solutions in various sectors. On-site human presence reduction became a strategic pillar of business organizations in efforts to curtail the spread of viruses. Operations intended to maintain business continuity thus became even more important since remote controls became essential tools. The pandemic encouraged many industries and sectors to reassess their operational strategies further to justify the point that businesses today needed more automation and contactless solutions. Besides making places safer for workers, the change pointed people's attention to some benefits of remote technology: it made things more efficient and productive. It is for this reason that the requirement for long-term wireless remote control systems increases and, above all, forms an integral part of modern operations within the industry. Companies are now looking to upgrade their safety measures and invest in high-tech technologies because such works can be undertaken safely from a distance. Investment has been made in anticipation of any future disruption thus making their operations stronger. Although embracing wireless technology does not present an immediate solution to the pressing health concerns, it places industries in a better position to exercise greater flexibility and innovation regarding the evolving challenges. In short, the pandemic may have precipitated the disruption of the industrial wireless remote control market as it has accelerated a more fundamental transformation toward operations that are utterly remote. The emphasis will be renewed on automation, safety, and contactless solutions. The future industrial facility will want these wireless control systems, and so demand for them will be sustained. Amidst all this change, wireless technology will continue to play a growing role in creating safer, more productive workplace conditions.

Latest Trends/Developments:

Industrial wireless remote control is changing significantly, driven by several key developments. Perhaps the most apparent of these developments has been 5G technology, which provides broader high-speed communication and lower latency rates. Potentially, this is a step into new connectivity that would enable the more precise control of complex machinery to pave the way to improved automation across industries. Another emerging trend has to do with the compact and modular design of remotes. They are supposed to be light and changeable with the required application. This factor of flexibility further contributes to good usability and promotes a wide range of applications in an industrial scenario. Alongside this, the industry is also seeing greater investment in research and development activities to overcome a few of the dilemmas like signal interference and battery performance. Manufacturers are continuing to produce and enhance the reliability and efficiency of wireless systems to ensure that they function and operate properly even in extreme conditions. Sustainability is another issue, as many companies strive to use the least harmful materials in their products. This aligns them with broader environmental goals and reflects rising consumer and regulatory pressure to create less damaging solutions. Furthermore, manufacturers of remote control devices increasingly cooperate with industrial automation companies. These partnerships would lead to the most comprehensive solutions of control, based on the best of both sectors, resulting in the final phases ultimately in more integrated and efficient systems. To sum up, this industrial wireless remote control market is developing rapidly under the influence of technological advancements, user-centric designs, and purposes of sustainability and strategic collaborations. These developments will make the remote controls not only more reliable but useful in their functionality at the same time, while equally positioning them as inevitable elements in the face of the future of industrial automation.

Key Players:

-

HBC-radiometric

-

Cattron Group International

-

ABB Ltd.

-

Telecrane

-

Hetronic Group

-

Schneider Electric SE

-

Ikusi

-

Conductix-Wampfler

-

Autec Safety Remote Control

-

Jay Electronique

Chapter 1. Industrial Wireless Remote Control Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Industrial Wireless Remote Control Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Industrial Wireless Remote Control Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Industrial Wireless Remote Control Market - Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Industrial Wireless Remote Control Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Industrial Wireless Remote Control Market – By Product

6.1 Introduction/Key Findings

6.2 Joystick Controls

6.3 Push Button Controls

6.4 Toggle Switch Controls

6.5 Touchscreen Controls

6.6 Others

6.7 Y-O-Y Growth trend Analysis By Product

6.8 Absolute $ Opportunity Analysis By Product, 2024-2030

Chapter 7. Industrial Wireless Remote Control Market – By Application

7.1 Introduction/Key Findings

7.2 Manufacturing

7.3 Construction

7.4 Mining

7.5 Oil & Gas

7.6 Logistics & Warehousing

7.7 Others

7.8 Y-O-Y Growth trend Analysis By Application

7.9 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. Industrial Wireless Remote Control Market , By Geography – Market Size, Forecast, Trends & Insights

8.1 North America

8.1.1 By Country

8.1.1.1 U.S.A.

8.1.1.2 Canada

8.1.1.3 Mexico

8.1.2 By Product

8.1.3 By Application

8.1.4 Countries & Segments - Market Attractiveness Analysis

8.2 Europe

8.2.1 By Country

8.2.1.1 U.K

8.2.1.2 Germany

8.2.1.3 France

8.2.1.4 Italy

8.2.1.5 Spain

8.2.1.6 Rest of Europe

8.2.2 By Product

8.2.3 By Application

8.2.4 Countries & Segments - Market Attractiveness Analysis

8.3 Asia Pacific

8.3.1 By Country

8.3.1.1 China

8.3.1.2 Japan

8.3.1.3 South Korea

8.3.1.4 India

8.3.1.5 Australia & New Zealand

8.3.1.6 Rest of Asia-Pacific

8.3.2 By Product

8.3.3 By Application

8.3.4 Countries & Segments - Market Attractiveness Analysis

8.4 South America

8.4.1 By Country

8.4.1.1 Brazil

8.4.1.2 Argentina

8.4.1.3 Colombia

8.4.1.4 Chile

8.4.1.5 Rest of South America

8.4.2 By Product

8.4.3 By Application

8.4.4 Countries & Segments - Market Attractiveness Analysis

8.5 Middle East & Africa

8.5.1 By Country

8.5.1.1 United Arab Emirates (UAE)

8.5.1.2 Saudi Arabia

8.5.1.3 Qatar

8.5.1.4 Israel

8.5.1.5 South Africa

8.5.1.6 Nigeria

8.5.1.7 Kenya

8.5.1.8 Egypt

8.5.1.9 Rest of MEA

8.5.2 By Product

8.5.3 By Application

8.5.4 Countries & Segments - Market Attractiveness Analysis

Chapter 9. Industrial Wireless Remote Control Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

9.1 HBC-radiometric

9.2 Cattron Group International

9.3 ABB Ltd.

9.4 Telecrane

9.5 Hetronic Group

9.6 Schneider Electric SE

9.7 Ikusi

9.8 Conductix-Wampfler

9.9 Autec Safety Remote Control

9.10 Jay Electronique

Download Sample

Choose License Type

2500

4250

5250

6900

Related Reports

Frequently Asked Questions

The Global Industrial Wireless Remote Control Market was valued at USD 1.1 billion in 2023 and is expected to grow to USD 2.1 billion by 2030, expanding at a CAGR of 10% from 2024 to 2030.

Key drivers include the focus on workplace safety, the adoption of automation, and the rise of Industry 4.0 practices, along with growing infrastructure development.

The market is segmented by Product (Joystick Controls, Push Button Controls, Toggle Switch Controls, Touchscreen Controls, Others) and by Application ( Manufacturing, Construction, Mining, Oil & Gas, Logistics & Warehousing, Others).

North America is the most dominant region due to high automation adoption and stringent safety regulations.

Key players include HBC-radiomatic, Cattron Group International, ABB Ltd., Telecrane, and Schneider Electric SE.