Hydraulic Force Transducer Market Size (2024 – 2030)

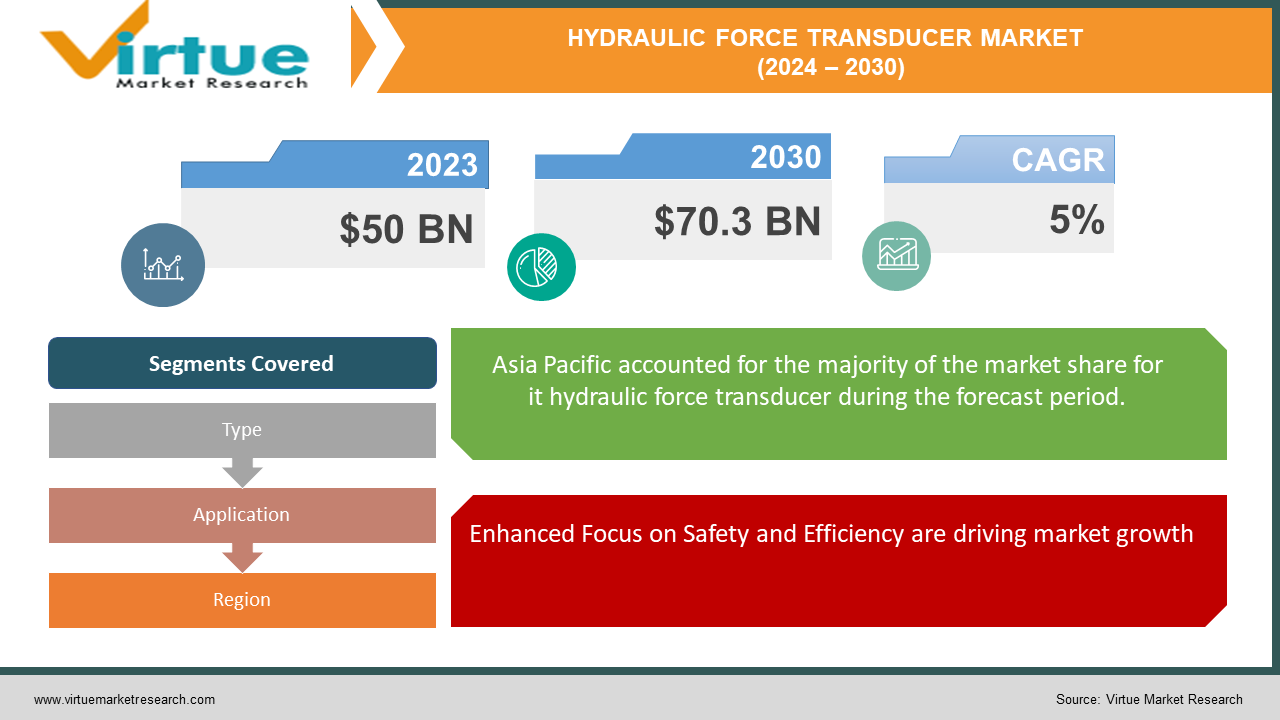

The Global Hydraulic Force Transducer Market was valued at USD 50 billion in 2023 and will grow at a CAGR of 5% from 2024 to 2030. The market is expected to reach USD 70.3 billion by 2030.

The Hydraulic Force Transducer market deals with sensors that convert applied force into a hydraulic pressure signal. Used in various industries like construction and testing, this market is expected to grow alongside the overall hydraulics market, reaching a size of $70 billion by 2030.

Key Market Insights:

The growth trajectory of the Hydraulic Force Transducer market is expected to mirror the growth of its parent markets, with a CAGR potentially ranging from 3.2% to 5.6%.

Increasing automation in manufacturing and construction industries is driving demand for precise force measurement solutions.

Growing focus on safety and efficiency in industrial processes necessitates accurate monitoring of hydraulic systems.

The development of miniaturized and cost-effective force transducers is expanding their application range.

North America, Europe, and Asia Pacific are expected to remain the dominant markets due to established industrial infrastructure and growing automation trends.

Emerging economies like China and India are expected to witness significant growth due to rising industrial investments.

The Hydraulic Force Transducer market size would reach USD 70 billion within the next few years.

Global Hydraulic Force Transducer Market Drivers:

Rising Automation in Manufacturing and Construction are driving market growth:

The surge of automation in manufacturing and construction necessitates highly precise force measurement solutions. Hydraulic force transducers rise to this challenge by delivering accurate data on the forces exerted by machinery, robots, and other automated systems. This information is an essential key that unlocks a treasure trove of benefits. By providing real-time insights into the exact forces being applied, manufacturers can optimize processes for peak efficiency, minimizing wasted materials and energy. Additionally, this data allows for the fine-tuning of automated systems, leading to a consistent and superior quality of products being produced. Furthermore, the ability to monitor forces translates to enhanced safety in the workplace. By identifying potential overloads or imbalances before they occur, accidents and equipment damage can be prevented, creating a safer environment for workers. In essence, hydraulic force transducers act as the silent guardians of automation, ensuring efficient, high-quality production while safeguarding the well-being of those on the factory floor.

Enhanced Focus on Safety and Efficiency are driving market growth:

Industrial processes are undergoing a paradigm shift, prioritizing both safety and efficiency. Hydraulic systems, the workhorses of many industries, demand meticulous monitoring to prevent accidents and costly downtime. Here's where hydraulic force transducers step in as silent saviors. These ingenious sensors provide real-time data on pressure and force within hydraulic circuits, acting like vigilant sentries. Imagine a sophisticated nervous system for your hydraulic equipment. By constantly monitoring these vital signs, potential issues are identified before they snowball into major problems. A slight pressure fluctuation or an unexpected surge in force could signal a leak, component wear, or even an impending equipment failure. With this early warning system, corrective actions can be taken promptly, preventing catastrophic breakdowns and safeguarding personnel. The benefits extend beyond immediate safety concerns. By pinpointing inefficiencies within the system, such as excessive pressure drops or unnecessary force exertion, optimizations can be made. This translates to smoother operation, reduced energy consumption, and ultimately, a more streamlined and cost-effective production process. In essence, hydraulic force transducers are the key to unlocking a win-win situation for industrial safety and efficiency.

Advancements in Technology are driving market growth:

The miniaturization and cost reduction of hydraulic force transducers are revolutionizing the way we measure force. Traditionally, these sensors were bulky and expensive, limiting their use to specific industrial applications. However, recent advancements have shrunk their size and brought down their price tag, opening doors to a whole new world of possibilities. These compact and affordable sensors can now be easily integrated into a broader range of machinery and equipment, from delicate robotics to complex construction vehicles. This expanded application range fuels significant market growth. In the medical field, for instance, miniaturized force transducers can be incorporated into surgical tools, providing surgeons with real-time feedback on the pressure applied to delicate tissues. Similarly, the automotive industry can benefit from these sensors by embedding them into car suspension systems, enabling engineers to optimize ride comfort and handling. The possibilities are truly endless, as miniaturized and cost-effective hydraulic force transducers pave the way for more precise force measurement across various sectors, ultimately leading to improved product design, enhanced process control, and a new era of data-driven innovation.

Global Hydraulic Force Transducer Market challenges and restraints:

Fluctuations in Raw Material Prices are a significant hurdle for Hydraulic Force Transducer:

The Global Hydraulic Force Transducer Market faces a tightrope walk due to the fluctuating prices of raw materials. Manufacturing these sensors relies heavily on steel, aluminum, and electronic components. When the prices of these materials experience volatility, it creates a ripple effect throughout the production chain. Manufacturers grapple with absorbing these cost increases entirely. If they can't shoulder the burden, they're forced to raise the prices of the transducers themselves. This price hike can be a double-edged sword. While it ensures they maintain profitability, it can also deter potential customers, especially those in cost-sensitive industries. To mitigate this challenge, manufacturers are constantly seeking innovative solutions. This could involve exploring alternative materials with more stable pricing, optimizing production processes to minimize material waste, or implementing strategic partnerships with raw material suppliers to secure more favorable pricing agreements. Ultimately, navigating the volatility of raw material prices requires a delicate balancing act between profitability and market competitiveness.

Stringent Regulations and Safety Standards are throwing a curveball at the Hydraulic Force Transducer market:

The ever-changing landscape of regulations and safety standards throws a curveball at manufacturers of hydraulic force transducers. While these regulations are crucial for ensuring safe and reliable equipment, adhering to them can be a complex and costly endeavor. To comply with the latest requirements, manufacturers often need to invest heavily in research and development (R&D). This involves redesigning or modifying existing sensors to meet the new standards, a process that can be time-consuming and resource-intensive. Additionally, rigorous testing procedures become necessary to demonstrate that the transducers meet the specified safety benchmarks. These tests add another layer of complexity and cost to the production process. The combined effect can be a decrease in production efficiency and a potential rise in manufacturing costs. Manufacturers are constantly seeking ways to navigate this challenge. Some strategies include implementing modular designs that can be easily adapted to meet changing regulations or collaborating with regulatory bodies during the development phase to ensure compliance from the outset. By being proactive and innovative, manufacturers can overcome the hurdles posed by evolving regulations while still delivering safe and reliable hydraulic force transducers.

Competition is a growing nightmare for Hydraulic Force Transducer:

New entrants in the hydraulic force transducer market face an uphill battle due to the dominance of established players in the broader force sensor market. These well-known brands have already carved out a significant chunk of the market share, making it challenging for newcomers to gain a foothold. The established players benefit from brand recognition, extensive distribution networks, and a loyal customer base. They can leverage these advantages to secure lucrative contracts and maintain their market position. New entrants need to be strategic in their approach to carve out their niche. This could involve focusing on specific industries or applications that are underserved by existing players. Innovation is also key. Developing unique features or functionalities that differentiate their transducers from the competition can attract customers seeking cutting-edge solutions. Additionally, offering competitive pricing and exceptional customer service can help them build a loyal following and gradually capture market share. Ultimately, success in this crowded landscape hinges on a combination of strategic differentiation, innovation, and a commitment to exceeding customer expectations.

Market Opportunities:

The Global Hydraulic Force Transducer Market presents a compelling landscape brimming with opportunities. Fueled by the rising tide of automation in manufacturing and construction, the demand for precise force measurement solutions is propelling market growth. Miniaturization and cost reduction of these sensors are acting as game-changers, expanding their application range to delicate medical equipment, complex construction vehicles, and even car suspension systems. This newfound accessibility across diverse industries is a key driver. Additionally, the growing emphasis on safety and efficiency in industrial processes creates a fertile ground for hydraulic force transducers. Their ability to provide real-time data on pressure and force within hydraulic circuits empowers proactive maintenance, preventing accidents, costly downtime, and optimizing energy consumption. Furthermore, the integration of these sensors with the Internet of Things (IoT) unlocks a treasure trove of possibilities. By enabling remote data collection and analysis, industries can achieve enhanced process control, implement predictive maintenance strategies, and make data-driven decisions for continuous improvement. The burgeoning robotics sector presents another lucrative opportunity. Hydraulic force transducers play a vital role in ensuring the smooth and precise operation of robotic arms by providing accurate force feedback, leading to improved product quality and production efficiency. Even stringent regulations, which necessitate the monitoring of forces exerted by machinery, can be viewed as an opportunity. By providing reliable and accurate force measurement solutions, hydraulic force transducer manufacturers can cater to this growing demand and ensure compliance for their clients. However, challenges like fluctuating raw material prices and ever-evolving regulations require innovative solutions. By navigating these hurdles and capitalizing on the vast opportunities presented by automation, safety concerns, technological advancements, and Industry 4.0 integration, the Global Hydraulic Force Transducer Market is poised for a robust and promising future.

HYDRAULIC FORCE TRANSDUCER MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

5% |

|

Segments Covered |

By Type, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

TE Connectivity, Honeywell International Inc., Sensata Technologies, Inc., Flintec, Kistler Instrument Corporation, Setra Systems, Inc. (Fortive), Omega Engineering Inc., Xmtronic, Burster Präzisionsmesstechnik GmbH & Co. KG, Druck (Parker Hannifin Corporation) |

Hydraulic Force Transducer Market segmentation - By Type

-

Piezoelectric

-

Strain Gauge

While both Piezoelectric and Strain Gauge transducers are important players in the Hydraulic Force Transducer Market, Strain Gauge currently holds the dominant position. This is due to their versatility: they offer high accuracy across a wide range of force measurements, making them suitable for diverse applications in manufacturing, construction, oil & gas, and more. Piezoelectric transducers, known for their fast response times, excel in measuring dynamic forces but may have limitations in terms of force range. However, as technology advances, Piezoelectric transducers could gain traction in specific applications requiring high-speed force measurement.

Hydraulic Force Transducer Market segmentation - By Application

-

Manufacturing

-

Construction

Deciding the most prominent sector between Manufacturing and Construction in the Hydraulic Force Transducer Market is difficult as both hold significant weight. However, Manufacturing currently has a slight edge due to its wider range of applications. While construction is a vital sector, the sheer volume and variety of force measurement needs within manufacturing currently position it as the more prominent user of hydraulic force transducers.

Hydraulic Force Transducer Market segmentation - Regional Analysis

-

North America

-

Asia-Pacific

-

Europe

-

South America

-

Middle East and Africa

Among the listed regions, Asia Pacific is expected to be the dominant market for the Hydraulic Force Transducer Market. This dominance is fueled by a confluence of factors. Firstly, established industrial infrastructure in countries like China and Japan creates a strong demand for these sensors in various sectors like manufacturing and construction. Secondly, the rapid growth of automation across these industries further amplifies the need for precise force measurement solutions. Finally, with rising disposable incomes and increasing investments in infrastructure development, South Korea and India are also expected to contribute significantly to the regional market growth. While North America and Europe currently hold a sizeable market share due to their well-developed industrial sectors, Asia Pacific's growth trajectory is projected to surpass them in the coming years.

COVID-19 Impact Analysis on the Global Hydraulic Force Transducer Market

The COVID-19 pandemic cast a shadow on the Global Hydraulic Force Transducer Market, disrupting supply chains and hindering growth. Lockdowns and travel restrictions hampered the production and transportation of raw materials and finished transducers. Additionally, the temporary shutdown of manufacturing and construction activities across the globe led to a decline in demand for these sensors. However, the impact wasn't uniform. While some industries like automotive and aerospace witnessed a significant slowdown, sectors like medical devices and essential manufacturing continued operations, creating a pocket of stability for the market. As economies recover and industrial activities resume, the demand for hydraulic force transducers is expected to bounce back. The growing emphasis on automation and Industry 4.0 advancements are likely to propel market growth in the long run. However, challenges like fluctuating raw material prices and stricter regulations persist. Overall, the COVID-19 pandemic caused a temporary setback, but the underlying drivers of automation, safety, and efficiency remain strong, positioning the Global Hydraulic Force Transducer Market for a gradual recovery and future expansion.

Latest trends/Developments

The Hydraulic Force Transducer Market is experiencing a wave of exciting developments fueled by advancements in technology and the growing prominence of automation. Miniaturization is a key trend, with manufacturers developing compact and cost-effective sensors that cater to a wider range of applications. This opens doors for integration into delicate medical equipment, complex construction machinery, and even car suspension systems. Additionally, the marriage of hydraulic force transducers with the Internet of Things (IoT) is unlocking new possibilities. By enabling real-time remote data collection and analysis, industries can achieve enhanced process control, implement predictive maintenance strategies, and leverage data-driven insights for continuous improvement. Furthermore, the burgeoning field of robotics presents a lucrative opportunity. Miniaturized and high-precision hydraulic force transducers play a vital role in ensuring the smooth and precise operation of robotic arms by providing accurate force feedback, leading to improved product quality and production efficiency. The market is also witnessing a rise in wireless and battery-powered transducers, offering greater flexibility and ease of use in field applications. As research and development efforts intensify, the future holds promise for even more sophisticated sensors with improved accuracy, faster response times, and enhanced connectivity capabilities, paving the way for a future where precise force measurement empowers a new era of automation and data-driven innovation across various industries.

Key Players:

-

TE Connectivity

-

Honeywell International Inc.

-

Sensata Technologies, Inc.

-

Flintec

-

Kistler Instrument Corporation

-

Setra Systems, Inc. (Fortive)

-

Omega Engineering Inc.

-

Xmtronic

-

Burster Präzisionsmesstechnik GmbH & Co. KG

-

Druck (Parker Hannifin Corporation)

Chapter 1. Hydraulic Force Transducer Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Hydraulic Force Transducer Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Hydraulic Force Transducer Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Hydraulic Force Transducer Market - Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Hydraulic Force Transducer Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Hydraulic Force Transducer Market – By Type

6.1 Introduction/Key Findings

6.2 Piezoelectric

6.3 Strain Gauge

6.4 Y-O-Y Growth trend Analysis By Type

6.5 Absolute $ Opportunity Analysis By Type, 2024-2030

Chapter 7. Hydraulic Force Transducer Market – By Application

7.1 Introduction/Key Findings

7.2 Manufacturing

7.3 Construction

7.4 Y-O-Y Growth trend Analysis By Application

7.5 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. Hydraulic Force Transducer Market , By Geography – Market Size, Forecast, Trends & Insights

8.1 North America

8.1.1 By Country

8.1.1.1 U.S.A.

8.1.1.2 Canada

8.1.1.3 Mexico

8.1.2 By Type

8.1.3 By Application

8.1.4 Countries & Segments - Market Attractiveness Analysis

8.2 Europe

8.2.1 By Country

8.2.1.1 U.K

8.2.1.2 Germany

8.2.1.3 France

8.2.1.4 Italy

8.2.1.5 Spain

8.2.1.6 Rest of Europe

8.2.2 By Type

8.2.3 By Application

8.2.4 Countries & Segments - Market Attractiveness Analysis

8.3 Asia Pacific

8.3.1 By Country

8.3.1.1 China

8.3.1.2 Japan

8.3.1.3 South Korea

8.3.1.4 India

8.3.1.5 Australia & New Zealand

8.3.1.6 Rest of Asia-Pacific

8.3.2 By Type

8.3.3 By Application

8.3.4 Countries & Segments - Market Attractiveness Analysis

8.4 South America

8.4.1 By Country

8.4.1.1 Brazil

8.4.1.2 Argentina

8.4.1.3 Colombia

8.4.1.4 Chile

8.4.1.5 Rest of South America

8.4.2 By Type

8.4.3 By Application

8.4.4 Countries & Segments - Market Attractiveness Analysis

8.5 Middle East & Africa

8.5.1 By Country

8.5.1.1 United Arab Emirates (UAE)

8.5.1.2 Saudi Arabia

8.5.1.3 Qatar

8.5.1.4 Israel

8.5.1.5 South Africa

8.5.1.6 Nigeria

8.5.1.7 Kenya

8.5.1.8 Egypt

8.5.1.9 Rest of MEA

8.5.2 By Type

8.5.3 By Application

8.5.4 Countries & Segments - Market Attractiveness Analysis

Chapter 9. Hydraulic Force Transducer Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

9.1 TE Connectivity

9.2 Honeywell International Inc.

9.3 Sensata Technologies, Inc.

9.4 Flintec

9.5 Kistler Instrument Corporation

9.6 Setra Systems, Inc. (Fortive)

9.7 Omega Engineering Inc.

9.8 Xmtronic

9.9 Burster Präzisionsmesstechnik GmbH & Co. KG

9.10 Druck (Parker Hannifin Corporation)

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Global Hydraulic Force Transducer Market was valued at USD 50 billion in 2023 and will grow at a CAGR of 5% from 2024 to 2030. The market is expected to reach USD 70.3 billion by 2030.

Rising Automation in Manufacturing and Construction, Enhanced Focus on Safety and Efficiency, and Advancements in Technology are the reasons that are driving the market.

Based on Application it is divided into two segments – Manufacturing, Construction.

Asia Pacific is the most dominant region for the Market.

TE Connectivity, Honeywell International Inc., Sensata Technologies, Inc., Flintec, Kistler Instrument Corporation.