Gunnable Sealant Market Size (2024 – 2030)

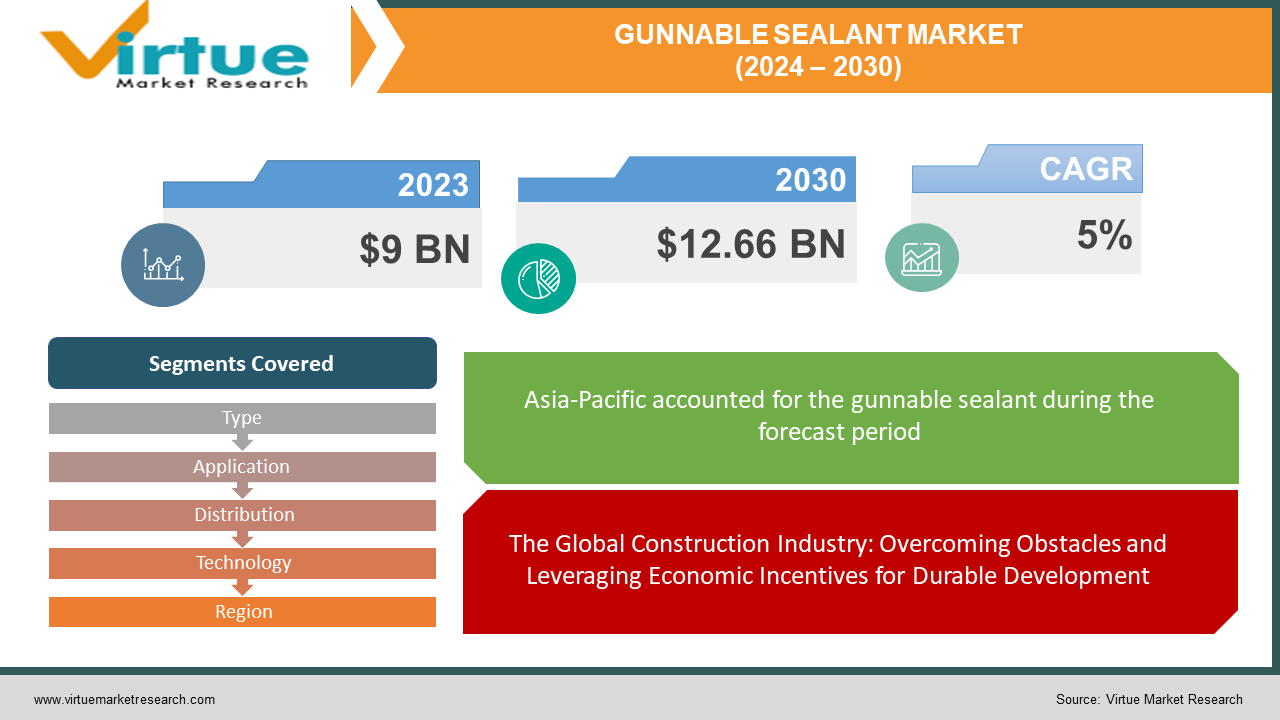

The global gunnable sealant market was valued at USD 9 billion in 2023 and is projected to reach a market size of USD 12.66 billion by the end of 2030. Over the forecast period of 2024–2030, the market is expected to grow at a CAGR of 5%.

Within the larger sealant industry, the gunnable sealant market is a crucial segment that serves a variety of applications in the construction, automotive, and other industries. One notable feature of gunnable sealants is their easy application with caulking guns, which makes them adaptable options for caulking joints and gaps in different kinds of structures. By stopping the infiltration of air and water, these sealants are essential in the construction industry for increasing the longevity of buildings. They are used on joints in buildings, bridges, and other structures, enhancing overall structural integrity and energy efficiency.

With constant R&D efforts focused on enhancing product performance and broadening application possibilities, sealant technologies are always evolving, adding to the market's vibrancy.

Key Market Insights:

The worldwide market for gunnable sealants offers important information about a sector of the economy that is essential to the automotive and construction sectors. Sealants that can be applied with caulking guns are known as gunnable sealants, and they are widely used to seal joints and gaps to stop the ingress of air and water. Growing consumer demand for low-VOC and ecologically friendly sealants is a noteworthy trend in the market that is consistent with the industry's broader emphasis on sustainability. The regional variations in construction activities and infrastructure development impact the dynamics of the gunnable sealant market, causing fluctuations in demand in various geographic regions.

When it comes to new product innovation, the market is seeing a shift towards specialty and high-performance sealants that cater to particular needs across a range of industries. The constant advancement of sealant technologies is a reflection of ongoing efforts to improve product functionality and meet a variety of application needs. Stakeholders and investors must remain up-to-date on the most recent advancements, market trends, and regional dynamics.

Market Drivers:

The Global Construction Industry: Overcoming Obstacles and Leveraging Economic Incentives for Durable Development.

Global economic growth has been significantly influenced by the building and construction sector, which grew steadily. Increased demand for single-family homes and heightened global economic activity were the main drivers of this growth. A major component of this industry is the construction boom, which is driven by several factors. The demand for construction projects has been fuelled by the increase in economic activity, especially in areas like Europe, North America, and the Asia-Pacific region. The governments of these areas have enacted financial assistance programs, like Australia's Homebuilder Programme and the EU's economic recovery plans, to boost construction-related economic activity. With the largest volume of construction activities, the Asia-Pacific region is particularly noteworthy as a construction powerhouse. Nations such as China, India, Japan, Indonesia, and South Korea make substantial contributions because of their large populations, rapid urbanization, and substantial infrastructure development investments. Up until 2028, this region is predicted to continue to have the biggest construction market.

Transformative Technology: Using BIM, drones, robotics, and 3D printing to revolutionize the construction industry.

A new era of efficiency and innovation in the construction industry has been brought about by technological advancements that have fundamentally changed traditional construction practices. The widespread use of Building Information Modeling (BIM), which offers a digital platform for cooperative project planning, design, and management, is an important development. Site surveying and monitoring have been completely transformed by the use of drones and aerial imaging, which provide high-resolution maps and 3D models that improve construction management and project analysis. Technological advancements have benefited prefabrication and modular construction, as off-site manufacturing shortens construction schedules without sacrificing quality standards

Furthermore, additive manufacturing, also known as 3D printing, is becoming more and more popular. It makes it possible to create entire buildings or just building components with less wasteful material usage and more design flexibility. Together, these technological advancements are pushing the construction sector towards increased digitization, sustainability, and efficiency. The industry experiences improvements in project outcomes as it adopts these innovations, but it also goes through a paradigm shift that creates a

Eco-Conscious Construction: Illuminating the Path to Energy Efficiency with Smart Technology and Sustainable Materials.

With the world attempting to achieve sustainable development and grappling with environmental issues, energy efficiency in the construction sector has taken on paramount importance. Building design, material, and technology advancements are major factors in construction projects reaching higher energy efficiency levels. The incorporation of smart building systems, which optimize energy consumption through real-time monitoring and control, is one noteworthy feature. These systems make sure that the HVAC (heating, ventilation, and air conditioning) systems run as efficiently as possible and react to occupancy and environmental changes dynamically by using sensors, automation, and data analytics. As energy codes and standards continue to evolve globally, the construction industry's commitment to energy efficiency not only supports environmental objectives but also demonstrates an understanding of the financial advantages connected with lower energy consumption and operating costs over a building's lifetime.

Market Restraints and Challenges:

Navigating Market Volatility: The construction industry's struggle with escalating raw material costs.

Growing raw material costs are a persistent problem for the construction sector, as they have a big impact on the viability and economics of projects. Many factors contribute to the price volatility of important building materials, such as steel, concrete, and timber. Raw material prices are erratic due to a combination of factors such as demand fluctuations, geopolitical tensions, and global market dynamics. For example, supply chain disruptions, trade tensions, and changes in global demand can all impact iron ore prices, which can have a significant impact on the steel industry. The cost of transportation, aggregates, and cement affects the price of concrete and is affected by variables like fuel prices and infrastructure development. Factors such as forest management practices have an impact on timber prices.

Construction Challenges Unveiled: The Complex Landscape of Project Delays and Strategies for Timely Mitigation.

In the construction industry, there is always a risk of project delays due to various factors that can cause meticulously planned project schedules to be upset. Unexpected events, like bad weather, geological difficulties, or unforeseen site conditions, frequently cause delays in construction projects. For example, inclement weather can cause delays and disruptions to construction projects, especially those that are conducted outdoors. Unexpected ground conditions or unstable soil are examples of geotechnical problems that may require modifying the construction strategy and delaying the intended stages of the project. Furthermore, unforeseen difficulties that arise during construction, like the discovery of hazardous materials or unanticipated structural problems, might necessitate extra time for in-depth analyses and remedial actions. Construction project delays can have a domino effect that impacts not only.

Market Opportunities:

Sealing Success: Gunnable sealants have become the main event in the global renaissance of infrastructure.

Global infrastructure projects, which cover a range of industries including energy, telecommunications, transportation, and urban development, are a major force behind economic expansion and development. Large-scale infrastructure projects have increased dramatically in recent years all over the world, especially in emerging economies. The aforementioned projects seek to cater to the increasing needs of rapidly urbanizing populations, improve connectivity, and invigorate the economy. To promote better accessibility and connectedness, for example, significant transportation infrastructure projects include building highways, bridges, and transit systems. Building power plants, renewable energy facilities, and transmission networks are all part of energy infrastructure projects that aim to supply the growing electricity demand. Urban development initiatives also prioritize building smart cities with cutting-edge infrastructure for sustainable living. Taking part in international infrastructure projects offers many benefits.

Eco-Seals: Transforming construction with sustainable formulations of gunnable sealants.

When it comes to gunnable sealants, sustainable formulations represent a major shift towards low-impact and ecologically friendly solutions in the construction sector. The need for sealants with the least amount of ecological impact has grown as environmental consciousness and laws continue to gain traction. The primary goal of sustainable gunnable sealant formulations is to lower emissions of volatile organic compounds (VOCs) to comply with environmental regulations and improve indoor air quality. Producers are investigating renewable and bio-based raw materials, like plant-based resins, to make sealants that are more eco-friendly at every stage of their lives.

In addition to lowering volatile organic compounds (VOCs), sustainable gunnable sealant formulations frequently include recyclable or biodegradable materials, highlighting the significance of circular economy ideas.

GUNNABLE SEALANT MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

5% |

|

Segments Covered |

By Type, Application, Distribution, Technology, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

3M, Sika AG, Soudal Holding N.V., Henkel AG & Co. KGaA, RPM International, Inc., Bostik SA, Huntsman International, H.B. Fuller, DowDuPont, Akzo Nobel |

Gunnable Sealant Market Segmentation: By Type

-

Silicone Sealants

-

Polyurethane Sealants

-

Polysulfide Sealants

-

Acrylic Sealants

-

Epoxy Sealants

-

Hybrid Sealants

Due to their extreme temperature resistance and durability, silicone sealants are widely used in automotive, electronic, and construction applications making it the most dominant segment in 2023. They work well for caulking gaps and joints in a variety of materials because of their exceptional adherence and flexibility. Conversely, polyurethane sealants, which are renowned for their adaptability, provide robust adherence to an extensive variety of substrates. They are popular in the automotive and construction industries because of their resistance to chemicals and weathering, which makes them suitable for both indoor and outdoor applications.

Due to their exceptional chemical resistance and longevity, polysulfide sealants are frequently utilized and are anticipated to be the fastest-growing segment during 2024-2030. They can be used to seal joints in important structures because of their resistance to fuels, oils, and adverse weather. Because they are inexpensive and simple to use, acrylic sealants are useful for general-purpose sealing applications where paintability and flexibility are crucial. On the other hand, epoxy sealants are frequently utilized in manufacturing and construction for applications needing structural integrity because of their strong bonding properties.

Gunnable Sealant Market Segmentation: By Application

-

Automotive

-

Construction

-

Aerospace and Defense

-

Electronics

-

Marine

-

Electrical

-

Medical

-

Others

Gunnable sealants are essential to the assembly and sealing of automotive components, which enhances the longevity and functionality of vehicles. These sealants are used to ensure the longevity and structural integrity of automotive structures by bonding windscreens, sealing seams, and stopping leaks. Gunnable sealants are widely used in the construction sector to seal joints and gaps in structures such as bridges, buildings, and infrastructure projects. These sealants support overall structural integrity, weatherproofing, and energy efficiency. Gunnable sealants are essential for keeping built structures functional and long-lasting, whether they are used in expansion joints, window installations, or general construction applications. Gunnable sealants are also used in the aerospace and defense industries, where they are employed to seal vital parts of defense systems and aircraft. The numerous uses of gunnable sealants in electronics, marine, electrical, medical, and other industries demonstrate the versatility and importance of these sealing solutions in a variety of fields.

Gunnable Sealant Market Segmentation: By Distribution

-

Retail stores

-

Online platforms

-

Specialized distributors

Customers can interact with and assess the Gunnabale Sealant products in person before purchasing physical sites ranging in size from large home improvement stores to neighborhood hardware stores. It is important to reach local customers who might prefer in-person sales and the chance to examine the sealant's quality, and this traditional distribution method aids in doing so.

Concurrently, the online platform sector recognizes the growing trend of consumers selecting digital channels. The market makes Gunnabale Sealant products available on e-commerce websites like Amazon and Home Depot's website, taking advantage of the convenience of online shopping. Customers now have more options and may purchase from the comfort of their homes because of this channel. The specialized distributor's channel also targets experts in the building sector because distributors in this category possess a deeper comprehension of the product and its uses. By employing this tactic, Gunnabale Sealant will be able to more effectively reach and support contractors and builders who require specific knowledge and a reliable supplier of high-quality sealant for their projects. Through the implementation of this varied distribution strategy, the market could reach its maximum potential.

Gunnable Sealant Market Segmentation: By Technology

-

Water-Based Sealants

-

Solvent-Based Sealants

-

Hot-Melt Sealants

-

Reactive Sealants

-

UV-Curable Sealants

-

Pressure-Sensitive Sealants

Water-based sealants are a more environmentally friendly option since they often contain fewer volatile organic compounds (VOCs) and are simpler to clean up after. This technique works better in applications like interior design and residential construction, where sustainability is a primary consideration. Conversely, solvent-based sealants are renowned for their strong bonding capabilities and ability to withstand adverse weather conditions. They are therefore regularly employed in demanding building projects. These sealants are effective in outdoor environments where a durable, robust seal is necessary.

Hot melt sealants are a different market segment that stands out due to their thermoplastic qualities, which allow them to be applied molten. Because of its exceptional adhesive properties and quick setting time, this technology is well-known in several industries, including the automotive and packaging sectors. Because reactive sealants undergo a chemical reaction to achieve their ultimate cured form, they have outstanding bonding strength and endurance. This method is frequently used in demanding industries like aerospace and automotive. UV-curable sealants are perfect for applications where quick turnaround times are crucial because they cure quickly when exposed to ultraviolet light. Lastly, tapes, labels, and temporary bonding are a few uses for pressure-sensitive sealants, which are distinguished by their capacity to stick to surfaces with incredibly low pressure. The gunnable sealant market offers a wide range of technologies that allow customized solutions for different sectors and uses.

Gunnable Sealant Market Segmentation: By Region

-

North America

-

Europe

-

Asia-Pacific

-

South America

-

Middle East and Africa

The demand for gunnable sealants is concentrated in the Asia-Pacific region, which holds a dominant share of 58% of the market in 2023. This is reflected in the distribution of market share by region. Due to the region's rapid industrialization, infrastructure development, and urbanization, the construction and manufacturing industries in Asia Pacific are growing and account for a significant portion of the market. The strong demand for gunnable sealants is largely driven by nations like China and India, whose infrastructure projects are receiving more attention than ever before. The region's expanding automobile industry and rising awareness of sealant applications across a range of industries support Asia Pacific's leadership in the market.

With a 19% market share in 2023, the demand for high-performance sealing solutions from the construction industry in North America has an impact on the use of gunnable sealants. These sealants are in constant demand in the region for use in infrastructure, commercial, and residential projects. Their dependability and versatility make them ideal for successful sealing applications. Building operations, particularly in developed economies, are the primary driver of gunnable sealant demand in Europe, where the product has a 16% market share. The European market is distinguished by its emphasis on energy-efficient and sustainable construction methods, which has resulted in a rising utilization of sophisticated sealant solutions. With shares of 4% and 2%, respectively, South America and the Middle East and Africa (MEA) regions show growth prospects, albeit on a smaller scale, driven by ongoing construction projects and

COVID-19 Impact Analysis on the Global Gunnable Sealant Market:

The COVID-19 pandemic has caused difficulties and disruptions in the industry, which has had a significant effect on the gunnable sealant market. Lockdowns, restrictions, and economic uncertainty brought about by the pandemic caused project delays, supply chain disruptions, and labor shortages in the construction industry, a significant user of gunnable sealants. During the early stages of the pandemic, there was less of a need for gunnable sealants because construction projects were postponed or stopped. The availability of raw materials was also impacted by disruptions in the global supply chain, which led to price fluctuations and had an effect on the overall production and distribution of gunnable sealants.

Conversely, as economies have progressively recovered and construction has started up again, there is a growing need for gunnable sealants. Many industries, such as healthcare and public infrastructure, are focusing on hygiene and safety, which has raised awareness of the significance of good sealing solutions. Additionally, the pandemic has accelerated the adoption of energy- and sustainably-efficient building techniques, which has an impact on sealant selection. The market for gunnable sealants is changing as a result of shifting market dynamics and industry priorities. Manufacturers and other stakeholders are developing strategies to deal with the pandemic's challenges while also looking for new opportunities.

Latest Trends/Developments:

A significant development in the post-pandemic aftermath has been the deliberate utilization of the construction sector to foster economic recuperation. Support programs have been put in place by nations in Europe, North America, and the Asia-Pacific region. Examples include the Homebuilder Programme in Australia and economic recovery plans in EU member states. These programs use the building industry as a major engine to jump-start economic cycles, generate jobs, and stimulate the economy. The industry's crucial role in the general economic well-being of nations is highlighted by its flexibility and responsiveness to economic challenges.

As we look to the future, the Asia-Pacific area has become a center of construction activity and is predicted to remain the largest construction market through 2028. The region's large population, the trend of rapid urbanization, and the significant investments made in infrastructure development in nations like China, India, Japan, Indonesia, and South Korea are all credited with this. The Asia-Pacific region's thriving construction activities represent a significant trend that is reshaping the world of construction as the industry continues to grow due to ongoing urbanization and infrastructure projects.

Key Players:

-

3M

-

Sika AG

-

Soudal Holding N.V.

-

Henkel AG & Co. KGaA

-

RPM International, Inc.

-

Bostik SA

-

Huntsman International

-

H.B. Fuller

-

DowDuPont

-

Akzo Nobel

Chapter 1. GUNNABLE SEALANT MARKET – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. GUNNABLE SEALANT MARKET – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. GUNNABLE SEALANT MARKET – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. GUNNABLE SEALANT MARKET Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. GUNNABLE SEALANT MARKET – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. GUNNABLE SEALANT MARKET – By Type

6.1 Introduction/Key Findings

6.2 Silicone Sealants

6.3 Polyurethane Sealants

6.4 Polysulfide Sealants

6.5 Acrylic Sealants

6.6 Epoxy Sealants

6.7 Hybrid Sealants

6.8 Y-O-Y Growth trend Analysis By Type

6.9 Absolute $ Opportunity Analysis By Type, 2024-2030

Chapter 7. GUNNABLE SEALANT MARKET – By Application

7.1 Introduction/Key Findings

7.2 Automotive

7.3 Construction

7.4 Aerospace and Defense

7.5 Electronics

7.6 Marine

7.7 Electrical

7.8 Medical

7.9 Others

7.10 Y-O-Y Growth trend Analysis By Application

7.11 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. GUNNABLE SEALANT MARKET – By Distribution

8.1 Introduction/Key Findings

8.2 Retail stores

8.3 Online platforms

8.4 Specialized distributors

8.5 Y-O-Y Growth trend Analysis By Distribution

8.6 Absolute $ Opportunity Analysis By Distribution, 2024-2030

Chapter 9. GUNNABLE SEALANT MARKET – By Technology

9.1 Introduction/Key Findings

9.2 Water-Based Sealants

9.3 Solvent-Based Sealants

9.4 Hot-Melt Sealants

9.5 Reactive Sealants

9.6 UV-Curable Sealants

9.7 Pressure-Sensitive Sealants

9.8 Y-O-Y Growth trend Analysis By Technology

9.9 Absolute $ Opportunity Analysis By Technology , 2024-2030

Chapter 10. GUNNABLE SEALANT MARKET , By Geography – Market Size, Forecast, Trends & Insights

10.1 North America

10.1.1 By Country

10.1.1.1 U.S.A.

10.1.1.2 Canada

10.1.1.3 Mexico

10.1.2 By Type

10.1.2.1 By Application

10.1.3 By Distribution

10.1.4 Countries & Segments - Market Attractiveness Analysis

10.2 Europe

10.2.1 By Country

10.2.1.1 U.K

10.2.1.2 Germany

10.2.1.3 France

10.2.1.4 Italy

10.2.1.5 Spain

10.2.1.6 Rest of Europe

10.2.2 By Type

10.2.3 By Application

10.2.4 By Distribution

10.2.5 By Technology

10.2.6 Countries & Segments - Market Attractiveness Analysis

10.3 Asia Pacific

10.3.1 By Country

10.3.1.1 China

10.3.1.2 Japan

10.3.1.3 South Korea

10.3.1.4 India

10.3.1.5 Australia & New Zealand

10.3.1.6 Rest of Asia-Pacific

10.3.2 By Type

10.3.3 By Application

10.3.4 By Distribution

10.3.5 By Technology

10.3.6 Countries & Segments - Market Attractiveness Analysis

10.4 South America

10.4.1 By Country

10.4.1.1 Brazil

10.4.1.2 Argentina

10.4.1.3 Colombia

10.4.1.4 Chile

10.4.1.5 Rest of South America

10.4.2 By Type

10.4.3 By Application

10.4.4 By Distribution

10.4.5 By Technology

10.4.6 Countries & Segments - Market Attractiveness Analysis

10.5 Middle East & Africa

10.5.1 By Country

10.5.1.1 United Arab Emirates (UAE)

10.5.1.2 Saudi Arabia

10.5.1.3 Qatar

10.5.1.4 Israel

10.5.1.5 South Africa

10.5.1.6 Nigeria

10.5.1.7 Kenya

10.5.1.8 Egypt

10.5.1.9 Rest of MEA

10.5.2 By Type

10.5.3 By Application

10.5.4 By Distribution

10.5.5 By Technology

10.5.6 Countries & Segments - Market Attractiveness Analysis

Chapter 11. GUNNABLE SEALANT MARKET – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

11.1 3M

11.2 Sika AG

11.3 Soudal Holding N.V.

11.4 Henkel AG & Co. KGaA

11.5 RPM International, Inc.

11.6 Bostik SA

11.7 Huntsman International

11.8 H.B. Fuller

11.9 DowDuPont

11.10 Akzo Nobel

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The global gunnable sealant market was valued at USD 9 billion and is projected to reach a market size of USD 12.66 billion by the end of 2030. Over the forecast period of 2024–2030, the market is expected to grow at a CAGR of 5%

The expanding building sector, the growing focus on energy efficiency, and the continuous technological advancements in sealant formulations are the primary factors propelling the global gunnable sealant market.

Silicone sealants, polyurethane sealants, polysulfide sealants, acrylic sealants, epoxy sealants, and hybrid sealants are among the most commonly used.

Asia-Pacific held the largest market share of 58% in the gunnable sealant market. This dominant position can be attributed to the region's use of modern technology in the fields of construction and other electrical, automotive, marine, and medical sectors.

3M, Sika AG, Soudal Holding N.V., Henkel AG & Co. KGaA, RPM International Inc., Bostik SA, Huntsman International, H.B. Fuller, DowDuPont, and Akzo Nobel are some of the key players in the global gunnable sealant market.