Radio Frequency Processing Market Size (2025 – 2030)

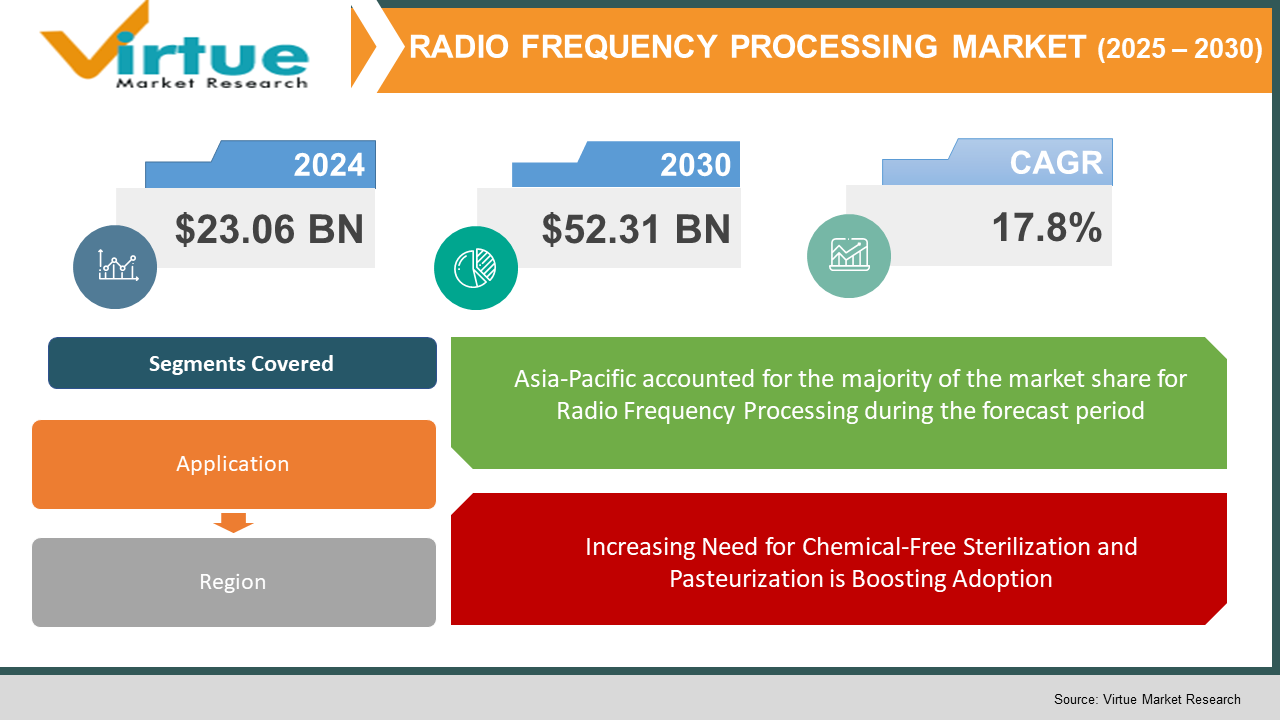

The Global Radio Frequency Processing Market was valued at USD 23.06 billion in 2024 and is projected to reach a market size of USD 52.31 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 17.8%.

The Radio Frequency (RF) Processing Market is witnessing rapid expansion as industries raspingly adopt RF technology for various thermal processing applications. RF processing utilizes electromagnetic waves to generate heat within materials, enabling efficient and uniform heating for applications such as drying, baking, defrosting, sterilization, pasteurization, and disinfestation. This technology is gaining traction across food processing, pharmaceuticals, healthcare, and industrial sectors due to its ability to enhance product quality, reduce processing time, and improve energy efficiency. With advancements in automation and precision control, RF processing is revolutionizing traditional thermal treatment methods, offering a sustainable and cost-effective alternative. The rising demand for non-invasive and chemical-free processing solutions, especially in food safety and medical sterilization, is further fueling market growth.

Key Market Insights:

- The Radio Frequency (RF) Processing Market is witnessing significant growth, driven by increasing adoption in food processing, healthcare, and industrial applications. RF technology offers faster and more energy-efficient thermal processing compared to conventional methods, reducing processing times by up to 50%. This efficiency makes RF processing highly attractive for industries focusing on productivity and sustainability. Additionally, RF-based drying solutions have demonstrated 30% lower energy consumption than traditional drying methods, positioning them as a preferred choice for cost-conscious manufacturers.

- In the food industry, RF technology is widely used for pasteurization, defrosting, and drying processes. Studies indicate that RF-assisted drying can improve product shelf life by 40% while maintaining nutritional value and texture. Moreover, RF defrosting technology is becoming a game-changer, reducing defrosting time from hours to minutes, remarkably minimizing product degradation. The demand for RF processing in food safety applications is also rising due to increasing regulatory scrutiny regarding microbial contamination, with food companies investing in RF sterilization techniques to ensure compliance.

- The healthcare and pharmaceutical sectors are also witnessing a rise in RF processing adoption, particularly in sterilization and medical device manufacturing. Research suggests that RF sterilization eliminates 99.9% of pathogens without the need for chemical disinfectants, making it an eco-friendly and safer alternative. Furthermore, RF technology is being explored for precision heating in medical treatments, such as tumor ablation and physiotherapy devices, highlighting its expanding role beyond traditional industrial applications.

Radio Frequency Processing Market Drivers:

Growing Demand for Efficient and Energy-Saving Processing Solutions is Driving Market Growth

Industries are increasingly adopting Radio Frequency (RF) processing because of its high energy efficiency and rapid heating capabilities. Unlike conventional heating methods that rely on conduction or convection, RF processing delivers heat directly to the target material, significantly reducing energy wastage. This technology is particularly beneficial in food processing, where RF-based drying and sterilization ensure faster processing times while maintaining product quality. Additionally, industries such as textiles, pharmaceuticals, and polymers are turning to RF technology to enhance productivity and reduce operational costs.

Increasing Need for Chemical-Free Sterilization and Pasteurization is Boosting Adoption

With increasing consumer demand for chemical-free and safe food processing methods, RF-based sterilization and pasteurization are gaining significant traction. Traditional sterilization often involves chemical treatments that may leave residues, affecting food quality and safety. RF technology provides a clean alternative, using electromagnetic waves to eliminate harmful microorganisms while preserving nutritional value. This growing preference for natural and minimally processed food products is pushing food manufacturers and regulatory bodies to embrace RF sterilization as a safer, non-invasive alternative.

Rising Applications in Healthcare and Pharmaceutical Industries are Expanding Market Scope

RF processing is being increasingly utilized in the pharmaceutical sector for drying and sterilizing heat-sensitive drugs and medical products. RF heating ensures uniform temperature distribution, preventing degradation and enhancing product stability. Additionally, RF technology is being explored for medical waste treatment, offering an eco-friendly alternative to incineration. The rising emphasis on hygiene and contamination control in healthcare facilities is driving the demand for RF-based disinfection systems, further expanding the market’s potential in medical applications.

Advancements in RF Technology and Automation are Enhancing Market Growth

Technological innovations in RF processing, including automated control systems and AI-driven precision heating, are improving efficiency and reliability. These advancements enable enhanced control over processing parameters, reducing the risk of overheating or under processing. Additionally, integration with IoT and real-time monitoring solutions allows industries to optimize RF applications, minimize energy consumption, and ensure consistent product quality. The continuous evolution of RF technology is opening new avenues across multiple industries, positioning it as a game-changer in thermal processing.

Radio Frequency Processing Market Restraints and Challenges:

High Initial Investment and Technical Complexities are Hindering Market Growth

Despite its advantages, the adoption of Radio Frequency (RF) processing is constrained by high initial investment costs and technical complexities. Setting up RF processing systems requires specialized equipment and infrastructure, which can be expensive for small and medium-sized enterprises. Additionally, the technology needs skilled professionals to manage frequency tuning, power control, and process optimization, posing a challenge for companies with limited technical expertise. Regulatory restrictions on RF exposure and electromagnetic interference also add to compliance burdens, making widespread adoption more challenging in certain industries.

Radio Frequency Processing Market Opportunities:

The growing advancements in Radio Frequency (RF) processing technology, coupled with its expanding applications across various industries, present significant growth opportunities. Innovations in RF-based sterilization, drying, and defrosting techniques are driving demand in the food, pharmaceutical, and healthcare sectors, where efficiency and safety are critical. Additionally, the rising adoption of RF processing in sustainable and energy-efficient manufacturing aligns with global efforts to reduce carbon footprints. Emerging markets in Asia-Pacific and Latin America are also witnessing growing interest in RF technology due to increasing industrialization and stringent quality standards, further opening new avenues for market expansion.

RADIO FREQUENCY PROCESSING MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2024 - 2030 |

|

Base Year |

2024 |

|

Forecast Period |

2025 - 2030 |

|

CAGR |

17.8% |

|

Segments Covered |

By application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Stalam S.p.A, RF Systems, Radio Frequency Co., Inc., and Thermex-Thermatron Systems |

Radio Frequency Processing Market Segmentation:

Radio Frequency Processing Market Segmentation: By Application:

- Drying & Baking

- Defrosting

- Sterilization and Pasteurization

- Disinfestation

Sterilization and Pasteurization is the dominant application in the Radio Frequency (RF) Processing Market, driven by the growing demand for safe and contamination-free food, pharmaceuticals, and medical products. RF-based sterilization and pasteurization provide an efficient, chemical-free, and rapid method to eliminate pathogens while preserving product quality, making it a preferred choice in industries requiring stringent hygiene standards. The growing emphasis on extending shelf life, reducing foodborne illnesses, and ensuring regulatory compliance has further strengthened its market leadership, particularly in developed regions with strict safety protocols.

Defrosting is the fastest-growing application, driven by the food industry's need for quick, uniform, and energy-efficient thawing solutions to maintain product quality and reduce processing time. RF defrosting significantly reduces thawing duration compared to conventional methods, preventing microbial growth and moisture loss while ensuring consistency in texture and flavor. With the rise in frozen food consumption and increasing demand for just-in-time inventory management, RF defrosting is gaining rapid adoption, especially in meat, seafood, and bakery industries, driving significant growth in the market.

Radio Frequency Processing Market Segmentation: Regional Analysis:

- North America

- Asia-Pacific

- Europe

- South America

- Middle East and Africa

Asia-Pacific is the dominant region in the Radio Frequency Processing Market holding around 35% of the total market share in 2024, fueled by the rapid industrialization, expansion of the food processing sector, and strong adoption of advanced RF-based technologies in countries like China, India, and Japan. The region benefits from government initiatives supporting food safety, increasing demand for efficient sterilization, and the presence of key manufacturing hubs that integrate RF processing in production. Additionally, the growing pharmaceutical and medical industries in the region further contribute to its leading market share.

North America is the fastest-growing region in the Radio Frequency Processing Market, driven by continuous technological advancements, strict food safety regulations, and the increasing adoption of RF technology in medical sterilization and food preservation. The presence of key players, strong R&D investments, and the rising demand for sustainable and energy-efficient processing solutions are accelerating market growth. Additionally, increasing consumer awareness regarding food quality and safety is driving the rapid adoption of RF processing across multiple industries.

COVID-19 Impact Analysis on the Global Radio Frequency Processing Market:

The COVID-19 pandemic significantly impacted the Global Radio Frequency (RF) Processing Market, primarily by disrupting supply chains, delaying industrial activities, and creating labor shortages. Many manufacturing units that relied on RF technology for drying, sterilization, and pasteurization faced operational setbacks due to lockdowns and restrictions. However, the food and pharmaceutical industries, which require high standards of hygiene and sterilization, witnessed increased demand for RF-based processing solutions. The demand for effective pathogen control in food and medical equipment sterilization during the pandemic accelerated the adoption of RF processing in these sectors.

Post-pandemic, the market has experienced a strong recovery and transformation, driven by the increased awareness of food safety, hygiene, and efficient sterilization methods. The need for RF processing solutions surged in industries focusing on reducing contamination risks, especially in healthcare and packaged food production. Companies have also invested in automation and smart RF-based systems to ensure business continuity and regulatory compliance. As industries continue to prioritize safety and energy-efficient processing, the RF processing market is expected to witness steady growth in the coming years.

Latest Trends/ Developments:

The Global Radio Frequency (RF) Processing Market is witnessing a rise in innovation, with industries integrating automation, artificial intelligence (AI), and IoT-driven monitoring systems to enhance efficiency and precision. One of the most significant trends is the increasing use of RF processing in food sterilization and pasteurization, as companies seek non-chemical, energy-efficient solutions to extend shelf life while maintaining nutritional value. The adoption of RF defrosting technology is also growing rapidly, as it significantly reduces thawing time from hours to minutes, ensuring better texture, moisture retention, and safety in frozen food products. Additionally, RF technology is becoming a preferred choice in the pharmaceutical and healthcare sectors, where demand for chemical-free sterilization of heat-sensitive drugs and medical equipment is on the rise.

Another major development in the RF processing market is the growing focus on sustainability and energy efficiency, as industries seek to reduce carbon footprints while enhancing production efficiency. RF-based drying and heating systems consume up to 30% less energy than conventional methods, making them an attractive solution for industries prioritizing cost reduction and eco-friendly operations. The adoption of RF technology in textile and polymer processing is also growing, as it offers superior drying, curing, and bonding capabilities with minimal environmental impact. Furthermore, the rise of Industry 4.0 has encouraged companies to integrate real-time monitoring, predictive analytics, and AI-powered RF process control, improving consistency and operational efficiency. As governments worldwide impose stricter food safety, pharmaceutical hygiene, and energy efficiency regulations, RF processing is expected to play a crucial role in transforming industrial heating, sterilization, and drying applications across multiple sectors.

Key Players:

- Stalam S.p.A

- RF Systems

- Radio Frequency Co., Inc.

- Thermex-Thermatron Systems

- Advanced Microwave Technologies

- Püschner GmbH

- Kerone Engineering Solutions Ltd.

- Strayfield RF Limited

- SAIREM

- COMBIIR

- CPS America

- Ferrite Microwave Technologies

- Evertz Microsystems Ltd.

Chapter 1. RADIO FREQUENCY PROCESSING MARKET – SCOPE & METHODOLOGY

1.1. Market Segmentation

1.2. Scope, Assumptions & Limitations

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. RADIO FREQUENCY PROCESSING MARKET – EXECUTIVE SUMMARY

2.1. Market Size & Forecast – (2025 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.2.1. Demand Side

2.2.2. Supply Side

2.3. Attractive Investment Propositions

2.4. COVID-19 Impact Analysis

Chapter 3. RADIO FREQUENCY PROCESSING MARKET – COMPETITION SCENARIO

3.1. Market Share Analysis & Company Benchmarking

3.2. Competitive Strategy & Development Scenario

3.3. Competitive Pricing Analysis

3.4. Supplier-Distributor Analysis

Chapter 4. RADIO FREQUENCY PROCESSING MARKET - ENTRY SCENARIO

4.1. Regulatory Scenario

4.2. Case Studies – Key Start-ups

4.3. Customer Analysis

4.4. PESTLE Analysis

4.5. Porters Five Force Model

4.5.1. Bargaining Power of Suppliers

4.5.2. Bargaining Powers of Customers

4.5.3. Threat of New Entrants

4.5.4. Rivalry among Existing Players

4.5.5. Threat of Substitutes Players

4.5.6. Threat of Substitutes

Chapter 5. RADIO FREQUENCY PROCESSING MARKET - LANDSCAPE

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. RADIO FREQUENCY PROCESSING MARKET – By Application

6.1 Introduction/Key Findings

6.2 Drying & Baking

6.3 Defrosting

6.4 Sterilization and Pasteurization

6.5 Disinfestation

6.6 Y-O-Y Growth trend Analysis By Application

6.7 Absolute $ Opportunity Analysis By Application , 2025-2030

Chapter 8. RADIO FREQUENCY PROCESSING MARKET - By Geography – Market Size, Forecast, Trends & Insights

7.1. North America

7.1.1. By Country

7.1.1.1. U.S.A.

7.1.1.2. Canada

7.1.1.3. Mexico

7.1.2. By Application

7.1.3. Countries & Segments - Market Attractiveness Analysis

7.2. Europe

7.2.1. By Country

7.2.1.1. U.K.

7.2.1.2. Germany

7.2.1.3. France

7.2.1.4. Italy

7.2.1.5. Spain

7.2.1.6. Rest of Europe

7.2.2. By Application

7.2.3. Countries & Segments - Market Attractiveness Analysis

7.3. Asia Pacific

7.3.1. By Country

7.3.1.1. China

7.3.1.2. Japan

7.3.1.3. South Korea

7.3.1.4. India

7.3.1.5. Australia & New Zealand

7.3.1.6. Rest of Asia-Pacific

7.3.2. By Application

7.3.3. Countries & Segments - Market Attractiveness Analysis

7.4. South America

7.4.1. By Country

7.4.1.1. Brazil

7.4.1.2. Argentina

7.4.1.3. Colombia

7.4.1.4. Chile

7.4.1.5. Rest of South America

7.4.2.By Application

7.4.3. Countries & Segments - Market Attractiveness Analysis

7.5. Middle East & Africa

7.5.1. By Country

7.5.1.1. United Arab Emirates (UAE)

7.5.1.2. Saudi Arabia

7.5.1.3. Qatar

7.5.1.4. Israel

7.5.1.5. South Africa

7.5.1.6. Nigeria

7.5.1.7. Kenya

7.5.1.7. Egypt

7.5.1.7. Rest of MEA

7.5.2. By Application

7.5.3. Countries & Segments - Market Attractiveness Analysis

Chapter 8. RADIO FREQUENCY PROCESSING MARKET – Company Profiles – (Overview, Packaging Product Portfolio, Financials, Strategies & Developments)

8.1 Stalam S.p.A

8.2 RF Systems

8.3 Radio Frequency Co., Inc.

8.4 Thermex-Thermatron Systems

8.5 Advanced Microwave Technologies

8.6 Püschner GmbH

8.7 Kerone Engineering Solutions Ltd.

8.8 Strayfield RF Limited

8.9 SAIREM

8.10 COMBIIR

8.11 CPS America

8.12 Ferrite Microwave Technologies

8.13 Evertz Microsystems Ltd.

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Global Radio Frequency Processing Market was valued at USD 23.06 billion in 2024 and is projected to reach a market size of USD 52.31 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 17.8%.

Rising demand for energy-efficient, rapid, and uniform heating solutions across industries.

Based on Application, the Global Radio Frequency Processing Market is segmented into Drying & baking, Defrosting, Sterilization and Pasteurization, and Disinfestation.

Asia-Pacific is the most dominant region for the Global Radio Frequency Processing Market.

Stalam S.p.A, RF Systems, Radio Frequency Co., Inc., and Thermex-Thermatron Systems are the leading players in the Global Radio Frequency Processing Market.