Loss-in-Weight Feeder Market Size (2024 - 2030)

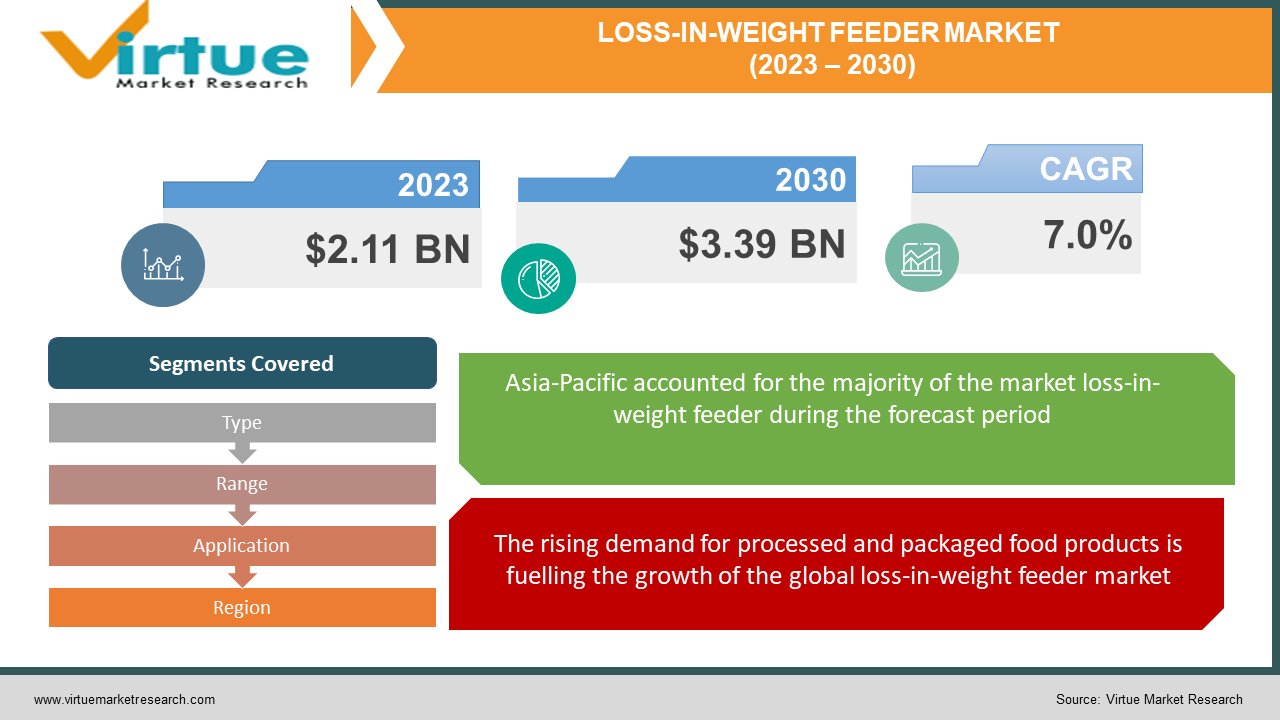

Global Loss-in-Weight Feeder Market is estimated to be worth USD 2.11 Billion in 2023 and is projected to reach a value of USD 3.39 Billion by 2030, growing at a CAGR of 7.0% during the forecast period 2024-2030.

A loss-in-weight feed is utilized in industries to precisely dose a product into a process at the desired rate of flow or in batches. In a loss-in-weight feeder, either a platform scale or load cells can be used to suspend the feeding device, which has a hopper that holds the product to be fed. The metering device discharges the product from the hopper, and the weighing and control system calculates the weight loss per unit of time. The desired weight loss per unit time and this actual weight loss per unit time are then compared. The feeding device's speed is adjusted for any difference between the desired and actual weight loss per unit of time. The control by weight loss is briefly interrupted and the hopper is refilled when the contents of the hopper reach a predetermined minimum weight level. The controller adjusts the feeding device's speed during the refill period in accordance with the weight and speed that were established during the previous weight loss cycle. Loss-in-weight feeders are best for application when it comes to both small and medium feeding ranges. They operate with extreme precision when under optimum ambient conditions. They can handle bulk solids, liquids, and even items that don't flow well due to their feature of great flexibility. They are utilized in numerous continuous processes that demand high levels of short-term feeding consistency, such as feeding extruders. Loss-in-weight feeders are also utilized in the food industry and laboratories with adapted feeding devices and storage containers. Depending on the application, the design can range from compact constructions to modular concepts. Due to their vast application in various industries, the global loss-in-weight feeder market is anticipated to grow at a fast rate during the forecast period.

Global Loss-in-Weight Feeder Market Drivers:

The rising demand for processed and packaged food products is fuelling the growth of the global loss-in-weight feeder market:

There is a rising demand for a variety of processed and packaged food products as a result of the innovation in products and rapid expansion of technology. In order to facilitate the production and packaging process, the weighing and filling equipment must be simple to operate, adaptable, and easy to clean. Loss-in-weight feeders fulfill all the aforementioned requirements and assist in providing high accuracy and speed for the production and packaging process. Therefore, this factor drives the demand for loss-in-weight feeders.

The increasing requirement for loss-in-weight feeders in the mining and metallurgy industries is another factor contributing to the growth of the global loss-in-weight Feeder Market:

Although mining and metallurgy are two distinct industries, both rely on loss-in-weight feeders to ensure a constant material flow rate into their processes. Any kind of bulk solid material, including powders, pellets, granules, or flakes, can be fed through loss-in-weight feeders. These materials include coal, iron ore, limestone, and so on. These materials are all processed in mining before being sold as finished goods like steel, aluminum, concrete bricks, building components, automobiles, and so on. Each type needs a feeding system that will deliver precise amounts at specific intervals to the crushers, grinders, and other processing machines. Therefore, this factor also drives the demand for loss-in-weight feeders.

Global Loss-in-Weight Feeder Market Challenges:

The global loss-in-weight feeder market is encountering challenges, primarily in terms of the high installation and maintenance costs of twin-screw feeders. Twin-screw feeders are popular in the plastics industry for the feeding and control of materials, including powders, pellets, granules, and flakes, as they offer better mixing and feeding capabilities than single-screw ones. However, their installation and maintenance costs are much higher than the single-screw feeders. Moreover, twin-screw drivers require skilled technicians due to the complex installation process and operation of these feeders. Thus, these challenges inhibit the growth of the global loss-in-weight feeder market.

Global Loss-in-Weight Feeder Market Opportunities:

The expansion of loss-in-weight feeders to emerging markets presents a lucrative opportunity in the global loss-in-weight feeder market. Given the rising industrialization and the growing demand for advanced production technologies in rapidly developing countries, major loss-in-weight feeder manufacturing companies can stand to gain significantly from this opportunity by expanding their product to these countries in order to broaden their customer base and boost their overall revenue.

COVID-19 Impact on the Global Loss-in-Weight Feeder Market:

The outbreak of the COVID-19 pandemic substantially impacted the global loss-in-weight feeder market. The implementation of strict lockdowns, traveling restrictions, and social distancing measures across several nations hindered many companies' manufacturing capacities and caused a shortage of skilled workforce. The pandemic caused disruptions in supply chains and distribution of goods and services, which highly affected the production and distribution of loss-in-weight feeders. Moreover, the demand for loss-in-weight feeders decreased in several industries due to reduced economic activity. These factors negatively impacted the growth of the global loss-in-weight feeder market. Despite these challenges, the global loss-in-weight feeder market is projected to recover and grow in the coming years.

Global Loss-in-Weight Feeder Market Recent Developments:

-

In September 2021, Thayer Scale, the pioneering designer of consistent weighing and feeding equipment, launched a new model of hygienic weigh feeder, Model HWF.

-

In July 2020, Coperion K-Tron launched the latest version of the time-tested KCM feeder controller. The new KCM-III has a number of new features, including a stainless steel enclosure, a larger 5-inch LCD screen with a better user interface, context-sensitive help, and built-in Ethernet with optional Wi-Fi. The KCM-III can be accessed through a feeder web page with a full-featured user interface if it has Ethernet capability (wired or wireless).

-

In May 2020, Gericke, designer and manufacturer of powder processing equipment and systems, unveiled the new hybrid loss-in-weight tare compensation feeder, DIW-PE-GZD hygienic, for powder feeding in clean production environments.

LOSS-IN-WEIGHT FEEDER MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

7.0% |

|

Segments Covered |

By Type, Range, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

WAMGROUP spa (Italy), Kubota Brabender Technologie GmBH & Co. KG (Germany), Sautelma Rotolok (France), The Conair Group, Inc. (United States), Hapman (United States), Novatec, Inc. (United States), Schenck Process LLC (Germany), Coperion GmbH (Germany), Yamato Scale (Japan), Monomex (Turkey) |

Global Loss-in-Weight Feeder Market Segmentation: By Type

-

Single-Screw Feeder

-

Twin-Screw Feeder

-

Others

In 2022, the single-screw feeder segment held the highest market share. The growth can be attributed to the vast application of single-screw feeders in a wide range of industries, including food and beverages, pharmaceuticals, chemicals, etc., as they are ideal for feeding free-flowing bulking materials. In addition, single-screw feeders are generally cheaper and easier to install and maintain than twin-screw feeders, which further propels this segment's growth.

Global Loss-in-Weight Feeder Market Segmentation: By Range

-

Small Feeding Range

-

Medium Feeding Range

In 2022, Medium Feeding Range held the highest market share. The growth can be attributed to the increasing application of medium-feeding range loss-in-weight feeders across various industry verticals. Also, the small feeding range loss-in-weight segment is anticipated to grow significantly and at the highest CAGR during the forecast period.

Global Loss-in-Weight Feeder Market Segmentation: By Application

-

Chemicals

-

Construction

-

Food & Beverages

-

Mining & Metallurgy

-

Pharmaceuticals

-

Plastics

-

Others

In 2022, the food and beverages segment held the highest market share. The growth can be attributed to the vast application of loss-in-weight feeders in the food and beverages industry for feeding and dosing ingredients, including sugar, flour, spices, and additives, with the highest accuracy and precision. In addition, the rising demand for processed and packaged food and beverages propels this segment's growth.

Global Loss-in-Weight Feeder Market Segmentation: By Region

-

North America

-

Europe

-

Asia-Pacific

-

Rest of the World

In 2022, the region of Asia-Pacific held the largest share of the global loss-in-weight feeder market and will continue to be the fastest-growing region during the forecast period. The growth can be attributed to growing industrialization, the rising demand for processed and packaged food, and the rising demand for pharmaceutical products in countries, including China and India. In addition, the region is home to several significant market players including Yamato Scale, Yoshikawa Corporation, Guang Dong High Dream Intellectualized Machinery Co Ltd, Amisy Machinery, and Shanghai Shigan Industrial Co. Ltd.

Global Loss-in-Weight Feeder Market Key Players:

-

WAMGROUP spa (Italy)

-

Kubota Brabender Technologie GmBH & Co. KG (Germany)

-

Sautelma Rotolok (France)

-

The Conair Group, Inc. (United States)

-

Hapman (United States)

-

Novatec, Inc. (United States)

-

Schenck Process LLC (Germany)

-

Coperion GmbH (Germany)

-

Yamato Scale (Japan)

-

Monomex (Turkey)

Chapter 1. Global Loss-in-Weight Feeder Market – Scope & Methodology

1.1. Market Segmentation

1.2. Assumptions

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. Global Loss-in-Weight Feeder Market – Executive Summary

2.1. Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.3. COVID-19 Impact Analysis

2.3.1. Impact during 2023 - 2030

2.3.2. Impact on Supply – Demand

Chapter 3. Global Loss-in-Weight Feeder Market – Competition Scenario

3.1. Market Share Analysis

3.2. Product Benchmarking

3.3. Competitive Strategy & Development Scenario

3.4. Competitive Pricing Analysis

3.5. Supplier - Distributor Analysis

Chapter 4. Global Loss-in-Weight Feeder Market - Entry Scenario

4.1. Case Studies – Start-up/Thriving Companies

4.2. Regulatory Scenario - By Region

4.3 Customer Analysis

4.4. Porter's Five Force Model

4.4.1. Bargaining Power of Suppliers

4.4.2. Bargaining Powers of Customers

4.4.3. Threat of New Entrants

4.4.4. Rivalry among Existing Players

4.4.5. Threat of Substitutes

Chapter 5. Global Loss-in-Weight Feeder Market - Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. Global Loss-in-Weight Feeder Market - By Type

6.1 Single-Screw Feeder

6.2 Twin-Screw Feeder

6.3 Others

Chapter 7. Global Loss-in-Weight Feeder Market - By Range

7.1 Small Feeding Range

7.2 Medium Feeding Range

Chapter 8. Global Loss-in-Weight Feeder Market - By Application

8.1 Chemicals

8.2 Construction

8.3 Food & Beverages

8.4 Mining & Metallurgy

8.5 Pharmaceuticals

8.6 Plastics

8.7 Others

Chapter 9. Global Loss-in-Weight Feeder Market - By Region

9.1 North America

9.2 Europe

9.3 Asia-Pacific

9.4 Rest of the World

Chapter 10. Global Loss-in-Weight Feeder Market - Key Players

10.1 WAMGROUP spa (Italy)

10.2 Kubota Brabender Technologie GmBH & Co. KG (Germany)

10.3 Sautelma Rotolok (France)

10.4 The Conair Group, Inc. (United States)

10.5 Hapman (United States)

10.6 Novatec, Inc. (United States)

10.7 Schenck Process LLC (Germany)

10.8 Coperion GmbH (Germany)

10.9 Yamato Scale (Japan)

10.10 Monomex (Turkey)

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Global Loss-in-Weight Feeder Market valued at USD 2.11 Billion and is projected to reach a market size of USD 3.39 Billion by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 7.0%.

The Global Loss-in-Weight Feeder Market is driven by the rising demand for processed and packaging food products and the increasing requirement for loss-in-weight feeders in the mining and metallurgy industries.

Based on the Type, the Global Loss-in-Weight Feeder Market is segmented into Single-Screw Feeders, Twin-Screw Feeders, and Others.

China and India are the most dominating countries in the region of Asia-Pacific for the Global Loss-in-Weight Feeder Market.

WAMGROUP spa, Kubota Brabender Technologie GmbH & Co. KG, and Sautelma Rotolok are the leading players in the Global Loss-in-Weight Feeder Market.