Level Measurement for Process Control Market Size (2025 – 2030)

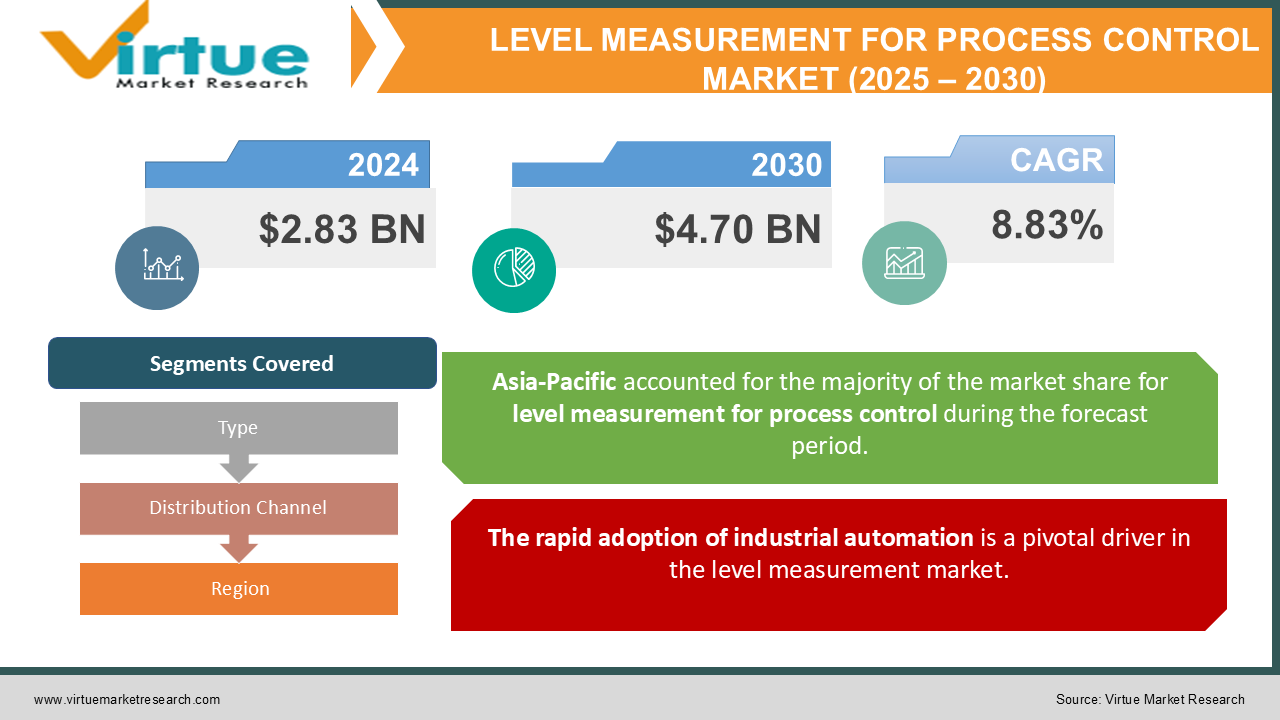

The Level Measurement for Process Control Market was valued at USD 2.83 Billion in 2024 and is projected to reach a market size of USD 4.70 Billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 8.83%.

The Level Measurement for Process Control Market plays a critical role in industrial operations, providing precise monitoring and control solutions across multiple sectors such as oil and gas, chemicals, pharmaceuticals, food and beverages, and water treatment. This market revolves around instruments and technologies designed to measure and regulate the level of liquids, solids, and slurries in containers, tanks, or processing units. Industries worldwide rely on level measurement to optimize processes, ensure product quality, reduce waste, and comply with safety and environmental standards. As industries embrace automation and digital transformation, the demand for advanced level measurement solutions is on an upward trajectory, propelled by the need for efficiency and real-time monitoring.

Key Market Insights:

Radar-based level measurement accounted for approximately 38% of total market sales in 2023.

Over 1.2 million ultrasonic level measurement devices were sold worldwide in 2023.

Industries such as oil and gas contributed to 27% of the total demand for level measurement systems in 2023.

IoT-enabled level measurement devices saw a 42% increase in adoption compared to 2022.

The food and beverage sector utilized 16% of the market’s total output in 2023.

Over 75% of the market’s sales were driven by non-contact level measurement technologies in 2023.

Approximately 1.8 million units of level measurement equipment were installed globally in 2023.

Market Drivers:

The rapid adoption of industrial automation is a pivotal driver in the level measurement market.

As factories and production facilities aim to enhance productivity and minimize operational errors, they increasingly rely on automated systems. Level measurement devices play a crucial role in this transformation, enabling precise control and monitoring of fluid and material levels. Integration with advanced technologies like IoT, machine learning, and AI has revolutionized the market by offering real-time insights, predictive maintenance, and enhanced process efficiency. Industries such as oil and gas, chemicals, and water treatment are spearheading this shift. Automated level measurement devices ensure uninterrupted operations, prevent overflows, and enable better inventory management. With the advent of smart factories, these devices are increasingly becoming interconnected, forming a critical component of Industry 4.0 initiatives. This trend is expected to grow further as more companies recognize the value of automation in achieving operational excellence.

Stringent regulations imposed by governments and environmental bodies worldwide are compelling industries to adopt advanced level measurement systems.

These regulations focus on minimizing industrial accidents, controlling emissions, and preventing environmental hazards caused by material overflows or leakages. For instance, the oil and gas industry is mandated to implement robust level monitoring systems to avoid spills that can have catastrophic consequences. The chemical and pharmaceutical sectors also face rigorous compliance requirements, necessitating precise level measurement to prevent contamination and ensure product safety. Furthermore, the water treatment industry requires accurate monitoring to comply with wastewater management regulations. These regulatory frameworks are driving the demand for reliable, high-precision level measurement systems, ensuring that companies adhere to safety and environmental standards while optimizing their operations.

Market Restraints and Challenges:

The Level Measurement for Process Control Market faces several challenges that could potentially hinder its growth and widespread adoption. While the demand for advanced level measurement systems is rising, certain limitations, such as high initial costs, operational complexities, and technical expertise requirements, act as significant barriers. One of the primary restraints is the high cost associated with advanced level measurement technologies. Radar and magnetostrictive systems, while highly accurate and versatile, require substantial investment, making them less accessible to small and medium-sized enterprises (SMEs). These organizations often opt for cost-effective, conventional methods, limiting the market's overall growth potential. Additionally, the maintenance and calibration requirements for these systems further add to their operational costs, creating an additional burden for budget-conscious industries. Another challenge lies in the technical complexity of modern level measurement systems. While advanced technologies like IoT-enabled devices and AI-integrated systems offer unparalleled precision, they require specialized expertise for installation, calibration, and operation. Many organizations face a shortage of skilled personnel, delaying the adoption of these technologies. In industries where downtime can result in significant financial losses, the lack of user-friendly interfaces and straightforward installation processes becomes a significant concern. The market also struggles with limitations in measuring specific materials or environments. For example, extreme temperatures, high-pressure conditions, or highly viscous substances can affect the accuracy and reliability of certain level measurement systems. These environmental constraints necessitate specialized devices, which can be expensive and time-consuming to develop and implement. Moreover, data integration and compatibility issues present a challenge in environments transitioning to digital ecosystems. Organizations often rely on legacy systems that are incompatible with modern level measurement devices, creating additional costs and technical hurdles during upgrades. These factors collectively underscore the need for continuous innovation and cost optimization to overcome the market's barriers.

Market Opportunities:

The Level Measurement for Process Control Market presents numerous opportunities for growth, driven by technological advancements, emerging industrial applications, and the global focus on sustainability. Industries worldwide are recognizing the potential of advanced level measurement systems to enhance efficiency, reduce costs, and meet stringent regulatory requirements, creating fertile ground for innovation and market expansion. One of the most promising opportunities lies in the integration of IoT and wireless communication technologies. As industries embrace digital transformation, IoT-enabled level measurement devices have emerged as game-changers, offering real-time data collection, remote monitoring, and predictive maintenance. These systems empower organizations to make data-driven decisions, optimize processes, and reduce downtime. The increasing adoption of smart factories and Industry 4.0 initiatives further amplifies this demand, encouraging manufacturers to develop innovative solutions tailored to these environments. Another significant opportunity is the rising demand for energy-efficient and environmentally friendly systems. With sustainability becoming a top priority, industries are seeking level measurement devices that minimize energy consumption and reduce environmental impact. Manufacturers that develop systems using renewable energy sources or recyclable materials are likely to gain a competitive edge in the market. Additionally, the expansion of emerging markets presents lucrative growth opportunities. Countries in Asia-Pacific, Latin America, and Africa are witnessing rapid industrialization and infrastructure development, driving the demand for reliable level measurement solutions. These regions offer untapped potential for market players, particularly for cost-effective and scalable systems. The increasing focus on customized solutions tailored to specific industries also represents a key growth avenue. For instance, the pharmaceutical and food industries require highly precise and hygienic level measurement systems, while the oil and gas sector demand robust devices capable of withstanding harsh conditions. Manufacturers that can deliver industry-specific solutions are poised to capture a significant market share.

LEVEL MEASUREMENT FOR PROCESS CONTROL MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2024 - 2030 |

|

Base Year |

2024 |

|

Forecast Period |

2025 - 2030 |

|

CAGR |

8.83% |

|

Segments Covered |

By Type, Distribution Channel and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Siemens AG, Emerson Electric Co., ABB Ltd., Honeywell International Inc., Schneider Electric, VEGA Grieshaber KG, Endress+Hauser AG, Yokogawa Electric Corporation, Krohne Messtechnik GmbH, Fuji Electric Co., Ltd. |

Level Measurement for Process Control Market Segmentation: By Type

-

Radar Level Measurement Systems

-

Ultrasonic Level Measurement Systems

-

Capacitive Level Measurement Systems

-

Magnetostrictive Level Measurement Systems

-

Differential Pressure Level Measurement Systems

-

Conductive Level Measurement Systems

-

Vibrating Fork Level Measurement Systems

-

Laser-Based Level Measurement Systems

Radar systems are witnessing exponential growth due to their non-contact nature, precision, and adaptability to challenging environments such as high temperatures, pressure, or dusty conditions. Their integration with IoT and wireless technologies further fuels their demand.

Ultrasonic systems dominate the market due to their affordability and versatility. These systems are widely used across industries, including water treatment, food processing, and chemicals, making them the go-to choice for cost-effective applications.

Level Measurement for Process Control Market Segmentation: By Distribution Channel

-

Direct Sales

-

Distributors

-

Online Platforms

Online platforms are emerging as the fastest-growing distribution channel due to the convenience, wide product range, and competitive pricing they offer. Industrial buyers increasingly prefer digital marketplaces for quick and efficient procurement. Direct sales remain the most dominant channel as they allow manufacturers to establish direct communication with customers, ensuring tailored solutions and efficient after-sales support.

Level Measurement for Process Control Market Segmentation: By Regional Analysis

-

North America

-

Europe

-

Asia-Pacific

-

Latin America

-

Middle East & Africa

Europe leads the market due to its robust industrial base, stringent safety regulations, and early adoption of advanced level measurement technologies. The presence of key market players further solidifies its dominance.

The Asia-Pacific region is the fastest-growing market, driven by rapid industrialization, infrastructure development, and increasing investments in automation technologies. Emerging economies like China and India are key contributors to this growth.

COVID-19 Impact Analysis:

The COVID-19 pandemic significantly impacted the Level Measurement for Process Control Market, with disruptions felt across the supply chain, production facilities, and end-user industries. During the initial phases of the pandemic, the market experienced a slowdown as industries scaled back operations due to lockdowns and reduced demand. However, as industries adapted to the new normal, the demand for automation and remote monitoring solutions surged. The need for contactless and automated level measurement systems gained prominence during the pandemic, as industries sought to minimize human intervention. IoT-enabled devices became a necessity, offering remote monitoring capabilities that allowed operations to continue uninterrupted despite restrictions. The pharmaceutical and healthcare industries, in particular, saw increased demand for level measurement systems to support the production and distribution of essential medicines and vaccines.

Latest Trends and Developments:

The Level Measurement for Process Control Market is undergoing a transformative phase characterized by technological innovation and evolving industry requirements. The integration of AI and machine learning in level measurement devices is enabling predictive maintenance, optimizing operational efficiency, and minimizing downtime. The rise of 5G technology is further enhancing the capabilities of IoT-enabled devices, providing faster data transmission and better connectivity. Sustainability remains a key focus, with manufacturers developing energy-efficient systems that align with global environmental goals. Compact, portable, and modular devices are gaining traction as industries seek flexible and cost-effective solutions. The adoption of cloud-based platforms for data analysis and storage is another significant trend, enabling real-time insights and improved decision-making.

Key Players in the Market:

-

Siemens AG

-

Emerson Electric Co.

-

ABB Ltd.

-

Honeywell International Inc.

-

Schneider Electric

-

VEGA Grieshaber KG

-

Endress+Hauser AG

-

Yokogawa Electric Corporation

-

Krohne Messtechnik GmbH

-

Fuji Electric Co., Ltd.

Chapter 1. Level Measurement for Process Control Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Level Measurement for Process Control Market – Executive Summary

2.1 Market Size & Forecast – (2025 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Level Measurement for Process Control Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Level Measurement for Process Control Market - Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Level Measurement for Process Control Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Level Measurement for Process Control Market – By Type

6.1 Introduction/Key Findings

6.2 Radar Level Measurement Systems

6.3 Ultrasonic Level Measurement Systems

6.4 Capacitive Level Measurement Systems

6.5 Magnetostrictive Level Measurement Systems

6.6 Differential Pressure Level Measurement Systems

6.7 Conductive Level Measurement Systems

6.8 Vibrating Fork Level Measurement Systems

6.9 Laser-Based Level Measurement Systems

6.10 Y-O-Y Growth trend Analysis By Type

6.11 Absolute $ Opportunity Analysis By Type, 2025-2030

Chapter 7. Level Measurement for Process Control Market – By Distribution Channel

7.1 Introduction/Key Findings

7.2 Direct Sales

7.3 Distributors

7.4 Online Platforms

7.5 Y-O-Y Growth trend Analysis By Distribution Channel

7.6 Absolute $ Opportunity Analysis By Distribution Channel, 2025-2030

Chapter 8. Level Measurement for Process Control Market , By Geography – Market Size, Forecast, Trends & Insights

8.1 North America

8.1.1 By Country

8.1.1.1 U.S.A.

8.1.1.2 Canada

8.1.1.3 Mexico

8.1.2 By Type

8.1.3 By Distribution Channel

8.1.4 Countries & Segments - Market Attractiveness Analysis

8.2 Europe

8.2.1 By Country

8.2.1.1 U.K

8.2.1.2 Germany

8.2.1.3 France

8.2.1.4 Italy

8.2.1.5 Spain

8.2.1.6 Rest of Europe

8.2.2 By Type

8.2.3 By Distribution Channel

8.2.4 Countries & Segments - Market Attractiveness Analysis

8.3 Asia Pacific

8.3.1 By Country

8.3.1.1 China

8.3.1.2 Japan

8.3.1.3 South Korea

8.3.1.4 India

8.3.1.5 Australia & New Zealand

8.3.1.6 Rest of Asia-Pacific

8.3.2 By Type

8.3.3 By Distribution Channel

8.3.4 Countries & Segments - Market Attractiveness Analysis

8.4 South America

8.4.1 By Country

8.4.1.1 Brazil

8.4.1.2 Argentina

8.4.1.3 Colombia

8.4.1.4 Chile

8.4.1.5 Rest of South America

8.4.2 By Type

8.4.3 By Distribution Channel

8.4.4 Countries & Segments - Market Attractiveness Analysis

8.5 Middle East & Africa

8.5.1 By Country

8.5.1.1 United Arab Emirates (UAE)

8.5.1.2 Saudi Arabia

8.5.1.3 Qatar

8.5.1.4 Israel

8.5.1.5 South Africa

8.5.1.6 Nigeria

8.5.1.7 Kenya

8.5.1.8 Egypt

8.5.1.9 Rest of MEA

8.5.2 By Type

8.5.3 By Distribution Channel

8.5.4 Countries & Segments - Market Attractiveness Analysis

Chapter 9. Level Measurement for Process Control Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

9.1 Siemens AG

9.2 Emerson Electric Co.

9.3 ABB Ltd.

9.4 Honeywell International Inc.

9.5 Schneider Electric

9.6 VEGA Grieshaber KG

9.7 Endress+Hauser AG

9.8 Yokogawa Electric Corporation

9.9 Krohne Messtechnik GmbH

9.10 Fuji Electric Co., Ltd.

Download Sample

Choose License Type

2500

4250

5250

6900