Glass Fiber Polyamide-imide Resin Market Size (2024 – 2030)

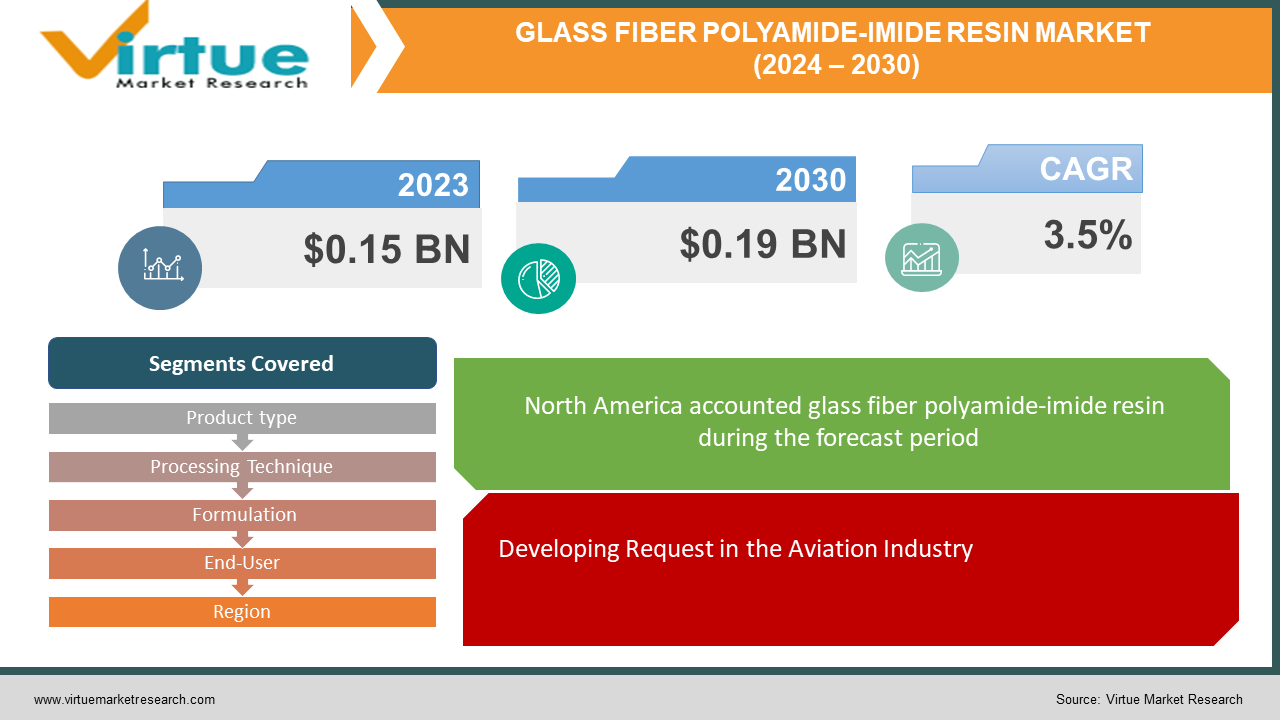

The market for glass fiber polyamide-imide resin market at the global level is expanding quickly; it was estimated to be worth 0.15 USD billion in 2023 and is expected to increase to 0.19 USD billion by 2030, with a projected compound annual growth rate (CAGR) of 3.5% from 2024 to 2030.

The glass fiber polyamide-imide tar advertise is encountering consistent development, driven by expanding requests over a wide extend of businesses. This progressed composite fabric offers remarkable mechanical properties, warm solidness, and chemical resistance, making it a favored choice in applications such as aviation, car, electrical & gadgets, and mechanical divisions. With its capacity to improve basic keenness, give electrical cover, and withstand unforgiving situations, glass fiber polyamide-imide tar finds broad utilization in basic composites, electrical components, coatings, and cement. The market's development direction is assisted by progressing innovative headways, extending the mechanical framework, and raising speculations in inquiries about advancement exercises. Also, exacting controls concerning natural maintainability and the developing accentuation on lightweight and high-performance materials are driving the appropriation of glass fiber polyamide-imide gum over different end-user businesses. As the request for lightweight and solid materials proceeds to rise, the glass fiber polyamide-imide gum advertisement is anticipated to witness critical development within the coming long time.

Key Market Insights:

The global glass fiber polyamide-imide resin market witnessed a robust CAGR of 7% during the period 2020-2025, reflecting strong demand across diverse end-user industries such as aerospace, automotive, and electrical & electronics. Technological advancements in resin formulations and processing techniques have led to improved performance characteristics, including enhanced mechanical properties and thermal stability, further stimulating market growth.

Global Glass Fiber Polyamide-imide Resin Market Drivers:

Developing Request in the Aviation Industry:

The aviation industry's expanding request for lightweight, high-performance materials may be a critical driver for the worldwide glass fiber polyamide-imide gum showcase. These gums offer uncommon mechanical properties, warm steadiness, and chemical resistance, making them perfect for applications such as airship basic components, motor parts, and inside boards. As the aviation segment proceeds to prioritize fuel proficiency and execution, the request for glass fiber polyamide-imide gum is anticipated to rise relentlessly.

Growing Car Applications:

The car industry is progressively receiving glass fiber polyamide-imide gum for different applications, counting under-the-hood components, inside parts, and outside boards. These tars give fabulous strength-to-weight proportion, affect resistance, and dimensional steadiness, contributing to moved-forward vehicle execution, fuel effectiveness, and solidness. With the car sector's developing accentuation on lightweight, electric vehicles, and supportability, the request for glass fiber polyamide-imide gum is forecasted to rise.

Rising Request in Electrical & Hardware Division:

The electrical & hardware division may be a key driver for the worldwide glass fiber polyamide-imide gum advertise, driven by the request for high-performance materials in electronic components, printed circuit sheets (PCBs), and electrical cover applications. Glass fiber polyamide-imide gum offers fabulous dielectric properties, warm soundness, and chemical resistance, making it suitable for demanding electrical situations. As mechanical progressions proceed to drive development in electronic gadgets and electrical frameworks, the request for these specialized gums is anticipated to develop quickly.

Global Glass Fiber Polyamide-imide Resin Market Restraints and Challenges:

Fetched Affectability in Rising Markets:

One critical limitation within the worldwide glass fiber polyamide-imide tar showcase is the fetched affectability watched in rising markets. Despite the prevalent execution characteristics of these tars, their generally higher toll compared to customary materials can hinder far-reaching selection, especially in locales with budget limitations. Price-conscious consumers and producers may prefer more reasonable choices, restricting the market's development potential in these economies.

Administrative Compliance and Natural Concerns:

Administrative compliance and natural concerns pose striking challenges for the glass fiber polyamide-imide gum advertise. Rigid directions overseeing the utilization of dangerous chemicals and emanations require compliance with strict measures, including complexity in fabricating forms and expanding generation costs. Besides, developing natural mindfulness among customers and weight to receive maintainable hones compel producers to investigate eco-friendly choices and contribute to cleaner generation innovations to moderate natural effects.

Supply Chain Disturbances and Crude Fabric Accessibility:

Supply chain disturbances and crude material availability show noteworthy challenges to advertising players within the glass fiber polyamide-imide gum industry. Reliance on key crude materials, such as polyamide and imide monomers, uncovered producers to dangers related to cost instability, deficiencies, and geopolitical instabilities. Disturbances within the supply chain, whether due to common fiascos, exchange debates, or calculated issues, can lead to generation delays, expanded costs, and compromised item quality, affecting advertising solidness and competitiveness.

Global Glass Fiber Polyamide-imide Resin Market Opportunities:

Development in Composite Fabricating Methods:

The worldwide glass fiber polyamide-imide tar showcase presents critical openings for advancement in composite fabricating methods. Progressions in forms such as compression molding, gum exchange molding (RTM), and fiber winding empower the generation of complex, high-performance components with made strides in proficiency and cost-effectiveness. By leveraging these inventive procedures, producers can improve item quality, extend plan capabilities, and address rising showcase requests for lightweight, solid materials over different businesses, including aviation, car, and electrical & hardware.

Development in Rising Economies:

Developing economies offer promising openings for the development of the glass fiber polyamide-imide gum showcase. Quick industrialization, urbanization, and foundation advancement in locales such as Asia-Pacific, Latin America, and the Center East make a conducive environment for expanded requests for progressed composite materials. With rising speculations in development, transportation, and vitality segments, there's a developing requirement for high-performance materials that offer prevalent mechanical properties, erosion resistance, and strength. Advertise players can capitalize on these openings by building up key organizations, growing dissemination systems, and customizing item offerings to cater to the particular necessities of developing markets.

Economical Arrangements and Green Innovations:

The developing accentuation on supportability and natural stewardship presents openings for the glass fiber polyamide-imide tar showcase to create feasible arrangements and green innovations. Shopper mindfulness almost the natural effect of materials and fabricating forms is driving requests for eco-friendly options that minimize carbon impression and advance circular economy standards. By contributing to the investigation and improvement of bio-based tars, recyclable composites, and energy-efficient generation strategies, industry partners can position themselves as pioneers in supportability and meet the advancing needs of ecologically cognizant shoppers and administrative bodies.

GLASS FIBER POLYAMIDE-IMIDE RESIN MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

3.5% |

|

Segments Covered |

By Product type, Processing Technique, Formulation, End-User, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Solvay SA, Evonik Industries AG, BASF SE, SABIC, Huntsman Corporation, DIC Corporation, Celanese Corporation, Arkema Group, Sumitomo Chemical Company Limited, Quadrant AG |

Glass Fiber Polyamide-imide Resin Market Segmentation: By Product Type

-

Unidirectional Tape

-

Fabric

-

Prepreg

-

Molded Parts

-

Others

Among the different item sorts within the glass fiber polyamide-imide tar showcase, prepreg stands out as one of the foremost viable choices. Prepreg, brief for pre-impregnated, alludes to composite materials where the support strands, such as glass fiber, are pre-impregnated with a gum network, in this case, polyamide-imide tar. This preparation guarantees uniform gum dissemination and exact fiber arrangement, coming about in reliable mechanical properties and improved execution characteristics. Prepregs offer great taking care of properties, permitting for ease of lay-up and molding amid fabricating forms. In addition, they give prevalent dimensional solidness, affect resistance, and warm execution, making them appropriate for a wide run of applications in aviation, car, and electrical businesses.

The flexibility of prepreg materials, coupled with their tall strength-to-weight proportion and fabulous surface wrap-up, makes them a perfect choice for basic components requiring exacting execution necessities and unwavering quality. By and large, prepreg stands as a profoundly viable item sort within the glass fiber polyamide-imide gum advertises, advertising producers and end-users alike a dependable arrangement for progressed composite applications.

Glass Fiber Polyamide-imide Resin Market Segmentation: By Processing Technique

-

Compression Molding

-

Injection Molding

-

Resin Transfer Molding (RTM)

-

Filament Win

Among the handling strategies utilized within the glass fiber polyamide-imide gum advertise, gum exchange molding (RTM) develops as an exceedingly compelling strategy. RTM includes infusing tar into a closed form containing dry fortification filaments, such as glass fiber, beneath weight. This procedure permits for exact control over the tar mixture, coming about in uniform dissemination all through the shape and the fortification filaments. RTM offers a few preferences, counting the capacity to deliver complex shapes with perplexing subtle elements, tall fiber volume division, and great surface wrap-up. Furthermore, RTM empowers the generation of large-scale components with negligible fabric squander and decreased cycle times compared to conventional strategies like compression molding. The capacity to tailor the gum definition and fiber introduction in RTM forms guarantees optimized mechanical properties, such as quality, firmness, and affect resistance, custom-made to particular application prerequisites. As a result, RTM has found broad utilization in businesses such as aviation, car, and marine, where lightweight, high-performance composite materials are in request. Generally, tar exchange molding stands as a highly effective handling method within the glass fiber polyamide-imide tar advertises, advertising producers the adaptability, productivity, and accuracy required to create progressed composite components for assorted applications.

Glass Fiber Polyamide-imide Resin Market Segmentation: By Formulation

-

Standard Grade

-

Reinforced Grade

Within the glass fiber polyamide-imide gum advertisement, the fortified review formulation stands out as the foremost compelling alternative. Fortified review details join extra support materials, such as glass filaments or other added substances, to improve the mechanical properties and execution characteristics of the gum. By fortifying the tar lattice, producers can altogether make strides in quality, firmness, and affect resistance, making the coming-about composite materials perfect for applications requiring tall solidness and auxiliary astuteness. Strengthened review details offer a prevalent strength-to-weight proportion compared to standard review gums, making them especially well-suited for lightweight basic components in aviation, car, and mechanical divisions. Besides, the custom-made support permits for customization of mechanical properties to meet particular application prerequisites, giving flexibility and adaptability in item plan and execution optimization. By and large, the reinforced grade detailing speaks to an exceedingly successful arrangement within the glass fiber polyamide-imide tar showcase, advertising upgraded execution, toughness, and flexibility for a wide run of progressed composite applications.

Glass Fiber Polyamide-imide Resin Market Segmentation: By End-User

-

Aerospace

-

Automotive

-

Electrical & Electronics

-

Oil & Gas

-

Industrial

-

Others

Among the different end-users within the glass fiber polyamide-imide tar showcase, the aviation division emerges as one of the foremost compelling fragments. The aviation industry requests materials that offer remarkable strength-to-weight proportion, warm soundness, and resistance to cruel natural conditions, making glass fiber polyamide-imide gum a perfect choice for a wide extend of applications. In aviation fabricating, components such as airplane auxiliary parts, motor components, inside boards, and composite materials require materials that can withstand extraordinary temperatures, tall push loads, and destructive situations. Glass fiber polyamide-imide gum offers predominant mechanical properties, including high malleable quality, solidness, and affect resistance, besides amazing warm and chemical solidness, assembly the exacting execution prerequisites of the aviation industry. Moreover, the lightweight nature of these composites contributes to fuel effectiveness, lessening general operational costs for aircraft and flying machine producers. With the aviation division ceaselessly enhancing and looking for progressed materials to improve aircraft execution and effectiveness, glass fiber polyamide-imide resin remains a key enabler of innovation and mechanical headway within the aviation industry, making it one of the foremost successful end-user fragments within the advertise.

Glass Fiber Polyamide-imide Resin Market Segmentation: Regional Analysis

-

North America

-

Europe

-

Asia-Pacific

-

South America

-

Middle East & Africa

The worldwide glass fiber polyamide-imide tar advertise is characterized by a conveyance of showcase share over diverse locales. North America holds the biggest advertising share at 33%, driven by vigorous requests from aviation, car, and electrical businesses, where progressed composite materials are broadly utilized. Europe takes after closely with an advertising share of 27%, ascribed to solid fabricating capabilities, innovative headways, and exacting administrative benchmarks driving appropriation in aviation and car divisions. The Asia-Pacific locale accounts for 26% of the advertising share, encountering fast industrialization, foundation advancement, and expanding speculations in aviation and car businesses. South America holds a smaller but outstanding share at 9%, fueled by development openings in car and oil & gas divisions. Finally, the Center East and Africa locale captured a 5% advertise share, driven by extending mechanical exercises and foundation ventures. In general, the dissemination of showcase share by locale reflects the different request scenes and development openings shown over distinctive geographic locales within the glass fiber polyamide-imide gum advertise.

COVID-19 Impact Analysis on the Global Glass Fiber Polyamide-imide Resin Market:

The worldwide glass fiber polyamide-imide gum advertises experienced a critical effect from the COVID-19 widespread, coming about in disturbances over the supply chain, generation slowdowns, and decreased requests from end-user businesses. The episode was driven to far-reaching lockdowns, travel limitations, and financial instabilities, causing a transitory end in fabricating exercises and venture delays in key segments such as aviation, car, and development. The diminished shopper investing and speculation estimations advance hosed showcase development amid the widespread period. In any case, as economies continuously revived and immunization endeavors quickened, the advertise saw a recuperation in request, upheld by continuing fabricating operations, expanding development exercises, and developing ventures in foundation ventures. Additionally, the widespread highlighted the significance of lightweight, high-performance materials in basic applications such as healthcare, transportation, and renewable vitality, driving reestablished centers and ventures in progressed composite materials like glass fiber polyamide-imide tar. Moving forward, the showcase is anticipated to bounce back and witness relentless development as businesses adjust to the modern typical and use progressed materials to improve execution, productivity, and maintainability in a post-pandemic world.

Latest Trends/ Developments:

The glass fiber polyamide-imide tar advertisement is seeing a few striking patterns and advancements that are forming its direction and driving development over different businesses. One unmistakable slant is the expanding selection of maintainable and eco-friendly materials, driven by developing natural concerns and administrative weights. Producers are investigating bio-based tars, reused strands, and green generation forms to play down natural effects and meet supportability objectives. Furthermore, there's a rising request for lightweight and high-performance materials in the car, aviation, and electrical businesses, fueled by the thrust towards fuel productivity, charge, and innovative progressions. This drift is driving the improvement of progressed composites with made strides in mechanical properties, warm steadiness, and toughness. Additionally, innovative headways in tar details, handling strategies, and added substance fabricating are empowering the generation of complex components with enhanced execution characteristics and have taken a toll on productivity. Besides, there's a developing accentuation on digitalization, computerization, and savvy fabricating arrangements to optimize generation forms, move forward item quality, and meet advancing client requests. By and large, these patterns and advancements emphasize the energetic nature of the glass fiber polyamide-imide gum showcase and its significant part in driving the development and advancement of different businesses.

Key Players:

-

Solvay SA

-

Evonik Industries AG

-

BASF SE

-

SABIC

-

Huntsman Corporation

-

DIC Corporation

-

Celanese Corporation

-

Arkema Group

-

Sumitomo Chemical Company Limited

-

Quadrant AG

Chapter 1. Glass Fiber Polyamide-imide Resin Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Glass Fiber Polyamide-imide Resin Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Glass Fiber Polyamide-imide Resin Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Glass Fiber Polyamide-imide Resin Market Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Glass Fiber Polyamide-imide Resin Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Glass Fiber Polyamide-imide Resin Market – By Product Type

6.1 Introduction/Key Findings

6.2 Unidirectional Tape

6.3 Fabric

6.4 Prepreg

6.5 Molded Parts

6.6 Others

6.7 Y-O-Y Growth trend Analysis By Product Type

6.8 Absolute $ Opportunity Analysis By Product Type, 2024-2030

Chapter 7. Glass Fiber Polyamide-imide Resin Market – By Processing Technique

7.1 Introduction/Key Findings

7.2 Compression Molding

7.3 Injection Molding

7.4 Resin Transfer Molding (RTM)

7.5 Filament Win

7.6 Y-O-Y Growth trend Analysis By Processing Technique

7.7 Absolute $ Opportunity Analysis By Processing Technique, 2024-2030

Chapter 8. Glass Fiber Polyamide-imide Resin Market – By Formulation

8.1 Introduction/Key Findings

8.2 Standard Grade

8.3 Reinforced Grade

8.4 Y-O-Y Growth trend Analysis By Formulation

8.5 Absolute $ Opportunity Analysis By Formulation , 2024-2030

Chapter 9. Glass Fiber Polyamide-imide Resin Market – By End-User

9.1 Introduction/Key Findings

9.2 Aerospace

9.3 Automotive

9.4 Electrical & Electronics

9.5 Oil & Gas

9.6 Industrial

9.7 Others

9.8 Y-O-Y Growth trend Analysis By End-User

9.9 Absolute $ Opportunity Analysis By End-User, 2024-2030

Chapter 10. Glass Fiber Polyamide-imide Resin Market, By Geography – Market Size, Forecast, Trends & Insights

10.1 North America

10.1.1 By Country

10.1.1.1 U.S.A.

10.1.1.2 Canada

10.1.1.3 Mexico

10.1.2 By Product Type

10.1.3 By End-User

10.1.4 By Formulation

10.1.5 Countries & Segments - Market Attractiveness Analysis

10.2 Europe

10.2.1 By Country

10.2.1.1 U.K

10.2.1.2 Germany

10.2.1.3 France

10.2.1.4 Italy

10.2.1.5 Spain

10.2.1.6 Rest of Europe

10.2.2 By Product Type

10.2.3 By Processing Technique

10.2.4 By Formulation

10.2.5 By End-User

10.2.6 Countries & Segments - Market Attractiveness Analysis

10.3 Asia Pacific

10.3.1 By Country

10.3.1.1 China

10.3.1.2 Japan

10.3.1.3 South Korea

10.3.1.4 India

10.3.1.5 Australia & New Zealand

10.3.1.6 Rest of Asia-Pacific

10.3.2 By Product Type

10.3.3 By Processing Technique

10.3.4 By Formulation

10.3.5 By End-User

10.3.6 Countries & Segments - Market Attractiveness Analysis

10.4 South America

10.4.1 By Country

10.4.1.1 Brazil

10.4.1.2 Argentina

10.4.1.3 Colombia

10.4.1.4 Chile

10.4.1.5 Rest of South America

10.4.2 By Product Type

10.4.3 By Processing Technique

10.4.4 By Formulation

10.4.5 By End-User

10.4.6 Countries & Segments - Market Attractiveness Analysis

10.5 Middle East & Africa

10.5.1 By Country

10.5.1.1 United Arab Emirates (UAE)

10.5.1.2 Saudi Arabia

10.5.1.3 Qatar

10.5.1.4 Israel

10.5.1.5 South Africa

10.5.1.6 Nigeria

10.5.1.7 Kenya

10.5.1.8 Egypt

10.5.1.9 Rest of MEA

10.5.2 By Product Type

10.5.3 By Processing Technique

10.5.4 By Formulation

10.5.5 By End-User

10.5.6 Countries & Segments - Market Attractiveness Analysis

Chapter 11. Glass Fiber Polyamide-imide Resin Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

11.1 Solvay SA

11.2 Evonik Industries AG

11.3 BASF SE

11.4 SABIC

11.5 Huntsman Corporation

11.6 DIC Corporation

11.7 Celanese Corporation

11.8 Arkema Group

11.9 Sumitomo Chemical Company Limited

11.10 Quadrant AG

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The advertising for glass fiber polyamide-imide gum at the worldwide level is growing rapidly; it was evaluated to be worth 0.15 USD billion in 2023 and is anticipated to extend to 0.19 USD billion by 2030, with an anticipated compound yearly development rate (CAGR) of 3.5% from 2024 to 2030.

The essential drivers of the Worldwide Glass Fiber Polyamide-imide Tar Advertise incorporate expanding requests from aviation, car, and electrical businesses for lightweight, high-performance materials.

The key challenges confronting the Worldwide Glass Fiber Polyamide-imide Gum Advertise incorporate fetched affectability in rising markets and administrative compliance concerns concerning natural maintainability.

In 2023, North America held the largest share of the global glass fiber polyamide-imide resin market.

Solvay SA Evonik Industries AG, BASF SE, SABIC, Huntsman Corporation, DIC Corporation, Celanese Corporation, Arkema Group, Sumitomo Chemical Company Limited, Quadrant AG, Mitsubishi Chemical Corporation, Toray Industries, Inc. Are the main players.