Global Fly Ash Cenospheres Market Size (2023 – 2030)

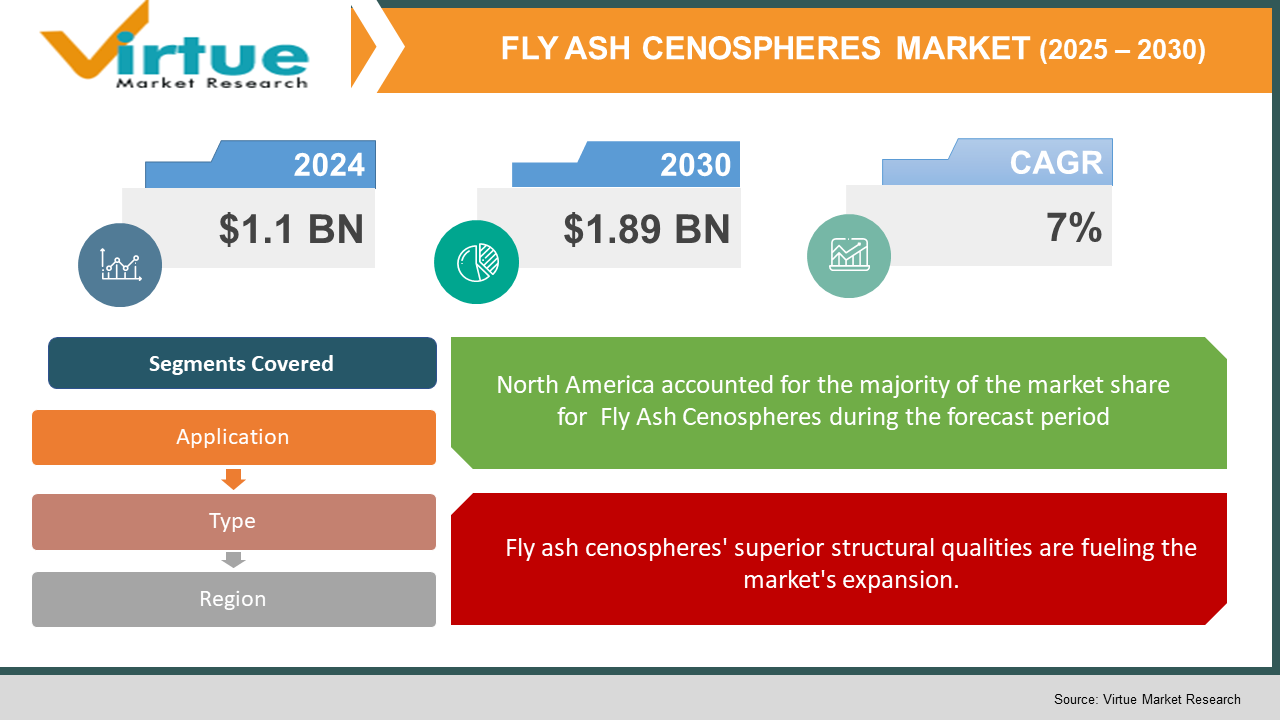

In 2022, the Global Fly Ash Cenospheres Market was valued at USD 1.1 billion and is projected to reach a market size of USD 1.89 billion by 2030. Over the forecast period of 2023-2030, the market is projected to grow at a CAGR of 7%. The market is driven by the increasing demand from end-use sectors like construction, paints & coatings, refractory, and oil & gas. Growth in non-ferrous metal production, construction activity, and infrastructure development, as well as material science and technological advancements, are the main market drivers.

Industry Overview:

Fly ash Cenospheres are extremely small, precisely spherical, and smooth fly ash particles. Fly ash microspheres are small material spheres that are created when coal is burned in a power plant. Microscopic glass particles are present in fly ash, a byproduct of coal combustion, and they collect into spheres as the material cools. Concrete and polymers can be made with the help of these small spheres. Fly ash microspheres are used in the automotive and energy industries. Fly ash cenospheres have a starting activity that is noticeably higher than typical fly ash but notably lower than silica fume. Fly ash cenospheres are capable of consuming Ca(OH)2, a byproduct of cement hydration, however more slowly than silica fume. Cenospheres, commonly referred to as microspheres, are utilized in a wide range of products, including caulking, paints, and coatings. The key factors anticipated to fuel the market's growth in the future are the expanding demand for cenospheres from sectors including construction, oil & gas, and automotive, as well as cenospheres' superior structural qualities. The main advantages of cenospheres are lightweight, viscosity reduction, improved lubricity, and improved refractoriness. Fly ash microspheres are frequently used in the construction industry. The market for fly ash microspheres is being propelled by new applications, from construction supplies to autonomous industrial applications. Fly ash microspheres were initially utilized as extenders for plastic compounds due to their compatibility with phenolic resins, thermoplastics, epoxies, polyesters, latex, urethanes, and plastisols. It is also utilized in synthetic foams, speciality cement, building materials such coatings and composites, vehicle bodywork, paint, marine craft hulls, insulations, and sporting goods. Conductive coatings, tiles, and fabrics use cenospheres with silver coatings for electromagnetic shielding and abrasion resistance. Fly ash cenospheres are very appealing to all end-use applications due to their water resistance, durability, lightness, rigidity, and insulating qualities. There are numerous applications for cenospheres in the automobile industry.

COVID-19 pandemic impact on the Fly Ash Cenospheres Market

The fly ash cenospheres industry was significantly impacted by the COVID-19 pandemic in terms of both production and demand from end-use industries as a result of the temporary suspension of economic and industrial activity. Many firms encountered a labor scarcity during lockdowns, which hampered market expansion. The market is projected to recover from the revenue loss in the post-pandemic phase owing to numerous improvements and upgrades. Suppliers of cenospheres are working to improve their market standing by acquiring more production capacity to meet demand and serve a range of applications.

MARKET DRIVERS:

Fly ash cenospheres' superior structural qualities are fueling the market's expansion.

Cenospheres are lightweight fillers with considerable financial advantages. Cenospheres are a viable option for use in a variety of end-use industries, including construction, oil and gas, paints and coatings, and refractory, because they have excellent structural advantages like reduced weight, low density, electrical characteristics, high melting temperature, and high fluidity. Due to their special combination of spherical shape, high compression, low specific gravity, superior thermal and acoustical insulation capabilities, and inertness to acids and alkalis, cenospheres are utilized in various industries. Cenospheres are 30% lighter than most resins and 75% lighter than various fillers like clay, talc, and calcium carbonate. All of the benefits of a spherical shape are combined with the extra advantages of low density in a cenosphere at a reasonable price. To create lightweight composite materials with more strength than existing foam materials, known as syntactic foam, some firms have begun to fill metals and polymers with cenospheres. The automotive industry is using syntactic foams made of aluminum.

Growing Use of Insulation Materials and Growing Use in Construction Industry is Driving Market Expansion

The market for cenospheres is anticipated to be driven by increased adoption of electric vehicles and rising utilization of insulation materials. Additionally, the demand is anticipated to be greatly impacted by the sharp rise in the worldwide end-use markets for cenospheres as well as the uses of fly ash microspheres in industries including ceramics, construction, plastic, recreation, and technology, automotive, energy, among others. One of the most important drivers of increased demand for cenospheres on the global market is anticipated to be the expanding production of the construction industry. The need for cenospheres in construction activities is predicted to increase as a result of the new construction activities brought on by rapid urbanization.

Material Science technological advances are driving the fly ash cenospheres market

The global market for cenospheres is primarily driven by the advantages of cenosphere powder as well as its application as a lightweight construction material. Cenospheres are used in infrastructure, domestic, commercial, and industrial building projects. The production of cenospheres is becoming increasingly automated and innovative, and there is a growing market demand for them in the construction industry. The automobile companies are attempting to create strong, durable, and compact cenospheres for all sorts of cars so that they can be utilized easily and support their weight. Due to improvements in material science technology, manufacturing industries have been able to use newly produced cenosphere materials, such as steel and aluminum alloys, to make the cenospheres of automobiles stronger and more resilient under difficult load conditions.

MARKET RESTRAINTS:

The primary issues reducing demand for cenospheres to some extent are the limited supply of raw materials and the availability of substitutes.

Fly ash used to be released directly into the atmosphere, but due to pollution concerns, it now needs to be caught before being released. Fly ash is therefore used in end-use industries because removing cenospheres would necessitate additional processing of the fly ash. Therefore, governments are interested in boosting fly ash over cenospheres. Because there are now few places to extract cenospheres, businesses find it challenging to create cenospheres as per demand. End users are therefore looking for innovative cenosphere substitutes. A few oilfield businesses, for instance, are switching from cenospheres to glass bubbles, while other construction companies have begun employing perlite as a cenosphere replacement.

Health issues and environmental concerns can restrain the growth of Fly Ash Cenospheres

Cenospheres are microstructured, light-weighted particles that are entrained in flue gases with superfine fly ash. Some of these particles have an exceptionally low density. Due to their low density, these microspheres and the ashes enter ash settling basins where they primarily accumulate at the exterior surface and are easily removed by wind and rain. The most hazardous scenario for these particles is their entrainment in the wind, which can transport them over great distances, allow them to enter the respiratory systems of both humans and animals, and can lead to cardiovascular and respiratory diseases.

GLOBAL FLY ASH CENOSPHERES MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

7% |

|

Segments Covered |

By Type, Applications, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

UAB SUEK Baltic, Omya, Durgesh Merchandise Pvt. Ltd, Envirospheres, Petra India Group, PR Ecoenergy Pvt. Ltd., Cenosphere India Pvt. Ltd, Qingdao Eastchem Inc., Salt River material, and Reslab Microfiller |

This research report on the global Fly Ash Cenospheres Market has been segmented based on sensor type, Applications, and region.

Fly Ash Cenospheres Market – By Type

- Gray cenospheres

- White cenospheres

Based on Type, the Fly Ash Cenospheres Market is bifurcated into Gray cenospheres and White cenospheres. In terms of value, the gray cenosphere segment is anticipated to exhibit the fastest growth during the forecast period. Fly ash typically contains gray cenospheres than white ones. Alumina is scarce in these cenospheres, whereas silica and iron are abundant. Gray cenospheres are utilized in many different products, including bricks, rubber, polymers, resins, and concrete.

Fly Ash Cenospheres Market – By Applications

- Oil & Gas

- Paints & Coatings

- Cosmetics

- Aerospace

- Medical Technology

- Automotive

- Life Science & Biotechnology

- Others

Based on Applications, the Fly Ash Cenospheres Market is bifurcated into Oil & Gas, Paints & Coatings, Cosmetics, Aerospace, Medical Technology, Automotive, Life Science & Biotechnology, and Others. The primary usage of the cenosphere is as a filter in all of the end-use sectors on the global market. In the construction business, cenospheres are being employed as filters, especially when producing cement for low-density concrete. New products are constantly being developed, ranging from roofing materials to plasters and grouts. The number of cenospheres used in the building sector keeps rising. To create lightweight composite materials with greater strength than foam materials, numerous firms have recently begun filling cenospheres with metals and polymers. Similarly, silver-coated cenospheres are utilized in textiles, tiles, and conductive coatings for electromagnetic shielding and antistatic coatings. The demand for cenospheres in the oil and gas industry is anticipated to be driven by increased shale gas exploration and production operations in North America and the Middle East.

Fly Ash Cenospheres Market - By Region:

- North America

- Europe

- Asia-Pacific

- Rest of the World

Geographically, the North American fly ash cenospheres market is anticipated to account for the largest market share due to the region's expanding oil & gas and automotive sectors. A third of the global cenospheres market, or 32.1 %, is dominated by North America. The strong presence of top cenosphere producers and numerous technological developments are propelling the market's expansion. The Asia Pacific Fly Ash Cenospheres Market is anticipated to expand at a high CAGR during the projected period. The use of cenospheres has increased across a variety of end-user industries, including oil & gas, automotive, paints, and coatings, among others, as a result of the fast industrialization in developing nations. The demand for cenospheres or fly ash microspheres is anticipated to rise sharply due to the expanding range of their applications and the abundance of raw materials, primarily from new and existing thermal power plants.

Major Players in the Market

Some of the major players operating in the Fly Ash Cenospheres market include

- UAB SUEK Baltic

- Omya

- Durgesh Merchandise Pvt. Ltd

- Envirospheres

- Petra India Group

- PR Ecoenergy Pvt. Ltd.

- Cenosphere India Pvt. Ltd

- Qingdao Eastchem Inc.

- Salt River material

- Reslab Microfiller.

Notable happenings in the Global Fly Ash Cenospheres Market in the recent past:

Collaboration- In September 2019, CenoStar and XG Sciences worked collaborated to create novel materials that contain graphene nanoplatelets for use in the manufacturing of concrete.

Chapter 1. Fly Ash Cenospheres Market – Scope & Methodology

1.1. Market Segmentation

1.2. Assumptions

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. Fly Ash Cenospheres Market – Executive Summary

2.1. Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.3. COVID-19 Impact Analysis

2.3.1. Impact during 2023 - 2030

2.3.2. Impact on Supply – Demand

Chapter 3. Fly Ash Cenospheres Market – Competition Scenario

3.1. Market Share Analysis

3.2. Product Benchmarking

3.3. Competitive Strategy & Development Scenario

3.4. Competitive Pricing Analysis

3.5. Supplier - Distributor Analysis

Chapter 4. Fly Ash Cenospheres Market Entry Scenario

4.1. Case Studies – Start-up/Thriving Companies

4.2. Regulatory Scenario - By Region

4.3 Customer Analysis

4.4. Porter's Five Force Model

4.4.1. Bargaining Power of Suppliers

4.4.2. Bargaining Powers of Customers

4.4.3. Threat of New Entrants

4.4.4. Rivalry among Existing Players

4.4.5. Threat of Substitutes

Chapter 5. Fly Ash Cenospheres Market - Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. Fly Ash Cenospheres Market – By Type

6.1. Gray cenospheres

6.2. White cenospheres

Chapter 7. Fly Ash Cenospheres Market – By Application

7.1. Oil & Gas

7.2. Paints & Coatings

7.3. Cosmetics

7.4. Aerospace

7.5. Medical Technology

7.6. Automotive

7.7. Life Science & Biotechnology

7.8. Others

Chapter 8. Fly Ash Cenospheres Market- By Region

8.1. North America

8.2. Europe

8.3. Asia-Pacific

8.4. Latin America

8.5. The Middle East

8.6. Africa

Chapter 9. Fly Ash Cenospheres Market – Company Profiles – (Overview, Product Portfolio, Financials, Developments)

9.1. UAB SUEK Baltic

9.2. Omya

9.3. Durgesh Merchandise Pvt. Ltd

9.4. Envirospheres

9.5. Petra India Group

9.6. PR Ecoenergy Pvt. Ltd.

9.7. Cenosphere India Pvt. Ltd

9.8. Qingdao Eastchem Inc.

9.9. Salt River material

9.10. Reslab Microfiller.

Download Sample

Choose License Type

2500

4250

5250

6900