Failure Analysis Market size (2024 - 2030)

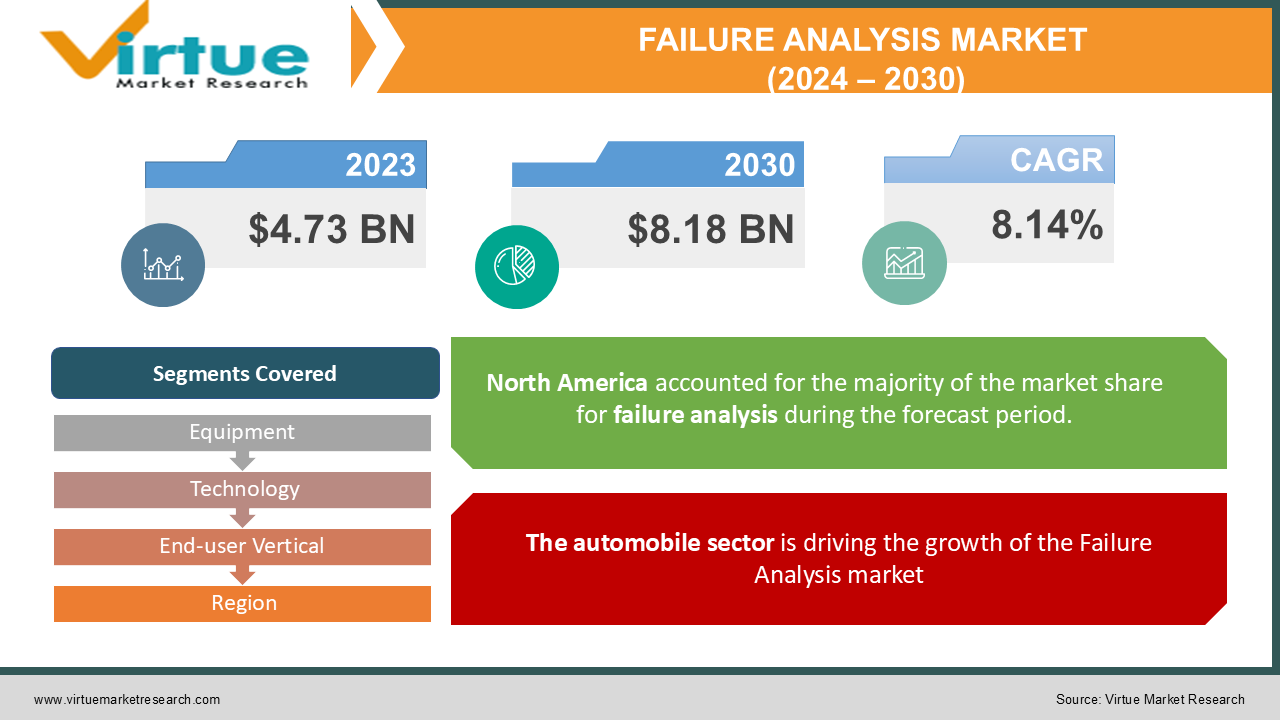

In 2023, the Global Failure Analysis Market was valued at USD 4.73 billion, and is projected to reach a market size of USD 8.18 billion by 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 8.14%.

Industry Overview

The increase in the growth of the industry is due to an increase in demand for failure analysis by automobile manufacturers. These manufacturers are also employing advanced tools for performance analysis and accident reconstruction. This is leading to the enhancement of the market’s growth.

Failure Analysis is a technique used to identify the reason for failure to correct or eliminate it. It involves understanding the root cause of failure to prevent failures in the future. These root causes of failure can occur due to assembly error, fastening failure, defects occurring while manufacturing, use of low-quality material, errors in design, environmental factors, discontinuities in casting, errors in quality assurance and control, and defects generated during operations.

Automation has propelled growth in the industry. The manufacturers of electric vehicles and electronic devices such as batteries, energy systems, and mobile phones use failure analysis to enhance the performance and output. These manufacturers use electron microscopy techniques to break down these devices to their basic structures at the atomic scale. Along with this, the spectroscopy technique is also used to check the reasons for inefficiency caused by the defects.

Service providers are trying to find out new avenues to provide effective failure analysis in the industry. For example, in 2021, SGS announced to invest in the Secondary ION Mass Spectrometry equipment for the testing of marine fuels. Another area where failure analysis is majorly used is to identify the cause of vehicular accidents for private and commercial vehicles. These vehicular accidents can cause severe damage to the property, body, or even loss of life.

Impact of COVID-19

Due to the lockdown imposed by countries to limit the spread of COVID-19 the failure analysis industry took a blow. The supply chain and production of semiconductors were disrupted. The testing plants in Asia Pacific had to suspend their operations. This created a problem for the semiconductor manufacturers as they relied on these testing plants to test the defects in the products.

Market Drivers

The automobile sector is driving the growth of the Failure Analysis market

Automobile companies have been facing numerous challenges regarding the prices of electronic equipment. To maintain the quality of the electronic components as well as to keep the prices low the manufacturing process must be highly efficient. The components should be able to withstand quality control procedures. The automobile sector is also investing highly in IoT devices, ADAS systems, and smart sensors. These devices aim to improve the safety of the vehicle while driving and prevent road accidents. Every year 1.3 million lose their lives due to road accidents, according to a report by WHO in 2021. These accidents also cause major non-fatal injuries and disabilities.

There can be numerous causes of these accidents such as fault in the product design, contamination, improper calibration, and handling. These have raised concerns regarding the quality of the components used to prevent these incidents in the future.

Government interventions are driving the growth of the Failure Analysis market

The government has intervened in the automotive market with tough rules and regulations regarding the safety of vehicles. There has been a surge in the demand for automobiles in the Asia Pacific region and due to this the automobile industry has grown considerably. Especially, the number of passenger vehicles has increased a lot. The increase in demand for the automobile sector has led to the growth of the Failure Analysis market.

The failure in the electronic components of automobiles can cause accidents. Hence, these components must be well-tested before being installed in the vehicles. This can be achieved by proper failure analysis techniques where the root cause of the failure can be found and can be corrected and eliminated in the future.

Failure analysis is also an important tool to determine which component led to the accident. Hence, it is used to establish the cause of the accident.

Market Restraints

The high cost of equipment is a market restraint for the growth of the Failure Analysis market

The equipment to conduct Failure analysis is very expensive. It is an exceptional investment that requires high entry barriers for new entrants. Although the cost is a restraining factor it saves labor costs, increases productivity, and saves time.

But most companies do not have enough money to cover the installation cost required for the Failure Analysis. This lack of funds is restraining the growth by affecting the supply. Additionally, there is maintenance cost that the company has to bear over the long run.

The complexity of operations is a market restraint for the growth of the Failure Analysis market

Failure analysis runs on cutting-edge technology in which the operations are highly technical and complex. To conduct these operations technical professionals are required in the team who can efficiently identify the root cause of the failure. Unfortunately, the market suffers from a low number of highly skilled professionals with which the industry is not able to meet the demand. It is further acting as a restraining force for the growth of the industry. As a smaller number of qualified and trained professionals are there the adoption of technology will also be lesser, affecting the industry badly.

FAILURE ANALYSIS MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

8.14% |

|

Segments Covered |

By equipment, technology, end-user vertical, and region. |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Eurofins Scientific (Luxembourg), Thermo Fisher Scientific, Inc. (US), Oxford Instruments (UK), Carl Zeiss (Germany), Leica Microsystems GmbH (Germany), Hitachi High-Technologies Corporation (Japan), Semilab (Hungary), TESCAN OSRAY HOLDING (Czech Republic), A&D Company, Ltd. (Japan) |

This research report on the failure analysis market has been segmented and sub-segmented based on equipment, technology, end-user vertical, and region.

Failure Analysis Market – By Technology

-

Secondary ION Mass Spectrometry (SIMS)

-

Energy Dispersive X-ray Spectroscopy (EDX)

-

Chemical Mechanical Planarization (CMP)

-

Other Technologies

There are different types of technology based on which we can further segment the Failure Analysis market. There are mainly four types as mentioned below. Secondary ION Mass Spectrometry uses the spectrometry technique to find the root cause of the failure by cutting a cross-section of the electronic device. Whereas Energy Dispersive X-ray Spectroscopy uses an integration of X-rays and spectroscopy to find the defects.

Failure Analysis Market – By Equipment

-

Scanning Electron Microscope (SEM)

-

Focused Ion Beam (FIB) System

-

Transmission Electron Microscope (TEM)

-

Dual Beam System

There are various types of equipment that can be used to conduct Failure Analysis. Mainly there are four types of equipment. This equipment either makes use of electron microscopy or ion beam depending on the electronic device used or the problem at hand. Majorly, Scanning Electron Microscope is used in Failure analysis to find the root cause of the failure which would be further eliminated or corrected.

Failure Analysis Market – By End-user Vertical

-

Automotive

-

Oil and Gas

-

Defense

-

Construction

-

Manufacturing

-

Other End-user Verticals

Failure Analysis can be segmented mainly into five verticals, based on end-use. The Failure Analysis technique is used in almost every manufacturing plant. The automotive industry is a major user of Failure Analysis which uses the technique to find the root cause of the accident. This technique is also used to find out the component responsible for the accident. Similarly, the Failure Analysis technique is used in Oil and Gas and other manufacturing industries.

Failure Analysis Market – By Region

-

North America

-

Europe

-

Asia-Pacific

-

South America

-

Middle-East and Africa

North America has the largest market for Failure analysis. It is predominantly due to the presence of the USA which invested highly in the Failure analysis from the start. The region is house to one of the biggest automobile manufacturers such as GM and Ford which makes it the home for Failure analysis.

Additionally, the USA is also one of the largest producers of crude oil and has various oil rigs across North America. The Deepwater Horizon spill accident of 2010 due to mechanical failure further underscored the importance of Failure analysis which helps to find out the root cause of the failure and prevents it from happening in the future.

There have been infrastructural mishappening also in North America. There have been multiple failures such as East Coast’s main gasoline pipeline, the Texas power grid, and a freeway bridge over the Mississippi River. These incidents have impacted businesses, lives, and loss of life.

The Biden administration passed infrastructural laws to seek investment in big projects in critical infrastructure. The main focus of these laws is to modernize the infrastructure of the country by a complete overhaul of public roads, transits, and airports. Walking on similar lines, Canada also invested CAD 81.6 bn in 2020 to improve the infrastructure of the country.

Failure Analysis Market – By Competition

-

Eurofins Scientific (Luxembourg)

-

Thermo Fisher Scientific, Inc. (US)

-

Oxford Instruments (UK)

-

Carl Zeiss (Germany)

-

Leica Microsystems GmbH (Germany)

-

Hitachi High-Technologies Corporation (Japan)

-

Semilab (Hungary)

-

TESCAN OSRAY HOLDING (Czech Republic)

-

A&D Company, Ltd. (Japan)

The failure Analysis market is highly competitive and has several key players. There are a few players with major market shares. All the companies have made new strategic ways to gain the market in the particular operational domain they operate in. Some companies have sought to do business collaboratively and join hands. This gives them access to other companies’ business, market share, and profitability. Major firms in the Failure Analysis market are Exponent Inc., Road Microtec GmbH, and EAG Inc.

Recent Developments

-

In September 2021, a semiconductor supply and quality services company called RoodMicrotec NV got the DAkkS accreditation for the operating unit Qualification & Failure Analysis at RoodMicrotec. Two new locations were renewed in this investment.

-

In September 2021, MASER Engineering agreed to sell its stake to Eurofins Scientific. Both are world-renowned Failure Analysis firms with a huge reputation. These firms are well-recognized globally.

Chapter 1. Failure Analysis Market– Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Failure Analysis Market– Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Failure Analysis Market– Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Failure Analysis MarketEntry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Failure Analysis Market– Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Failure Analysis Market– By Technology

6.1 Introduction/Key Findings

6.2 Secondary ION Mass Spectrometry (SIMS)

6.3 Energy Dispersive X-ray Spectroscopy (EDX)

6.4 Chemical Mechanical Planarization (CMP)

6.5 Other Technologies

6.6 Y-O-Y Growth trend Analysis By Technology

6.7 Absolute $ Opportunity Analysis By Technology, 2024-2030

Chapter 7. Failure Analysis Market– By Equipment

7.1 Introduction/Key Findings

7.2 Scanning Electron Microscope (SEM)

7.3 Focused Ion Beam (FIB) System

7.4 Transmission Electron Microscope (TEM)

7.5 Dual Beam System

7.6 Y-O-Y Growth trend Analysis By Equipment

7.7 Absolute $ Opportunity Analysis By Equipment, 2024-2030

Chapter 8. Failure Analysis Market– By End-user Vertical

8.1 Introduction/Key Findings

8.2 Automotive

8.3 Oil and Gas

8.4 Defense

8.5 Construction

8.6 Manufacturing

8.7 Other End-user Verticals

8.8 Y-O-Y Growth trend Analysis By End-user Vertical

8.9 Absolute $ Opportunity Analysis By End-user Vertical, 2024-2030

Chapter 9. Failure Analysis Market, By Geography – Market Size, Forecast, Trends & Insights

9.1 North America

9.1.1 By Country

9.1.1.1 U.S.A.

9.1.1.2 Canada

9.1.1.3 Mexico

9.1.2 By Technology

9.1.3 By Equipment

9.1.4 By End-user Vertical

9.1.5 Countries & Segments - Market Attractiveness Analysis

9.2 Europe

9.2.1 By Country

9.2.1.1 U.K

9.2.1.2 Germany

9.2.1.3 France

9.2.1.4 Italy

9.2.1.5 Spain

9.2.1.6 Rest of Europe

9.2.2 By Technology

9.2.3 By Equipment

9.2.4 By End-user Vertical

9.2.5 Countries & Segments - Market Attractiveness Analysis

9.3 Asia Pacific

9.3.1 By Country

9.3.1.1 China

9.3.1.2 Japan

9.3.1.3 South Korea

9.3.1.4 India

9.3.1.5 Australia & New Zealand

9.3.1.6 Rest of Asia-Pacific

9.3.2 By Technology

9.3.3 By Equipment

9.3.4 By End-user Vertical

9.3.5 Countries & Segments - Market Attractiveness Analysis

9.4 South America

9.4.1 By Country

9.4.1.1 Brazil

9.4.1.2 Argentina

9.4.1.3 Colombia

9.4.1.4 Chile

9.4.1.5 Rest of South America

9.4.2 By Technology

9.4.3 By Equipment

9.4.4 By End-user Vertical

9.4.5 Countries & Segments - Market Attractiveness Analysis

9.5 Middle East & Africa

9.5.1 By Country

9.5.1.1 United Arab Emirates (UAE)

9.5.1.2 Saudi Arabia

9.5.1.3 Qatar

9.5.1.4 Israel

9.5.1.5 South Africa

9.5.1.6 Nigeria

9.5.1.7 Kenya

9.5.1.8 Egypt

9.5.1.9 Rest of MEA

9.5.2 By Technology

9.5.3 By Equipment

9.5.4 By End-user Vertical

9.5.5 Countries & Segments - Market Attractiveness Analysis

Chapter 10. Failure Analysis Market– Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

10.1 Eurofins Scientific (Luxembourg)

10.2 Thermo Fisher Scientific, Inc. (US)

10.3 Oxford Instruments (UK)

10.4 Carl Zeiss (Germany)

10.5 Leica Microsystems GmbH (Germany)

10.6 Hitachi High-Technologies Corporation (Japan)

10.7 Semilab (Hungary)

10.8 TESCAN OSRAY HOLDING (Czech Republic)

10.9 A&D Company, Ltd. (Japan)

Download Sample

Choose License Type

2500

4250

5250

6900