Extreme Pressure Grease Market Size (2024 –2030)

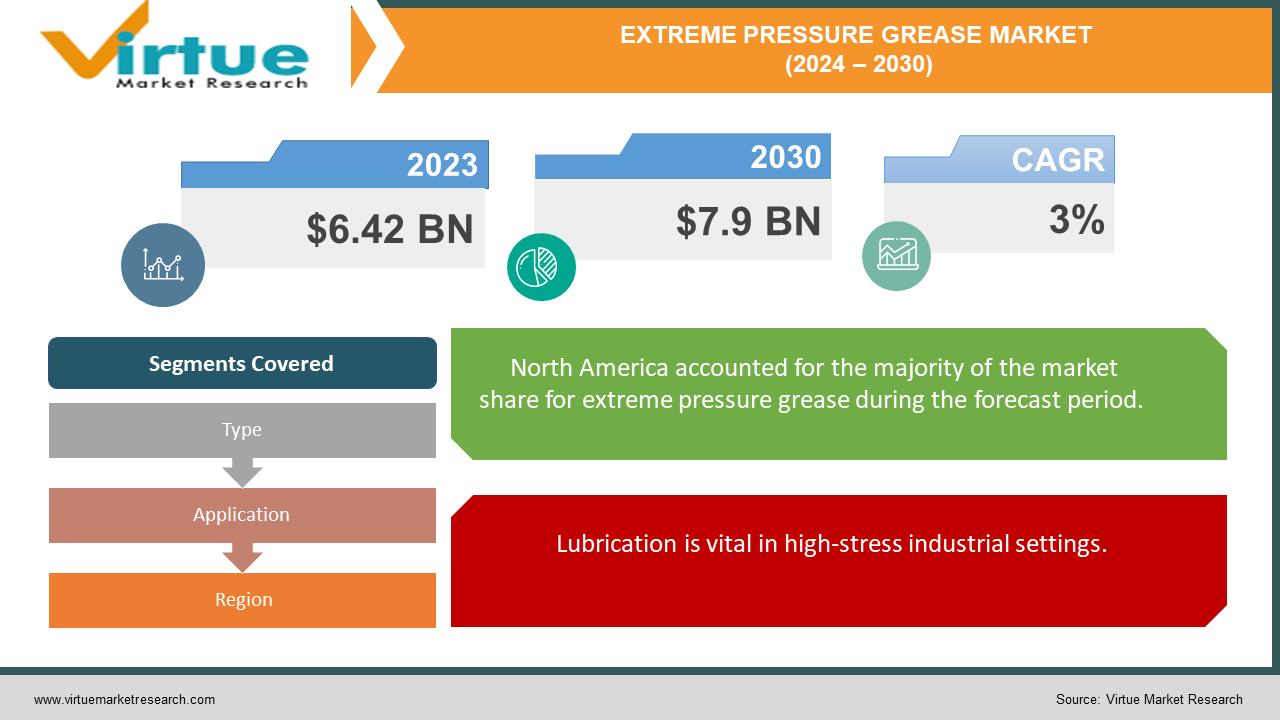

The Global Extreme Pressure Grease Market was valued at USD 6.42 billion in 2023 and is projected to reach a market size of USD 7.9 billion by the end of 2030. The market is anticipated to expand at a compound annual growth rate (CAGR) of 3% between 2024 and 2030.

Demand is booming in the large market for special greases that function under extreme pressure due to growing industries and pushing machines to their limits. These greases are essential because they lessen wear and friction in machinery that must handle large loads. This indicates that they're crucial to the proper operation of machines. Businesses are starting to realize that by using these greases, they can save money on maintenance and downtime by keeping machines operating smoothly for longer periods of time. Large corporations such as WD-40 manufacture various types of these greases, such as lithium or molybdenum disulfide, to meet the requirements of various industries, such as metalworking or aviation. This range ensures that all types of machinery, regardless of how demanding their function, receive the proper lubricant to maintain optimal performance in harsh industrial environments. Extreme pressure greases are typically utilized in sectors of the economy that are expanding due to increased production, such as metalworking, machinery, and aviation. More than half of all grease is made of one extremely popular type called lithium complex grease. Its resistance to water and its ability to withstand extremely high temperatures make it popular. Special types of grease used in aircraft, boats, and food production account for about 15% of total grease usage. When it comes to grease, people are more concerned with its performance and longevity than with its initial cost. They want it to last a long time and require less upkeep.

Key Market Insights:

The global extreme pressure grease market is estimated to be around $6.4 billion in value, driven by the increasing demand from various industrial sectors, such as manufacturing, mining, and construction.

Asia-Pacific region accounts for nearly 30% of the global extreme pressure grease market share, attributed to the rapid industrialization and growth of the manufacturing sector in the region.

The lithium-based greases segment holds a market share of over 45% in the extreme pressure grease market, owing to their excellent performance under high temperatures and pressure conditions.

The automotive and transportation industry contributes to around 30% of the overall extreme pressure grease market, driven by the need for high-performance lubricants in various automotive components and equipment.

The mining and construction segment is expected to grow at a rate of around 5% annually, driven by the increasing demand for extreme-pressure greases in heavy machinery and equipment used in these industries.

Global Extreme Pressure Grease Market Drivers:

Lubrication is vital in high-stress industrial settings.

Extreme pressure grease becomes crucial when factories and machinery are operating at maximum capacity. It functions similarly to specialized oil, enabling machinery to continue operating efficiently under extreme conditions. It keeps them from malfunctioning and improves their performance, even under demanding circumstances. Because of this grease's ability to withstand harsh conditions and heavy loads, machinery can continue to operate without experiencing unplanned stops or costly repairs. This grease is essential to many industries, including mining and manufacturing, as it keeps machinery operating efficiently every day. Therefore, using the proper, high-quality grease is essential to keeping machines functioning properly and lasting a long time as they are forced to work even harder.

Utilizing High-Pressure Grease to Extend the Life of Machinery.

Businesses are focusing more on maintaining their machinery because they want it to last as long as possible. They use grease under extreme pressure as one method of doing this. This particular type of grease helps lessen the wear and tear that machines sustain over time and is designed to function well in challenging environments. It prevents excessive rubbing between parts, which could hasten their deterioration. Businesses save money on repairs and replacements when machines have a longer lifespan. They save a ton of money as a result. Furthermore, longer-lasting, more efficient machines use resources more effectively and produce less waste. Thus, a growing number of companies are realizing how crucial it is to use this grease in order to prolong the life of their machinery.

Extreme Pressure Grease Market Challenges and Restraints:

Although the market for extreme pressure grease is expanding swiftly, there are certain issues. The desire for greases that are more environmentally friendly is one major problem. There are restrictions on the use of certain greases because they contain potentially hazardous chemicals. Businesses need to find greases that are not only environmentally friendly but also perform well. Grease removal is another issue that can be difficult. If done incorrectly, it can contaminate the land and water, putting businesses in hot water and endangering the ecosystem. Manufacturers of grease are subject to numerous regulations regarding the safe disposal of their products. This issue might be resolved by finding better ways to handle or recycle grease.

Extreme Pressure Grease Market Opportunities:

The Extreme Pressure Grease Market offers businesses a lot of excellent opportunities for expansion and success. The creation of environmentally friendly greases presents a significant opportunity. Using environmentally friendly products piques people's interest. In addition, there is a growing need for greases to keep machinery operating smoothly as more nations throughout the world begin to construct factories and use more machinery. Maintaining the advancement of grease manufacturing technology presents another opportunity. Companies can now create greases that perform even better under challenging circumstances by incorporating unique ingredients or utilizing cutting-edge concepts like nanotechnology. Additionally, since various industries require different kinds of greases, there's a chance that businesses will develop specialized greases for things like automobiles, aircraft, or large mining machinery. Grease manufacturers have an opportunity to develop greases that are compatible with these new technologies as more businesses use sensors and computers to monitor when machines require maintenance. Finally, businesses can expand their customer base and increase grease sales by collaborating with additional distributors and devising innovative marketing strategies. Therefore, businesses can succeed in the extreme pressure grease market and continue to expand by seizing these opportunities.

EXTREME PRESSURE GREASE MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

3% |

|

Segments Covered |

By Type, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

WD-40, SKF, Exxon Mobil Corporation. CRC Industries, Lubrication Engineers, Shell plc, Phillips 66, Sinopec, Chevron Corporation, Total Energies SE |

Global Extreme Pressure Grease Market Segmentation: By Type

-

Lithium Base Grease

-

Molybdenum Disulfide Extreme

-

Pressure Grease

It is anticipated that Lithium Base Grease will continue to be the most popular type of Extreme Pressure Grease for the foreseeable future. Because of their exceptional resistance to wear and tear, ability to withstand high temperatures, and resistance to being washed away by water, lithium greases are widely used. This makes them excellent for a wide range of tasks, from large industrial machinery to crucial automotive components. They're also a great option for companies looking to cut maintenance costs because they provide a good balance between performance and cost. Furthermore, they have a solid track record and have been in business for a long time, which makes people trust them. Lithium greases remain the best option for the majority of industries despite the existence of alternative types such as molybdenum disulfide that may be more suitable for specific tasks due to their excellent performance, reasonable price, and well-known dependability.

Global Extreme Pressure Grease Market Segmentation: By Application

-

Aviation

-

Metal

-

Mechanical

The metals sector was the largest user of Extreme Pressure Grease last year, and this trend is probably going to continue. Many heavy machinery are used in metal factories, and to keep these machines operating smoothly, special greases are required. However, other sectors, such as energy, automobiles, and aviation, are also expanding quickly. They also require specific greases for their more sophisticated machinery. Different types of greases are required for different jobs, even in the metal industry. Thus, the industries that use the most grease may change in the future. Companies will require more specialized greases as they strive to extend the life and improve the performance of their machinery. This could imply that grease use in the metal industry is not as advanced as it currently is.

Global Extreme Pressure Grease Market Segmentation: By Region

-

North America

-

Asia-Pacific

-

Europe

-

South America

-

Middle East and Africa

North America dominated the Extreme Pressure Grease Market last year, and it's probably going to continue doing so for some time. This is a result of the abundance of factories in North America and their strong emphasis on production efficiency. They also use a lot of these specialty greases to keep their machines operating smoothly because they think it's important to maintain machinery before it breaks down. Furthermore, large corporations produce these greases and have efficient means of distributing them to the required locations. However, regions like Asia Pacific—particularly China and India—are currently expanding quickly. In addition to constructing numerous new factories, they are also giving machine maintenance more thought. Thus, they may gain greater clout in the grease business in the future, and North America may lose its current hegemony.

COVID-19 Impact on the Global Extreme Pressure Grease Market:

The market for extreme-pressure grease was severely disrupted by the COVID-19 pandemic. International grease shipping was disrupted by travel restrictions and lockdowns. Furthermore, a lot of factories reduced or stopped production, which reduced the amount of grease required for their machinery. However, things are now gradually returning to normal. Industries will require more grease as they reopen in order to maintain the smooth operation of their machinery. In addition, they'll need to make up for any maintenance they neglected during the pandemic. This means that as businesses put a lot of effort into making sure their equipment is in good working order, the demand for grease is predicted to return to levels seen prior to the pandemic, if not higher. Therefore, the grease market is improving even though COVID-19 caused a decline in demand.

Latest Trend/Development:

The market for extreme pressure grease has seen some significant changes recently. Environmentally friendly greases are in greater demand as people become more conscious of their environmental impact. Producers are attempting to produce biodegradable greases without the use of hazardous chemicals. Simultaneously, significant advancements have been achieved in the creation of longer-lasting and more effective greases. To create greases that can withstand extremely harsh conditions, scientists are utilizing cutting-edge technologies like nanotechnology and adding unique ingredients. Additionally, businesses are beginning to use digital technology to monitor when equipment needs maintenance so they can address issues before they arise. To expand their product offerings and strengthen their businesses, large corporations are acquiring smaller ones or forming alliances with one another. Furthermore, there is a high demand for these greases to keep machinery operating smoothly in regions like Asia-Pacific and Latin America where industries are expanding quickly.

Key Players:

-

WD-40

-

SKF

-

Exxon Mobil Corporation

-

CRC Industries

-

Lubrication Engineers

-

Shell plc

-

Phillips 66

-

Sinopec

-

Chevron Corporation

-

Total Energies SE

Chapter 1. Extreme Pressure Grease Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Extreme Pressure Grease Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Extreme Pressure Grease Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Extreme Pressure Grease Market - Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Extreme Pressure Grease Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Extreme Pressure Grease Market – By Type

6.1 Introduction/Key Findings

6.2 Lithium Base Grease

6.3 Molybdenum Disulfide Extreme

6.4 Pressure Grease

6.5 Y-O-Y Growth trend Analysis By Type

6.6 Absolute $ Opportunity Analysis By Type, 2024-2030

Chapter 7. Extreme Pressure Grease Market – By Application

7.1 Introduction/Key Findings

7.2 Aviation

7.3 Metal

7.4 Mechanical

7.5 Y-O-Y Growth trend Analysis By Application

7.6 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. Extreme Pressure Grease Market , By Geography – Market Size, Forecast, Trends & Insights

8.1 North America

8.1.1 By Country

8.1.1.1 U.S.A.

8.1.1.2 Canada

8.1.1.3 Mexico

8.1.2 By Type

8.1.3 By Application

8.1.4 Countries & Segments - Market Attractiveness Analysis

8.2 Europe

8.2.1 By Country

8.2.1.1 U.K

8.2.1.2 Germany

8.2.1.3 France

8.2.1.4 Italy

8.2.1.5 Spain

8.2.1.6 Rest of Europe

8.2.2 By Type

8.2.3 By Application

8.2.4 Countries & Segments - Market Attractiveness Analysis

8.3 Asia Pacific

8.3.1 By Country

8.3.1.1 China

8.3.1.2 Japan

8.3.1.3 South Korea

8.3.1.4 India

8.3.1.5 Australia & New Zealand

8.3.1.6 Rest of Asia-Pacific

8.3.2 By Type

8.3.3 By Application

8.3.4 Countries & Segments - Market Attractiveness Analysis

8.4 South America

8.4.1 By Country

8.4.1.1 Brazil

8.4.1.2 Argentina

8.4.1.3 Colombia

8.4.1.4 Chile

8.4.1.5 Rest of South America

8.4.2 By Type

8.4.3 By Application

8.4.4 Countries & Segments - Market Attractiveness Analysis

8.5 Middle East & Africa

8.5.1 By Country

8.5.1.1 United Arab Emirates (UAE)

8.5.1.2 Saudi Arabia

8.5.1.3 Qatar

8.5.1.4 Israel

8.5.1.5 South Africa

8.5.1.6 Nigeria

8.5.1.7 Kenya

8.5.1.8 Egypt

8.5.1.9 Rest of MEA

8.5.2 By Type

8.5.3 By Application

8.5.4 Countries & Segments - Market Attractiveness Analysis

Chapter 9. Extreme Pressure Grease Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

9.1 WD-40

9.2 SKF

9.3 Exxon Mobil Corporation

9.4 CRC Industries

9.5 Lubrication Engineers

9.6 Shell plc

9.7 Phillips 66

9.8 Sinopec

9.9 Chevron Corporation

9.10 Total Energies SE

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

By 2023, the Global Extreme Pressure Grease market is expected to be valued at USD 6.42 billion.

Through 2030, the global Extreme Pressure Grease market is expected to grow at a CAGR of 3%.

By 2030, the global Extreme Pressure Grease is expected to grow to a value of USD 7.9 billion.

North America is predicted to lead the market globally for Extreme Pressure Grease.

The Extreme Pressure Grease Market has segments Type (Lithium Base Grease, Molybdenum Disulfide Extreme, Pressure Grease), Application ( Aviation, Metal, Mechanical ), and Region.