Epoxy Polysiloxane Market Size (2024 – 2030)

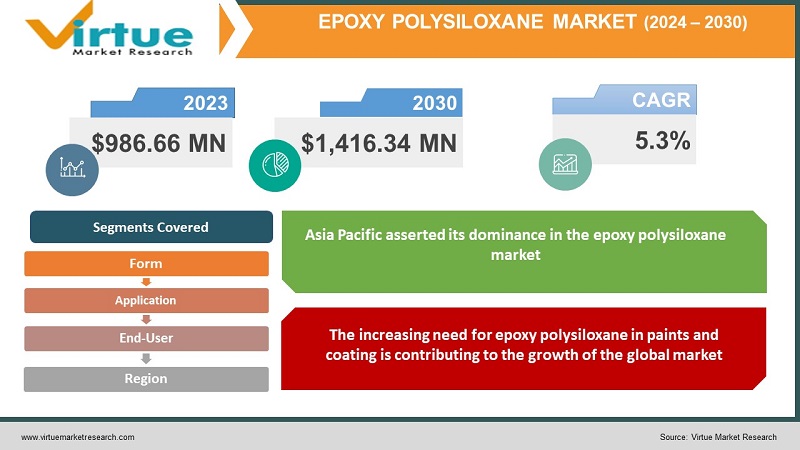

Epoxy Polysiloxane Market is estimated to be USD 986.66 Million in 2023 and is estimated to reach the value of USD 1,416.34 Million by 2030, growing at a CAGR of 5.3% during the forecast period of 2024 – 2030.

Epoxy polysiloxane is a type of coating material that combines the properties of epoxy and polysiloxane (also known as silicone) to create a durable and versatile protective coating. This coating is commonly used in industrial and marine applications due to its excellent resistance to harsh environmental conditions, chemicals, abrasion, and UV exposure. They provide long-lasting protection against corrosion, weathering, and chemical exposure, adhere well to various substrates, including metals, concrete, and fiberglass, withstand exposure to a wide range of chemicals, making them suitable for industrial settings, and often have low levels of volatile organic compounds (VOCs), which is beneficial for environmental and health reasons. The epoxy polysiloxane market encompasses the production, distribution, and utilization of epoxy polysiloxane products. These products find diverse applications, including electrical insulation in the electronics sector, incorporation into personal care items like hair conditioners and cosmetics, and serving as release agents in the manufacturing of rubber and plastic goods. The epoxy polysiloxane market experiences growth driven by factors such as heightened demand from various industries, especially automotive and construction, owing to the exceptional properties of epoxy polysiloxane. Furthermore, the increasing preference for environmentally friendly and sustainable materials has contributed to the rising demand for products based on epoxy polysiloxane.

Key Market Insights:

The epoxy polysiloxane market has been witnessing consistent growth owing to its versatile properties and extensive applications across industries such as construction, automotive, marine, and aerospace. Epoxy polysiloxane coatings and paints have gained significant popularity, particularly in the construction and automotive sectors, due to their remarkable attributes, including exceptional durability, chemical resistance, and UV stability, making them well-suited for harsh environmental conditions.

The global surge in construction activities, especially in emerging economies, has led to an increased demand for high-performance coatings like epoxy polysiloxane. These coatings played a vital role in safeguarding structures against corrosion and weather-related damage. For instance, in Europe, the German government had announced plans to construct approximately 1.5 million housing units by the end of 2021. Similarly, rising construction activities in countries like Russia, France, and the United Kingdom were expected to propel the epoxy polysiloxane market forward.

In the automotive industry, epoxy polysiloxane coatings found extensive use in various applications, including protective coatings for vehicle underbodies and high-performance automotive paints. The automotive sector's growth and its emphasis on sustainability were key drivers for the increasing demand. Notably, the report estimated the production of 21.8 million light commercial vehicles, heavy buses, and trucks globally in 2020, indicating a growing market for epoxy polysiloxane within the automotive coatings segment.

Ongoing research and development efforts were dedicated to enhancing the performance characteristics of epoxy polysiloxane materials, including properties such as scratch resistance, adhesion, and flexibility. However, it's important to note that fluctuations in raw material costs could potentially impact the manufacturing prices of epoxy resin, thereby affecting market growth over the forecast period.

Global Epoxy Polysiloxane Market Drivers:

The increasing need for epoxy polysiloxane in paints and coating is contributing to the growth of the global market

Railways, roads, bridges, public parks, and other infrastructure elements face ongoing exposure to harsh environmental conditions. Epoxy Polysiloxane coatings play a crucial role in ensuring the longevity and appearance of these structures by providing protection against corrosion, high temperatures, and fire hazards. In the railway industry, mild steel remains the preferred choice for construction purposes due to its cost-effectiveness, mechanical strength, and ease of fabrication. However, a significant drawback of using mild steel is its susceptibility to corrosion, particularly in extreme weather conditions. Without adequate protection, mild steel can deteriorate rapidly, potentially leading to structural failures. To mitigate this issue, epoxy polysiloxane coatings with anti-corrosive properties are applied to the exterior surfaces of railway tracks and related infrastructure.

The enhanced properties of the hybrid of Epoxy and polysiloxane are finding applications in various sectors

Epoxy polysiloxane products are highly sought-after for their ability to resist corrosion and withstand high temperatures in the oil and gas industry. They are not only used for these purposes but also play a crucial role in ensuring electrical insulation and effective sealing. In the oil and gas sector, where electrical equipment like cables, connectors, and transformers must operate safely without short circuits, epoxy polysiloxane-based insulating materials shine. They possess outstanding dielectric properties, which ensure reliable electrical insulation, even in the harsh and demanding conditions commonly encountered in the oil and gas industry. Moreover, epoxy polysiloxane sealants are relied upon for their exceptional sealing capabilities. They effectively prevent leaks, ensuring the integrity of pipelines, tanks, and various other critical infrastructure components. Beyond the oil and gas industry, these versatile materials are finding applications in diverse sectors such as automotive, aerospace, healthcare, and construction, thanks to their dynamic properties

Increasing use of anti-fouling coating in marine applications is propelling the Global Epoxy Polysolixane Market

The epoxy polysiloxane coatings market is witnessing significant growth due to rising demand for anti-fouling applications. Epoxy polysiloxane coatings are particularly well-suited for marine purposes, where their exceptional anti-fouling properties prove invaluable. In sectors like shipbuilding and offshore construction, effective anti-fouling solutions are essential to combat biofouling and enhance fuel efficiency. Market analysis underscores that the increasing need for anti-fouling coatings is a driving force behind the expansion of the epoxy polysiloxane market.

The eco-friendly nature of Epoxy Polysiloxane is augmenting the growth of the global market

Epoxy polysiloxane coatings and materials are generally regarded as environmentally friendlier compared to traditional epoxy coatings. They often come in formulations with low levels of VOCs (volatile organic compounds). These low-VOC coatings release fewer harmful chemicals into the air, which can lead to improved indoor and outdoor air quality while reducing health risks for both workers and the environment. Epoxy polysiloxane coatings can be made water-based, and this contributes to their enhanced eco-friendliness. Water-based coatings usually contain fewer VOCs and facilitate easier cleanup, reducing the necessity for using harmful solvents.

Global Epoxy Polysiloxane Market Opportunities:

The epoxy polysiloxane market stands to gain from the growing adoption of renewable energy sources, as there is an increasing demand for coatings applied in wind turbines, solar panels, and other infrastructure related to renewable energy production. Additionally, the shift towards environmentally responsible coatings creates opportunities for the development and promotion of eco-friendly epoxy polysiloxane formulations. Manufacturers can tap into this trend by creating coatings with reduced VOC content and minimized environmental impact. Moreover, the market is poised to benefit from ongoing research and development endeavors, which are expected to result in innovative epoxy polysiloxane products boasting enhanced properties. This innovation will expand the range of applications for these coatings, broadening their market reach. In terms of geographical potential, economies in the Asia-Pacific and South America regions are emerging as key players in the global epoxy polysiloxane market. These regions exhibit significant growth prospects and have the potential to become leading marketing destinations worldwide.

Global Epoxy Polysiloxane Market Restraints and Challenges:

A substantial portion of epoxy resins is typically derived from oils, either for their chemical composition or as an energy source in the extraction process, which is subsequently utilized in coatings production. The prices of oil are known for their high volatility, influenced by numerous factors that can cause fluctuations in either direction. Consequently, oil price fluctuations have a notable impact on the cost of raw materials for coatings. It is important to note that generalizing non-toxic behavior for various poly-siloxanes is not always appropriate. The toxicity and absorption of these substances in the human and animal body can be influenced by factors such as the molecule's structure and size. This issue of silicone safety becomes particularly critical in contexts involving contact with adults, children, and newborns. The potential toxicity of polysiloxane compounds is expected to pose challenges to market growth during the forecast period.

EPOXY POLYSILOXANE MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

5.3% |

|

Segments Covered |

By Form, Application, End-User, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

BASF SE, The Hunstman Corporation, The Dow Chemical Company, Nippon Paint Holding, Kansai Paint, Valspar Corporation, PPG Industries, Jotun Group, Asian Paints Ltd., KCC Corporation |

Global Epoxy Polysiloxane Market Segmentation: By Form

-

Solvent-based

-

Liquid-based

-

Powder-based

The most dominant type in the market is the liquid-based epoxy polysiloxane, which held a significant market share of approximately 50% in 2022. This particular grade of epoxy polysiloxane is renowned for its ability to withstand chemical and physical reactions, making it highly resistant to corrosion. Liquid epoxy polysiloxane finds extensive application across various sectors, including coatings, sealants, marine components, electrical and electronics, and composites. Among the segments, the solvent-based epoxy polysiloxane market is experiencing the most rapid growth and is expected to maintain a substantial market share throughout the forecast period.

Global Epoxy Polysiloxane Market Segmentation: By Application

-

Paints & Coating

-

Medical

-

Adhesives & Sealants

-

Elastomers

-

Adhesives & Sealants

-

Electrical & Electronics

-

Others

In 2022, the paints and coatings application segment emerged as the leading sector in the industry, accounting for more than 37.4% of the total revenue share. Epoxy resin-based paints and coatings are extensively employed across various sectors, including residential and commercial buildings, shipbuilding industries, automotive manufacturing, and wastewater treatment facilities, among others. This popularity stems from their exceptional resistance to stains, cracks, extreme temperature fluctuations, blistering, and exposure to chemicals. Additionally, these coatings exhibit outstanding adhesion properties, deliver robust anti-corrosion performance, and boast low levels of Volatile Organic Compounds (VOCs).

The electrical and electronics submarket is the fastest growing in the segment. This surge in demand can be attributed to the superior electrical insulation properties offered by epoxy polysiloxane-based coatings, rendering them ideal for insulating a wide range of electrical components and devices. This insulation capability effectively prevents short circuits and electrical failures, thus ensuring the safe and reliable operation of various electrical equipment and systems.

Global Epoxy Polysiloxane Market Segmentation: By End-User

-

Oil & Gas

-

Healthcare

-

Construction

-

Energy & Power

-

Food & Beverages

-

Textiles

-

Others

In 2022, the dominant market within this segment was the oil and gas industry, accounting for the largest share of the market. Epoxy polysiloxane-based coatings play a pivotal role in the oil and gas sector due to their exceptional corrosion resistance properties. Given the challenging environments, exposure to chemicals, and corrosive elements inherent in oil and gas exploration, production, and transportation, the potential for significant damage to metal surfaces is high. However, the application of polysiloxane coatings acts as a protective shield, effectively preventing corrosion and significantly extending the operational lifespan of equipment and critical infrastructure.

Additionally, the construction industry is experiencing the most rapid growth within this segment. This growth can be attributed to the ongoing urbanization trends and the increasing global population. As a result, there is a growing need for eco-friendly alternatives to traditional epoxy-based resins in construction applications.

Global Epoxy Polysiloxane Market Segmentation: Regional Analysis

-

North America

-

Europe

-

Asia-Pacific

-

South America

-

Middle East & Africa

During the forecast period, Asia Pacific asserted its dominance in the epoxy polysiloxane market, capturing a substantial share of over 45%. Notably, countries like China and India are making substantial investments in industrial expansion and development. China, in particular, stands out due to its extensive production capabilities in areas such as adhesives, sealants, medical devices, electronics, and elastomers, which contributed to its leadership in the Asia-Pacific segment.

The Asia-Pacific region is expected to maintain robust growth in the epoxy polysiloxane market, driven by the expansion of various end-user industries, ongoing investments, and strong support from regional governments.

North America is projected to experience rapid market growth, primarily attributed to increasing demand within the automotive sector, a surge in industrialization, and a growing market for electric vehicles.

COVID-19 Impact on the Global Epoxy Siloxane Market:

The epoxy polysiloxane market was significantly impacted by the COVID-19 pandemic. Initially, the industry faced supply chain disruptions stemming from lockdowns, trade restrictions, and reduced manufacturing activities, leading to challenges in sourcing raw materials and finished products. This, in turn, caused supply shortages and project delays in sectors such as construction, automotive, and electronics, all of which are prominent users of epoxy polysiloxane coatings and materials. However, as economies gradually reopened and businesses adapted to new health and safety protocols, the market showed signs of recovery. The renewed focus on infrastructure development, sustainability, and the increasing demand for protective coatings across various applications played a pivotal role in bolstering the resilience of the epoxy polysiloxane market. As a result, the market is anticipated to rebound and continue its growth trajectory in the post-pandemic era.

Latest Trends/ Development:

Epoxy polysiloxane coatings remained in high demand across various industries, driven by their exceptional attributes such as durability, corrosion resistance, and UV stability. Sectors like construction, automotive, marine, and aerospace continued to embrace these coatings for both protective and aesthetic purposes. Ongoing research and development efforts yielded advanced epoxy polysiloxane formulations, enhancing their properties. Leading market players invested significantly in R&D to diversify their product lines, further fueling the growth of the epoxy resin market.

To expand their global presence, major market players pursued various strategic initiatives, including product launches, contractual agreements, mergers, acquisitions, increased investments, and collaborations with other organizations. Manufacturers also prioritized customized solutions to meet specific industry and application needs, resulting in specialized epoxy polysiloxane coatings tailored for purposes like high-temperature resistance, chemical resistance, and fire protection.

Furthermore, the integration of digital technologies and principles from Industry 4.0 into coating processes gained momentum. This trend aimed to bolster quality control, real-time monitoring, and predictive maintenance, ultimately enhancing the efficiency and effectiveness of epoxy polysiloxane coating applications.

In the competitive landscape of the epoxy polysiloxane industry, players are compelled to offer cost-effective products to expand their presence and thrive in an increasingly competitive and growing market environment.

Key Market Players:

-

BASF SE

-

The Hunstman Corporation

-

The Dow Chemical Company

-

Nippon Paint Holding

-

Kansai Paint

-

Valspar Corporation

-

PPG Industries

-

Jotun Group

-

Asian Paints Ltd.

-

KCC Corporation

In 2021, Covestro completed the acquisition of Royal DSM's Resins and Functional Materials business (RFM). This strategic acquisition positions Covestro to expand its portfolio of environmentally sustainable coating resins, benefiting from the broader range of offerings now available to the company.

In 2019, At the ABRAFATI trade show in Brazil, Hexion Inc. introduced EPOSIL Resin 5550, a hybrid epoxy/polysiloxane resin. This innovative high-performance product, which boasts durability, presents a viable alternative to conventional aliphatic polyurethane coatings. Notably, EPOSIL Resin 5550 excels in performance and is free from isocyanates, rendering it a highly suitable choice for graffiti-resistant topcoats.

Chapter 1. EPOXY POLYSILOXANE MARKET– Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. EPOXY POLYSILOXANE MARKET– Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. EPOXY POLYSILOXANE MARKET– Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. EPOXY POLYSILOXANE MARKET - Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. EPOXY POLYSILOXANE MARKET– Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. EPOXY POLYSILOXANE MARKET– By Form

6.1 Introduction/Key Findings

6.2 Solvent-based

6.3 Liquid-based

6.4 Powder-based

6.5 Y-O-Y Growth trend Analysis By Form

6.6 Absolute $ Opportunity Analysis By Form, 2024-2030

Chapter 7. EPOXY POLYSILOXANE MARKET– By Application

7.1 Introduction/Key Findings

7.2 Paints & Coating

7.3 Medical

7.4 Adhesives & Sealants

7.5 Elastomers

7.6 Adhesives & Sealants

7.7 Electrical & Electronics

7.8 Others

7.9 Y-O-Y Growth trend Analysis By Application

7.10 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. EPOXY POLYSILOXANE MARKET– By End-User

8.1 Introduction/Key Findings

8.2 Oil & Gas

8.3 Healthcare

8.4 Construction

8.5 Energy & Power

8.6 Food & Beverages

8.7 Textiles

8.8 Others

8.9 Y-O-Y Growth trend Analysis By End-User

8.10 Absolute $ Opportunity Analysis By End-User, 2023-2030

Chapter 9. EPOXY POLYSILOXANE MARKET, By Geography – Market Size, Forecast, Trends & Insights

9.1 North America

9.1.1 By Country

9.1.1.1 U.S.A.

9.1.1.2 Canada

9.1.1.3 Mexico

9.1.2 By Form

9.1.3 By Application

9.1.4 By End-User

9.1.5 Countries & Segments - Market Attractiveness Analysis

9.2 Europe

9.2.1 By Country

9.2.1.1 U.K

9.2.1.2 Germany

9.2.1.3 France

9.2.1.4 Italy

9.2.1.5 Spain

9.2.1.6 Rest of Europe

9.2.2 By Form

9.2.3 By Application

9.2.4 By End-User

9.2.5 Countries & Segments - Market Attractiveness Analysis

9.3 Asia Pacific

9.3.1 By Country

9.3.1.1 China

9.3.1.2 Japan

9.3.1.3 South Korea

9.3.1.5 Australia & New Zealand

9.3.1.6 Rest of Asia-Pacific

9.3.2 By Form

9.3.3 By Application

9.3.4 By End-User

9.3.5 Countries & Segments - Market Attractiveness Analysis

9.4 South America

9.4.1 By Country

9.4.1.1 Brazil

9.4.1.2 Argentina

9.4.1.3 Colombia

9.4.1.4 Chile

9.4.1.5 Rest of South America

9.4.2 By Form

9.4.3 By Application

9.4.4 By End-User

9.4.5 Countries & Segments - Market Attractiveness Analysis

9.5 Middle East & Africa

9.5.1 By Country

9.5.1.1 United Arab Emirates (UAE)

9.5.1.2 Saudi Arabia

9.5.1.3 Qatar

9.5.1.4 Israel

9.5.1.5 South Africa

9.5.1.6 Nigeria

9.5.1.7 Kenya

9.5.1.8 Egypt

9.5.1.9 Rest of MEA

9.5.2 By Form

9.5.3 By Application

9.5.4 By End-User

9.5.5 Countries & Segments - Market Attractiveness Analysis

Chapter 10. EPOXY POLYSILOXANE MARKET– Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

10.1 BASF SE

10.2 The Hunstman Corporation

10.3 The Dow Chemical Company

10.4 Nippon Paint Holding

10.5 Kansai Paint

10.6 Valspar Corporation

10.7 PPG Industries

10.8 Jotun Group

10.9 Asian Paints Ltd.

10.10 KCC Corporation

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

Epoxy Polysiloxane Market is estimated to be USD 986.66 Million in 2023 and is estimated to reach the value of USD 1,416.34 Million by 2030, growing at a CAGR of 5.3% during the forecast period of 2024 – 2030.

Its application in various sectors is coupled with alternatives to traditional epoxy resin.

Based on End-User the Global Epoxy Polysiloxane Market is segmented into Oil & Gas, Healthcare, Construction, Energy & Power, Food & Beverages, Textiles, and Others.

China is the most dominant country in the region of Asia-Pacific in the Epoxy Polysiloxanne Market.

BASF SE, The Hunstman Corporation, The Dow Chemical Company, Nippon Paint Holding, Kansai Paint, Valspar Corporation, PPG Industries, Jotun Group, Asian Paints Ltd., KCC Corporation