Epoxy Gel Coat Market Size (2024 –2030)

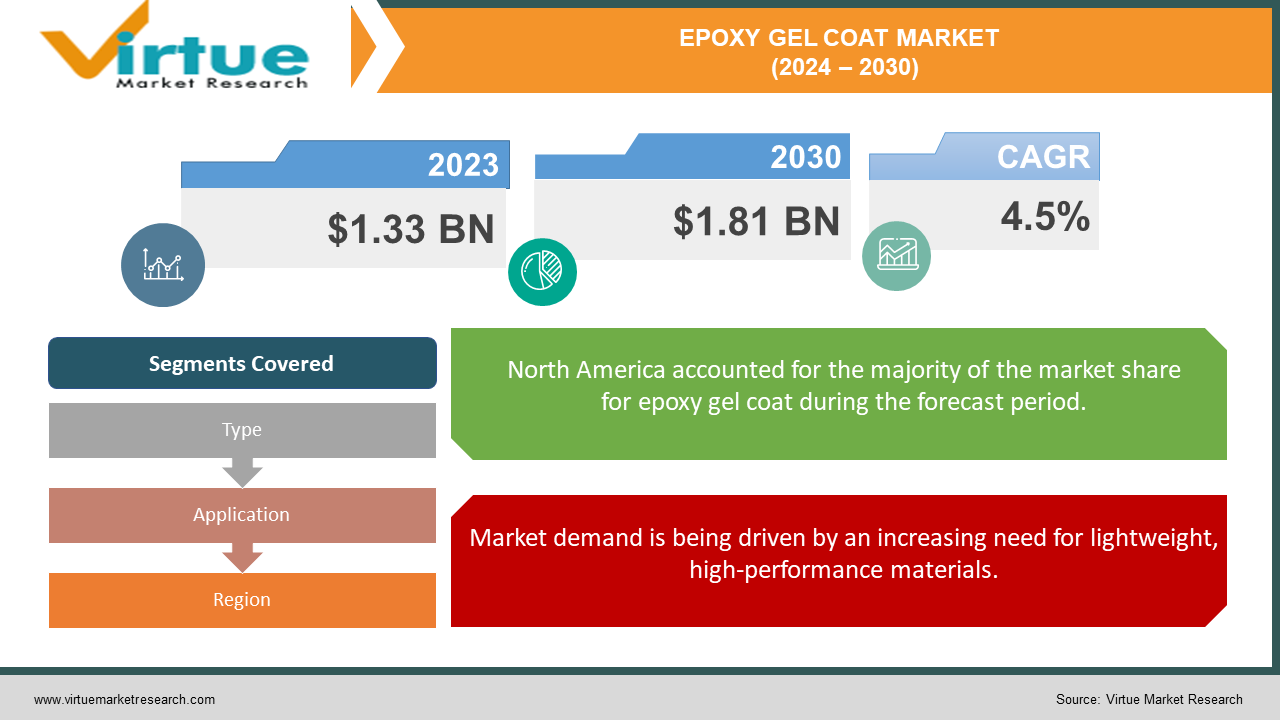

The Global Epoxy Gel coat Market is estimated to be worth USD 1.33 Billion in 2023 and is projected to reach a value of USD 1.81 Billion by 2030, growing at a CAGR of 4.5% during the outlook period 2024-2030.

Specialty coatings or laminates called epoxy gel coats are created from epoxy resin, a kind of polyester resin. They act as a protective layer or surface finish and are essential to the production of composites. Epoxy gel coats are highly valued in the marine industry because they improve the performance and longevity of boats and yachts by providing exceptional resistance to moisture, chemicals, and UV light. Epoxy gel coats are used in a variety of industries outside of the marine sector, such as construction, transportation, and medicine. They work well in challenging environments where resistance to corrosion, abrasion, and impact is necessary. Automotive, aircraft, and wind turbine blade manufacturing all depend on epoxy gel coats. They extend the life of concrete structures and architectural elements in construction by providing protection. With new growth opportunities created by innovations like self-healing and anti-microbial formulations, the epoxy gel coat market appears to have a bright future. The market is expanding due to the growing use of composite materials in industries like electronics and wind energy. Notwithstanding obstacles like the price of raw materials and environmental laws, the industry is well-positioned to grow steadily due to consumer demand for eco-friendly products and lightweight materials.

Key Market Insights:

Marine applications account for approximately 40% of the epoxy gel coat market share, driven by the material's excellent water resistance, durability, and ability to protect boat hulls and other marine structures from harsh environmental conditions.

The white-colored epoxy gel coats constitute around 50% of the market demand, reflecting their versatility and popularity across various industries due to their clean appearance and ability to be easily tinted.

In terms of region, Asia-Pacific holds the largest market share of about 35% for epoxy gel coats, attributed to the rapid growth in marine, automotive, and construction industries in countries like China, Japan, and South Korea.

The adoption of low-VOC and environmentally friendly epoxy gel coat formulations is growing at a rate of approximately 8% annually, driven by increasing environmental regulations and consumer demand for more sustainable coating options.

Global Epoxy Gel Coat Market Drivers:

Market demand is being driven by an increasing need for lightweight, high-performance materials.

The growing need for lightweight, high-performance materials in sectors like wind energy, aerospace, automotive, and marine is driving the global epoxy gel coat market. These sectors are looking more and more for materials that perform better but weigh less. Because epoxy gel coats are lightweight and have excellent mechanical properties, they are especially well-suited to meet this demand. They are frequently employed in the creation of composite materials that combine kevlar, carbon fiber, and fiberglass to improve their strength, toughness, and visual appeal. Epoxy gel coats are used in the aerospace industry to help make aircraft parts lighter, which enhances performance and fuel efficiency. Similarly, they support energy efficiency objectives when found in lightweight panels and auto body parts.

Market expansion is being driven by the construction industry's growing demand for waterproofing and insulation applications.

The construction industry has a significant impact on the worldwide epoxy gel coat market, especially when it comes to applications involving insulation and waterproofing. In the construction industry, epoxy gel coats are highly prized for their superior resistance to water, chemicals, and environmental deterioration. They are frequently applied as protective coatings to fiberglass panels, architectural elements, and concrete surfaces to stop rust, deterioration, and water intrusion. Furthermore, epoxy gel coats can insulate against heat, which makes them appropriate for applications where insulation is needed, like tanks, pipelines, and chilled storage facilities. Global infrastructure development and urbanization are expected to drive up demand for epoxy gel coats in the construction industry. The demand for strong, long-lasting coatings and the growing focus on green building techniques both contribute to the growing acceptance of epoxy gel coats in the building sector.

Epoxy Gel Coat Market Challenges and Restraints:

The price volatility of raw materials, especially epoxy resins, is posing serious challenges to the global epoxy gel coat market. Since epoxy resins are necessary components for making epoxy gel coats, changes in their price can have a big effect on the total cost of production for manufacturers. Unbalances in supply and demand as well as changes in the price of crude oil can cause wild swings in the prices of epoxy resins. Market participants find it difficult to control expenses, guarantee profitability, and uphold competitive pricing as a result of these factors. Manufacturers need to take a cautious approach to monitoring and controlling the costs of their raw materials to lessen the impact of price volatility and guarantee market stability. This entails putting protective measures in place against price swings, securing advantageous supply agreements, and, where practical, looking into alternate sourcing options. Manufacturers can better navigate the difficulties presented by price volatility in the epoxy gel coat market and preserve their competitiveness in the industry by proactively managing raw material costs.

Epoxy Gel Coat Market Opportunities:

The growing application of composites in the wind energy industry is expected to propel the global market for epoxy gel coats. There is a corresponding rise in wind energy project installations worldwide as the demand for renewable energy sources continues to rise. Wind turbine blades rely heavily on composite materials, like carbon fiber reinforced polymers and fiberglass, because of their exceptional strength, durability, and lightweight. For these composite materials to be protected and perform better, epoxy gel coats are necessary. Epoxy gel coats have a lot of opportunities as the wind energy industry grows to meet the increasing demand for durable and effective wind turbine blades. The demand for epoxy gel coats is being driven by these coatings, which help to maximize performance and prolong the lifespan of composite materials used in wind energy applications.

EPOXY GEL COAT MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

4.5% |

|

Segments Covered |

By Type, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Scott Bader, Resoltech, Adhesive Technologies, Axson, AMT Composites, Smooth-On, Inc., Ashland, RAMPF Group |

Global Epoxy Gel Coat Market Segmentation: By Type

-

Anti-corrosion

-

UV Protected

Anti-corrosion and UV protection coatings are the two primary types of epoxy gel coats that are in great demand on the international market. These coatings are extremely valuable in industries like chemical processing, offshore, and maritime because they provide excellent protection against corrosion. They are essential for prolonging the life of structures and machinery subjected to adverse conditions. Anti-corrosion gel coats are in high demand because it's important to guarantee longevity and durability in harsh environments. Because these gel coats are UV resistant, they reduce color fading, deterioration, and surface damage from prolonged sun exposure. They are extensively utilized in outdoor applications in industries such as marine, construction, and automotive, where UV protection is essential to preserving structural integrity and aesthetic appeal. Based on regional variations, technological developments in gel coat formulations, and industrial needs, the market dynamics of these gel coat segments can change. Anti-corrosion and UV protection gel coats are essential for improving the durability and performance of materials in a variety of applications, which underscores their significance for preserving the integrity of equipment and infrastructure.

Global Epoxy Gel Coat Market Segmentation: By Application

-

Marine

-

Transportation

-

Construction

-

Medical

-

Others

Numerous industries are served by the global epoxy gel coat market, and each one gains from these coatings differently. Epoxy gel coats are used in the maritime industry to shield yachts and boats from UV and water damage. They are used in the aerospace and automotive industries in the transportation sector for parts that are robust and lightweight. These coatings prolong the life of architectural elements and concrete in construction. They are also essential for healthcare facilities and instruments in the medical industry. Sports equipment, electronics, and wind energy are some additional uses. The market's expansion is reliant on regional demands as well as developments in gel coat technology, which serves sectors looking for increased performance and durability.

Global Epoxy Gel Coat Market Segmentation: By Region

-

North America

-

Europe

-

Asia Pacific

-

South America

-

Middle East & Africa

The North American, European, Asia Pacific, South American, Middle Eastern, and African markets for epoxy gel coats are the main segments of the worldwide market. Due to their robust marine, automotive, and aerospace industries, North America and Europe have historically led this industry. However, the Asia Pacific region is experiencing significant growth due to the quick industrialization and infrastructure advancements in nations like China and India. The market is expected to grow due in part to the growing need for lightweight materials and the widespread use of composites in a variety of industries. Growth prospects can also be found in South America, the Middle East, and Africa, particularly in the infrastructure and maritime industries. The key factors influencing the market dynamics in each region are industrial development, government initiatives, economic growth, and R&D investments.

COVID-19 Impact on the Global Epoxy Gel Coat Market:

The global epoxy gel coat market experienced varying effects from the COVID-19 pandemic on different segments. In the markets for personal protective equipment (PPE) like face shields, safety goggles, and medical supplies, there was a rise in demand for epoxy gel coats. For these products to be durable and protected, coatings were necessary, which momentarily increased demand. However, the pandemic also had a serious negative impact on the epoxy gel coat market in several ways. Lockdowns and restrictions caused a decline in activity in the construction sector, which is a major consumer of epoxy gel coats for projects like infrastructure and healthcare facilities. As a result, there was less of a need for epoxy gel coats in building applications. In addition, temporary pauses in industrial operations and disturbances in supply chains impacted overall market demand. During the pandemic, output and consumer spending fell in sectors like automotive, aerospace, and marine, which significantly rely on epoxy gel coats for lightweight and durable materials. Transportation and trade restrictions made it more difficult for manufacturers to source raw materials and deliver completed goods.

Latest Trend/Development:

The market for epoxy gel coats has seen recent trends that showcase innovations like the creation of sustainable and environmentally friendly formulations to satisfy growing consumer demands and environmental regulations. Gel coats that provide improved durability, resistance to corrosion, and UV protection are becoming more and more popular in sectors like construction, automotive, and marine. In addition, regional expansions in developing markets like the Asia Pacific and Latin America are opening up new growth opportunities for manufacturers, and technological advancements are concentrating on increasing application efficiency and lowering maintenance costs.

Key Players:

-

Scott Bader

-

Resoltech

-

Adhesive Technologies

-

Axson

-

AMT Composites

-

Smooth-On, Inc.

-

Ashland

-

RAMPF Group

Chapter 1. Epoxy Gel Coat Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Epoxy Gel Coat Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Epoxy Gel Coat Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Epoxy Gel Coat Market - Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Epoxy Gel Coat Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Epoxy Gel Coat Market – By Application

6.1 Introduction/Key Findings

6.2 Marine

6.3 Transportation

6.4 Construction

6.5 Medical

6.6 Others

6.7 Y-O-Y Growth trend Analysis By Application

6.8 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 7. Epoxy Gel Coat Market – By Type

7.1 Introduction/Key Findings

7.2 Anti-corrosion

7.3 UV Protected

7.4 Y-O-Y Growth trend Analysis By Type

7.5 Absolute $ Opportunity Analysis By Type, 2024-2030

Chapter 8. Epoxy Gel Coat Market , By Geography – Market Size, Forecast, Trends & Insights

8.1 North America

8.1.1 By Country

8.1.1.1 U.S.A.

8.1.1.2 Canada

8.1.1.3 Mexico

8.1.2 By Application

8.1.3 By Type

8.1.4 Countries & Segments - Market Attractiveness Analysis

8.2 Europe

8.2.1 By Country

8.2.1.1 U.K

8.2.1.2 Germany

8.2.1.3 France

8.2.1.4 Italy

8.2.1.5 Spain

8.2.1.6 Rest of Europe

8.2.2 By Application

8.2.3 By Type

8.2.4 Countries & Segments - Market Attractiveness Analysis

8.3 Asia Pacific

8.3.1 By Country

8.3.1.1 China

8.3.1.2 Japan

8.3.1.3 South Korea

8.3.1.4 India

8.3.1.5 Australia & New Zealand

8.3.1.6 Rest of Asia-Pacific

8.3.2 By Application

8.3.3 By Type

8.3.4 Countries & Segments - Market Attractiveness Analysis

8.4 South America

8.4.1 By Country

8.4.1.1 Brazil

8.4.1.2 Argentina

8.4.1.3 Colombia

8.4.1.4 Chile

8.4.1.5 Rest of South America

8.4.2 By Application

8.4.3 By Type

8.4.4 Countries & Segments - Market Attractiveness Analysis

8.5 Middle East & Africa

8.5.1 By Country

8.5.1.1 United Arab Emirates (UAE)

8.5.1.2 Saudi Arabia

8.5.1.3 Qatar

8.5.1.4 Israel

8.5.1.5 South Africa

8.5.1.6 Nigeria

8.5.1.7 Kenya

8.5.1.8 Egypt

8.5.1.9 Rest of MEA

8.5.2 By Application

8.5.3 By Type

8.5.4 Countries & Segments - Market Attractiveness Analysis

Chapter 9. Epoxy Gel Coat Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

9.1 Scott Bader

9.2 Resoltech

9.3 Adhesive Technologies

9.4 Axson

9.5 AMT Composites

9.6 Smooth-On, Inc.

9.7 Ashland

9.8 RAMPF Group

Download Sample

Choose License Type

2500

4250

5250

6900

Related Reports

Frequently Asked Questions

The Global Epoxy Gel Coat Market was esteemed at USD 1.33 Billion in 2023 and is projected to a value of USD 1.81 Billion by 2030, growing at a fast CAGR of 4.5% during the outlook period 2024-2030.

The Global Epoxy Gel Coat Market is driven by the Growing Demand from the Construction Industry for Applications in Waterproofing and Insulation.

The Segments under the Global Epoxy Gel Coat Market by Technology Type are Marine, Construction, Transportation, and Medical.

China, Japan, South Korea, Singapore, and India are the most dominating countries in the Asia Pacific region for the Global Epoxy Gel Coat Market.

Scott Bader, Resoltech, and Ashland are the three major leading players in the Global Epoxy Gel Coat Market.