Electrically Conductive Coating Market Size (2024 – 2030)

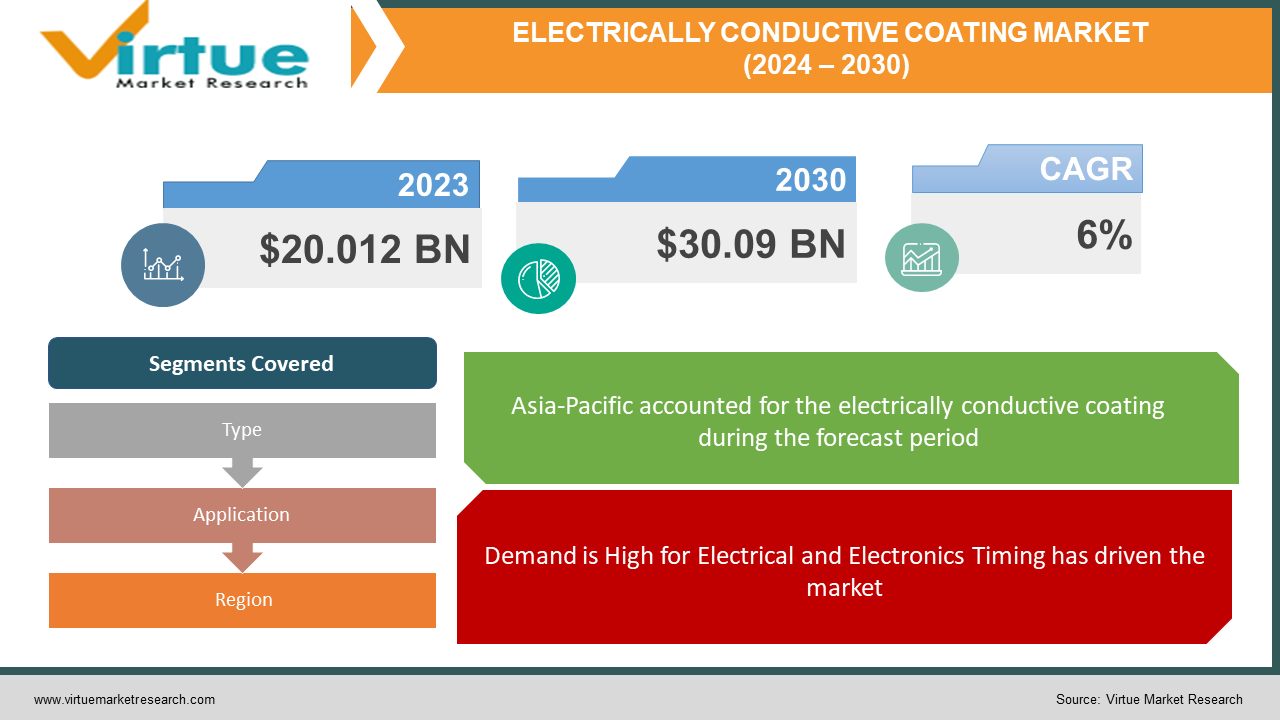

The Global Electrically Conductive Coating Market was valued at USD 20.012 Billion and is projected to reach a market size of USD 30.09 Billion by the end of 2030. The market is anticipated to expand at a compound annual growth rate (CAGR) of 6% between 2024 and 2030.

Conductive coatings provide a transformative solution by integrating electrical capability into non-conductive materials, dramatically expanding their applications in electronics. These coatings act as a vital link between traditional materials and electronic components by allowing electric currents to flow across the surface of non-conductive substrates. This novel method allows for the use of a wide range of materials that were previously thought to be incompatible with electronic applications, revolutionizing design possibilities and increasing efficiency across industries. Conductive coatings have a wide range of applications, including shielding against electromagnetic interference (EMI), static protection in situations like aircraft, and assisting thermal dissipation in various electronic components such as photocopier parts. Furthermore, conductive coatings are widely used in printed circuit inks and electrically conductive couplings, demonstrating their versatility and usefulness in modern technology. To achieve conductivity, these coatings are infused with materials such as graphite, nickel, copper, silver, or gold, which are selected based on specific application needs. Copper, aluminium, and molybdenum are common candidates due to their high conductivity. Materials with great thermal resistance, such as iron-chrome-aluminium and molybdenum-disilicate, are chosen. Furthermore, many oxide ceramics have specialized properties as conductors and semiconductors, broadening the potential applications of conductive coatings in cutting-edge electronic systems. In essence, conductive coatings represent a paradigm leap in material science, allowing for the seamless integration of electronics into a broader range of substrates, and supporting innovation and growth across multiple industries.

Key Market Insights:

The global electrically conductive coating market is expected to increase significantly, driven by the thriving electronics and semiconductor industries, particularly in large economies such as India and China. Advances in coating technology, as well as an increased demand for electrostatic protection in a variety of applications such as automotive, aerospace, and bioscience, are driving the market forward. While constraints such as high initial investment costs and severe environmental laws exist, the market has a bright future. Epoxy now reigns supreme due to its exceptional qualities, while the consumer electronics display segment accounts for the highest application share, driven by the growing demand for touchscreens and other advanced displays. Overall, the diversified applications across various industries provide a promising outlook for the electrically conductive coating market.

Global Electrically Conductive Coating Market Drivers:

Demand is High for Electrical and Electronics Timing has driven the market.

Electrically conductive coatings are used to protect electronic equipment from static and electromagnetic interference. Only two industries use electrically conductive coatings: electronics and aerospace. Electrically conductive coatings incorporate a variety of chemicals, including acrylics, epoxy, and polyester. Epoxies are one type of material that is employed for its high chemical resistance, abrasion and impact resistance, and durability. They're also scratch-resistant. Acrylics are the most commonly used coatings for electronics, satellite dishes, and electronic-board-level applications. When combined with specific chemistry, pigments can successfully shield electronics and electro-medical devices that generate electromagnetic waves. The primary function of these materials is to protect against electrostatic and electromagnetic interferences. The increasing need for anti-static protection will accelerate the expansion of the electrically conductive coating industry. Furthermore, the widespread use in numerous end-use sectors for a variety of applications will boost market value growth. As the popularity of smartphones and consumer gadgets grows, so will the demand for electrical conductive coatings.

ESD: A Spark for Conductive Coating Growth.

Electrostatic Discharge (ESD) has emerged as a significant hazard to fragile electronics in a variety of industries, driving the demand for electrically conductive coatings. ESD, or a sudden zap of static electricity, can damage sensitive components in electronics such as cellphones, pacemakers, and even aircraft avionics. Electrically conductive coatings serve as knights in shining armour, providing a safe channel for static to disperse harmlessly. The increased requirement for ESD protection in a variety of areas, from automobile manufacturing to healthcare facilities, is driving up demand for these specialised coatings. Electrically conductive coatings are becoming an increasingly important component in today's technology-driven society because they ensure the smooth operation and long life of electronics in a variety of industries.

Global Electrically Conductive Coating Market Restraints and Challenges:

The market for electrically conductive coatings confronts obstacles due to high initial equipment costs and rigorous statutory controls on hazardous air pollutant emissions. Tightening environmental laws on air pollutants and volatile hazardous chemicals released during coating processes are projected to have a further negative influence on market growth. Despite these hurdles, the electrically conductive coating market research focuses on the latest developments, trade legislation, import-export analysis, production analysis, value chain optimisation, market share, and the influence of both domestic and local market participants. The research also examines opportunities in terms of emerging revenue streams, regulatory changes, strategic market growth, market size, category market growth, application niches, product approvals, product launches, global expansions, and technological advancements.

For detailed insights into the electrically conductive coating market, interested parties could contact Data Bridge Market Research for an Analyst Brief, where their experts will aid in making informed market decisions to drive growth.

Global Electrically Conductive Coating Market Opportunities:

In addition to the hurdles posed by regulatory restraints, the electrically conductive coating industry has substantial development potential, driven by increased knowledge of its benefits and rising demand in the industrial sector. This increased awareness among stakeholders creates attractive prospects for market players over the projection period of 2022–2029. Furthermore, the market stands to profit from ongoing technological developments and improvements in manufacturing methods. The development of sophisticated technologies, particularly the incorporation of nanotubes, has the potential to revolutionize the industry, paving the door for improved performance and expanded applications of electrically conducting coatings. These technical advancements not only promise to accelerate the market's growth trajectory but also to position it for continued expansion and innovation in the coming years, solidifying its central role in the worldwide industrial scene.

ELECTRICALLY CONDUCTIVE COATING MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

6% |

|

Segments Covered |

By Type, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Akzo Nobel N.V. (Netherlands), Axalta Coating Systems (U.S.), BASF SE (Germany), Covestro AG (Germany), Dupont (U.S.), Esdee Paints (India), Jotun (Norway), Kansai Paints Co., Ltd. (Japan), KCC Corporation (South Korea), Lubrizol Corporation (U.S.) |

Global Electrically Conductive Coating Market Segmentation: By Type

-

Acrylics

-

Epoxy

-

Polyesters

-

Polyurethanes

-

Other Types

The Global Electrically Conductive Coating Market Segmented by Type, Epoxy held the largest market share last year and is poised to maintain its dominance throughout the forecast period. Epoxy and acrylic resins are the most common in electrically conductive coatings, and they are well-known for their versatility and adaptability for a wide range of applications. These coatings are essential in the production of a wide range of products, including LCDs, control panels, and a variety of electrical gadgets. Epoxy is preferred for its exceptional durability and mechanical qualities, making it important in areas that require strong wear and tear resistance. Acrylic, on the other hand, has an outstanding glossy surface, making it ideal for architectural and ornamental applications where aesthetics are important. Together, these resin types provide a comprehensive solution for improving the functioning and aesthetics of a variety of electrical and industrial goods.

Global Electrically Conductive Coating Market Segmentation: By Application

-

Electronics and Electrical

-

Automotive

-

Aerospace and Defense

-

Other Applications

The Global Electrically Conductive Coating Market Segmented by Application, Electronics, and Electrical held the largest market share last year and is poised to maintain its dominance throughout the forecast period.

Electrically conductive coatings serve an important role in protecting electronic equipment by providing anti-static protection and electromagnetic shielding, especially in industries like electronics and aerospace. These coatings use a variety of compounds, including acrylics, epoxies, and polyesters. Epoxies are known for their scratch resistance and chemical resistance, making them excellent for applications that require durability and protection against abrasion and impact. Acrylics, on the other hand, are frequently used in electronics, satellite dishes, and electronic-board-level applications due to their utility and versatility. Furthermore, pigments mixed with specialized chemistries improve shielding capabilities, especially for electronics and electro-medical equipment, reducing electrostatic and electromagnetic interferences (EMI). With advancements in electronics, increased requirements for safety in electronic boards, and rising needs in the construction and aerospace industries, the market for electrically conductive coatings is expected to rise significantly shortly.

Global Electrically Conductive Coating Market Segmentation: By Region

-

North America

-

Asia-Pacific

-

Europe

-

South America

-

Middle East and Africa

The Asia-Pacific region is projected to dominate the global market for electrically conductive coatings, owing to the highly developed electronics sectors in China, Japan, and South Korea. These countries have consistently invested in the advancement of aerospace and automotive technologies throughout the years, increasing demand for such coatings. The region has seen a huge increase in demand for electronics such as mobile phones, televisions, tablets, keyboards, and laptop computers as a result of technological improvements. China, Japan, and Taiwan are home to numerous electronic manufacturing factories, which contribute to the region's strong position in electronics production. Furthermore, the adoption of electric vehicles in Asia-Pacific has increased, aided by supportive government regulations and increased investment, boosting demand for electrically conductive coatings in the automotive sector. According to GFU Consumer & Home Electronics, Asia-Pacific dominates the worldwide consumer electronics sales market, with China, Vietnam, and Taiwan serving as significant electronic manufacturing hubs and exporters. With the growing electric vehicle industry, improvements in electrical technology, and expansions in the aerospace and defence sectors, the region's demand for electrically conductive coatings is likely to rise further in the coming years.

COVID-19 Impact Analysis on the Global Electrically Conductive Coating Market:

The recent coronavirus outbreak negatively impacted the electrically conductive coating business. The rate of expansion will drastically slow as the epidemic worsens due to weak markets and rising financial hardship. Restrictions on movement had a severe economic impact. Significant economic upheavals are also happening in Southeast Asian countries and India. Lockdowns imposed by various governments forced businesses and offices to close, and all activity ceased. To keep industries going during these difficult times, the government established legislation and personnel restrictions. Many industries, including construction, automotive, white goods, and electronics, have slowed as a result of the threat to the coatings business. Because of the rigorous laws and limits that must be observed, industries are expected to respect the government's dignity. However, the market is expected to rebound once individual regulatory agencies begin to ease the imposed lockdowns. Furthermore, the market might recover from losses caused by a surge in certain businesses and end-use industries. The market's product and service portfolio is also being developed with the assistance of well-known companies operating in various global regions, which will accelerate the market's growth by the end of the forecast period.

Latest Trends/ Developments:

The global electrically conductive coatings industry is humming with new advancements. Sustainability is a top priority, with producers producing low-VOC, bio-based, and aqueous coatings to reduce environmental effects. Nanocomposite coatings, which incorporate nanoparticles for improved performance, are gaining popularity, particularly in high-technology applications. Additionally, multifunctional coatings that integrate capabilities like as conductivity and self-healing simplify production and improve product performance. 3D printing technology is also gaining traction, allowing for the production of intricate and customized conductive structures for a variety of purposes. Furthermore, the need for these coatings is spreading beyond conventional sectors such as electronics and automotive, to new frontiers like biosensors, energy harvesting, and wearable electronics, pushed by modern device miniaturization and increased functionality. These developments present a positive picture for the future of electrically conductive coatings, with ongoing innovation opening the way for even more efficient and diverse solutions for a variety of industries.

Key players:

-

Akzo Nobel N.V. (Netherlands)

-

Axalta Coating Systems (U.S.)

-

BASF SE (Germany)

-

Covestro AG (Germany)

-

Dupont (U.S.)

-

Esdee Paints (India)

-

Jotun (Norway)

-

Kansai Paints Co., Ltd. (Japan)

-

KCC Corporation (South Korea)

-

Lubrizol Corporation (U.S.)

Chapter 1. Electrically Conductive Coating Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Electrically Conductive Coating Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Electrically Conductive Coating Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Electrically Conductive Coating Market - Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Electrically Conductive Coating Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Electrically Conductive Coating Market – By Type

6.1 Introduction/Key Findings

6.2 Acrylics

6.3 Epoxy

6.4 Polyesters

6.5 Polyurethanes

6.6 Other Types

6.7 Y-O-Y Growth trend Analysis By Type

6.8 Absolute $ Opportunity Analysis By Type, 2024-2030

Chapter 7. Electrically Conductive Coating Market – By Application

7.1 Introduction/Key Findings

7.2 Electronics and Electrical

7.3 Automotive

7.4 Aerospace and Defense

7.5 Other Applications

7.6 Y-O-Y Growth trend Analysis By Application

7.7 Absolute $ Opportunity Analysis By Application , 2024-2030

Chapter 8. Electrically Conductive Coating Market , By Geography – Market Size, Forecast, Trends & Insights

8.1 North America

8.1.1 By Country

8.1.1.1 U.S.A.

8.1.1.2 Canada

8.1.1.3 Mexico

8.1.2 By Type

8.1.3 By Application

8.1.4 Countries & Segments - Market Attractiveness Analysis

8.2 Europe

8.2.1 By Country

8.2.1.1 U.K

8.2.1.2 Germany

8.2.1.3 France

8.2.1.4 Italy

8.2.1.5 Spain

8.2.1.6 Rest of Europe

8.2.2 By Type

8.2.3 By Application

8.2.4 Countries & Segments - Market Attractiveness Analysis

8.3 Asia Pacific

8.3.1 By Country

8.3.1.1 China

8.3.1.2 Japan

8.3.1.3 South Korea

8.3.1.4 India

8.3.1.5 Australia & New Zealand

8.3.1.6 Rest of Asia-Pacific

8.3.2 By Type

8.3.3 By Application

8.3.4 Countries & Segments - Market Attractiveness Analysis

8.4 South America

8.4.1 By Country

8.4.1.1 Brazil

8.4.1.2 Argentina

8.4.1.3 Colombia

8.4.1.4 Chile

8.4.1.5 Rest of South America

8.4.2 By Type

8.4.3 By Application

8.4.4 Countries & Segments - Market Attractiveness Analysis

8.5 Middle East & Africa

8.5.1 By Country

8.5.1.1 United Arab Emirates (UAE)

8.5.1.2 Saudi Arabia

8.5.1.3 Qatar

8.5.1.4 Israel

8.5.1.5 South Africa

8.5.1.6 Nigeria

8.5.1.7 Kenya

8.5.1.8 Egypt

8.5.1.9 Rest of MEA

8.5.2 By Type

8.5.3 By Application

8.5.4 Countries & Segments - Market Attractiveness Analysis

Chapter 9. Electrically Conductive Coating Market – Company Profiles – (Overview, Product Type Portfolio, Financials, Strategies & Developments)

9.1 Akzo Nobel N.V. (Netherlands)

9.2 Axalta Coating Systems (U.S.)

9.3 BASF SE (Germany)

9.4 Covestro AG (Germany)

9.5 Dupont (U.S.)

9.6 Esdee Paints (India)

9.7 Jotun (Norway)

9.8 Kansai Paints Co., Ltd. (Japan)

9.9 KCC Corporation (South Korea)

9.10 Lubrizol Corporation (U.S.)

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The market is expected to grow at a 6% CAGR through 2030.

The market is expected to reach USD 30.09 Billion by 2030.

The Packaging sector drives the Global Electrically Conductive Coating market.

By 2023, the market is expected to be valued at USD 20.012 Billion.

Asia-Pacific dominates the Global Electrically Conductive Coating market.