Electric Welding Market Size (2024-2030)

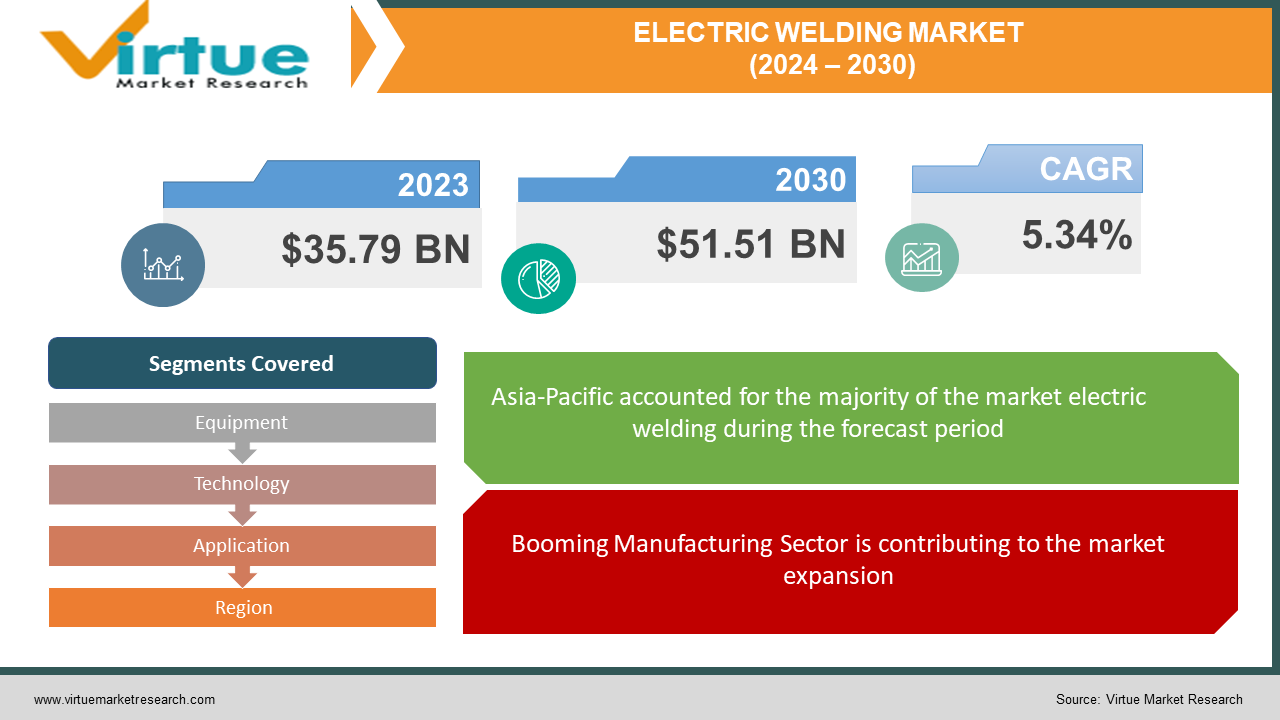

The Electric Welding Market was valued at USD 35.79 billion in 2023 and is projected to reach a market size of USD 51.51 billion by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 5.34%.

The electric welding market is a dynamic landscape, where tradition and innovation tango. Arc welding may remain the king, but the whispers of change grow louder with each passing day. Advanced technologies and eco-conscious practices are poised to take center stage, paving the way for a future where every weld is not just strong, but sustainable.

Key Market Insights:

Arc welding reigns supreme, holding over 70% of the market share. Its versatility, affordability, and adaptability to various metals and thicknesses make it the undisputed champion. But beneath the surface, exciting shifts are brewing.

The Asia-Pacific region, with its manufacturing juggernaut status, is leading the charge with the fastest growth. China and India, fueled by booming industrialization, are driving this surge. Meanwhile, automation and robotics are quietly revolutionizing the market, boosting efficiency and precision with robotic arms and AI-powered welding systems. Safety and sustainability are also taking center stage. Concerns about emissions and resource depletion are pushing for cleaner technologies like laser cladding and cold wire welding, minimizing environmental impact while conserving precious resources.

In essence, the electric welding market is a dynamic landscape where tradition and innovation are coexisting and evolving. While arc welding remains the king, the winds of change are whispering of a future where advanced technologies and eco-conscious practices take the lead. This market is not just about joining metals; it's about joining forces with progress and sustainability, paving the way for a brighter future.

Electric Welding Market Drivers:

Booming Manufacturing Sector is contributing to the market expansion:

Imagine a global symphony of factories churning out cars, planes, ships, and countless other products. This industrial orchestra relies heavily on electric welding to join metal components, creating the backbone of our modern world. Rising demand in sectors like automobiles, infrastructure development, and shipbuilding fuels the need for welding services and equipment. Developing economies like China and India contribute significantly to this growth, as their manufacturing sectors surge ahead.

Technological Advancements is contributing largely to the market expansion:

Imagine robots wielding welding torches with near-perfect precision, guided by the watchful eye of artificial intelligence. This is the future of welding, driven by exciting technological advancements. Automation and robotics are revolutionizing the market, boosting productivity, ensuring consistent quality, and minimizing human error. AI-powered systems optimize welding parameters, adapt to different materials, and predict potential problems, making the process smarter and more efficient.

The Focus on Quality and Efficiency is fuelling the market expansion:

In today's competitive world, manufacturers prioritize flawless welds and maximum output. Electric welding technologies are evolving to meet these demands. Advanced welding techniques like laser welding and friction stir welding offer superior precision and strength, minimizing rework and material waste. Automated production lines equipped with sensors and monitoring systems ensure consistent quality and optimize resource utilization.

Emerging Economies is contributing to the market expansion:

Imagine a continent like Africa, rich in resources and teeming with potential. As these economies develop, their infrastructure needs soar, creating a fertile ground for the electric welding market. Government investments in infrastructure projects, power grids, and transportation networks fuel the demand for welding equipment and services. Rising urbanization and industrialization further contribute to the market's growth in these regions.

Electric Welding Market Restraints and Challenges:

Skilled Labor Shortage is a major cause of market slowdown:

Imagine a conductor desperately searching for talented musicians but finding only empty chairs. This is the dilemma many welding companies face due to a global shortage of skilled welders. This lack of qualified workers hampers growth and creates bottlenecks in production, impacting project timelines and costs. The issue is particularly acute in developed countries with aging populations and declining interest in vocational trades.

Volatile Raw Material Prices is a major cause of market slowdown:

Imagine the orchestra tuning its instruments, but the strings keep snapping due to fluctuating prices. Volatile raw material prices, particularly of metals, pose another challenge for the market. Sudden spikes in metal prices can significantly increase production costs, squeezing profit margins and impacting equipment affordability. The unpredictability of resource markets makes budgeting and long-term planning difficult for businesses.

Stringent Safety Regulations is a major cause of market slowdown:

Imagine every musician wearing cumbersome safety gear, slowing down the tempo. Stringent safety regulations, while essential for worker protection, can add complexities and costs to the welding process. Implementing and adhering to safety standards requires investments in equipment, training, and monitoring systems, impacting smaller businesses disproportionately. Navigating the ever-evolving regulatory landscape can be a bureaucratic hurdle for some companies.

Environmental Concerns is a major cause of market slowdown:

Imagine the stage lights casting a dark shadow due to environmental concerns. Fumes and emissions generated by welding raise concerns about air pollution and the health of workers and communities. Growing awareness of these environmental impacts puts pressure on the industry to develop and adopt cleaner welding technologies. Balancing productivity with environmental responsibility poses a significant challenge for manufacturers and equipment producers.

Electric Welding Market Opportunities:

While the electric welding market navigates the rhythm of growth, it simultaneously juggles hidden melodies of opportunity. Advanced technologies like laser cladding and friction stir welding serenade specialized applications, promising strength and precision for sectors like aerospace and automotive. Meanwhile, the aging infrastructure in developed nations and the rapid expansion in developing ones orchestrate a booming maintenance and repair segment, offering stability and specialized service opportunities. The environmental crescendo demands a focus on sustainability, with cleaner solutions like cold wire welding and laser ablation harmonizing with eco-conscious regulations. Finally, the digital baton conducts a symphony of sensors, IoT, and data analytics, optimizing processes and enhancing efficiency. These hidden melodies paint a vibrant picture of the electric welding market's potential, inviting businesses to embrace innovation, cater to specialized needs, and prioritize sustainability to dance their way towards a prosperous and eco-friendly future.

ELECTRIC WELDING MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

5.34% |

|

Segments Covered |

By Equipment, Technology, Application, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Yaskawa Motoman Robotics, Hypertherm, Jiangsu Riland Technology Co., Ltd, Panasonic, ESAB, Lincoln Electric, Kemppi, Fronius International, Daihen Corporation |

Electric Welding Market Segmentation: By Equipment

-

Arc welding

-

MIG/MAG welding

-

TIG welding

-

Resistance welding

-

Laser welding

In the equipment orchestra of the electric welding market, two instruments dominate the stage with distinct melodies. Arc welding, the seasoned veteran, holds firm as the dominant segment, its adaptability, and affordability echoing across over 70% of the market like a classic rock band filling stadium. From joining car chassis to building bridges, arc welding seamlessly switches between genres, a jack-of-all-trades captivating audience with its timeless versatility. But a new beat emerges, the rising star of MIG/MAG welding. Its user-friendly charm and high-speed deposition rates, ideal for thicker materials, make it the trendy new wave band electrifying the scene. Imagine sizzling welds weaving their magic on ships and heavy machinery, captivating crowds with their swift efficiency. While arc welding retains its kingly crown, MIG/MAG welding's meteoric rise underscores the market's dynamic rhythm.

Electric Welding Market Segmentation: By Technology

-

Conventional welding

-

Automated welding

-

Robotic welding

In the tech sector of the electric welding market, two melodies weave a contrasting tapestry: the familiar and the futuristic. Conventional welding, like a seasoned maestro, conducts the orchestra with traditional techniques like arc and resistance. Its well-rehearsed routines, reliable in construction and manufacturing, form the solid backbone of this vibrant market. Yet, a thrilling counterpoint emerges with robotic welding, the rising star whose swift, precise movements add a futuristic layer to the symphony. Imagine dazzling robotic arms dancing with unmatched accuracy, injecting high-speed efficiency into repetitive tasks like automotive and aerospace welding. Fueled by automation, robotic welding's growth outpaces all others, its electrifying rhythm highlighting the market's innovative potential. While conventional welding retains its orchestral lead, the rise of robotic technology reminds us that the market's melody is constantly evolving.

Electric Welding Market Segmentation: By Application

-

Automotive

-

Construction

-

Shipbuilding

-

Energy

-

Aerospace

In the bustling marketplace of electric welding applications, two giants clash like titans, each holding its ground with contrasting strengths. Automotive, like a sleek sports car, roars ahead with over 50% of the market share. Its powerful engine runs on the ever-growing global demand for cars, trucks, and other vehicles. From welding chassis to joining engine components, the automotive sector keeps the market's pistons pumping with a relentless pace. But a challenger rises from the concrete jungle: construction. Imagine a towering skyscraper under construction, its rapid growth fueled by the insatiable need for infrastructure development around the globe. Bridges, buildings, pipelines, power plants – the construction sector casts a long shadow of future potential, attracting investments and opportunities like moths to a flame. While the automotive sector maintains its established dominance, construction's meteoric rise paints a fascinating picture of the market's diverse potential. These contrasting champions offer unique opportunities for businesses, whether seeking the established might of a global industry or the thrilling potential of an infrastructure boom.

Electric Welding Market Segmentation: Regional Analysis

-

North America

-

Asia-Pacific

-

Europe

-

South America

-

Middle East and Africa

Asia-Pacific holds the majority of the market share of around 45% in 2023 and is anticipated to be the fastest-growing segment as well, fueled by China and India's industrial boom. Europe, considered to be a mature market with strong focus on automation and high-precision welding. North America holds a significant demand from automotive and aerospace industries, but facing a skilled labor shortage. South America’s growing infrastructure investments create potential, but infrastructure needs improvement.

COVID-19 Impact Analysis on the Electric Welding Market Market:

The COVID-19 pandemic flung a spanner into the electric welding market, causing supply chain disruptions, manufacturing slowdowns, and project delays. Yet, like a spark igniting opportunity, it also fueled automation adoption, local manufacturing shifts, and digital tool integrations. While the initial jolt was negative, the market's resilience and focus on future-proof technologies like robotics and sustainability suggest a potential for faster long-term growth, navigating challenges like skilled labor shortages and volatile material prices. The post-pandemic landscape promises a fusion of automation, digitalization, and eco-conscious solutions, with businesses that prioritize adaptability and talent development poised to weld their way to success.

Latest Trends/ Developments:

Innovation ignites the electric welding market, forging exciting trends that reshape its landscape. Imagine tireless robots dancing through intricate geometries, wielding torches with superhuman precision. This isn't a futuristic vision; it's the reality of robotic welding, revolutionizing the industry with speed, consistency, and efficiency.

But the market isn't just about brute force. A green conscience hums beneath the surface, evident in eco-friendly techniques like laser cladding and cold wire welding. These minimize heat and emissions, leaving a lighter footprint on the planet. The symphony of progress intensifies with the addition of artificial intelligence, its invisible hand optimizing every weld parameter for flawless results. Gone are the days of trial and error; data now dictates the perfect bead, minimizing waste and downtime.

And the dance floor expands beyond traditional metals. Advanced techniques extend their reach to exotic materials like composites and ceramics, opening doors for groundbreaking applications in aerospace and medical technology. The electric welding market, once confined to joining steel and iron, now joins forces with innovation, paving the way for a future where efficiency, precision, and environmental responsibility go hand in hand.

Key Players:

-

Yaskawa Motoman Robotics

-

Hypertherm

-

Jiangsu Riland Technology Co., Ltd

-

Panasonic

-

ESAB

-

Lincoln Electric

-

Kemppi

-

Fronius International

-

Daihen Corporation

Chapter 1. Electric Welding Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Electric Welding Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Electric Welding Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Electric Welding Market Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Electric Welding Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Electric Welding Market – By Equipment

6.1 Introduction/Key Findings

6.2 Arc welding

6.3 MIG/MAG welding

6.4 TIG welding

6.5 Resistance welding

6.6 Laser welding

6.7 Y-O-Y Growth trend Analysis By Equipment

6.8 Absolute $ Opportunity Analysis By Equipment, 2024-2030

Chapter 7. Electric Welding Market – By Application

7.1 Introduction/Key Findings

7.2 Automotive

7.3 Construction

7.4 Shipbuilding

7.5 Energy

7.6 Aerospace

7.7 Y-O-Y Growth trend Analysis By Application

7.8 Absolute $ Opportunity Analysis By Application , 2024-2030

Chapter 8. Electric Welding Market – By Technology

8.1 Introduction/Key Findings

8.2 Conventional welding

8.3 Automated welding

8.4 Robotic welding

8.5 Y-O-Y Growth trend Analysis By Technology

8.6 Absolute $ Opportunity Analysis By Technology, 2024-2030

Chapter 9. Electric Welding Market , By Geography – Market Size, Forecast, Trends & Insights

9.1 North America

9.1.1 By Country

9.1.1.1 U.S.A.

9.1.1.2 Canada

9.1.1.3 Mexico

9.1.2 By Equipment

9.1.3 By Application

9.1.4 By By Technology

9.1.5 Countries & Segments - Market Attractiveness Analysis

9.2 Europe

9.2.1 By Country

9.2.1.1 U.K

9.2.1.2 Germany

9.2.1.3 France

9.2.1.4 Italy

9.2.1.5 Spain

9.2.1.6 Rest of Europe

9.2.2 By Equipment

9.2.3 By Application

9.2.4 By Technology

9.2.5 Countries & Segments - Market Attractiveness Analysis

9.3 Asia Pacific

9.3.1 By Country

9.3.1.1 China

9.3.1.2 Japan

9.3.1.3 South Korea

9.3.1.4 India

9.3.1.5 Australia & New Zealand

9.3.1.6 Rest of Asia-Pacific

9.3.2 By Equipment

9.3.3 By Application

9.3.4 By Technology

9.3.5 Countries & Segments - Market Attractiveness Analysis

9.4 South America

9.4.1 By Country

9.4.1.1 Brazil

9.4.1.2 Argentina

9.4.1.3 Colombia

9.4.1.4 Chile

9.4.1.5 Rest of South America

9.4.2 By Equipment

9.4.3 By Application

9.4.4 By Technology

9.4.5 Countries & Segments - Market Attractiveness Analysis

9.5 Middle East & Africa

9.5.1 By Country

9.5.1.1 United Arab Emirates (UAE)

9.5.1.2 Saudi Arabia

9.5.1.3 Qatar

9.5.1.4 Israel

9.5.1.5 South Africa

9.5.1.6 Nigeria

9.5.1.7 Kenya

9.5.1.8 Egypt

9.5.1.9 Rest of MEA

9.5.2 By Equipment

9.5.3 By Application

9.5.4 By Technology

9.5.5 Countries & Segments - Market Attractiveness Analysis

Chapter 10. Electric Welding Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

10.1 Yaskawa Motoman Robotics

10.2 Hypertherm

10.3 Jiangsu Riland Technology Co., Ltd

10.4 Panasonic

10.5 ESAB

10.6 Lincoln Electric

10.7 Kemppi

10.8 Fronius International

10.9 Daihen Corporation

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Electric Welding Market was valued at USD 35.79 billion in 2023 and is projected to reach a market size of USD 51.51 billion by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 5.34%.

Booming Manufacturing Sector, Technological Advancements, the Focus on Quality and Efficiency, Emerging Economies

Based on Application, the Electric Welding Market is segmented into Automotive, Construction, Shipbuilding, Energy, and Aerospace.

Asia Pacific is the most dominant region for the Electric Welding Market.

Yaskawa Motoman Robotics, Hypertherm, Jiangsu Riland Technology Co., Ltd, Panasonic, ESAB, Lincoln Electric, Kemppi, Fronius International, Daihen Corporation are the key players operating in the Electric Welding Market.