Electric Vehicle Insulation Materials Market Size (2024 – 2030)

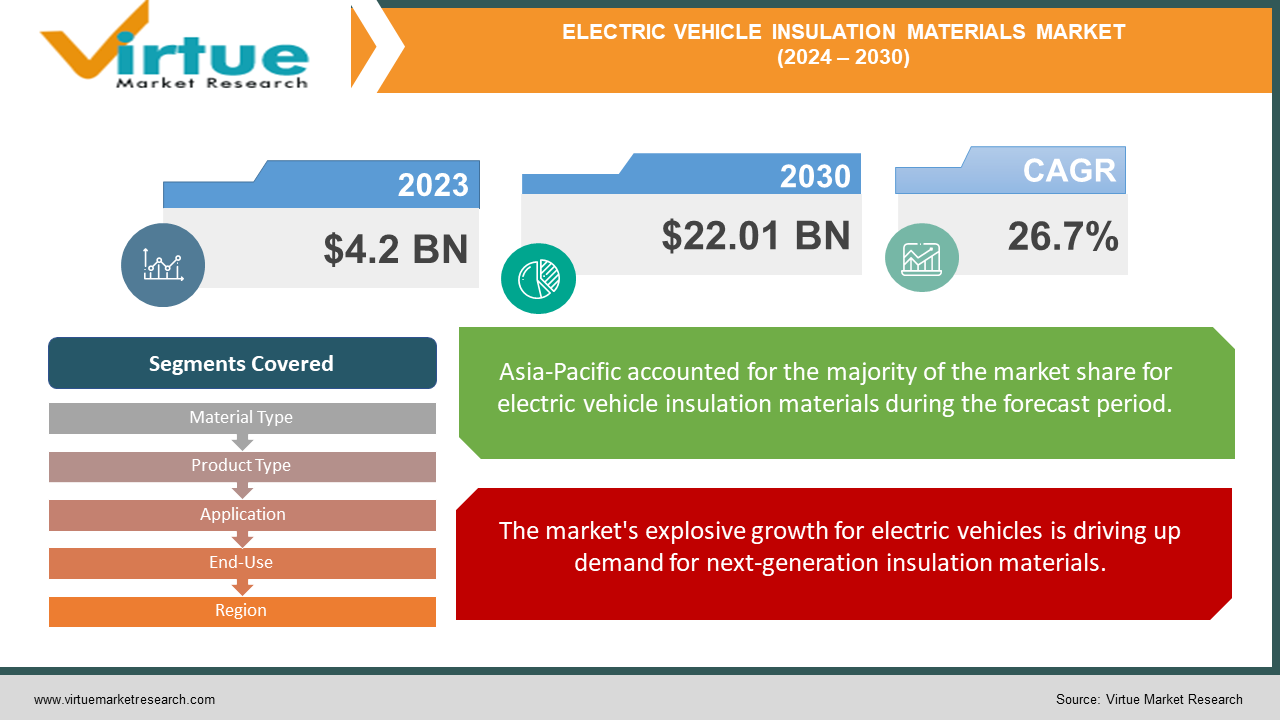

The Global Electric Vehicle Insulation Materials Market was valued at USD 4.2 billion in 2023 and is projected to reach a market size of USD 22.01 billion by 2030. Over 2024-2030, the market is projected to grow at a CAGR of 26.7%.

Electrical and thermal insulation plays a major role in electric vehicles (EVs). Electrical insulation guarantees the safe management of the high voltage within the battery, while thermal insulation keeps the battery from overheating. Various polymers, such as silicone for heat resistance, Nomex aramid fibre for all-around strength, and polyester films, such as Mylar and Kapton, for mechanical and thermal stability, are frequently used for EV insulation. For thermal and acoustic insulation, polyimide foams have a good temperature range and vibration-damping properties. Epoxies, aramid paper, and silicone foams are other alternatives. The application, temperature requirements, voltage rating, and cost all influence the material selection.

Key Market Insights:

The market for electric vehicles is projected to increase at a compound annual growth rate (CAGR) of 23.9% from 2023 to $ 802.8 billion by 2027. The substantial increase in EV usage is immediately translating into a spike in demand for the different insulating materials utilised in these cars.

Because batteries are getting higher to allow for longer ranges, the high-voltage insulation segment of the EV insulation market is anticipated to develop at the quickest rate. The requirement for high-performance insulating materials that can withstand these elevated voltages and temperatures becomes critical as automakers aim for greater range and faster charging times.

The market for bio-based insulation is expected to reach USD 19.2 billion by 2028, as all industries place an increasing emphasis on eco-friendly materials. Manufacturers are being forced to create and implement these solutions because of the growing consumer demand for bio-based and recyclable insulating materials for electric vehicles.

In 2023, the Asia Pacific region accounted for 43.2% of the global market for EV insulation, mostly because of the area's fast adoption of EVs and strict regulatory restrictions. Due to the existence of significant battery and electric vehicle manufacturers in the area as well as favourable government policies encouraging EVs, the Asia Pacific region is projected to continue to dominate.

Global Electric Vehicle Insulation Materials Market Drivers:

The Demand for Insulation Materials is Increasing Due to the Booming Production of Electric Vehicles an Examination of Material Advancements, Government Support, and Environmental Drivers

The electric car industry is expanding rapidly due to growing environmental concerns and government incentives that lower the cost of these vehicles. The increased need for insulating materials which are essential for minimising current leakage in high-voltage wiring, guaranteeing efficient motor performance, and protecting batteries from overheating is a direct result of the spike in EV manufacturing. To fulfil the ever-increasing demands of the EV sector, insulating material producers are increasing production and creating innovative solutions, such as lighter materials for high-voltage systems and enhanced thermal conductors for battery packs.

The market's explosive growth for electric vehicles is driving up demand for next-generation insulation materials.

The rise in popularity of electric vehicles (EVs) is fueling a need for cutting-edge insulating materials. Strong insulation is required in many EV components because of the rapid rise of EVs driven by government incentives and environmental concerns. These components are essential to battery packs because they protect them from overheating, which may drastically impair their performance or even cause fires. Proper insulation has a major role in controlling heat generation and preventing electrical shorts, two activities that are essential to the effective running of motors. Insulation is also necessary for high-voltage wire systems to stop current leakage and keep them operating at peak efficiency. The need for various insulating materials will rise proportionately to this increase in EV manufacturing. To accommodate this demand, manufacturers are increasing output and are always coming up with new ideas. The development of more effective battery heat management systems is made possible by improvements in thermal conductivity, which will eventually extend the life and health of batteries. Lightweight materials that can withstand higher electrical demands are prioritised for high-voltage systems since this will improve the overall performance and range of EVs. In essence, the rapidly expanding electric vehicle (EV) industry is driving up demand for insulating materials and pushing the frontiers of material science to develop stronger, lighter, and more thermally efficient solutions for a cleaner future.

Global Electric Vehicle Insulation Materials Market Restraints and Challenges:

There are several obstacles facing the electric vehicle insulating materials business. Automakers may find it difficult to afford the greater cost of sophisticated materials, particularly in markets where cost is a concern. Moreover, long approval procedures and strict safety rules might hinder innovation. Manufacturers face additional complications because of the absence of standardised materials for various EV variants. Even if bio-based products are being used in sustainability initiatives, a sizable section of the industry still uses less environmentally friendly materials. Furthermore, flame-retardant insulation needs to be developed even further because fire safety is still a worry. To overcome these obstacles and guarantee a balance between performance, cost, safety, and sustainability for electric vehicle insulating materials in the future, cooperation amongst all stakeholders is essential.

Global Electric Vehicle Insulation Materials Market Opportunities:

The market for electric vehicle insulating materials is seeing tremendous growth because of the electric vehicle (EV) revolution. To enable longer range and quicker charging EVs, high-performance materials with excellent thermal management, electrical insulation, and fire resistance are in great demand. The goal of making electric vehicles lighter generates demand for cutting-edge insulating materials that function well without gaining bulk. Sustainability is still another important factor, with bio-based and recyclable materials offering manufacturers a big chance to appeal to automakers and consumers who care about the environment. Technological developments in material science provide new avenues for investigating aerogels, nanomaterials, and other creative solutions. The expanding electric vehicle fleet generates a profitable aftermarket for replacement insulating materials beyond the initial car manufacture.

ELECTRIC VEHICLE INSULATION MATERIALS MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 - 2030 |

|

Base Year |

2023 |

|

Forecast Period |

2024 - 2030 |

|

CAGR |

26.7% |

|

Segments Covered |

By Material Type, Product Type, Application, End-Use, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

BASF SE, Celanese Corporation, Continental AG, Denso Corporation, Dow Inc., DuPont, Huntsman Corporation, LyondellBasell Industries Inc., Nippon Electric Glass Co., Ltd., Robert Bosch GmbH, Rogers Corporation, SABIC, Saint-Gobain |

Global Electric Vehicle Insulation Materials Market Segmentation: By Material Type

-

Thermal interface materials (TIMs)

-

Foamed plastics

-

Ceramics

-

Others

The market for insulating materials for electric vehicles is divided into material types, with foamed plastics at the top of the list. These materials are popular among manufacturers because they are affordable, lightweight, and provide superior thermal insulation in a variety of EV components.

Global Electric Vehicle Insulation Materials Market Segmentation: By Product Type

-

Battery insulation

-

Motor insulation

-

Power electronics insulation

-

Charging system insulation

The market for insulating materials for electric vehicles is divided into several categories, with the most important categories being battery, motor, power electronics, and charging system insulation. This analysis emphasises the vital role insulation plays in different EV components, even if it cannot conclusively identify a leader or the fastest-growing area. Specific temperature control and electrical safety requirements for the EV drivetrain and charging infrastructure are covered in each phase. To determine the market share or growth trajectory of the largest segment, more investigation or industry studies are required.

Global Electric Vehicle Insulation Materials Market Segmentation: By Application

-

Under the hood & battery pack

-

Passenger compartment

-

Wiring & cables

The market for insulating materials for electric vehicles is further divided into applications, which include wire and cable insulation, battery pack and under-the-hood insulation, and passenger compartment insulation. Each of the three applications is essential for EV performance and safety, even though data is required to identify the top and fastest-growing industries. Given the vital function that under-the-hood and battery pack insulation play, these segments of the market probably account for a sizable amount, but further study is required to validate this and find any trends that may favour a certain application.

Global Electric Vehicle Insulation Materials Market Segmentation: By End-Use

-

Passenger cars

-

Commercial vehicles

-

Two-wheeled electric vehicles

The market for insulating materials for electric vehicles serves a wide variety of vehicles, although passenger cars now lead the field because of their large manufacturing volume. As the market for electric cars grows, there are exciting growth prospects for commercial vehicles and two-wheeled electric vehicles. All three categories—passenger cars, commercial vehicles, and two-wheeled electric vehicles—represent a sizable potential for insulating material makers in the changing electric transportation scenario, while data is still needed to identify the fastest-growing area.

Global Electric Vehicle Insulation Materials Market Segmentation: By Region

-

North America

-

Asia-Pacific

-

Europe

-

South America

-

Middle East and Africa

Region-wise, North America, Asia-Pacific, Europe, South America, the Middle East, and Africa are the leading markets for electric car insulating materials. Asia-Pacific probably leads because of well-established EV manufacturers and encouraging government regulations. As the worldwide adoption of electric vehicles picks up speed, every location has potential.

COVID-19 Impact Analysis on the Global Electric Vehicle Insulation Materials Market:

Unquestionably, the COVID-19 outbreak caused changes in the market for insulating materials for electric vehicles. Travel bans and lockdowns put a kink into international supply chains, leading to shortages and delays in produced insulating materials as well as raw materials. This knock-on effect affected both total market growth and output. The epidemic caused a brief drop in the manufacture of automobiles, particularly electric ones, which in turn decreased the market for insulating materials designed specifically for EVs. The economic crisis also had an impact on consumer purchasing, which could have delayed the purchase of EVs and so reduced the market for EV insulating materials. Still, there were a few bright spots. The pandemic's focus on personal automobiles may have persuaded some customers to switch to electric vehicles, which might eventually cause the market for EV insulating materials to gradually increase. The good news is that the market for electric vehicles has recovered and is still growing after the pandemic, which bodes well for this insulating material niche's future. The epidemic also acted as a wake-up call, emphasising the necessity of more robust supply systems for essential commodities. The market for insulating materials for electric vehicles may have long-term stability because of this emphasis on strengthening infrastructure.

Recent Trends and Developments in the Global Electric Vehicle Insulation Materials Market:

The market for insulating materials for electric vehicles is seeing a boom in innovation due to the changing demands of the EV sector. The creation of high-performance materials with an emphasis on improved thermal conductivity, electrical insulation, and flame retardancy that can withstand the thermal demands of a longer range and faster charging is a major trend. The quest for innovative lightweight materials that provide superior insulation without increasing bulk is prompted by the necessity of lightweight to optimise electric vehicle range and efficiency. Another important subject is sustainability, as bio-based and recyclable materials become more popular in response to environmental laws and concerns. Future research on nanotechnology and other cutting-edge materials might lead to even more ground-breaking solutions. Beyond the original production of cars, an increasing number of electric vehicles (EVs) generates a profitable aftermarket for replacement insulating materials, and astute manufacturers are extending their reach into emerging EV markets.

Key Players:

-

BASF SE

-

Celanese Corporation

-

Continental AG

-

Denso Corporation

-

Dow Inc.

-

DuPont

-

Huntsman Corporation

-

LyondellBasell Industries Inc.

-

Nippon Electric Glass Co., Ltd.

-

Robert Bosch GmbH

-

Rogers Corporation

-

SABIC

-

Saint-Gobain

Chapter 1. Electric Vehicle Insulation Materials Market – Scope & Methodology

1.1 Market Segmentation

1.2 Scope, Assumptions & Limitations

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Electric Vehicle Insulation Materials Market – Executive Summary

2.1 Market Size & Forecast – (2024 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.2.1 Demand Side

2.2.2 Supply Side

2.3 Attractive Investment Propositions

2.4 COVID-19 Impact Analysis

Chapter 3. Electric Vehicle Insulation Materials Market – Competition Scenario

3.1 Market Share Analysis & Company Benchmarking

3.2 Competitive Strategy & Development Scenario

3.3 Competitive Pricing Analysis

3.4 Supplier-Distributor Analysis

Chapter 4. Electric Vehicle Insulation Materials Market Entry Scenario

4.1 Regulatory Scenario

4.2 Case Studies – Key Start-ups

4.3 Customer Analysis

4.4 PESTLE Analysis

4.5 Porters Five Force Model

4.5.1 Bargaining Power of Suppliers

4.5.2 Bargaining Powers of Customers

4.5.3 Threat of New Entrants

4.5.4 Rivalry among Existing Players

4.5.5 Threat of Substitutes

Chapter 5. Electric Vehicle Insulation Materials Market – Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Electric Vehicle Insulation Materials Market – By Material Type

6.1 Introduction/Key Findings

6.2 Thermal interface materials (TIMs)

6.3 Foamed plastics

6.4 Ceramics

6.5 Others

6.6 Y-O-Y Growth trend Analysis By Material Type

6.7 Absolute $ Opportunity Analysis By Material Type, 2024-2030

Chapter 7. Electric Vehicle Insulation Materials Market – By Application

7.1 Introduction/Key Findings

7.2 Under the hood & battery pack

7.3 Passenger compartment

7.4 Wiring & cables

7.5 Y-O-Y Growth trend Analysis By Application

7.6 Absolute $ Opportunity Analysis By Application, 2024-2030

Chapter 8. Electric Vehicle Insulation Materials Market – By Product Type

8.1 Introduction/Key Findings

8.2 Battery insulation

8.3 Motor insulation

8.4 Power electronics insulation

8.5 Charging system insulation

8.6 Y-O-Y Growth trend Analysis By Product Type

8.7 Absolute $ Opportunity Analysis By Product Type, 2024-2030

Chapter 9. Electric Vehicle Insulation Materials Market – By End-User

9.1 Introduction/Key Findings

9.2 Passenger cars

9.3 Commercial vehicles

9.4 Two-wheeled electric vehicles

9.5 Y-O-Y Growth trend Analysis By End-User

9.6 Absolute $ Opportunity Analysis By End-User, 2024-2030

Chapter 10. Electric Vehicle Insulation Materials Market, By Geography – Market Size, Forecast, Trends & Insights

10.1 North America

10.1.1 By Country

10.1.1.1 U.S.A.

10.1.1.2 Canada

10.1.1.3 Mexico

10.1.2 By Material Type

10.1.2.1 By ApplicationApplication

10.1.3 By Product Type

10.1.4 Countries & Segments - Market Attractiveness Analysis

10.2 Europe

10.2.1 By Country

10.2.1.1 U.K

10.2.1.2 Germany

10.2.1.3 France

10.2.1.4 Italy

10.2.1.5 Spain

10.2.1.6 Rest of Europe

10.2.2 By Material Type

10.2.3 By ApplicationApplication

10.2.4 By Product Type

10.2.5 By End-User

10.2.6 Countries & Segments - Market Attractiveness Analysis

10.3 Asia Pacific

10.3.1 By Country

10.3.1.1 China

10.3.1.2 Japan

10.3.1.3 South Korea

10.3.1.4 India

10.3.1.5 Australia & New Zealand

10.3.1.6 Rest of Asia-Pacific

10.3.2 By Material Type

10.3.3 By ApplicationApplication

10.3.4 By Product Type

10.3.5 By End-User

10.3.6 Countries & Segments - Market Attractiveness Analysis

10.4 South America

10.4.1 By Country

10.4.1.1 Brazil

10.4.1.2 Argentina

10.4.1.3 Colombia

10.4.1.4 Chile

10.4.1.5 Rest of South America

10.4.2 By Material Type

10.4.3 By ApplicationApplication

10.4.4 By Product Type

10.4.5 By End-User

10.4.6 Countries & Segments - Market Attractiveness Analysis

10.5 Middle East & Africa

10.5.1 By Country

10.5.1.1 United Arab Emirates (UAE)

10.5.1.2 Saudi Arabia

10.5.1.3 Qatar

10.5.1.4 Israel

10.5.1.5 South Africa

10.5.1.6 Nigeria

10.5.1.7 Kenya

10.5.1.8 Egypt

10.5.1.9 Rest of MEA

10.5.2 By Material Type

10.5.3 By ApplicationApplication

10.5.4 By Product Type

10.5.5 By End-User

10.5.6 Countries & Segments - Market Attractiveness Analysis

Chapter 11. Electric Vehicle Insulation Materials Market – Company Profiles – (Overview, Product Portfolio, Financials, Strategies & Developments)

11.1 BASF SE

11.2 Celanese Corporation

11.3 Continental AG

11.4 Denso Corporation

11.5 Dow Inc.

11.6 DuPont

11.7 Huntsman Corporation

11.8 LyondellBasell Industries Inc.

11.9 Nippon Electric Glass Co., Ltd.

11.10 Robert Bosch GmbH

11.11 Rogers Corporation

11.12 SABIC

11.13 Saint-Gobain

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Global Electric Vehicle Insulation Materials Market size is valued at USD 4.2 billion in 2023.

The worldwide Global Electric Vehicle Insulation Materials Market growth is estimated to be 26.7 % from 2024 to 2030.

Global Electric Vehicle Insulation Materials Market segmentation covered in the report is By Material Type (Thermal interface materials (TIMs), Foamed plastics, Ceramics, Others); By Product Type (Battery insulation, Motor insulation, Power electronics insulation, Charging system insulation); By Application (Under the hood & battery pack, Passenger compartment, Wiring & cables); By End-Use (Passenger cars, Commercial vehicles, Two-wheeled electric vehicles) and by region.

With an emphasis on environmentally friendly solutions, the insulating materials for electric vehicles are expected to increase sustainably in the future. Environmental concerns will lead to a boom in the market's demand for recyclable and bio-based goods. Furthermore, new materials like aerogels and nanomaterials will be investigated because of material science breakthroughs, offering improved insulating qualities. The replacement insulating material aftermarket offers producers a profitable way to serve this expanding market as the world's EV fleet grows.

Due to problems with the supply chain and a decrease in vehicle manufacturing, the COVID-19 epidemic briefly disrupted the market for electric car insulation. Long-term prospects, however, are still favourable as the EV industry recovers and the emphasis on supply chain resilience fortifies the sector's base.