GLOBAL COMPACT SPINNING MACHINE MARKET SIZE (2023 – 2030)

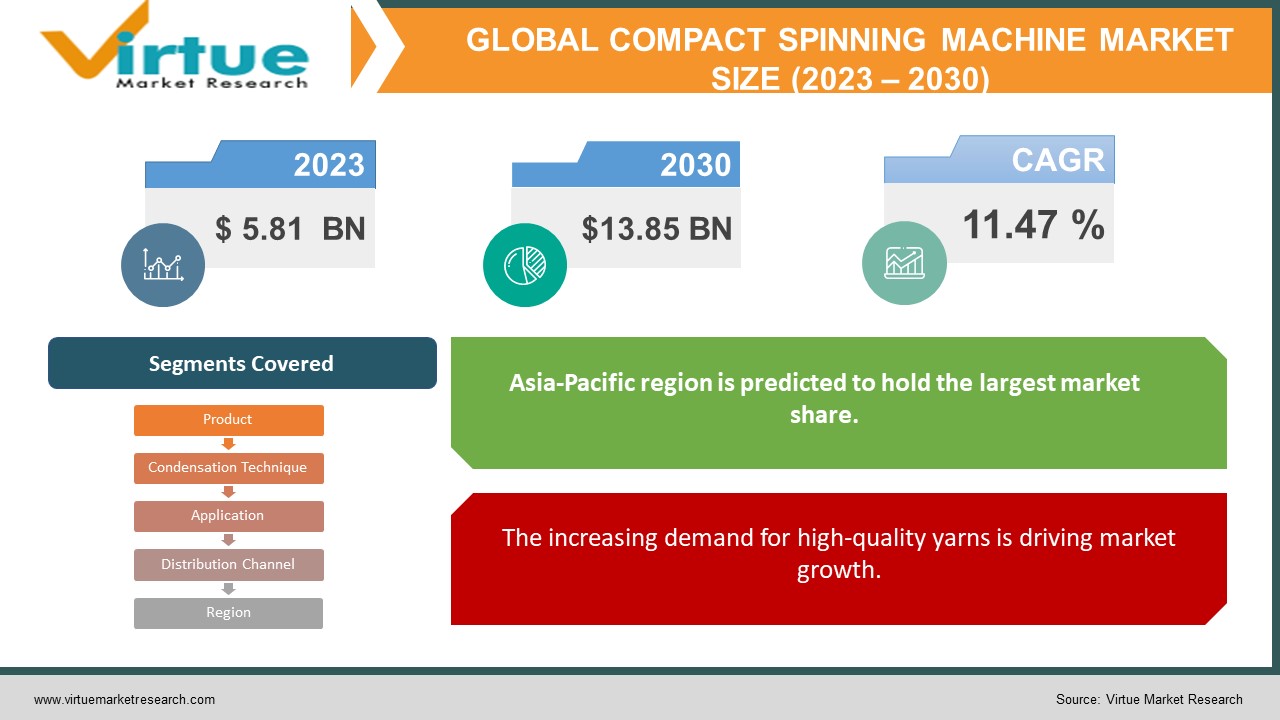

Global Compact Spinning Machine Market is estimated to be worth USD 5.81 Billion in 2023 and is projected to reach a value of USD 13.85 Billion by 2030, growing at a CAGR of 11.47% during the forecast period 2023-2030.

During the compact spinning process, the fibres are compressed before being twisted, creating a stronger cloth with less fibre fly and hairiness. The compact spinning machine uses less energy and produces less waste than conventional ring spinning machines, making it more ecologically friendly. Additionally, it is very automatic and requires little human input. Because of the growing need for fibres with better quality and sustainability in the textile industry, the market for compact spinning machines is growing.

Due to the need for high-quality fibres in the textile industry, the market for compact spinning machines is anticipated to grow steadily in the coming years. Due to the growing demand for textile products coming from nations like China, India, Bangladesh, and Vietnam, it is anticipated that the Asia-Pacific region will continue to control the majority of the market. The high cost of compact spinning machines, along with the cost and availability of fundamental materials, could pose issues for textile producers. However, because the textile industry is stressing sustainability and environmental kindness more and more, it is anticipated that the use of compact spinning machines will rise over the next few years.

Global Compact Spinning Machine Market Drivers:

The increasing demand for high-quality yarns is driving market growth.

One of the key factors propelling the global market for compact spinning machines is the textile industry's rising demand for high-quality fibres. Compared to conventional ring-spinning machines, compact spinning machines create yarns that are of higher quality, stronger, and more even. Before they are twisted, the fibres are compressed during the compact spinning process, which produces a stronger fabric with less fibre fly and hairiness. Compact spun yarns are therefore very sought-after by textile producers who need strong, premium fibres for their goods. Additionally, the demand for compact spinning machines is being fuelled by the textile industry's growing adoption of automation. These machines are highly automated and can create yarn with little to no human involvement. This lowers labour expenses and boosts production effectiveness, making it simpler for textile producers to satisfy the rising demand for premium yarns.

The rising focus on sustainability and eco-friendliness is augmenting market growth.

Another significant factor propelling the global market for compact spinning machines is the textile industry's increasing emphasis on sustainability and environmental kindness. Compact spinning is a more environmentally friendly alternative to conventional ring spinning because it uses less energy and generates less waste. This is so that there is less fibre fly and debris produced by compact spinning machines, which compact the fibres before they are twisted. Additionally, the compact spinning technique lessens skein breakage and increases yarn strength, resulting in less yarn being lost during production. The adoption of compact spinning machines is being fuelled by consumers' growing knowledge of the negative environmental effects of textile production as well as the demand for eco-friendly and sustainable textile products. Compact spinning machines enable textile producers to create premium, long-lasting yarns that are appealing to customers who care about the environment. This is particularly crucial for textile makers who want to stand out in a crowded market and draw in clients who value sustainability.

Global Compact Spinning Machine Market Challenges:

The current dearth of uses for compact spun yarns is one of the biggest issues confronting the global market for compact spinning machines. Despite producing high-quality yarns appropriate for a variety of textile applications, compact spinning machines are not the best option for all applications. Compact spun yarns are inappropriate for use in activewear or stretch denim, for example, due to their lack of flexibility or elasticity. Small spinning machines have fewer uses as a result, which might ultimately restrain market growth.

Global Compact Spinning Machine Market Opportunities:

The global market for compact spinning machines has a lot of room to expand in emerging markets. Because of their expanding populations and rising disposable incomes, nations like India, China, and Bangladesh are seeing rapid growth in their textile industries. There is an increasing need for high-quality, sustainable yarns made by small spinning machines as these nations modernise their textile sectors and place an emphasis on sustainability. Compact spinning machine producers who can take advantage of these emerging markets have a huge chance for growth.

COVID-19 Impact on Global Compact Spinning Machine Market:

COVID-19 has had a conflicting effect on the market for small spinning machines worldwide. On the one hand, the pandemic has caused a delay in the textile sector as a result of factory closures and supply chain disruptions brought on by lockdowns and social exclusion measures. Because of this, there is less demand for compact spinning machines and associated machinery. The pandemic, on the other hand, prompted a greater emphasis on sustainability and eco-friendliness, which increased demand for premium, sustainable fibres made by small spinning machines. Therefore, compact spinning machine producers should profit from this development as the textile industry bounces back and adjusts to the new standard.

Global Compact Spinning Machine Market Recent Developments:

-

In April 2022, the German manufacturer of automatic winding machines is one of the three Saurer businesses that Rieter has completely acquired. Through this acquisition, Rieter's position in the market for staple fibres is reinforced. Germany is the home country of Accotex and Temco, the two extra-acquired businesses. While Temco specialises in elastomer technology for spinning machines, Accotex concentrates on filament machine technology components.

-

In March 2023, to take advantage of the expanding nonwovens market in China, Trützschler increased its presence there by establishing a new plant.

GLOBAL COMPACT SPINNING MACHINE MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

11.47 % |

|

Segments Covered |

By Product, Condensation Technique, Application, Distribution Channel and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Rieter, TOYOTA INDUSTRIES CORPORATION, SHIMA SEIKI MFG., LTD Jingwei Textile Machinery, Truetzschler Group, Murata Machinery, Ltd, Itema S.p.a. Stoll Industries, Saurer AG. |

Global Compact Spinning Machine Market Segmentation:

Global Compact Spinning Machine Market Segmentation: By Product

-

Automated Semi-automatic spinning Machine

-

Semi-automated Spinning Machine

The small spinning machine industry offers automated, semi-automatic, and semi-automated spinning machines. Due to their high level of automation and capacity to create high-quality yarns with little human involvement, automated semi-automatic spinning machines are predicted to dominate the market. But because they are less expensive than automated machines, semi-automated spinning machines are also anticipated to expand considerably. A disproportionately large part of the market is anticipated to come from Asia-Pacific because nations like China and India have sizable textile manufacturing industries. Due to the arising demand for environmentally friendly and sustainable textile products, North America and Europe are predicted to experience substantial growth.

Global Compact Spinning Machine Market Segmentation: By Condensation Technique

-

Aerodynamic Compacting System

-

Mechanical Compacting System

-

Magnetic Compacting System

By condensation method, the market for compact spinning machines can be divided into three categories: airflow compacting systems, mechanical compacting systems, and magnetic compacting systems. Due to its effectiveness in producing high-quality yarns with little fibre protrusion, the mechanical compacting method is predicted to dominate the market. However, because it can create yarns with a high degree of evenness and strength, the aerodynamic compacting system is also anticipated to experience substantial growth. Due to the existence of sizable textile manufacturing industries in nations like China and India, the Asia-Pacific region is anticipated to hold a disproportionately large share of the market.

Global Compact Spinning Machine Market Segmentation: By Application

-

Cotton Textile Industry

-

Woolen Textile Industry

-

Linen Textile Industry

There are distinct application-specific segments of the global market for compact spinning machines for the cotton, woollen, and linen textile businesses. The cotton textile business is projected to rule the market due to the high demand for cotton yarns in a variety of applications, including clothing, home textiles, and industrial textiles. The luxury apparel and fashion industries’ growing need for high-end woollen yarns will also likely drive substantial growth in the woollen textile industry.

Global Compact Spinning Machine Market Segmentation: By Distribution Channel

-

Online

-

Offline

The market for small spinning machines can be split into online and offline channels based on the way of distribution. The offline channel is projected to dominate the market due to the high level of technical expertise required for the installation and maintenance of compact spinning machines, which frequently requires the participation of technical experts. However, it is also projected that the online channel will expand significantly due to the arising popularity of e-commerce and the convenience of online shopping.

Global Compact Spinning Machine Market Segmentation: By Region

-

North America

-

Europe

-

Asia Pacific

-

Rest of the World

Given the sizeable textile manufacturing sectors found in nations like China and India, the Asia-Pacific region is predicted to hold the largest market share. Due to the rising demand for textile products that are environmentally friendly and sustainable, the area is also experiencing significant development. As compact spinning machines become more prevalent in the textile business, North America and Europe are also anticipated to experience significant growth. Due to the region's rising demand for textile products, moderate development is anticipated in the Middle East and Latin America.

Global Compact Spinning Machine Market Key Players:

-

Rieter

-

TOYOTA INDUSTRIES CORPORATION

-

SHIMA SEIKI MFG., LTD

-

Jingwei Textile Machinery

-

Truetzschler Group

-

Murata Machinery, Ltd

-

Itema S.p.a.

-

Stoll Industries

-

Saurer AG

Chapter 1. COMPACT SPINNING MACHINE MARKET– Scope & Methodology

1.1. Market Segmentation

1.2. Assumptions

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. COMPACT SPINNING MACHINE MARKET– Executive Summary

2.1. Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.3. COVID-19 Impact Analysis

2.3.1. Impact during 2023 - 2030

2.3.2. Impact on Supply – Demand

Chapter 3. COMPACT SPINNING MACHINE MARKET– Competition Scenario

3.1. Market Share Analysis

3.2. Product Benchmarking

3.3. Competitive Strategy & Development Scenario

3.4. Competitive Pricing Analysis

3.5. Supplier - Distributor Analysis

Chapter 4. COMPACT SPINNING MACHINE MARKET- Entry Scenario

4.1. Case Studies – Start-up/Thriving Companies

4.2. Regulatory Scenario - By Region

4.3 Customer Analysis

4.4. Porter's Five Force Model

4.4.1. Bargaining Power of Suppliers

4.4.2. Bargaining Powers of Customers

4.4.3. Threat of New Entrants

4.4.4. Rivalry among Existing Players

4.4.5. Threat of Substitutes

Chapter 5. COMPACT SPINNING MACHINE MARKET- Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6.COMPACT SPINNING MACHINE MARKET – By Product

6.1. Automated Semi-automatic spinning Machine

6.2. Semi-automated Spinning Machine

Chapter 7. COMPACT SPINNING MACHINE MARKET– By Condensation Technique

7.1. Aerodynamic Compacting System

7.2. Mechanical Compacting System

7.3. Magnetic Compacting System

Chapter 8. COMPACT SPINNING MACHINE MARKET– By Application

8.1. Cotton Textile Industry

8.2. Woolen Textile Industry

8.3. Linen Textile Industry

Chapter 9. COMPACT SPINNING MACHINE MARKET– By Distribution Channel

9.1. Online

9.2. Offline

Chapter 10. COMPACT SPINNING MACHINE MARKET– By Region

10.1. North America

10.2. Europe

10.3. Asia-P2acific

10.4. Latin America

10.5. The Middle East

10.6. Africa

Chapter 11. COMPACT SPINNING MACHINE MARKET– By Companies

11.1. Companies 1

11.2. Companies 2

11.3. Companies 3

11.4. Companies 4

11.5. Companies 5

11.6. Companies 6

11.7. Companies 7

11.8. Companies 8

11.9. Companies 9

1110. Companies 10

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

Global Compact Spinning Machine Market is estimated to be worth USD 5.81 Billion in 2022 and is projected to reach a value of USD 13.85 Billion by 2030, growing at a CAGR of 11.47% during the forecast period 2023-2030.

The Global Compact Spinning Machine Market is primarily driven by the Increasing Demand for High-Quality Yarns.

The Global Compact Spinning Machine Market by the Condensation Technique are Mechanical Compacting System, Aerodynamic Compacting System, and Magnetic Compacting System.

China, Japan, South Korea, Singapore, and India are the most dominating countries in the Asia Pacific region for the Global Compact Spinning Machine Market.

Rieter, Toyota Industries, and Saurer AG are the three major leading players in the Global Compact Spinning Machine Market.