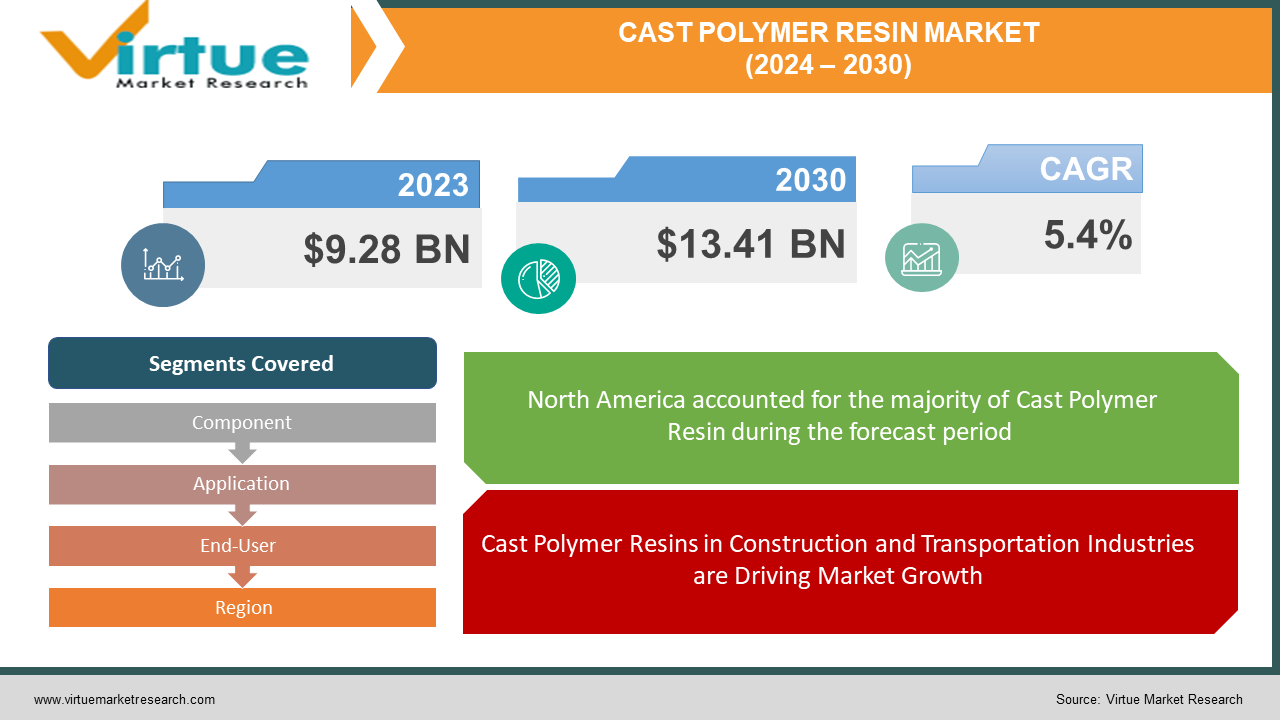

Cast Polymer Resin Market Size (2024 – 2030)

The Global Cast Polymer Resin Market was valued at USD 9.28 Billion and is projected to reach a market size of USD 13.41 Billion by the end of 2030. Over the forecast period of 2024-2030, the market is projected to grow at a CAGR of 5.4%.

Materials like cast polymer resins are frequently employed in the creation of diverse composite materials. These resins are created by mixing synthetic and natural components together, such as polyester, acrylic, and other resins. The final product is robust, long-lasting, and resistant to a variety of external variables once the material is produced and poured into a mold and given time to cure. Cast polymer resins have shown steady growth in recent years, driven by rising demand for these materials across a variety of industries, including consumer goods, transportation, and construction. The growing use of cast polymer materials as a durable, affordable replacement for conventional materials like wood is one of the major drivers boosting market expansion. The market for cast polymer resins is anticipated to expand over the upcoming years due to both the rising need for affordable and environmentally friendly substitutes for conventional materials and the expanding usage of these materials in a variety of applications. The demand for lightweight and strong materials in a variety of end-use industries, including construction, automotive, and aerospace, is one of the main drivers of market expansion. In the upcoming years, it is also anticipated that increased consumer awareness of environmentally friendly and sustainable materials would increase demand for cast polymer resins.

Global Cast Polymer Resin Market Drivers:

Cast Polymer Resins in Construction and Transportation Industries are Driving Market Growth:

Cast polymer resins are a popular option for a variety of applications because of their low cost and good durability. Additionally, because they need fewer resources to make and are simpler to recycle, they are more environmentally friendly than conventional materials like wood, metal, and concrete. The greatest end-use market for cast polymer resins, accounting for a sizeable portion of total demand, is the building industry. The demand for new housing and infrastructure is anticipated to rise as the world's population expands, which will propel expansion in the construction sector and, consequently, the market for cast polymer resin. Cast polymer resins are frequently employed in the transportation sector to provide lightweight components that can assist lower emissions and fuel consumption.

Cast Polymer Resins Drive Demand for Composite Materials in Wide-Ranging Applications:Cast polymer resins play a significant role in creating composite materials, which are increasingly used in a variety of applications because of their excellent strength-to-weight ratio and other characteristics. The need for cast polymer resins will increase along with the uptake of composite materials. The greatest market for cast polymer resins is in the Asia-Pacific region, driven by the substantial demand for these products in quickly growing nations like China and India. The market for cast polymer resins is anticipated to rise along with these economies' ongoing expansion and modernization.

Global Cast Polymer Resin Market Challenges:

Cast polymer resins are created through the blending of synthetic and natural elements, such as polyester, acrylic, and other resins. These raw materials' costs and availability can change depending on a number of variables, including disruptions in the supply chain and shifts in commodity prices. Cast polymer resins have a number of advantages, including low cost and excellent durability, but they are up against competition from materials like wood, metal, and concrete, which may be more suitable for some purposes. Even though cast polymer resins are typically more environmentally friendly than conventional materials, there are still issues with their manufacture and disposal. The industry may face difficulties due to the use of specific chemicals in the manufacturing process as well as the possibility of waste and emissions.

Global Cast Polymer Resin Market Opportunities:

Cast polymer resins are used in a variety of industries, such as the marine, transportation, and construction sectors. Manufacturers can increase their product offerings and enter new markets when new applications for these materials are found. The market for ecologically friendly and sustainable materials is expanding quickly. Cast polymer resins are well-positioned to benefit from this trend due to their low carbon footprint and recyclable nature. New cast polymer resin products with improved characteristics, such as increased durability, fire resistance, and thermal insulation, may be created as a result of developments in materials science and production technology. Cast polymer resins are in greater demand as emerging nations' economies improve and modernize. By boosting their operations in these markets, manufacturers can profit from this trend.

COVID-19 Impact on the Global Cast Polymer Resin Market:

Supply chains have been hampered by the pandemic, which has delayed the delivery of both raw materials and completed goods. As a result, manufacturers now face higher expenses and slower production. Cast polymer resin demand has decreased as a result of the economic downturn brought on by the pandemic, particularly in the construction and transportation sectors. The transportation industry also experienced a downturn, and many construction projects were postponed. Due to the pandemic, many production facilities had to temporarily close, either as a result of a government-mandated shutdown or to protect employees from viral infection. As a result, there was a backlog of orders and a reduction in production capacity. Consumer behavior has changed as a result of the epidemic, with a stronger emphasis now placed on safety and hygiene.

Global Cast Polymer Resin Market Recent Developments:

In October 2022, the production of TDI (toluene diisocyanate), a crucial ingredient in the creation of polyurethane, will be increased globally, according to plans made public by The Dow Chemical Company. The development is anticipated to boost Dow's capacity by 20% and assist in supplying the expanding demand for polyurethane in numerous industries.

- In January 2022, the developer of specialty chemical solutions for the coatings, adhesives, and composites markets, Gabriel Performance Solutions, has been acquired by US-based chemical firm Huntsman Corporation. Huntsman will be able to improve its position in North America and increase its product offerings due to this acquisition.

- In August 2022, the US-based specialty chemicals business Ashland Global Holdings recently announced the introduction of a new line of high-performance adhesives for the packaging, construction, and transportation sectors. The polyester and vinyl ester resin-based adhesives provide great strength, tenacity, and flexibility.

CAST POLYMER RESIN MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

5.4% |

|

Segments Covered |

By Component, Application, End-User and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

DuPont de Nemours, Inc., Ashland Global Holdings Inc., Polynt S.p.A., The R.J. Marshall Company, Cosentino S.A., Caesarstone Ltd., Wilsonart LLC, The Dow Chemical Company, Breton S.p.A., LG Hausys Ltd., Eastern Marble & Granite Supply, Inc., Hanwha L&C Corporation, Vicostone Joint Stock Company, LOTTE Advanced Materials Co., Ltd., Kuraray Co., Ltd. |

Global Cast Polymer Resin Market Segmentation: By Component

-

Polyester Resin

-

Acrylic Resin

A synthetic resin called polyester resin is frequently utilized in the creation of cast polymer components. It has many advantages, including great strength, longevity, and resistance to chemicals and water. Polyester resin is frequently utilized in the creation of decorative laminates like imitation marble as well as solid surface materials like countertops and shower enclosures.

Another synthetic resin that is frequently utilized in the creation of cast polymer materials is acrylic resin. Along with great transparency, UV resistance, and weather ability, it has a number of advantages. Acrylic resin is frequently utilized in the fabrication of solid surface materials, including bathtubs and vanity tops, as well as decorative laminates like imitation granite and quartz.

Global Cast Polymer Resin Market Segmentation: By Application

-

Solid Surface

-

Cultured Marble

-

Engineered Stone

-

Other

Cast polymer resins are frequently used in the production of solid surface materials. For countertops, vanity tops, shower enclosures, and other surfaces in residential and commercial structures, these materials are employed. Due to their excellent strength and durability, cast polymer resins, in particular polyester resins, are frequently utilized in the manufacturing of solid surface materials. Cast polymer resins are also used to create cultured marble. This substance, which is a mixture of marble dust and resin, is used to make bathroom fixtures including bathtubs, sinks, and shower pans. Due to their capacity to replicate the appearance of genuine marble, polyester resins are frequently employed in the creation of cultured marble. Crushed quartz and resin are used to create engineered stone, commonly referred to as quartz surfacing. For countertops, floors, and other surfaces in residential and commercial structures, this material is used. Because of their great transparency and UV resistance, acrylic resins are frequently employed in the manufacture of engineered stone.

Global Cast Polymer Resin Market Segmentation: By End-User

-

Residential Construction

-

Commercial Construction

-

Transportation

-

Others

Several building components utilized in residential construction, including solid surface countertops and shower enclosures, are produced using cast polymer resins. Cast polymer resins will be more in demand as new residential development becomes more necessary to accommodate the expanding world population. Cast polymer resins are also employed in the manufacturing of flooring, wall panels, and ornamental laminates, which are used in commercial construction. The demand for new commercial construction is anticipated to rise as the global economy continues to expand, which will fuel the demand for cast polymer resins. Cast polymer resins are used to create composite materials for the transportation sector, including lightweight vehicles and aviation parts.

Global Cast Polymer Resin Market Segmentation: By Region

-

North America

-

Europe

-

Asia Pacific

-

Middle East and Africa

-

South America

The growing demand for solid surface materials in the residential and commercial construction sectors is what drives the market for cast polymer resin in North America. Due to its extensive construction sector and high consumer demand for kitchen and bathroom remodelling projects, the United States is the largest market for cast polymer resin in North America. The growing demand for solid surface materials in nations with developing economies like China and India is what drives the cast polymer resin market in the Asia-Pacific region. Due to urbanization and population increase, the construction sector in these nations is expanding quickly, which increasing demand for contemporary building materials such as cast polymer resins. The growing demand for engineered stone and solid surface materials in the residential and commercial construction sectors is what drives the market for cast polymer resin in Europe. Due to their extensive construction industries and high demand for contemporary building materials, nations like Germany, Italy, and Spain are significant users of cast polymer resin.

Global Cast Polymer Resin Market Key Players:

-

DuPont de Nemours, Inc.

-

Ashland Global Holdings Inc.

-

Polynt S.p.A.

-

The R.J. Marshall Company

-

Cosentino S.A.

-

Caesarstone Ltd.

-

Wilsonart LLC

-

The Dow Chemical Company

-

Breton S.p.A.

-

LG Hausys Ltd.

-

Eastern Marble & Granite Supply, Inc.

-

Hanwha L&C Corporation

-

Vicostone Joint Stock Company

-

LOTTE Advanced Materials Co., Ltd.

-

Kuraray Co., Ltd.

Chapter 1. Cast Polymer Resin Market – Scope & Methodology

1.1. Market Segmentation

1.2. Assumptions

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. Cast Polymer Resin Market – Executive Summary

2.1. Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.3. COVID-19 Impact Analysis

2.3.1. Impact during 2023 - 2030

2.3.2. Impact on Supply – Demand

Chapter 3. Cast Polymer Resin Market – Competition Scenario

3.1. Market Share Analysis

3.2. Product Benchmarking

3.3. Competitive Strategy & Development Scenario

3.4. Competitive Pricing Analysis

3.5. Supplier - Distributor Analysis

Chapter 4. Cast Polymer Resin Market - Entry Scenario

4.1. Case Studies – Start-up/Thriving Companies

4.2. Regulatory Scenario - By Region

4.3 Customer Analysis

4.4. Porter's Five Force Model

4.4.1. Bargaining Power of Suppliers

4.4.2. Bargaining Powers of Customers

4.4.3. Threat of New Entrants

4.4.4. Rivalry among Existing Players

4.4.5. Threat of Substitutes

Chapter 5. Cast Polymer Resin Market - Landscape

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. Cast Polymer Resin Market - By Component

6.1 Polyester Resin

6.2 Acrylic Resin

Chapter 7. Cast Polymer Resin Market - By Application

7.1 Solid Surface

7.2 Cultured Marble

7.3 Engineered Stone

7.4 Other

Chapter 8. Cast Polymer Resin Market - By End-User

8.1 Residential Construction

8.2 Commercial Construction

8.3 Transportation

8.4 Others

Chapter 9. Cast Polymer Resin Market - By Region

9.1 North America

9.2 Europe

9.3 Asia-Pacific

9.4 Rest of the World

Chapter 10. Cast Polymer Resin Market - Key Players

10.1 DuPont de Nemours, Inc.

10.2 Ashland Global Holdings Inc.

10.3 Polynt S.p.A.

10.4 The R.J. Marshall Company

10.5 Cosentino S.A.

10.6 Caesarstone Ltd.

10.7 Wilsonart LLC

10.8 The Dow Chemical Company

10.9 Breton S.p.A.

10.10 LG Hausys Ltd.

10.11 Eastern Marble & Granite Supply, Inc.

10.12 Hanwha L&C Corporation

10.13 Vicostone Joint Stock Company

10.14 LOTTE Advanced Materials Co., Ltd.

10.15 Kuraray Co., Ltd.

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Global Cast Polymer Resin Market was estimated at USD 8.8 Billion in 2022 and is projected to reach a value of USD 13.4 Billion by 2030, growing at a fast CAGR of 5.4% during the forecast period 2023-2030.

The Global Cast Polymer Resin Market is driven by Growth in the construction industry, Increasing demand for lightweight and high-strength materials, Growing consumer preference for modern and stylish interior design, and Technological advancements in manufacturing processes.

The Segments under the Global Cast Polymer Resin Market by application are Solid Surface, Cultured Marble, Engineered Stone, and Others.

China, Japan, South Korea, Singapore, and India are the most dominating countries in the Asia Pacific region for the Global Cast Polymer Resin Market.

DuPont de Nemours, Inc., Ashland Global Holdings Inc., and Polynt S.p.A. are the three major leading players in the Global Cast Polymer Resin Market.