Aerospace Carbon Fiber Composite Market Size (2023-2030)

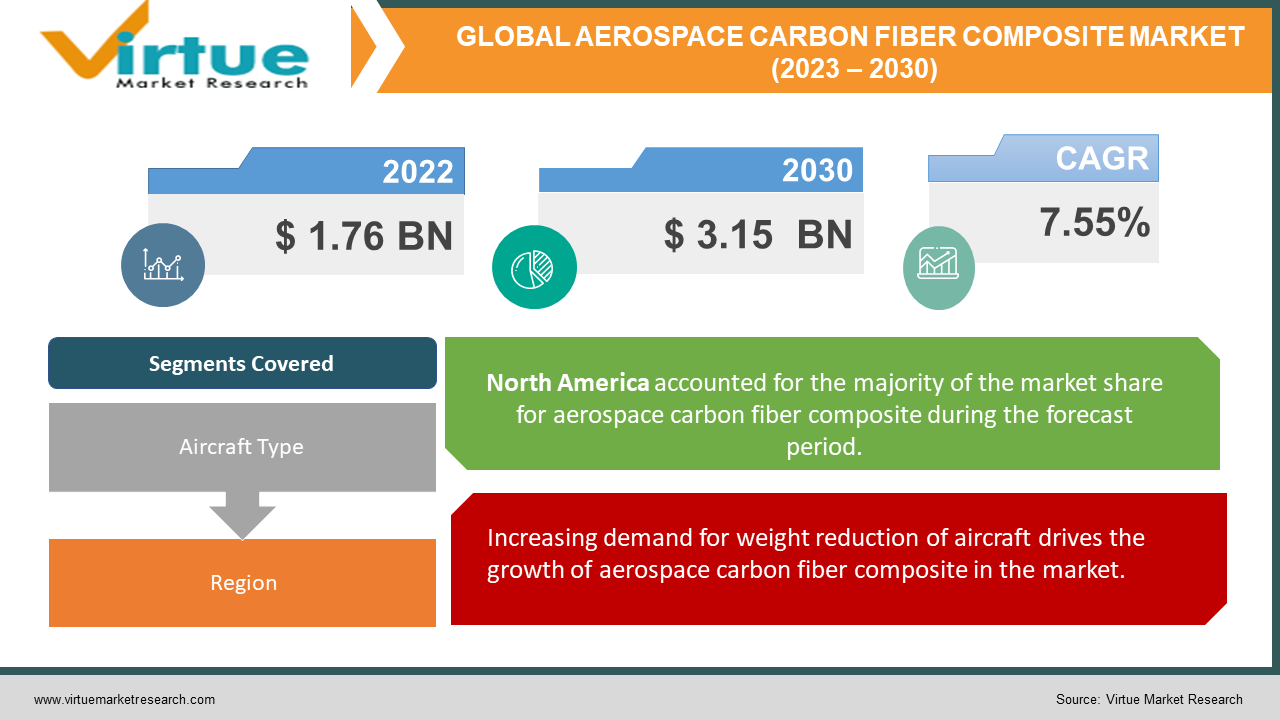

The Global Aerospace Carbon Fiber Composite Market was estimated to be worth USD 1.76 Billion in 2022 and is anticipated to reach a value of USD 3.15 Billion by 2030, growing at a fast CAGR of 7.55% during the forecast period 2023-2030.

Aerospace carbon fibers are materials that are composed of carbon fibers embedded in a polymer matrix. These composites are robust and are known for their strength-to-weight ratio. Hence, they are used widely in the aerospace industry where weight reduction is essential without compromising on the structural integrity of the component. Carbon fibers are typically made of carbon atoms that are produced by the carbonization process, which involves the heating of a precursor material, such as polyacrylonitrile to high temperatures without oxygen. Further, this process removes the non-carbon elements, which results in fibers with mechanical properties. In the aerospace industry, these fibers are combined with polymer matrix such as epoxy resin that helps in creating composite material. Moreover, these carbon fiber composites are widely used for aerospace components, which include aircraft structures such as wings, fuselages, and empennages. Further, these composites help in reducing structural weight which increases fuel efficiency, offers a longer range, improves payload capacity, and enhances the maneuverability of aircraft. In addition to that, aerospace carbon fiber composites are resistant to corrosion and extreme temperature, making them a popular choice in the aerospace industry. Furthermore, increasing demand from the military and aerospace industry for agile and robust structures has boosted the demand for aerospace carbon fiber composite in the market.

Global Aerospace Carbon Fiber Composite Market Drivers:

Increasing demand for weight reduction of aircraft drives the growth of aerospace carbon fiber composite in the market.

Carbon fiber composites are lightweight compared to conventional materials like aluminum and steel. Weight reduction of aircraft in the aerospace industry is essential because the weight has a direct impact on fuel efficiency. The weight reduction can considerably reduce the consumption of fuel and helps in declining the operational costs of manufacturers and technical personnel. Moreover, the lightweight nature of carbon fiber composites substantially reduces the weight of aircraft components such as wings, fuselages, empennages, and others, which further helps in reducing the overhead costs such as replacement costs of fleet operators. Additionally, many aircraft have benefitted from the incorporation of carbon fiber composite. These include Boeing Co.’s 787 and Airbus A350 XWB and A380 which have benefitted from carbon fiber composite as it reduced their fuel consumption and emissions and also their maintenance, assembly, and tooling costs considerably. Moreover, composite materials provide an enhanced passenger experience as it helps to dampen the engine noise or vibration and provide a cabin atmosphere that is less conducive to dehydration.

Innovations and research in aircraft manufacturing have bolstered the growth of aerospace carbon fiber composite in the market.

Research & Developments in aircraft manufacturing is constantly making efforts in the field of carbon fiber composites. This has led to the development of innovative carbon composites with other materials that can provide increased efficiency and integrity to aircraft. Further, these include advanced resin systems that have excellent mechanical properties such as high strength, heat, and temperature resistance, which can be combined with carbon fiber composites to enhance the overall performance of the aircraft. Further, the development of hybrid composites can provide superior strength and damage tolerance to aircraft. Moreover, hybrid composites enable manufacturers and aircraft designers in developing innovative aircraft designs. In addition to that, the recent trend of nanocomposites has led to the amalgamation of nanoparticles with carbon to create carbon nanotubes that offer great strength, agility, and electric and thermal stability to the structure. Moreover, the integration of technology in the production of carbon fiber composites such as the use of CAD software and finite element analysis software (FEA) has helped engineers in designing and analyzing the structure of carbon fiber composites. These also include simulating and predicting the behavior of composite materials in various conditions that can help the engineers in optimizing the design for enhanced performance. Additionally, simulation software tools enable prototyping and virtual testing of these materials that help to find defects and thereby reduce upfront costs.

Global Aerospace Carbon Fiber Composite Market Challenges:

The expensive cost of carbon fiber composite can limit the demand for aerospace carbon fiber composites in the market. Carbon fiber composite is more costly than conventional materials such as aluminum and steel. The higher cost of these materials is primarily due to the intricate manufacturing process, testing equipment that ensures the quality and performance of carbon fiber composites, and difficulty in sourcing raw materials that are used in the production process.

Further, maintenance and repair costs can become a deterrent to the market demand for aerospace carbon fiber composite. Carbon fiber composites are complex structures that require specialized maintenance and repair services, which can lead to an additional increase in the costs of hiring trained and expert individuals.

Global Aerospace Carbon Fiber Composite Market Opportunities:

The Global Aerospace Carbon Fiber Composite Market is anticipated to deliver lucrative opportunities for businesses, which include acquisitions, partnerships, collaborations, product launches, and agreements during the forecasted period. Furthermore, owing to the increase in demand for robust aircraft structures that help in fuel consumption and cost reduction is predicted to develop the market for Aerospace Carbon Fiber Composite and enhance its future growth opportunities.

COVID-19 Impact on Global Aerospace Carbon Fiber Composite Market:

The pandemic hurt the aerospace industry. Due to the global lockdown, there was a decrease in air travel, which reduced the usage of aircraft and in turn declined the demand for carbon fiber composite in the market. Further, due to restrictions on travel and trade, there was a shortage of sourcing raw materials required in the production of carbon fiber composite, which led to supply chain disruptions in the aerospace industry.

Global Aerospace Carbon Fiber Composite Market Recent Developments:

In July 2021, Markforged launched two aerospace composite materials – Onyx FR and Carbon Fiber FR materials. The materials are designed to withstand flame, smoke, and toxicity requirements for many interior parts of an aircraft.

AEROSPACE CARBON FIBER COMPOSITE MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2022 - 2030 |

|

Base Year |

2022 |

|

Forecast Period |

2023 - 2030 |

|

CAGR |

7.55% |

|

Segments Covered |

By Aircraft Type, and Region |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Key Companies Profiled |

Nippon Graphite Fiber Corporation, Hexcel, SGL Carbon, Mitsubishi Chemical Corporation, Zoltek, Hexagon, Toray Industries, Solvay S.A., DowAksa |

Global Aerospace Carbon Fiber Composite Market Segmentation: By Aircraft Type

-

Commercial Aircraft

-

Business Jets

-

Military Aircraft

-

Helicopters

-

Others

Based on market segmentation by aircraft type, commercial aircraft occupies the highest share in the market. Carbon fiber composites are used in the construction of fuselage that help in weight reduction. Moreover, they are also used in the preparation of aircraft wings to provide them strength and increase fuel efficiency by weight reduction.

The military aircraft segment occupies a significant share of the market. Carbon fiber composites are used in military craft for stealth capabilities that help to reduce radar signature and enhance the aircraft’s stealth. Moreover, they are also used in airframe components such as wings, fuselage sections, tail assemblies, and others that help to balance the strength and weight of the aircraft.

The helicopter segment occupies a sizeable share of the market. Carbon fiber composites are used in the rotor blades of a helicopter to reduce weight and provide enhanced performance.

The business jets segment is the fastest-growing segment during the forecast period. Carbon fiber composite is widely used in the interior components such as cabin panels, seats, furnishings, and others of these jets which helps in weight reduction and enhances the aesthetic appeal of the jet.

Global Aerospace Carbon Fiber Composite Market Segmentation: By Region

-

North America

-

Europe

-

Asia Pacific

-

Middle East and Africa

-

South America

Based on market segmentation by region, North America occupies the highest share of the market. Due to the established aerospace industry, which included aircraft manufacturers such as Boeing and Lockheed Martin, the demand for carbon fiber composite has increased in the region. Moreover, technological advancements in aircraft maintenance and manufacturing have induced manufacturers of carbon fiber composite to produce eco-friendly and fuel-efficient materials that provide stability, integrity, and safety to aircraft structures. Apart from this, carbon fiber composites witness increasing applications in the defense and military segment of the region such as for fighter jets, unmanned aerial vehicles or drones, and military transport craft, which require high-strength and lightweight materials for enhanced performance. Asia-Pacific witnessed significant growth during the forecast period. Due to government support in the form of investments and research and development in the aerospace manufacturing industry, the market for aerospace carbon fiber composites is predicted to develop in the region.

Global Aerospace Carbon Fiber Composite Market Key Players:

-

Nippon Graphite Fiber Corporation

-

Hexcel

-

SGL Carbon

-

Mitsubishi Chemical Corporation

-

Zoltek

-

Hexagon

-

Toray Industries

-

Solvay S.A.

-

DowAksa

Chapter 1. Aerospace Carbon Fiber Composite Market – Scope & Methodology

1.1 Market Segmentation

1.2 Assumptions

1.3 Research Methodology

1.4 Primary Sources

1.5 Secondary Sources

Chapter 2. Aerospace Carbon Fiber Composite Market – Executive Summary

2.1 Market Size & Forecast – (2023 – 2030) ($M/$Bn)

2.2 Key Trends & Insights

2.3 COVID-19 Impact Analysis

2.3.1 Impact during 2023 – 2030

2.3.2 Impact on Supply – Demand

Chapter 3. Aerospace Carbon Fiber Composite Market – Competition Scenario

3.1 Market Share Analysis

3.2 Product Benchmarking

3.3 Competitive Strategy & Development Scenario

3.4 Competitive Pricing Analysis

3.5 Supplier - Distributor Analysis

Chapter 4. Aerospace Carbon Fiber Composite Market - Entry Scenario

4.1 Case Studies – Start-up/Thriving Companies

4.2 Regulatory Scenario - By Region

4.3 Customer Analysis

4.4 Porter's Five Force Model

4.4.1 Bargaining Power of Suppliers

4.4.2 Bargaining Powers of Customers

4.4.3 Threat of New Entrants

4.4.4 .Rivalry among Existing Players

4.4.5 Threat of Substitutes

Chapter 5. Aerospace Carbon Fiber Composite Market - Landscape

5.1 Value Chain Analysis – Key Stakeholders Impact Analysis

5.2 Market Drivers

5.3 Market Restraints/Challenges

5.4 Market Opportunities

Chapter 6. Aerospace Carbon Fiber Composite Market - By Aircraft Type

6.1 Commercial Aircraft

6.2 Business Jets

6.3 Military Aircraft

6.4 Helicopters

6.5 Others

Chapter 7. Aerospace Carbon Fiber Composite Market – By Region

7.1 North America

7.2 Europe

7.3 Asia-Pacific

7.4 Rest of the World

Chapter 8. Aerospace Carbon Fiber Composite Market - Key Players

8.1 Nippon Graphite Fiber Corporation

8.2 Hexcel

8.3 SGL Carbon

8.4 Mitsubishi Chemical Corporation

8.5 Zoltek

8.6 Hexagon

8.7 Toray Industries

8.8 Solvay S.A.

8.9 DowAksa

Download Sample

Choose License Type

2500

4250

5250

6900

Frequently Asked Questions

The Global Aerospace Carbon Fiber Composite Market was estimated to be worth USD 1.76 Billion in 2022 and is anticipated to reach a value of USD 3.15 Billion by 2030, growing at a fast CAGR of 7.55% during the forecast period 2023-2030.

Rising demand for weight reduction in aircraft and advancements in aircraft manufacturing are the market drivers for Global Aerospace Carbon Fiber Composite Market.

Commercial Aircraft, Business Jets, Military Aircraft, Helicopters, and Others are the segments under the Global Aerospace Carbon Fiber Composite Market by aircraft type.

North America dominates the market for Global Aerospace Carbon Fiber Composite Market.

Asia-Pacific is the fastest-growing region in the Global Aerospace Carbon Fiber Composite Market.