Closed Cell Metal Foam Market Size (2025 - 2030)

As per our research report, the Closed Cell Metal Foam Market size is estimated to be growing at a CAGR of 6% from 2025 to 2030.

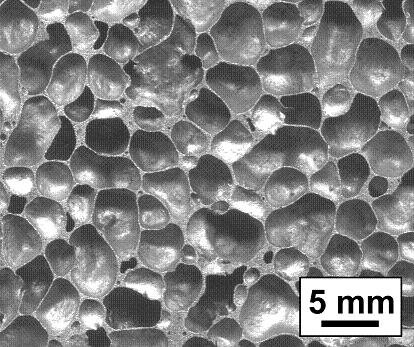

To enhance the stability of bubbles within molten metal, the introduction of a foaming agent or gas is employed to produce closed-cell metal foams. Typically, the size of the resulting pores or cells falls within the 1 to 8 mm range. Similar to the polymer-based foams found in bicycle helmets, closed-cell metal foams serve as energy-absorbing materials for applications involving high-impact forces. Unlike most polymer foams, metal foams are designed for single-use deformation and retain their compressed form following impact. Distinctive characteristics of closed-cell metal foams include buoyancy, energy dissipation, elevated specific strength and rigidity, and excellent crash performance.

In sectors such as automotive and aerospace, this contributes to the production of lighter vehicles, resulting in enhanced fuel efficiency and performance. However, the advantages of closed-cell metal foam extend beyond lightweight design. It demonstrates superior capabilities in impact and vibration absorption, making it well-suited for use in protective packaging, athletic gear, and earthquake-resilient construction materials. Additionally, its closed-cell structure functions effectively as a thermal barrier, supporting heat dissipation in thermal management systems and battery technologies.

COVID-19 caused a temporary slowdown in the closed-cell metal foam market, especially during 2020, as global lockdowns disrupted supply chains and halted manufacturing activities in key sectors like aerospace, automotive, and construction industries that heavily rely on these advanced lightweight materials. Demand dipped sharply during the early phase of the pandemic, but as industries adapted to new safety standards and production gradually resumed by late 2021, the market began to recover, driven by increased interest in energy-efficient and crash-resistant materials. Post-pandemic recovery has been steady, with many companies now focusing on localized manufacturing and sustainable materials. As a result, the closed-cell metal foam market is projected to grow at a healthy pace, with a strong push coming from green construction and electric vehicle manufacturing by 2025.

Closed-cell metal foam is influencing industry applications far beyond its physical attributes. The automotive sector, in particular, is witnessing the replacement of heavier components with these foams, enabling vehicle weight reduction without compromising structural integrity—thereby improving both fuel efficiency and operational performance. In the construction industry, these foams are being explored for multiple functions, such as acoustic insulation in loud environments and enhancing the durability of structures against seismic activity. The energy sector is also leveraging these foams, especially in the development of safer, more efficient batteries by optimizing thermal regulation and impact protection. Wind energy technologies may also benefit, as the incorporation of lightweight components can enhance turbine performance.

Despite their promising advantages, the broader adoption of closed-cell metal foams is currently constrained by production limitations. Unlike conventional materials manufactured at high volumes, closed-cell foams are still produced on a comparatively small scale. This limited output presents two key challenges: it reduces availability, potentially delaying project timelines, and contributes to higher production costs. The absence of large-scale manufacturing prevents the realization of economies of scale, making these materials less cost-effective than more readily available alternatives.

KEY MARKET INSIGHTS:

- Based on the Material, Aluminum stands out as both the most widely used and the fastest-growing material in various sectors. Its exceptional lightness, coupled with its versatility across numerous applications, underpins its market leadership. As industries increasingly prioritize operational efficiency and sustainability, aluminum’s role as a lightweight alternative to heavier materials becomes ever more significant. The demand for closed-cell metal foam made from aluminum is rising rapidly, contributing to notable market growth. This trend is driven by its expanding use in sectors such as electronics, construction, and automotive manufacturing.

- Based on the Application, Anti-intrusion bars represent the largest and most rapidly expanding application area. With the implementation of increasingly stringent safety regulations in the automotive and construction industries, the demand for advanced anti-intrusion solutions is on the rise. Closed-cell metal foam, known for its exceptional energy absorption capabilities and low weight, is ideally suited for enhancing safety in both vehicles and buildings. Additionally, the application of closed-cell metal foam in anti-intrusion bars has experienced substantial growth, driven by continuous advancements in material engineering and manufacturing processes that ensure improved crash performance and greater occupant protection.

- Based on the End-Users, the automotive industry represents the largest and fastest-growing sector for the adoption of closed-cell metal foam. The integration of this material into automotive manufacturing is primarily driven by the demand for lightweight solutions that enhance fuel efficiency and lower emissions. This growth is further supported by stringent regulatory requirements aimed at reducing vehicle weight to meet environmental compliance standards. With continuous innovations in material science and technology, the automotive sector remains at the forefront of leveraging closed-cell metal foam to achieve higher performance and greater sustainability.

- Based on the region, the Asia-Pacific region is experiencing the most rapid growth in the closed-cell metal foam market. Demand across key industries such as electronics, construction, automotive, and aerospace is driving this expansion. Contributing factors include accelerated industrialization, ongoing urban development, and large-scale infrastructure projects in countries. Additionally, increased investments in research and development, along with the presence of major industry players, are further fueling regional growth. The market's upward trajectory is also supported by a growing focus on sustainability and the adoption of lightweight materials in modern manufacturing practices.

- Companies playing a leading role in the Closed Cell Metal Foam Market profiled in this report are Cymat Technologies Ltd., Alantum and Ultramet.

Global Closed Cell Metal Foam Market Segmentation:

By Material:

- Aluminum

- Copper

- Zinc

- Titanium

By Application:

- Heat Exchangers

- Anti-Intrusion Bars

- Sound Absorbers

- Others

By End-Users:

- Automotive

- Aerospace

- Building & Construction

- Healthcare

- Energy

- Others

By Region:

- North America

- Europe

- Asia-Pacific

- South America

- Middle East and Africa

Request for the sample of this report @ https://virtuemarketresearch.com/report/closed-cell-metal-foam-market/request-sample