France Metal Fabrication Equipment Market (2025-2030)

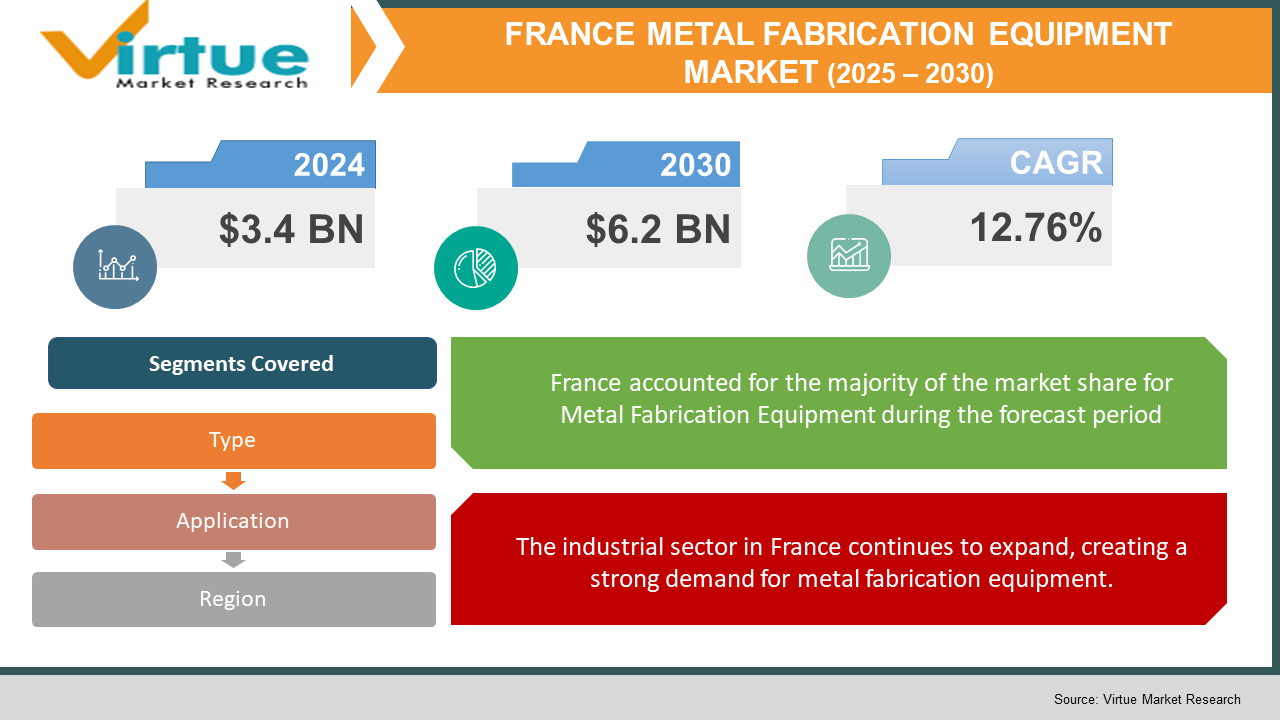

The France Metal Fabrication Equipment Market was valued at USD 3.4 billion in 2024 and is projected to reach a market size of USD 6.2 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 12.76%.

Metal fabrication is the process of bending, cutting, and joining metal parts. It is applied for both stock and custom products. The making of machines and other structures from various raw materials is taken into account in metal fabrication. Metal fabrication machinery is utilized in the manufacturing of springs & wire, nuts & bolts, and forging & stamping. Different sectors like automotive, energy utilities, and oil & gas are raising the demand for metal fabrication equipment in the nation. Most custom metal fabricated items are made from commonly used metals and their alloys. Some of the most common metals used for custom metal fabrication include aluminum, brass, copper, gold, iron, nickel, silver, magnesium, tin, titanium, and steel grades. The first and most critical task is designing the part/product.Growth in the demand for manufactured metal products in various industries is one of the primary growth drivers for the metal fabrication equipment market in France. Such products are used in the construction, automotive, and aerospace industries, among others.

Key Market Insights:

- The basic metal and fabricated metal products sector constitutes approximately 12% of France's entire manufacturing industry, highlighting its significance in the nation's industrial landscape.

- The emphasis of France on infrastructure development initiatives, i.e., road and rail networks, bridges, and airports, generates high demand for metal fabrication equipment. Such projects necessitate structural component fabrication and drive market expansion.

- The use of cutting-edge technology, including automation and CNC machines, has changed the face of metal fabrication. They increase efficiency, productivity, and accuracy, thereby increasing the demand for new metal fabrication equipment.

- France's manufacturing sector is facing significant challenges, with factory closures threatening thousands of jobs. Key industries, including chemicals, automotive, and metallurgy, are particularly affected due to intense international competition and subsidized industries in countries like China and the United States.

France Metal Fabrication Equipment Market Drivers:

The industrial sector in France continues to expand, creating a strong demand for metal fabrication equipment.

France's industrial sector is experiencing consistent growth, fueled by the development of manufacturing, building, and automation. The industry has seen dramatic growth in its demand for metal fabrication machinery with high-precision equipment for cutting, welding, and forming metal pieces. As the emphasis on making France's industry base modern is coupled with incorporating Industry 4.0 innovations, the demand for sophisticated tools for fabrication has accelerated. Besides this, the increasing number of infrastructure projects, aerospace production, and the automotive industry's demand for lightweight materials drive the market for metal fabrication machinery further. As businesses focus more on efficiency and productivity, spending on automated and CNC-based fabrication solutions increases steadily, cementing the market growth path.

Technological advancements, including automation, robotics, and CNC machines, have improved the efficiency of metal fabrication processes.

Technological innovation, especially in automation, robotics, and CNC machines, is transforming the metal fabrication sector by dramatically enhancing efficiency, accuracy, and productivity. The use of smart manufacturing solutions allows manufacturers to maximize production processes, minimize material waste, and improve quality control. Automated fabrication systems and robotic welding solutions optimize operations, reducing human errors and maximizing throughput. In addition, the use of CNC machines facilitates detailed designs and high-precision metal cutting to meet the increasing demand for complex and customized metal parts. As industries keep moving toward digitalization and Industry 4.0, the move toward technologically superior metal fabrication equipment is likely to accelerate market growth even further.

France Metal Fabrication Equipment Market Restraints and Challenges:

The capital-intensive nature of metal fabrication equipment poses a challenge for market growth.

Technological innovation, especially in automation, robotics, and CNC machines, is transforming the metal fabrication sector by dramatically enhancing efficiency, accuracy, and productivity. The use of smart manufacturing solutions allows manufacturers to maximize production processes, minimize material waste, and improve quality control. Automated fabrication systems and robotic welding solutions optimize operations, reducing human errors and maximizing throughput. In addition, the use of CNC machines facilitates detailed designs and high-precision metal cutting to meet the increasing demand for complex and customized metal parts. As industries keep moving toward digitalization and Industry 4.0, the move toward technologically superior metal fabrication equipment is likely to accelerate market growth even further.

France Metal Fabrication Equipment Market Opportunities:

The market for metal fabrication equipment holds promise for serious opportunities based on changing industry requirements and technology push. Among its most important areas of growth is the growing sector for renewable power, as an escalating demand for wind and sun power creates the need for customized fabrication equipment to build key components such as wind turbines and solar panels. As governments across the globe drive towards cleaner energy solutions, the need for precision-engineered metal structures in this area is likely to increase, offering profitable opportunities for equipment makers. Moreover, the increasing focus on lightweight materials, especially in the automotive and aerospace sectors, offers another opportunity for market growth. With industries aiming to increase fuel efficiency and sustainability through the use of advanced lightweight composites and alloys, the demand for metal fabrication equipment capable of processing such materials efficiently and accurately is increasing. In addition, the increased trend towards customization and innovation in most industries is necessitating the demand for versatile and flexible fabrication solutions. Producers that provide sophisticated CNC systems, automated fabrication equipment, and modular equipment that can accommodate complex and specialized designs will be best placed to take advantage of this trend. Through ongoing innovation and responding to these changing market demands, metal fabrication equipment producers can open up new sources of revenue and reinforce their competitive advantage in the global marketplace.

FRANCE METAL FABRICATION EQUIPMENT MARKET REPORT COVERAGE:

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2024 - 2030 |

|

Base Year |

2024 |

|

Forecast Period |

2025 - 2030 |

|

CAGR |

12.76% |

|

Segments Covered |

By Type, application, and Region |

|

Various Analyses Covered |

Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regional Scope |

france |

|

Key Companies Profiled |

Amada Co, Bystronic, Tebis, JIER Group, AIA, Hurco, Hardinge, and Schuco International |

France Metal Fabrication Equipment Market Segmentation:

France Metal Fabrication Equipment Market Segmentation: By Type

- Machining

- Cutting

- Forming

- Welding

- Others

The French metal fabrication machinery market is divided based on type, covering machining, cutting, forming, welding, and other specialized operations. Machining machinery like lathes, milling machines, and drills are critical to shaping and finishing metal parts with precision. Cutting machinery like laser, plasma, and waterjet cutters are used extensively for cutting metal sheets and structures cost-effectively. Forming machines, for example, press brakes, stamping equipment, and rollers, are important for folding metal to appropriate shapes for applications in industries such as automotive and construction. Welding devices, for instance, MIG, TIG, and robot welding units, are essential for metal joining in industries like shipbuilding, aerospace, and heavy machinery. The other segment includes specialized hardware such as finishing tools, automation machinery, and hybrid fabrication technologies that facilitate advanced manufacturing requirements. This segmentation caters to the differing requirements of the French manufacturing industry, with every segment helping the overall efficiency and development of metal fabrication in France.

France Metal Fabrication Equipment Market Segmentation: By Application

- Automotive

- Job Shops

- Aerospace and Defence

- Mechanical Components

- Others

The French metal fabrication equipment market is divided according to application, serving many diversified industries, such as the automotive, job shops, aerospace and defence, mechanical components, and other speciality markets. The automotive market dominated the demand for metal fabrication equipment with its use of sophisticated machining, cutting, and welding technologies to produce lightweight yet strong vehicle components to enhance fuel efficiency and safety. Job shops, provide metal fabrication services on a custom basis to several industries, depend on flexible and adaptive equipment to serve demanding customers, and this is a major market segment. The aerospace and defence industry demands extremely accurate and long-lasting metal parts for aircraft, missiles, and defence systems, resulting in demand for high-precision machining and forming equipment. Fabrication for mechanical components manufacturing, serving industries such as industrial machinery, electronics, and construction, relies on streamlined fabrication processes to make high-precision and reliable parts. The other category consists of specialty applications such as shipbuilding, renewable energy, and medical device manufacturing, for which customized fabrication solutions are necessary. This segmentation showcases the extensive and diverse uses of metal fabrication machines in France, a reflection of its imperative role in backing industrial innovation as well as economic development.

France Metal Fabrication Equipment Market Segmentation: Regional Analysis:

- France

The France Metal Fabrication Equipment Market is segmented based on various factors, including equipment type, application, and end-user industries. Regionally, France holds a significant share in the European metal fabrication industry due to its strong manufacturing sector, advanced industrial automation, and rising demand for precision-engineered metal components. The country's automotive, aerospace, construction, and energy sectors drive the demand for cutting, welding, machining, and forming equipment. Additionally, government initiatives supporting local manufacturing, coupled with increasing investments in Industry 4.0 and smart manufacturing technologies, further propel market growth. The adoption of CNC machines and robotic fabrication systems is also on the rise, enhancing productivity and efficiency across industries.

COVID-19 Impact Analysis on the France Metal Fabrication Equipment Market:

The COVID-19 pandemic greatly affected the France metal fabrication equipment market, with disruptions in supply chains, delays in manufacturing operations, and a decrease in industrial production. Lockdowns and restrictions caused a temporary shutdown of production in major industries like automotive, aerospace, and construction, which are heavy users of metal fabrication equipment. The industry also had to contend with shortages of manpower, volatility in raw material prices, and transportation issues, further retarding the process of equipment acquisition and installation. But with industries slowly coming to terms with new business realities, there was a rapid move toward automation and digitalization to increase efficiency and decrease labour dependency. The pandemic also accentuated the need for localizing supply chains and embrace cutting-edge fabrication technologies to develop resilience against potential future disruptions. With post-pandemic restoration activities and augmented government spending on infrastructure and renewable energy initiatives, demand for metal fabrication equipment will recover, propelling long-term growth in the industry.

Latest Trends/ Developments:

The French metal fabrication machinery market is experiencing several recent trends and innovations fueled by technological developments and changing industry needs. One of the most prominent trends is the growing use of automation and robotics, wherein CNC machines, robotic welding equipment, and AI-based fabrication machinery are improving accuracy, efficiency, and productivity. Also, Industry 4.0 and smart manufacturing are on the rise, with manufacturers incorporating IoT-enabled machinery, predictive maintenance, and real-time monitoring of data to maximize production. The market is also witnessing a move toward eco-friendly and energy-efficient fabrication solutions as sustainability becomes a focus across industries. The emergence of lightweight materials, particularly in the automotive and aerospace industries, has resulted in the creation of specialized equipment that can handle advanced alloys and composites. In addition, modular fabrication solutions and customization are gaining traction, enabling manufacturers to meet industry-specific needs more flexibly. As the industry keeps moving forward, such developments are influencing the future of metal fabrication in France, driving innovation and competitive development.

Key Players:

- JIER Group

- AIA

- Hurco

- Schuco International

- Hardinge

- Amada Co.

- Tebis

- Bystronic

- Messer Cutting Systems

Chapter 1. FRANCE METAL FABRICATION EQUIPMENT MARKET – SCOPE & METHODOLOGY

1.1. Market Segmentation

1.2. Scope, Assumptions & Limitations

1.3. Research Methodology

1.4. Primary Sources

1.5. Secondary Sources

Chapter 2. FRANCE METAL FABRICATION EQUIPMENT MARKET – EXECUTIVE SUMMARY

2.1. Market Size & Forecast – (2025 – 2030) ($M/$Bn)

2.2. Key Trends & Insights

2.2.1. Demand Side

2.2.2. Supply Side

2.3. Attractive Investment Propositions

2.4. COVID-19 Impact Analysis

Chapter 3. FRANCE METAL FABRICATION EQUIPMENT MARKET – COMPETITION SCENARIO

3.1. Market Share Analysis & Company Benchmarking

3.2. Competitive Strategy & Development Scenario

3.3. Competitive Pricing Analysis

3.4. Supplier-Distributor Analysis

Chapter 4. FRANCE METAL FABRICATION EQUIPMENT MARKET - ENTRY SCENARIO

4.1. Regulatory Scenario

4.2. Case Studies – Key Start-ups

4.3. Customer Analysis

4.4. PESTLE Analysis

4.5. Porters Five Force Model

4.5.1. Bargaining Power of Suppliers

4.5.2. Bargaining Powers of Customers

4.5.3. Threat of New Entrants

4.5.4. Rivalry among Existing Players

4.5.5. Threat of Substitutes Players

4.5.6. Threat of Substitutes

Chapter 5. FRANCE METAL FABRICATION EQUIPMENT MARKET- LANDSCAPE

5.1. Value Chain Analysis – Key Stakeholders Impact Analysis

5.2. Market Drivers

5.3. Market Restraints/Challenges

5.4. Market Opportunities

Chapter 6. FRANCE METAL FABRICATION EQUIPMENT MARKET – By Type

6.1 Introduction/Key Findings

6.2 Machining

6.3 Cutting

6.4 Forming

6.5 Welding

6.6 Others

6.7 Y-O-Y Growth trend Analysis By Type

6.8 Absolute $ Opportunity Analysis By Type , 2025-2030

Chapter 7. FRANCE METAL FABRICATION EQUIPMENT MARKET – By Application

7.1 Introduction/Key Findings

7.2 Automotive

7.3 Job Shops

7.4 Aerospace and Defence

7.5 Mechanical Components

7.6 Others

7.7 Y-O-Y Growth trend Analysis By Application

7.8 Absolute $ Opportunity Analysis By Application , 2025-2030

Chapter 8. FRANCE METAL FABRICATION EQUIPMENT MARKET - By Geography – Market Size, Forecast, Trends & Insights

8.1. Europe

8.1.1. By Country

8.1.1.3. France

8.1.2. By Type

8.1.3. By Application

8.1.4. Countries & Segments - Market Attractiveness Analysis

Chapter 9. FRANCE METAL FABRICATION EQUIPMENT MARKET– Company Profiles – (Overview, Packaging Type Portfolio, Financials, Strategies & Developments)

9.1 JIER Group

9.2 AIA

9.3 Hurco

9.4 Schuco International

9.5 Hardinge

9.6 Amada Co.

9.7 Tebis

9.8 Bystronic

9.9 Messer Cutting Systems

Download Sample

Choose License Type

2500

3400

3900

4600

Related Reports

Frequently Asked Questions

The France Metal Fabrication Equipment Market was valued at USD 3.4 billion in 2024 and is projected to reach a market size of USD 6.2 billion by the end of 2030. Over the forecast period of 2025-2030, the market is projected to grow at a CAGR of 12.76%.

Technological advancements, including automation, robotics, and CNC machines, have improved the efficiency of metal fabrication processes.

Based on the Service Provider, the France Metal Fabrication Equipment Market is segmented into Machine Equipment Suppliers, Forming Equipment Suppliers, Cutting Equipment Suppliers, and Automation and Robotics Suppliers.

. Ile-de-France is the most dominant region for the France Metal Fabrication Equipment Market.

Amada Co, Bystronic, Tebis, JIER Group, AIA, Hurco, Hardinge, and Schuco International are the key players in the France Metal Fabrication Equipment Market.